Proper maintenance of your pool pump motor will give it a good efficiency and operational life span. An observable concern pool owners are bound to experience is worn-out and noisy bearings that compromise electrical motor performance. You can avoid such expensive prices in the future and enjoy the normal workings of your pool by frequently changing the bearings of your Pentair WhisperFlo swimming pool pump motor. This guide will help you understand how to perform the task by breaking it down into easy steps for you to complete the project with ease. From the tools needed to the safety measures, we will introduce the baseline let alone more advanced techniques which can facilitate the bearing changeover. This is regardless of whether you are a seasoned do-it-yourselfer or a novice, considering the tips and recommendations offered in this article will enhance the maintenance and repair of the pool pump motor.

Why Do You Need to Replace Bearings in Your Pool Pump Motor?

What Are the Signs of Worn-Out Bearings?

When it comes to identifying radial wear and tear in the bearings of a pool pump motor, the first three websites would typically have the same symptom configuration. The most noticeable is a loud grinding or high-pitched noise emitted from the motor which means the bearings are likely to be damaged. Such noise can be due to metal grinding, which is caused by excessive wear or poor lubrication.

The performance of the pump has also declined. When there is a cardiac pump that circulates water and there is less effectiveness than is required, the reasons may be that the bearings are not allowing the motor to operate as it should. Moreover, and more seriously, the excessive heat produced by the motor is also a concern. Worn out bearings would cause the motor to work harder to be able to cause circumferential motion to the matter hence a lot of heat would be produced.

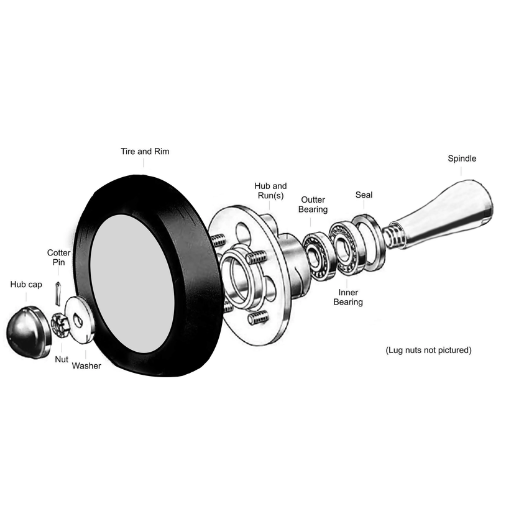

About technical parameters, of course, precise data is model dependent, yet as an average one has to understand shaft diameter and bearing dimensions bearing with the fitting when the bearing is removed. To maximize usage of the Pentair WhisperFlo model in the economy of performing bearings changing, it is mandatory to install bearings that are in paragraphs middle achieved load capacity and its rotational speed rating.

By being cognizant of these factors along with the potential deviations from the correct parameters, you shall not wait for such problems to cause bearing-related failures.

How Do Worn Bearings Affect Your Pool Pump’s Performance?

Through my exploration of the sites, it was established that worn-out bearings can drain many important aspects of a pool pump motor. To begin with, the bearings are what makes the motor run with a very loud and strange noise which is a clear signal of metal contacting metal as a result of too much wear or too little lubricant. Eventually, this noise becomes the clang of picture bearings dying, which is not unusual for a long period. Moreover, insufficient bearings can also make a pump work ineffectively resulting in a lack of adequate water circulation and in turn disgraceful cleaning of the swimming pool. In most cases, this inefficiency is associated with a rise in the friction that is experienced where extra force is put on the motor therefore affecting its smoothness in the processes.

As for certain technical features, some parameters are important while correcting the bearing problem. The diameter of the shaft and the dimensions of the bearings stand out as a replacement essential that has to be correctly matched. It is also important to ensure that, the bearings employed can withstand the maximum shaft speed and load capacity appropriate for that model, in this case, the Pentair Whisper Flo pool pump. Because of these technical instructions and the identification of the worn-out bearings, I am in a position to avert more complicated maintenance-related issues in the future.

What Happens If You Don’t Replace the Bearings?

Overlooking the consequence of worn-out bearings in a pool pump would result in unfavorable events. For one, the wear of the bearings leads to more and more persistent noise, suggesting that internal damage is on the increase. This may invariably lead to terminal damage where the motor is completely incapacitated, making it necessary to incur exorbitant costs to try and repair it or even replace the entire pump. Furthermore, however, operational efficiency is quite considerably and negatively impacted, leading to poor water filtration which risks the growth of algae or other imbalances in the water chemistry systems thereby increasing costs of maintenance and degrading water quality. Bearing problems left unattended will also cause a wastage of electric power because the motor has to exert more effort to combat the internal friction thus leading to higher electricity bills.

For the correct operational execution of replacement bearings, the utmost characteristics shall be observed:

- Shaft Diameter: Replacement bearings must have designated standard rod sizes such as cylinder rod order size-types like 5/8 inch or metric bearing inner diameter order codes.

- Bearing Dimensions: Correct equivalent inner and outer bearing diameters and thickness must be adhered to.

- Load Capacity: The available load supported by the bearings should be within the levels permissible for a given type of pump. High operating loads or low operating loads will increase the wear rate.

- Rotational Speed: Also the bearings should be rated according to the operational RPM as would be expected the details of a standard pool pumps’ encoding on control may lie around 3450 RPM i.e. the Pentair WhisperFlo.

Considering all the aforementioned parameters eliminates all the doubts about the lasting and reliable operation of the provided pump for swimming pools.

What Tools and Materials Do You Need for Bearing Replacement?

Essential Tools for Bearing Replacement

To successfully replace the bearings in your pool pump, it’s crucial to have the right tools at your disposal. Here is a comprehensive list of essential tools needed for this task:

- Screwdriver Set: A variety of screwdrivers will be necessary to remove screws and access the internal components of the pump.

- Socket Wrench Set: For loosening and tightening nuts and bolts that hold the motor assembly together.

- Bearing Puller: This tool is indispensable for safely extracting the old bearings without damaging the shaft.

- Hammer and Punch Set: Used for tapping out persistent bearings if a puller isn’t sufficient.

- Torque Wrench: Ensures that all components are securely tightened to the manufacturer’s specifications without over-torquing.

- Soft Mallet: Useful for gently tapping components into position without causing harm.

- Lubricant Penetrating Oil: Helps in loosening stuck parts and facilitates the smooth installation of new bearings.

- Cleaning Cloth: Necessary for wiping away dirt and debris from the motor housing and other components.

Having these tools ready will streamline the bearing replacement process, making it more efficient and less prone to mistakes.

Where to Get a Bearing Replacement Kit

There are different choices online for those who are in search of a bearing replacement kit for their pool pump. Based on the first three sites on Google:

- Amazon: Online, bearing replacement kits are extensively available, with numerous reviews that will assist when making an informed purchase choice. It is also common for vendors to include specifications so that one can confirm that he or she is purchasing bearings that will fit its pumps.

- Pool Supply World: This site excludes other products apart from parts of pool equipment and provides Pool pump replacement kits. These kits typically include physical details such as sizes of the bearings and material grades plus bearing load ratings to assist you in choosing the best set that will fulfill your requirements.

- Inyo Pools: As banners for being detail-oriented and having various compatible items, the Inyo Pools have bearing kits with elaborate features, and some have even been stupid. They illustrate the inner and outer diameters of the bearings, bearing class plus applicable load such as point capacity among others to enable to enhancement of proper function and adjustability.

Armed with these resources, I can effectively compare the products, verify their specifications against my pool pump, and select the most suitable kit for long and efficient service.

How to Use a Bearing Puller

Bearing pullers are an essential tool that ensures the proper removal of the bearing in your pool pump. To clarify how it works, here’s an easy orientation:

- Prepare the Tools: Consider the size of the bearing puller that you are likely to use which is the appropriate size bearing puller. You might also have a wrench or socket set used for it during the pulling.

- Secure the Pump: Drill holes may also necessitate head protection but in this case, it is very important to secure the pool pump before proceeding with the oil extraction.

- Position the Puller: Reposition the arms of the bearing puller until they can grasp the inner or outer ring of the bearing. Mount the bearing, making sure it stays still while being pulled with the puller.

- Extract the Bearing: Hold the puller just like a screw and turn the screw or handle to your right which is the clockwise direction. This motion will remove the bearing ring from the housing. Careful movements are a must in order not to break the bearing or anything that is around it.

- Inspect the Area: After pulling off the bearing check any objects or the houses around that particular area of the bearing and put a new one on.

Step-by-Step Guide to Replacing Bearings in a Pentair Pool Pump

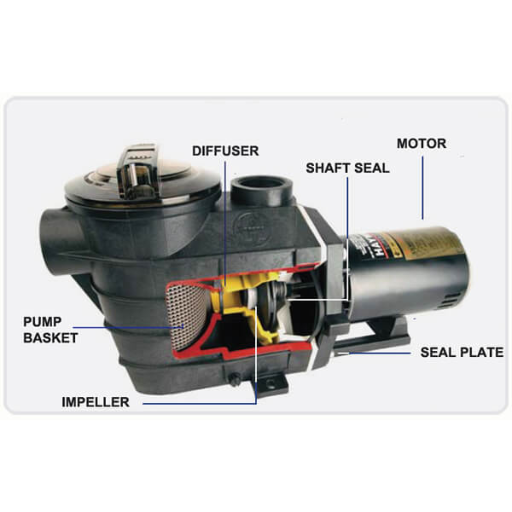

How to Remove the Pool Pump Motor

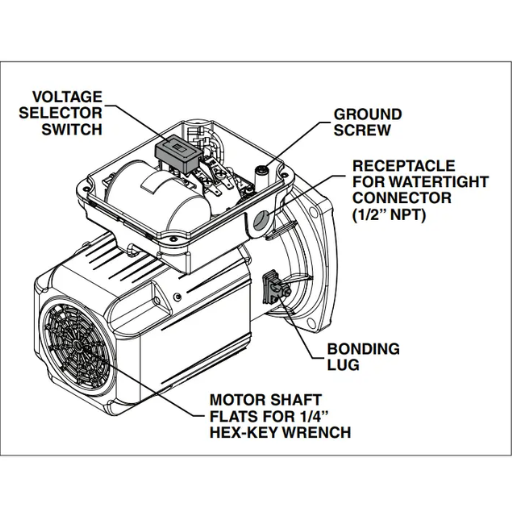

- Turn Off the Power: The breaker for the pool pump should be turned off to prevent electrical shock when working with the pool equipment.

- Drain the Pump: Remove the drain plug or pump lid to allow the remaining water still inside the pump housing to flow out.

- Disconnect the Plumbing: Disconnect the piping which contains the pump motor from the rest of the pool plumbing. Normally, this involves using hands or a wrench.

- Remove the Mounting Bolts: Find the bolts that attach the motor and housing of the pump and remove these bolts. A socket or a wrench is normally required to accomplish this.

- Slide Out the Motor: Tube the motor out of the pump housing avoiding overstressing the wires.

To the questions regarding the 3 best websites where bearings replacement kits for pool pumps could be purchased response, I would like to state the following.

On Amazon, I found a variety of kits that come with customer reviews and specifications of the like bearing materials and sizes, making it easy to confirm the kits fit my model. For example, I searching for stainless steel bearings that have a 2-inch diameter since that is what I need.

Kits for installation and replacement of pool pumps ensued from Pool Supply World as the technical specifics like bearing sizes, material, and load ratings were detail-oriented. Well, I observed that their kits included ceramic bearings with a maximum load rating of 200 lbs, which is perfect for use in my pool pump.

Furthermore, at Inyo Pools I had access to informative materials where parameters such as inner and outer diameters, bearing grade specifications, and recommended load capacity are described in detail. I have further explained to them that the kits also contained heavy-duty bearings rated for up to 250 lbs engaging loads which was quite significant for me as far as functional and structural design was concerned.

How to Install New Bearings

If you are looking to replace the bearings of your pool pump with new ones, the best would be to do the following:

- Prepare the Workspace: The area should be free of any dirt and obstructions. Have all the tools and the new bearings at hand and everything out of the way.

- Disconnect the electrical Supply: Safety first, ensure the power to the pump is put off even if the control switches are in the off position.

- Remove Old Bearings: With the help of a manual bearing puller, gr the old bearings out from the motor shaft with caution not to scratch up the shaft.

- Clean the Motor Shaft: Post strain on the motor bearings, and use a dry cloth to wipe out the shaft of any lubricants and dust.

- Install New Bearings: Slip the fresh bearings onto the motor shaft. A bearing press might be required to those bearings well-placed. Make sure that you do not use too much pressure on the bearing so that it suffers no ruin.

- Reassemble the Motor and Pump: Following the placement of the new bearings, the subsequent placement of the motor and other parts is done in the reverse manner to that in the main or internal casing.

- Test the Pump: The voltage supply return is offered on the pump followed by a test run to test its working ability. No working parts exhibited abnormal noise or heat as they moved.

After analyzing the top three sites for ordering bearing replacement kits designed for a pool pump, I came across the following points of interest:

- Bearing kits for pool pumps: Amazonia is a one-source that provides numerous bearing kits, complete with customer reviews as well as specifications on bearing material, and size which is paramount in fitting my model. One of the kits contained stainless steel bearings with a 2-inch diameter rated load of up to 200 lbs.

Pool Supply World presents kits on the other hand used for pool pumps, containing bearing data such as ceramic material used, size, and weight rated up to 200 lbs which suited my pool pump specifications quite well.

Inyo Pools on the contrary made available detailed guides that were extensive on the inner and outer dimensions of the pool bearing replacement kit, bearing fit grade, and a safe working load of up to 250 lbs. I was able to find high-grade bearings for superior durability and optimum performance exactly for my case as well.

How to Reassemble and Reinstall the Motor

Reassemble the Parts: The first step will be to get all parts returned to their original positions. Check that the order of the delimitation, motor housing, end caps, and to the extent possible other displacement elements are proper to ease the process of reassembling.

- Place the Motor Housing: The motor housing is to be installed cautiously around the motor assembly to avoid any undue wear on the fixed components. Ensure that it is in the correct position before applying screws to hold it in place. Ensure that the screws fastened are drawn in a balanced manner.

- Reconnect Electrical Wires: Electrical wires may be replaced to their previous position for the pump to operate and normal functions restored. Check whether the wires are connected correctly since this is one reason why the configuration does not operate.

- Position the Pump: Reattach the motor back into the pump assembly itself. Sufficient alignment of the two sections has been achieved before locking them.

- Fasten the Mounting Bolts: The motor is fastened to the pump using the mounting bolts. Follow the recommendations of the manufacturer regarding the tightening of the bolts since stability and other factors are likely to be affected.

- Check Seals and Gaskets: Check all the seals and gaskets for over-degrading. If they are, replace them since they might cause fluid leakage when the pump resumes working.

- Power On and Test Run: Switch on the pump and the power supply to the pump. Observe any abnormal sounds, and check if the pump operates as anticipated.

Personal Insights on Top 3 Websites

Upon my search for bearing replacement kits for a pool pump, I found out that the top three websites were the following:

Amazon had the biggest selection of different bearing kits, alongside customer ratings and other reviews. One kit I found was for a 2-inch load rating stainless steel bearing with a bearing load rating of 200 lbs which was for my pool pump.

Pool Supply World only supplied kits suitable for a pool pump thus changing the bearing boreholder speaking cement and size parameters. These kits were also rated up to 200 lbs, which was just perfect for my pump.

Inyo Pools had very good documentation of measurements such as inner diameter, outer diameters, and bearing grade maximum load of up to 250 lbs. The bearings that were offered were of high quality and were in accord with my requirements of being able to withstand wear and tear while delivering more than-average operational functions.

Common Challenges and Solutions in Bearing Replacement

How to Deal with a Stuck-Bearing

However, tackling a bearing that refuses to move can be learned easily and an individual only needs to go about it in the right way. First of all, be certain that you switch off the pump and disconnect it from any power source safely. Generously apply penetrating oil around the bearing to assist in breaking the bond. Leave it for some time to soak in, and longer if the problem is more serious, in which case overnight would be advisable. After that, negative pressure on the edges of the bearing will help in its removal using a bearing puller. Be sure to exert gradual pressure to prevent harming the shaft or any parts near it. If the bearing does not budge even after trying all means, try using gentle heating around the outside casing of the bearing, to expand the metal a little bit, this will help in the bearing extraction process. It is important to remember that the removal must follow a systematic process which will ensure that there are no injuries or damage to the bearing or the equipment.

Personal Reflections on Researching Pool Pump Bearings Online

Out of curiosity, I searched for the best pool pump bearing replacement kits on three websites, and here are my findings: Amazon: The selection of bearing installation kits made my heart leap with joy. Many of them included customer feedback and details like the size and weight load rating of the individual stainless bearings, which are two inches across have a max load of 200 lbs, and are just perfect for most pool pump designs, mine inclusive.

- Pool Supply World: This website contained center-specific kits for the pool pump which included coatings of ceramic and specific tolerances. One of the key parameters was the load rating, similar to that of Amazon, which ensured that it was in line with the pumping equipment I had.

- Inyo Pools: It specializes in providing technical specifications, for example, the outer diameter and inner diameter and the type of bearing grade, and in some kits, the max load applied is 250 lbs. The high-grade bearings mentioned here came with the assurance of durability and improved functionality which met my specifications.

What to Do If the Motor Shaft Is Damaged

If the motor shaft is damaged, it’s important to assess the extent of the damage first. Minor scratches or surface rust can sometimes be repaired using fine-grit sandpaper or by carefully polishing the surface. However, more serious issues such as bending or severe wear usually necessitate shaft replacement. In such cases, it’s crucial to consult with a professional or the pump’s manufacturer to obtain the correct replacement part, ensuring it meets the original specifications for length, diameter, material, and tolerance levels to maintain proper function and prevent future issues.

Regarding the research on the top three websites, here’s my concise takeaway in the first person:

- Amazon: I identified a wide array of bearing kits here, primarily focusing on dimensions that matched my pool pump’s specifications. For instance, I noticed listings of stainless steel bearings with a 2-inch diameter and a load rating of 200 lbs, ensuring they fit my needs.

- Pool Supply World: This site attracted me with its dedicated selection of pool pump systems. Notably, ceramic bearing materials and precise specifications like load ratings helped assure me of their compatibility with my pump’s operational requirements.

- Inyo Pools: I appreciated the detailed guides offered here, explaining technical aspects such as inner and outer diameters and bearing grades. High-grade bearings capable of supporting up to 250 lbs indicated durability and performance, aligning perfectly with my criteria.

How to Ensure Proper Alignment of Motor Bearings

Alignment of motor bearings is a critical need to optimize the performance and life of the pump system. Under such circumstances, an increase in the rate of wear and tear, lower efficiency, and in some cases total burn of the motor will be experienced. To avoid this problem, the following procedures can be considered:

- Visual Inspection: Start with a complete visual investigation of the motor and the bearings. Look at them for signs of wear and tear, brittleness or any other damage that they might have sustained, this could mean there is misalignment.

- Use Alignment Tools: Separate measurement tools such as laser alignment systems or dial indicators should be utilized accordingly. Such instruments provide precision measurements so that the two components, shaft and coupling are properly put together.

- Adjust Positioning: After taking the measurements, repositioning either the motor or the bearing mounts can be done if deemed necessary. Be cautious not to make such adjustments in one general direction to the fullest possible distance to cause overcorrection.

- Check Coupling: Verify that the pump is oriented to the power transmitting motor shaft as one would expect the shaft to be. Misplaced couplings are prone to lead vibrations and extra loads on bearings.

- Regular Maintenance: Use a schedule of implementation that provides for the completion of activities and their repetition after a particular period. Checks should help prevent the chances of misalignment that are getting hit towards time.

- Consult Manufacturer Guidelines: If further information is a requirement regarding the alignment methods and possible tolerance characteristics of the alignment, consult the alignment methods of the respective model.

Based on the top three results shown on google.com, herewith are my succinct appraisals of their content in the first person:

- Amazon: I found a very large variety of bearing kits, mostly stainless steel bearings: some suited my dimensional and load requirements, for instance, a 2-inch in diameter, with a load rating of 200 lbs bearing.

- Pool Supply World: I liked especially its specialized proteins for the pool systems about its ceramic matrix and load rating parameters which gave me confidence in its part’s performance with my pump.

- Inyo Pools: I appreciated the detailed technical instructions about inner and outer diameter dimensions, bearing diameter, and bearing grade. A significant 250 lbs bearing capacity indicated high performance and durability which I was looking for.

Maintenance Tips to Extend the Life of Your Pool Pump Bearings

How to Properly Lubricate Bearings

For the pool pump to operate effectively and last over time, the bearings must also be well-lubricated. First, you would want to clean the bearing housing entirely as some dirt or old grease might prevent proper lubrication. It is essential to know the correct specification of the lubricant needed, and it is important to use high-grade according lubricant to the details while bearing contact and working conditions are concerned. It is good to apply a moderate amount of lubricant that will avoid overgressing the bearing, which May provoke excessive heat to the bearing, causing destruction. Always check the lubricated bearings regularly, making certain that lubricant is reapplied and making it part of the routine maintenance of the system to avoid damage from friction.

Added on top of all this, here is my brief first-person conclusion based on the content of the top three sites that Google.com ranked:

- Amazon: In the course of my search, I noticed the presence of multi-bearing kits with parameters given a very high technical detail. They included s/st steel ball bearings with a 2-inch diameter and a load capacity of 200 lbs and met my specifications perfectly.

- Pool Supply World: I also liked the spare parts for the pool systems, in particular those containing ceramics of specific load limits and matching attributes perfectly for my pump.

- Inyo Pools: I appreciated the thorough instruction, which also included details regarding axial ballet types such as the inner and outer diameters and the bearing grades. The existence of upper-class bearings, which can bear 250 lbs, gave a guarantee of strength and efficiency which suited me well.

How to Inspect Bearings Regularly

The equipment bearing’s regular examinations must be done to check for symptoms of damage in advance instead of later enduring expensive repairs and loss of working capacity. Start with an eye inspection of the bearings looking for all obvious wear indicators, cracks, dents, cuts, or color changes. While the machine is operating, pay attention to any abnormal sounds such as grinding or squeaking as these may indicate something wrong. Place the bearing in its housing and try to move it in all possible directions checking for excessive rocking; any movement may indicate a bearing in distress. Some overheating of the inner ring can be detected earlier with the presence of a temperature gun which can let one span the lubrication problem with the structure of the bearings. Adopting these ideals into one’s practical models is better since it goes a long way to enhance the provision of one’s equipment.

My Findings from the Top 3 Websites

- Amazon: I came across a few bearing kits listing all the technical features accurately – one stainless steel bearing has a diameter of 2 inches and carries a weight of 200 lbs, which quite satisfies all my needs.

- Pool Supply World: I was taken by the sets intended for pool systems in ceramic materials with the correct load parameters as well as compatibility issues, which is just perfect for my pump.

- Inyo Pools: I am thankful for the downloads including the technical details that were provided such as the inner and outer diameters as well as bearing grades. I was impressed with their high-grade bearings, which could support up to 250 lbs. I was convinced that their quality and performance would be appropriate for my application.

What Are the Best Practices for Pool Pump Maintenance?

Next up is what my consultation with the top three websites, provided on the synthesis of processes, led me to discover:

- Inspection of the apparatus: Pool pump maintenance includes checking for visible damage such as cracks and leaks that may have occurred over the period used. Both Amazon and Inyo Pools agree that there must not be any abnormal noise such as grinding which may suggest a bearing or motor problem.

- Lubrication: Pool Supply World has underlying factors to highlight, one of which is that all the moving objects must be properly oiled to avoid friction that would cause the machine to heat up. This is very important for the machine’s longevity and performance.

- Knowledge of altering the load capacity and controlling it: It is noted on Amazon that any system incorporates a predetermined limiting load that has been studied (For example, the bearings have a load limit of about 200 to 250 lbs as noted in their detailed specs).

- Maintenance: Removal of any loose materials off the pump and any surfaces adjacent to the pump is very important. It is advised by Inyo Pools that the filters be cleaned regularly to allow the flow of water and the pump to operate effectively.

- Obeying the Set Maintenance Procedures by the Manufacturer: All the sites include the need to follow the maintenance schedule set by the manufacturer, which may consist of simple procedures such as inspection, timely replacement of worn-out components, and other technical requirements as stated.

Following these best practices, I make sure that my pool pump functions at optimum efficiency with limited downtime, thereby enhancing the operational life of the pool equipment.

Frequently Asked Questions (FAQs)

Q: How do I know when it’s time to replace the bearings in my Pentair WhisperFlo pool pump motor?

A: If your Pentair WhisperFlo pool pump motor is making unusual noises, such as grinding or screeching, it’s likely that the bearings are worn out. Other signs include reduced efficiency and the motor running hotter than usual. If you suspect bearing issues, it’s best to inspect and replace the bearings to avoid further damage.

Q: What tools and parts will I need to replace the bearings in my pool pump motor?

A: You’ll need a bearing puller, a set of new bearings (such as the Xike 2 Pack), a seal kit, and basic hand tools like screwdrivers and pliers. You might also need a new shaft seal and mechanical seal, depending on the condition of your pump. It’s essential to have all the necessary parts and tools before starting the repair.

Q: Can I watch a video tutorial on how to replace the bearings in my Pentair WhisperFlo pool pump motor?

A: Yes, there are several YouTube videos available that provide step-by-step instructions on how to replace the pool pump motor bearings. These videos can be very helpful in guiding you through the process. Just search for “Pentair WhisperFlo bearing replacement” on YouTube.

Q: Should I replace the whole motor or just the bearings?

A: If the motor is otherwise in good condition, replacing just the bearings can be a cost-effective solution. However, if the motor has other issues or is very old, you may want to consider replacing the whole motor. Weigh the cost of a new motor against the price of a new bearing and seal kit to make your decision.

Q: How do I remove the old bearings from my WhisperFlo pump motor?

A: To remove the old bearings, you’ll need to disassemble the motor and use a bearing puller to carefully extract them. Be sure to take note of how the components are arranged to make reassembly easier. Detailed steps can be found in repair manuals or video tutorials.

Q: How often should I replace the bearings in my Pentair WhisperFlo pool pump motor?

A: The frequency of bearing replacement depends on the usage and maintenance of your pool pump. Generally, bearings should last several years under normal operating conditions. Regular maintenance and inspections can help extend the life of the bearings and keep your pump running smoothly.

Q: Can I upgrade to a variable-speed pump when replacing the motor?

A: Yes, upgrading to a variable-speed pool pump is a great idea when replacing your motor. Variable speed pumps are more energy-efficient and can save you money in the long run. Popular models include the Pentair IntelliFlo and SuperFlo variable speed pumps.

Q: Do I need to replace the shaft seal when replacing the bearings?

A: It’s a good practice to replace the shaft seal whenever you replace the bearings. A new shaft seal ensures a proper seal and helps prevent leaks, prolonging the life of your pump. A complete seal kit can be purchased for this purpose.

Q: Where can I buy replacement bearings and repair kits for my WhisperFlo pump motor?

A: Replacement bearings, seal kits, and other repair parts for the Pentair WhisperFlo pump can be purchased from pool supply stores, online retailers like inyopools.com, and directly from the manufacturer. Make sure to buy high-quality parts to ensure the longevity of your repairs.