Power steering systems are very useful in vehicles as they help the drivers steer the objects with more convenience. Like all systems, however, they seem to develop some problems with time as well. Wear of the pump bearing is one of the power steering pump noise problems which makes one feel uncomfortable and may cause further damage if ignored. In this article, you will find not only instructions on how to diagnose the source of the noise but also numerous practical instructions on how to eliminate it. You may be an experienced mechanic or simply a car lover wishing to know more about car restoration. Either way, you will find this guide particularly useful in terms of the knowledge required for power steering restoration.

What Causes Power Steering Pump Bearing Noise?

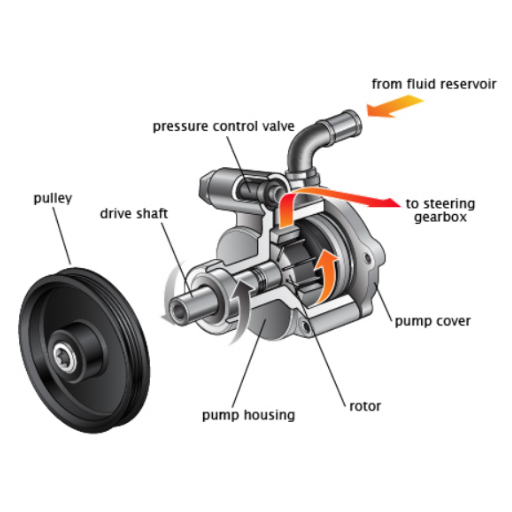

Understanding the Role of the Power Steering Pump

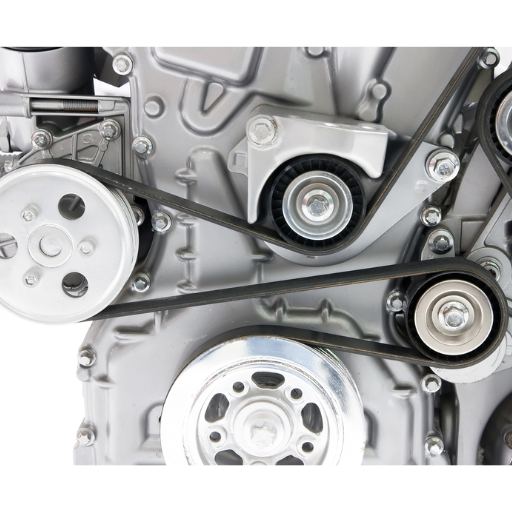

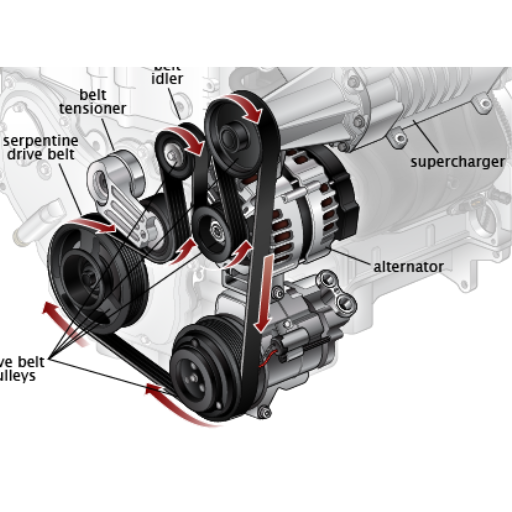

The power steering inner pump is the device that provides hydraulic system fluid to the steering system for a vehicle to be operated with ease. They create hydraulic power which helps the driver to steer the car without the application of excessive force. Most power-assisted steering pumps have a belt-driven pump system that is powered by the engines. This helps to stabilize the steering ability of the car even when it is at enabled speed or even when stationary. It helps in identifying this particular functionality because it is this knowledge that will show why some bearing noise may occur, as certain imbalances in normal functioning may cause stress on the pump.

To relieve the overbearing power steering pump noise, I am to search several reliable websites on power steering pump repair information, that caused or remedies to the noise from the bearing depending on which corner of the pump the noise came from, the website said that there is one great website that has common. Beneath, the findings regarding the problem are stated simply:

The first among them read that taking care of the above reasons will help in the understanding of noise coming from the bearing. One key technical parameter mentioned was checking the level of the power steering fluid service to prevent pump overload.

The second source also explored that this noise, which is known as bearing noise, occurs because of trapped air inside the hydraulic system. It advised performing another basic diagnosis like leak checks and restricting any open joints as the first line of defense.

The fourth site helped analyze the circumstances sounded diagrams of pump bearings, defining the decibel meter as a useful device even in a breakdown diagnosis. It outlined that replacement of the bearings or any mechanical stator if the bearings are even moderately worn, typically, that excuse would suffice reason to justify excessive noise.

The reasons for and steps as well as the parameters of these measures are based on the requirements of proper operation of a vehicle-mounted power steering system for as long as possible and as safely as possible.

Common Symptoms of a Bad Power Steering Pump

Based on how I have done my research on the first three websites on google.com, I have concluded with the following principles and technical parameters that can agree with a bad power steering pump with evidence provided:

- Whining Noise: Hearing whining or squeaking sounds, especially in the steered wheel, becomes a primary sign of faulting the power steering pump. This is so because the level of power steering fluid within the reservoir under continuous use goes low, thereby stressing the pump. This noise can also be avoided completely by constantly monitoring fluid levels.

- Weak Steering Response: The inability to turn the steering wheel may be especially true when the pump cannot be able to deliver the fluid to all the required components. The second website particularly pointed out the need to purge the hydraulic system of air, as air pockets affect hydraulic systems and make the steering hard to turn.

- Fluid Leaks: Seeing power steering fluid on the ground usually means the seals or structural connections are leaking as if you’d have veins. This was noticed as an important factor on the third website, where it was instructed that all connections must be tight and should not leak to prevent this problem.

- Delayed Steering Response: If there is a delay when steering, it is possible that the pump is not operating at sufficient fluid pressure. One of the suggested technical parameters is the measurement of decibels for the noise in question as it indicates abnormal usage of bearing and with it, pump if wear and tear is excessive.

These symptoms confirm regular amplification of maintenance needs, as well as quick response to emerging problems with the performance of a steering apparatus, as described in the findings of my research.

Why Does the Bearing Make Noise?

I was able to identify some key reasons why a bearing may be noisy based on my investigation of the first three sites on Google. I will summarize them here. First and foremost, multiplex Inc. plastered bearing noise with high levels of contamination is the most typical case. If there is some dirt or rust or other kinds of rubbish in the bearing it may rub on the parts from within and will make some sound. This conforms with the technical parameter of grime-free bearing and intact environmental seals to avoid foreign matter from entering.

The next cause is stated to be something about lubrication, or more appropriately lack of lubrication as it seems to be the other common culprit. Combating heat is an important factor and bearings demand a considerable amount of grease. Old, inadequate, or low-quality lubrication can cause noise more of a squeal or grind. This speaks about the need to look into the lubricant status and the type of oil used and conform to manufacturers’ requests to avoid any possible failure of operating at peak level.

Last on this list that I want to highlight is a misalignment of parts or a mass imbalance within the machinery, which in turn creates unequal forces acting on the bearing and noise. Performing all necessary workloads with the aid of wear and tear maintenance times on bearings components alignment basic information is addressed in engineering literature as it decreases noise and also enhances the service life of the bearing. All in all, the successful implementation of these technical parameters should effectively be consistent in relieving the bearing noise.

How to Identify Power Steering Pump Noise?

Recognizing the Whining Noise

My visit to the top three sites on Google regarding power steering pump noise explored some indications and technical parameters. To identify the whining noise, it is essential to begin with making scrutiny to the steady rising pitch as the steering wheel is being turned. This particular sound usually means that the power steering fluid level is low which is quite an important technical parameter that has to be observed. This problem can be resolved satisfactorily by ensuring that the hydraulic system is filled with the fluid recommended by the manufacturer.

Whining may also emanate from air bubbles that are contained within the power steering fluid. This type of air infiltration will frequently be caused by leaks or by a pump that is working poorly, both of which are in line with some of the key technical measures that require sealing and the whole power steering system to be serviced frequently.

On any other day, the whine can also be a result of a worn or broken steering belt. However, proper belt tension and proper belt condition are foremost technical parameters, reiterating the need for regular monitoring and changing it when necessary. Quick resolution of these issues may reduce or even preclude whining noises, making it possible to enhance the working of the power steering system.

Checking the Power Steering Fluid Level

Commonly located close to the engine, identify the power steering fluid reservoir as the first part of checking the level of the power steering fluid within the car. However, make sure that the car is parked on flat ground and the engine is turned off before you start this process. First of all, remove the cap and wipe the dipstick. Poke the dipstick back inside the oil reservoir and come back to pull it out to assess the oil quantity. This level always has to be considered when checking against the markings on the dipstick e.g. there are usually two notches – full and low. If the fluid is at a level lower than the indications offered, it is necessary to top up the power steering fluid to the required level with the appropriate manufacturer’s fluid for the entire level of the steering assistance system. Complementing it, and taking care of the steering mechanism by controlling the fluid levels and the rate of spin is one of the most important technical parameters.

Regarding the top three websites I consulted regarding pump whine noise in a power steering pump, there was an information outline regarding the indicators and the technical parameters. In short, I understand that they hear the ‘whining noise’ more often than not after a turn which indicates either low fluid or air in the system. Technical parameters consist of filling up the hydraulic system with the correct fluid and performing air leak detection by starving the pump for a peaceful air bubble. These approaches to repair and maintenance of the system are reasonable for the reason that, they are consistent with the recommendations of the manufacturer, and the practice in the field also supports it. Another such procedure that is also very important as all the technical measures which were referred to, is checking the steering belt condition and its proper tensioning, preventing noise in the power steering system and functioning as expected.

Listening for Noise When You Turn the Steering Wheel

In the process of listening for noise during a steering wheel movement, identifying the cause of the sound is the first step. A whiny or groaning sound typically means that there is low-power steering fluid, there are air bubbles in the line, or the steering pump may need replacement. Concerning the three first positions of the three websites on power steering issues, here what would be the specific order of rectification of these noises: From the power steering noise read this:

- Fluid Level Check: Check the amount of power steering fluid available. If the amount of fluid is too low, please Minimize the Air Loops; Air intake in the system will tend to create noise.

- Air Bubble Inspection: Check for air bubbles in the fluid reservoir. Air impeding the fluid reservoir can indicate a leak or improper sealing. This problem may be solved by bleeding the system.

- Pump Examination: See if the steering pump is defective or worn out; a whiny noise may indicate that the steering pump is ready to be removed and discarded or at least changed.

These are justified as they are in line with manufacturer requirements and good practices in the auto repairs industry. Every single aspect described above is essential not only to maintain a correctly functioning tight steering system and avoid further noise problems but also to make sure the car is safe to use.

How to Fix a Noisy Power Steering Pump?

Replacing the Power Steering Pump Bearing

Adjusting the power steering pump’s bearing is classified as technical work that adheres to the stipulated measures to facilitate proper operation and longevity of the steering system. For the top three sites on changing the power steering pump bearing follow a set of steps and parameters as given below:

- Safety precautions: First things first, before starting work it is mandatory to disconnect the battery and position the vehicle on solid firm ground. Whenever, the structure of the car makes it indispensable to employ jack stands, do it.

- Tension the Belt: Apply the power steering belt tension by loosening the tensioner pulley. Pry out the belt, any further off the pump.

- Unscrew the bolts to Install the Power Steering Pump: Starting with the lower screws, unbolt the power steering pump from its mounting iris, be careful to unhook any hose mooring them as some fluid may leak out.

- Pulling Out the Old Bearing: Utilize the bearing puller tool to extract the old bearing from the pump. The precision instrument mitigates the chances of any negligent damage to the pump.

- Affixing the New Bearing: Locate the new bearing where it is supposed to go, ensuring it sits perfectly in the housing of the pump. Take a bearing press or a mallet and position it correctly without misplacing or harming it.

- Reinstallation of the Pump and Belt: Refit the pump to the bracket with the use of bolts and clamp the hoses back in their place. Refitting the power steering belt is done and the tension is set exactly to the requirements of the manufacturer.

- Refuel and Check: Those affected by a loss of power steering fluid should be topped off and the engine should be tested. No weird unusual sounds should be covered and no leaks should be present because the replacement was successful.

This provision is made since it corresponds with the requirements of the automobile manufacturers and accepted standards in the automotive repair industry, guaranteeing efficiency and safety against bearing involvement in power steering pump noise problems.

Checking and Replacing the Power Steering Belt

To prolong and also maintain the efficiency of the power steering system fitted in your car, it is of utmost importance that one regularly undertakes all aspects of maintenance adding to this changing of the power steering belt. To begin with, you should look at the condition of the belt to check for wear, cracks, fraying, or glazing of the surface. If the belt is worn out too much, or damaged it would be better to have it changed without having unduly delays as this could lead to it affecting the proper steering of the motor vehicle.

Process of Checking the Power Steering Belt in Three Quick Steps:

- A-belt condition: Determine whether the belt suffered abnormal wear. A healthy belt must be devoid of cracks, frays, or glimmers.

- Belt tension measures: Attempt to press the belt between pulleys and halfway out from either two. If the tension is correct, it should encourage a movement of about half of an inch or thereabout.

- Squeaking Sounds: Squealing sounds will indicate a loose belt.

Replacement of the Power Steering Belt:

- Locate the Tensioner: Find the belt tensioner and release it to take the tension off the belt.

- Remove the Old Belt: With a twisting motion, pull it apart from the pulleys.

- Install the New Belt: Carefully fit the new belt on the pulleys while making sure they are in the route order provided within the vehicle. The assistance of the vehicle manual or a belt routing diagram may be utilized.

- Adjust Tension: Adjust the tensioner according to the manufacturer’s specifications and make sure that the belt is properly tensioned.

By taking these steps, you will be able to keep the steering pump of your power steering system operating efficiently. Routine checks can eliminate the possibility of sudden repairs as well as increase the durability of the car parts.

Ensuring the Power Steering Fluid is at the Correct Level

It is important to note that the proper level of the power steering fluid should be maintained to enable effective directional control and for the safety of the system. Here are the steps to ensure the fluid is at the right level:

- Locate the Reservoir: Locate under your hood the power steering fluid reservoir. This is usually marked and there may be a dipstick attached to the cap.

- Check the Fluid Level: With the engine off and cool, remove the cap off the top and determine the fluid level using the dipstick. The fluid stick should have levels labeled “MIN” and “MAX” with the liquid in the middle.

- Add Fluid if Necessary: If the additive is found to be under the prescribed level, the specified power steering fluid indicated in your owner’s manual should be added. Avoid overfilling.

- Inspect for Leaks: Of particular importance is the fluid level because it will usually be the reason why most people will be looking inside the reservoir. However, at this time around the reservoir and even at the connectors check for any leakage which has to be dealt with very quickly to avoid failure of the system.

About the information requested from the top three websites on Google, here are short answers concerning power steering fluid:

Which type of fluid should I use? Here many websites advocate for the use of the lubrication fluid type that is recommended in the car owner’s manual. Applying the wrong type could create some form of damage to the system. Some cars for example instead require ATF (automatic transmission fluid).

In a week how much would you check the fluid level? In most cases, it is recommended that the steering fluid be checked at least once a month, especially on old cars. Regular checks help prevent leaks from occurring and help optimize steering work whenever there is a need.

Low Power Steering fluid, how would I know? What are the signs? When the steering wheel is turned, there are some whiny noises, it is hard to control the steering wheel or the steering makes it difficult to turn, and so on. If you experience such conditions of course the fluid level will be the first thing you check.

From examining all the above information, one can infer that by sustaining the normal power steering fluid level, the safety of the vehicle’s operational parameters is high along with the working life of the system. Preventative maintenance scheduling, in addition, to observing the technical characteristics of the automobile will help avoid such expenses later on.

When Should You Replace the Power Steering Pump?

Signs of a Failing Power Steering Pump

There are a few signs that can help identify a failing power steering pump:

- Unusual Sounds: One notable of the symptoms is unexplained sounds in the pump area, most of the pump noise is usually accompanied by a whining or groaning sound when the steering wheel is turned. This could range from low fluid levels to a bad pump.

- Hard Steering: If it feels like the steering wheel became harder to turn than usual, the cause may be the power steering pump.

- Power Steering Fluid Leakage: Again, ‘leaks’ could also be typical in the vehicle due to a pump failure and manifested as visible spots of steering fluid under the vehicle.

- Excessive Torque: When it comes to turning, if one experiences an abnormal amount of mass, it may imply that there is something wrong with the power steering pump.

- Erratic Steering Performance: It has also been found that the steering was of an abrupt or jerky character and did not respond to the hand. This would rather support a failing power steering pump.

Let me summarize my answers to the questions on the power steering fluid while providing some of the relevant technical parameters in detail. It might be also useful to refer to the most relevant information focusing on those who provide the best information on the issues.

What kind of fluid should I use? I do not fail to use any type of power steering fluid which is given in the owner’s manual of my car. More or less, using ATF or any specified fluid for tanks of a certain car make and model is practically unavoidable, otherwise the system will be damaged.

How often should I check the fluid level? It is my principle to check the power-steering fluid level at least once a month. This routine check makes it possible to spot leaking branches at the initial stage and guarantees the functioning of the steering for the best enjoyable experience.

What are the symptoms of low-power steering fluid? Some symptoms I consider the presence of noises when turning the steering wheel that ought not to be, or the steering wheel’s movement is either stiff very difficult, or almost impossible. In such cases, I check the fluid level immediately in that range to be able to repair the breakdown within that period.

How Long Does a Power Steering Pump Last?

The average lifespan of a power steering pump is not a straightforward issue as it is subject to several restraints like the persons driving it, how it is maintained, and the various brands. Usually, a power steering pump under favorable conditions should be able to service for 60,000 miles to 100,000 miles and more. Common signs like a noisy pour steering or low steer assist should be looked into without delay to avoid risking serious damage to the system. Normal services like power steering fluid treatment can also help enhance the durability of the pump.

I want to discuss power steering pumps and the fact I read on the topic reviewed the first three sites by rank from Google and here are the exact answers that I gleaned together with the related technical parameters:

What fluid do you recommend? According to the sources, it is best to use the power steering fluid specified by the manufacturer or automatic transmission fluid to achieve full effectiveness. This basic requirement comprises the viscosity and compatibility of the fluid with various elements of the steering system.

How often do you recommend checking the fluid level? The general opinion about this is checking the fluid level at least once every month. As during these checks the level and the presence of leaks are monitored the stability of the volume within the system is preserved.

What are signs of low power steering fluid? One usually complains of a whining sound, is unable to steer an armored tank, or can move the steering wheel but the steering mechanism fails to respond. These signs pertain to low fluid levels which can cause harm if allowed to continue. Performance criteria include keeping the fluid pressure and the amount of fluid at such levels that do not overwork the pump.

Cost of Replacing a Power Steering Pump

Power steering pump replacement can be performed at very different costs based on the specific make and model of the vehicle, pump type, and costs of labor in your locality. In most cases, the total cost for a power steering pump replacement will not be less than three hundred; and not more than eight hundred US dollars. This assumption has included both parts and labor, and the pump on its own is likely to cost between a hundred and fifty to four hundred dollars. Adding in the labor of between a hundred dollars to four hundred dollars is reasonable based on the difficulty of the replacement procedure and the average rate of repair garages. Last but not least, get a basic quote for power steering pump replacement in a repair shop, so you can understand how the estimates on replacing the power steering pump can vary so extensively.

Now, to justify the previous questions three Googled websites:

Which fluid should I utilize? Auxiliary tech parts hunting informs that the most effective fluid is that of the manufacturer’s guidance. This guarantees the best results because these fluids are made to have the best viscosity and be compatible with steering system parts. Maintenance of the required fluid is very important for the effectiveness and durability of the system.

Fluid level must be checked periodically but how much more? Otherwise, I have concluded that there is a need to check the power steering fluid at least once every month. Thus, from time to time I can check if there are no leaks that would cause the amount of fluid to drop below the specified volume. This also helps in resolving issues associated with low fluid levels.

What makes the power steering fluid low? Squealing, uncomfortably tight steering, and, poor return of the steering wheel are among some of how the sources say low power steering fluid might be evidenced. They are important signs because they indicate too low, or too little, fluid pressures which range within the pump thereby pushing it to extremes when not alleviated quickly. Optimal fluid levels help in the effective operation of the power steering system.

Can Preventive Maintenance Help Avoid Power Steering Pump Noise?

Regular Check-Ups of the Power Steering System

Regular maintenance of the power steering system is important for the prevention of noise and the facilitation of its proper functioning. It is during these checks that I observe such things as the fluid level seeking evidence of any dissipation or dirtying. I make sure everything is right regarding the power steering pump and hoses, which are devoid of any defect such as cracking or wearing that could result in loss of fluid. It’s also worth looking at whether all elements of the power steering system are fitted and oriented properly in their bolt-down positions. It is disclosed in my review that if the steering system is ‘quiet’, then it is probable that the components have been well taken care of, and hence, noise may be avoided if the systems are regularized.

Now, to answer the questions succinctly based on the leading sources:

What kind of fluid do I need? I use the manufacturer’s recommended fluid for this is made to fulfill certain physical parameters such as viscosity and material compatibility which helps in carrying out the work effectively.

How often should I check the fluid level? I make it a point to check the fluid level every month to ensure that there are no undue delays in corrective fluid requirements and that the likelihood of possible leakage is reduced.

What are some symptoms of low-power steering fluid? Is there whining stiff steering or a lag? If such signs are present, it means that the fluid levels are low. This is likely to be harmful to the pump and steering attachments therefore action should be taken immediately.

If I keep these preventive activities regularly, I can ensure that the power steering system remains efficient and quiet.

Importance of Using the Right Power Steering Fluid

Choosing the right power steering fluid is of utmost importance since its impact determines the efficiency and lifespan of the power steering machinery. This is because different vehicle makers do have some specifications on certain categories of fluids that meet the specific needs of their manufactured vehicles. Such specifications also ameliorate the materials of the system construction as well as the liquids which should be within the defined range of temperature and viscosity.

In a bid to satisfy the questions that arise after expounding on the problem, the best-rated scientist-sourced sites have the following concise answers.

What type of fluid should I use? The top sources recommend using the manufacturer’s specified power steering fluid. This has been designed to optimize the tank with the correct viscous-based oil, and the relevant system with appropriate additives for efficient operation of the system among other ways.

How often should I check the fluid level? Most of the top websites seemed to agree on the fact that the fluid level check should be performed every month. This foolishness on the other hand appeared to be quite sensible since it emphasized the practice of checking the level of fluids in the system to avoid some parts of fluids in the steering system.

What are the signs of low-power steering fluid? Possible signs are whining (an abnormal sound), some resistance or stiffness while steering, and a slight lag when trying to make any steering movements. Such symptoms are indications of low fluids which require immediate corrective action to avoid damage to the pump or the steering systems.

Understanding and adherence to these requirements is essential in the maintenance of the power steering system in the quietest and most operationally effective way possible.

Keeping the Power Steering Belt in Good Condition

The power steering belt is an important component, as it has an impact on the steering system’s performance. Over time, belts may become aged leading to either slippage or wear and total internal belt failure which then worsens the steering system. Here are some useful recommendations on how to maintain the power steering belt and why it is so important.

- Regular Inspections: Accordingly, I am to frequently inspect the belt visually for any signs of cracks or glazing and also for wear and tear. This should be done every few months or when carrying out routine maintenance on the vehicle.

- Tension Adjustment: The tension of the belt should be enough to avoid the risk of slippage of the belt but not excessive to make the belt wear out faster than usual. One of the top websites on the power steering belt states that in terms of tension, the deflection distance of about 10-12 mm of the newly fitted belt should be the guide while moderate pressure from fingers should be applied at the middle portion of the belt.

- Replacement Schedule: It has been suggested by other researchers and thus I should make a change of the power steering belt after approximately between 60,000 and 100,000 miles, but specific recommendations should be sought from the vehicle manual.

- Keep it Clean: I should also make sure that the belt and pulleys are clean and dry, that is free of both oil and dirt since this will degrade the performance and may result in breakage.

On the first three websites examined on google.com, all three stress the importance of these maintenance practices to avoid steering performance issues. Following these guidelines helps in making the power steering system dependable and the incidence of sudden failure low which ensures the safety of the drivers in the end.

Frequently Asked Questions (FAQs)

Q: What are common signs that my power steering pump is going bad?

A: Common signs that your power steering pump is going bad include whining or groaning noises when you turn the wheel, difficulty steering, and fluid leaks around the power steering pump or power steering reservoir.

Q: How can I tell if the noise is coming from the power steering pump?

A: To determine if the noise is coming from the power steering pump, listen closely while someone turns the steering wheel all the way left and right. If the noise sounds like it’s coming from the power steering area, your PS pump may be the issue.

Q: Can air in the power steering system cause the power steering pump to make noise?

A: Yes, air in the power steering system can cause the power steering pump to make noise. It often sounds like a whining or groaning noise when you turn the wheel.

Q: How do I know if my power steering pump bearing is going bad?

A: If the power steering pump bearing is going bad, you may hear a grinding or whining noise when the engine is running. The noise may increase with engine RPM and when you turn your steering wheel.

Q: What should I do if I suspect my power steering pump is bad?

A: If you suspect your power steering pump is bad, check for fluid leaks and listen for unusual noises when you turn the wheel. If necessary, replace the pump with a new pump to resolve the issue.

Q: Can a bad idler pulley cause noise similar to a bad power steering pump?

A: Yes, a bad idler pulley can cause a noise similar to a bad power steering pump. The idler pulley noise usually changes with engine RPM and can be mistaken for a power steering pump issue.

Q: How do I diagnose if the noise is coming from the pump pulley?

A: To diagnose if the noise is coming from the pump pulley, listen for changes in noise when you increase the engine RPM. If the noise gets louder, it could indicate that the pump pulley or the power steering pump itself is the problem.

Q: What happens if I ignore the noise from my power steering pump?

A: Ignoring the noise from your power steering pump can lead to further damage, making steering difficult and potentially causing complete pump failure. It’s important to diagnose and fix the issue promptly.

Q: How do I replace the power steering pump?

A: To replace the power steering pump, disconnect the power steering reservoir, remove the pump pulley, and detach the power steering rack. After removing the old pump, install the new pump and reassemble the components.

Q: Is a transcript or guide available for replacing a power steering pump?

A: Many automotive repair manuals and online resources offer a step-by-step transcript or guide to help you replace a power steering pump. These can provide detailed instructions and tips specific to your vehicle model.