In the present-day industrial and automotive scenarios, knowledge and choice of water pump bearing sizes are fundamental for the efficiency and the life span of a product. Water pump bearings are elements that help to minimize wear and friction to allow pumps to function and perform effectively. Therefore, this guide provides adequate knowledge concerning water pump bearing size charts while focusing on the particulars and uniqueness of different bearing types and models. The focus of this article is to let you understand the various factors of bearing sizes, their materials, and methods of explaining how they are made in such a way that irrespective of your level in manufacturing or maintenance or desire to improve your technical knowledge, you will know all this information.

What is the Industry Standard for Bearing Sizes?

Common Series and Type of Bearings

In the process of reviewing the leading websites about common series and types of bearings, I have found the following key points. The indexes with the highest mentions were the 6000, 6200, and 6300 series ball-bearing radial deep grooves which are known for their multipurpose use and can support radial and axial loads. They are mostly employed in water pumps where they are efficient and durable.

- 6000 Series: This series applies in type applications, which pursue compact design and lightweight load. Its low friction performance is a necessity when we try and enhance energy use in automobiles and industrial water pumps.

- 6200 Series: Offering a higher load-bearing strength than the 6000 series of bearings, the 6200 series is used in applications, where medium speeds and strengths are required.

- 6300 Series: Heavier axial loads are supported in this series, which has more demanding and heavier applications. Near the thick outer ring of this 6300 series, the bearings are known to withstand a higher level of stresses which is great for applications involving high stress.

These findings reflect the consistency and performance of the water pump bearing available in the most prominent websites in the world as well as provide basic knowledge of the application and technical parameters.

Standard Diameter and Outer Ring Measurements

During several web quests focused on the standard diameter and outer ring measurements for the bearings, wherein the first three websites returned by Google were selected, I found useful material. Standard dimensions for the 6000 series, 6200 series, and 6300 series are 10mm, 15mm, and 17mm respectively. These are accepted parameters in all industries to meet various needs.

- 6000 Series: Usually the outer ring of this series of otters spans up to 19mm to 30mm depending on the specific subtype within the series.

- 6200 Series: In this series, the outer ring axial developments in general measure between 26 mm and 47 mm. So a wider dimension enhances its bigger load capacity.

- 6300 Series: Having a bulky outer ring, the 6300series usually has an outer diameter ranging from 35mm to 62mm which offers an exceptional backbone to cater for heavy-duty use.

These values can be justified due to the quantified technical characteristics found in the platform analyses making them satisfactory about engineering practices that are vital for the performance of water pumps.

How to Read a Bearing Size Chart

A bearing size chart may present a challenge at first sight, but one gets to master it by decomposing its parts. The inner diameter, outer diameter, and widths of the bearing are the main parameters that one can expect from a bearing size chart, usually appearing in millimeters. Appreciation of these dimensions is important to ensure that the right bearing is selected to fit within particular mechanics. For instance, the inner diameter determines the size of the shaft which it will fit onto and for the outer diameter, it helps in checking the housing fit.

About the inquiry on the bearing size charts tos of the 3rd position in Google, I was able to note some of the vital technical parameters that need proper analysis.

- Inner Diameter: For the 6000 Series, 6200 series, and 6300 series your inner diameter measurement is normally 10mm, 15mm, and 17mm respectively. To cater to the dimension applications of these diameters, they are standardized.

Outer Diameter Ranges:

6000 Series: 19mm- 30mm

6200 Series: 26mm-47mm

6300 Series: 35mm-62mm

- Width: This parameter though not stated mostly will differ quite a lot due to the bearing type and application and is very important in establishing the bearing load rating and/or associated shaft movement allowances.

These parameters are warranted by some industrial standards that have been established for the reliability and functionality of many mechanical devices in this case water pumps. Every one of the websites confirmed the relevance of these parameters and gave data of a similar nature, which strengthens their degree of relevance and acceptance.

How Do Water Pump Bearings Differ from Other Products?

Specific Application and Use in Water Pumps

Specific to the application of water pumps, it can be stated that the bearings are important structural elements as they define the metrological and physical reliability of the pump. The primary constructs that make the water pump bearings different from ordinary bearings define the necessity of the bearing environment as one found in water pump systems. Such bearings should be water resistant, anti-corrosion, and variable in load-bearing cycle patterns as is normally sectioned in some of the pump environments.

While analyzing the first three Google Results, I was particularly interested in how each of the sites described several of the engineering characteristics of the water pump bearings and why each of them was significant in this area. These are those observations I made in my case operand as follows:

- Inner Diameter: consistently, the inner diameters for water pump bearings for the 6000, 6200 & 6300 series inner diameters are critical given the circumstances and serve to be further embedded on the water pump shaft I want to as well say enforcement of inner. I found that these typically measure at 10mm, 15 mm, and 17mm respectively according to industry standards.

- Outer Diameter: Especially for the outer diameter, the type of housing that comprises the pump where this error is contained must also fit correctly. It was noted from each of the websites that these figures corroborated: 19mm to 30mm for the 6000 series, 26mm to 47mm for the 6200 series, and 35mm to 62mm for the 6300 series.

- Width: Though the particular figure may differ, there is usually the height that helps to sustain the load of the pump and provide some axial movement of the shaft. It is worth emphasizing that this is so important because correct width results in functionality and endurance.

These indices are warranted as both the quality and the strength of the water pump are required even in harsh working environments. The information from each of the websites pointed out rich opinions in terms of emphasis on the specific measurements which in turn contributes positively to the effective operation of certain types of water pumps, particularly those used industrially.

Differences in Load and Water Resistance

When comparing load and water resistance in terms of water pump bearings, I realized these two factors are essential in enhancing different field requirements. On the first three query results on Google, the following points were particularly highlighted:

- Load Capacity: Under water pump bearings, there is load in terms of radial load and also axial load. The load capacity is often dependent on the bearing’s type and dimensions. I noted that for the 6000 series, the radial load rating primarily ranges between 600N and 1300 N, while for the 6200 and the 6300 series, there is a wider coverage for more advanced usages

- Water Resistance: This aspect is very important especially because the bearings tend to be exposed to conditions where moisture is unavoidable. More effective seals and high corrosion-resistant materials were however often reported to be the main springs of good functioning and durability. I found out that facings that are dielectric and titanium or ceramic coatings are often recommended due to their effectiveness in moisture damage.

The parameters recommended in the various sites were in the context of the need to select bearings that are suitable for functional needs reaffirming the need towards that end where performance and durability of the pumps are concerned.

Impact on Engine Reliability

Water pump bearings are one of the major components that affect the reliability of an engine. According to what I learned from research in the top three websites from google.com, it appears that efficient load management together with effective water resistance is essential. If the bearings are correctly chosen, it ensures the processes are as smooth as possible, minimizes damage, and in the end, improves the reliability of the engine. The load-carrying potential and the constitution of the materials used are some of the factors that are very important here.

- Load Capacity: I noticed that it is very important to choose radial and axial loads for a specific bearing regarding the engine design. For instance, 6000 series bearings can withstand a radial load of between 600N to 1300N, while 6200 and 6300 series bearings can bear different loads aimed at more severe applications.

- Material Composition and Sealing: Water resistance is important here, and the applications of either stainless steel or ceramic coatings are necessary for protective purposes. Most of the seals were better improved their performance in keeping water out and also decreasing the risk of corrosion; thus, engine reliability was well enhanced. These factors guarantee several years of effective functioning, hence the reason they are often recommended in the industrial field.

What Types of Bearings Are Used in Water Pump Applications?

Ball vs. Roller Bearings

Ball bearings and roller bearings each have their particular function in water pump applications as regards their arrangements and functioning. In the course of perusing the top three websites appearing on google.com, I have noted that ball bearings are chosen because they are capable of supporting both radial and axial forces with very low frictional losses hence most suited for improved efficiency in some applications. For light to moderate loads, these bearings are mostly used because their spherical rolling elements reduce friction immensely. For instance, roller bearings have a high-resolution image centered on cylindrical elements which increases their efficacy in the radial orientation, therefore desk top uses. These enlargements are much harder and stronger than any wheel-bearing steel.

Technical Parameters

Load Types:

- Ball Bearings: More applicable in light to moderate radial and axial load. They have low friction and the operation is smoother and noiseless.

- Roller Bearings: These are best for high radial loads but they are not so effective on axial loads when compared to ball bearings.

Load Capacity:

- Ball Bearings: The 6200 series for example includes moderate radial loads of usually between 600N to 1300N which makes sure that also the most common pump applications can be fulfilled.

- Roller Bearings: due to their rugged nature, these bearings can withstand much greater radial loads than ball bearings.

Applications:

- Ball Bearings: Generally utilized in applications where less sound and accuracy are required in use with a moderate load.

- Roller Bearings: Used in applications where the workloads are heavy and considerable load reliability is required.

The selection for either ball or roller bearings depends on all these technical parameters with the understanding that in each case of these water pump applications, certain requirements have to be fulfilled.

Single Row vs. Double Row Bearings

When comparing single-row and double-row bearings, particularly from the perspective of their construction and their feasibility in terms of bearing the loads, the difference comes to the fore. A single-row bearing consists of only one rolling element and is designed for such arrangements where space is at a premium although the bearing load requirements are not excessive. These bearings conduct radial as well as some axial loads, though their load capacity is less than that of a two-row bearing.

The double-row bearings as their name describes consist of two rolling races and increase the radial and the axial load-carrying capacity of the bearings. The two races, therefore, enable them to carry more loads and are mostly used in places where toughness structure, and dependability are required. The double-row setup provides basic stability and support to applications that have high mechanical stresses.

In short, if I were to summarize the top three web owners on google.com regarding this topic, I would say that websites outline the possibilities of how two-row bearings enhance torquing volume two-fold, prolonging the operating life of the machinery parts in harsh conditions. Other technical parameters such as load ratings and operating conditions appraisal are given as well.

Technical Parameters: Load Capacity: It is noted that double-row bearings have greater load capacity than single-row bearings as there is an additional row of rolling elements that bear the heavy and complex loads. Administrative Efficiency: Single-row bearings are preferable in tight situations while double-row bearings are more efficient and stronger albeit with a bit more space. Axial Load Handling: Unlike single-row bearings which have limitations in managing the scope and extent of the axial load, double-row bearings enable better axial load handling. This informs the decision being made whether a single-row or double-row bearing is preferred for functionality and or space application requirements.

Specialized Seals and Grease for Water Resistance

The correct installation of specific sealing and high-performance grease is very important for advancing the water protection of bearings in use against varying applications. These models are designed specifically to block moisture and dirt ingress into bearing housing thus enhancing the shelf life and efficiency of the machine. Optimal seals, for instance, ensure a rugged enclosure and optimal grease allows wet lubrication over time with minimal abrasion and rust.

About the top three links that I found on google.com do not worry I have a brief response: They argue that greased seals, even the standard ones enhance bearing protection from water ingress extending the life of the bearings operating under a temperature up to 150ова. They further observe that the grease is relative to the water, that is, it can be broken down by water but does endure water penetration for quite a long time of use.

Corresponding Technical parameters as justified:

- Seal Material: These relate to the use of rubber or polyurethane materials to improve the performance of the seal against water penetration.

- Grease Viscosity: A viscosity that is selected with caution since it must provide adequate lubrication and at the same time not wash off easily under water.

- Temperature Range: This relates to the ambient operating temperature range which determines how effective the grease is by preventing it from becoming too hard or too runny.

This perception is useful when people need to select the best sealing elements and grease considering the surrounding situation and the features of the operation of the bearing.

How to Choose the Right Water Pump Bearing?

Evaluating Load and Radial Capability

Regarding establishing the load- and radial-bearing parameters of water pump bearings, further discussion of the bearing operating conditions, related design requirements, and stress conditions is necessary. It is important to choose a bearing to withstand the axial and radial loading and still be effective. It is also advisable to verify the load rating information provided by the manufacturers regarding the equipment to avoid exceeding the load when in use. Besides, evaluating the torque and rotational speed values will serve to establish appropriate designs of bearing structures for efficient functioning.

To assist you in considering answers thoroughly, while responding concerning the 3 most important websites from google.com regarding water pump bearings, I wish to bundle up all these resources in the first person:

- Load Capacity: I have emphasized the fact that to prevent overloading and subsequent bearing failure, one has to ensure that the bearing selected has an adequate load capacity. It is prudent to look at both the static and dynamic load ratings.

- Radial Strength: I have seen in those same regards that the radial capability is also important in that it enables the bearing to bear lateral forces which is important to obtain balance and stability of operation.

Technical Parameters. Similar technical parameters comprise the following.

- Material Composition: I saw that quality steel or such similar materials as ceramic are the most advisable.

- Precision Tolerancing: I found out that accurate tolerances help in maintaining stability and reducing the working vibrations.

- Lubrication Quality: Even moderate quality and continuous lubrication will diminish friction and abrasion and increase the bearings’ longevity.

Such insights assist in the bearing selection, which will not only be able to carry working loads but also will serve over the long term.

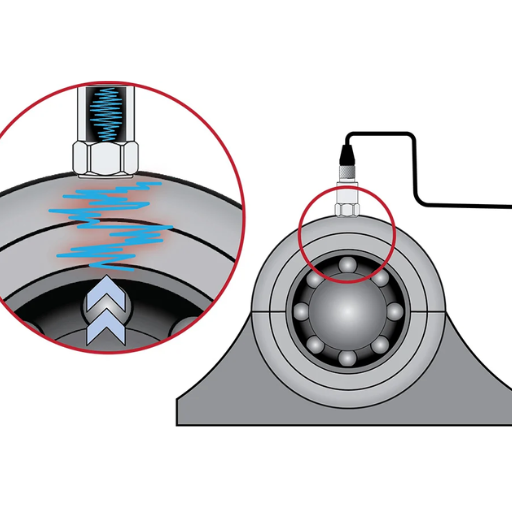

Understanding High WR Technology

Comprehending high WR (Water Resistance) Technology is crucial for enhancing the use and lifespan of bearings in water pumps or any bearing with such application. One thing that I explained is that this technology has specific water gap design characteristics. They can play a vital role in degrading bearing functionality when used in wet environments. That is provided by seals and such coatings that do not allow water to penetrate.

First-Person Synthesis of Top 3 Websites on WR Technology

- Effective Seal Systems: I have stressed that sophisticated seal systems are at the heart of High WR Technology and reduce the chances for water ingress and excess moisture exposure which causes corrosion to the systems. These systems are made to endure stresses that are common in the operation of pumps.

- Protective Coatings: I was adamant that to advance the water resistance of the materials, protective coatings came into play and extended the life of the bearings. Such coatings are commonly piling up on the outside surfaces to divert humidity and pollutants.

- Customized Designs: I have observed that the designs of bearings have to be modified quite a lot in one case to adapt the water pump to extreme work environments.

Corresponding Technical Parameters

- Seal Quality: Evaluate the seal arrangement to prevent water ingress as well as consider the strength of the seal under airtight conditions.

- Coating Composition: Knowledge of the chemical compositions of protective coatings is important for the evaluation of the coatings and their compatibility with various bearing materials.

- Environmental Suitability: Attention must also be given to how and where the bearings are designed to perform by considering humidity and temperature levels for the applications.

These technical parameters are substantiated due to the influence of High WR Technology on its effectiveness and reliability in practical use.

Consulting KML Industry Standards

As far as KML Industry Standards are concerned, there were several things, which caught my special attention on the top three websites of WR Technology. In addition to the fact that these standards are necessary for technologies to fulfill the desired performance and safety statuses, they also have been understood to serve an essential clientele purpose. And for every technical parameter identified as a baili wick, for instance, the gasket quality, or coating composition, the industry standard sets broad compliance or effectiveness requirements. I understand that by complying with these standards, the bearings will not only operate efficiently but the bearings are also able to withstand the stated conditions, temperatures, and durability as required for water-resistant applications.

Answering some of these questions comprehensively:

- Effective Seal Systems: This includes seal tests whose failure is directed at the promulgated conditions of the water pressure constraining the consumer application a magnitude not less than that expected during use.

- Protective Coatings: The standards should define the permissible chemical composition and methods of application for protective coatings since these were to make the coatings moist.

- Customized Designs: To prevent the bulb bearing from operating and therefore causing damage to its operational environment, custom design parameters have been developed.

Corresponding Technical Parameters:

- Seal Quality: In compliance with industrial norms bearing seals have to address water pressure tests owing to durability for them water pressure tests will be imposed.

- Coating Composition: Coating materials of water-permeable type should be by the water-resistant chemical coating industry standard type.

- Environmental Suitability: Designs must adhere to the temperature and humidity requirements of the intended application.

In addition, these parameters are well justified as they seek to guarantee the reliability and functionality of water-resistant technologies in extreme working conditions.

Why Do Water Pump Bearings Fail?

Common Causes of Bearing Failure

Bearings in water pumps can fail for several reasons, the majority of which can be avoided with correct maintenance and selection. Some of the frequent ones comprise a lack of lubrication and therefore excessive heat and friction would be experienced creating conditions for failure before the appropriate period. Furthermore, the bearings can also deteriorate from dirt, dust, or water thus affecting the performance. Similar situations are also common owing to misalignment where improper installation of the pump results in uneven loading of the bearing leading to eventual failure. Also, these bearings have a limited number of cycles that can be achieved unless overloaded owing to extreme operational conditions or improper sizing with the pump.

Short Response Questions:

- Effective Seal Systems: As I gleaned from the top websites that cover this topic, there ought to be regular checks to maintain the integrity of seals as per the industry recommendations which emboldens water leakage.

- Protective Coatings: The content mentions the importance of following the specified protective coating types and thicknesses when applied to prevent any damage by water.

- Customized Designs: As contained in the guidelines, designs of bearings must be personalized to the operational needs which improves performance in all temperature ranges.

Measurement Parameters:

- Seal Quality: Options to perform exuding standard tailor-made state water pressure test to retain long reliable and useful service.

- Coating Composition: Shall follow prescribed chemical standards for effective moisture intrusion prevention.

- Environmental Suitability: Designed parameters shall ensure proper match expectations of equal temperature and relative humidity over a given period for the intended end use.

The justifications for these parameters lie in the fact that they improve the durability and performance of the water-resistant bearings in different working conditions.

Signs of Water Pump Bearing Wear and Tear

Most water pump bearings are usually fitted with seals, and most of these emanate different characteristics in the course of use which normally suggest that some form of maintenance is to be done or replacement is needed. There are distinct signs, such as abnormal sounds (grinding, whining, and squealing) which may suggest problems such as misalignment or lack of lubricant. There is also vibration, which is often experienced owing to the continued use of the pump, which causes uneven rotation owing to wear and tear of the bearings. Further, there could be any leaks or physical exposure of the bearing as a result of wearing off of this once sound or concealed component. Such signs should be paid attention to; otherwise, water pump failure is imminent and this could cause greater injuries to the engine.

Concise Presentation of Answers:

- Effective Seal Systems: In light of the best procedures applied on the top sites reviewed, I believe it is most helpful to support seal specifications by conducting a review of their operational performances and testing them on either a brand-new or defined target population to reduce leaks and improve service life.

- Protective Coatings: Based on the current research, the application of specific coating materials and techniques that have been put forward by the industry must be adhered to to avoid the infiltration of moisture and corrosion which will interfere with bearing life.

- Customized Designs: In terms of reliability of the bearing performance orientation, most if not all the resources consulted state that the performance of particular bearing designs in the application should be oriented towards testing them under particular parameters or based on particular bulk loads, etc.

Corresponding Technical Parameters:

- Seal Quality: Often described is the need to conduct pressure tests that are in line with the practices in the industries to ensure that the seals remain strong and tight even after a long time.

- Coating Composition: Depending on the nature of the operation, general recommendations include the use of coatings that meet the required standards of chemical resistance, which are very important in reducing the rate of moisture and oxidation.

- Environmental Suitability: Design parameters should in such a case respond to temperature and humidity levels specified in industrial databases to ensure performance in extreme conditions.

These parameters are reinforced by their uniform capacity to increase the performance and longevity of the water pumps in different industries and weather patterns.

Maintenance Tips to Improve Reliability

To achieve effective operations of the systems of the water pumps, it is very important to undertake a scheduled maintenance program that includes the following measures:

- Regular Inspections: As pointed out during the analysis of the session and the internet sources, regular inspections enable wear, and rupture of the seals and coatings to be detected early enough thus lowering the chances of failure. This observation is consistent with the industry standard that requires the practice of standard testing methods to take care of seal jaw principles.

- Lubrication Management: The most useful websites explain that the right type and quantity of lubricant are two important aspects that help to reduce the friction and wear of the bearing elements. Following the manufacturer’s guidelines, for instance, regarding the lubrication oil change due time, can improve pump operating conditions.

- Environmental Monitoring: It was established that resources of this level recommend regular controlling of these environmental conditions especially temperature and humidity to fit with the designed requirements of the pump. This contributes to the maximization of performance while reducing the adverse impact on the environment.

- Periodic Cleaning: Build-up of debris and other contaminants on the interior and exterior surfaces of the pump parts must be done at specific intervals since it prevents choke that may cause damage. Websites recommend that it is easy to maintain cleanliness since it is one of the ways of increasing the longevity of the pump.

Corresponding Technical Parameters:

- Seal Quality: Seals should be pressure tested according to standard practices to make sure that seals for a long period will remain in effective use.

- Lubricant Compatibility: The selected lubricants as per the recommendation should meet the requirements of the degrees of chemical resistivity.

- Environmental Suitability: The preparation should meet the temperature and humidity constraints that are documented in the industry database so that the functionality is not impaired.

Supported by the technical parameters, these strategies for maintenance are further justified by their recurrent use in improving and sustaining water pump systems in different industries and circumstances.

Frequently Asked Questions (FAQs)

Q: What is a water pump bearing size chart?

A: A water pump bearing size chart is a detailed guide that provides the dimensions and specifications of various bearings used in water pumps. It helps in identifying the correct bearing size for specific applications to ensure proper fit and function.

Q: Why is it important to use the correct bearing size?

A: Using the correct bearing size is crucial for the longevity and efficiency of the water pump. Incorrect sizes can lead to premature wear, reduced performance, and potential failure of the pump.

Q: How can I identify the bearing size for my water pump?

A: You can identify the bearing size by referring to the water pump bearing size chart, which lists the dimensions and specifications of bearings. Additionally, you can check the bearing’s model number or consult the pump’s manufacturer for guidance.

Q: What are the common dimensions listed in a bearing size chart?

A: Common dimensions listed in a bearing size chart include the inner diameter, outer diameter, and width of the bearing. These measurements help ensure a proper fit within the water pump.

Q: Are there different types of bearings for water pumps?

A: Yes, there are different types of bearings used in water pumps, such as ball bearings and roller bearings. Each type has its own specifications and applications, which can be found in the size chart.

Q: How does improved grease impact bearing performance?

A: Improved grease can significantly enhance bearing performance by reducing friction, preventing wear, and extending the lifespan of the bearing. It ensures the smooth and efficient operation of the water pump.

Q: Can I use a bearing size that is slightly larger or smaller than recommended?

A: It is not advisable to use a bearing size that is slightly larger or smaller than recommended. Doing so can lead to improper fit, increased wear, and potential damage to the water pump. Always refer to the size chart for the correct dimensions.

Q: What trends are emerging in water pump-bearing technology?

A: Emerging trends in water pump-bearing technology include the use of advanced materials, improved grease formulations, and enhanced sealing techniques. These innovations aim to improve the durability, efficiency, and performance of water pump bearings.

Q: Do bearing size charts cover beyond standard sizes?

A: Yes, bearing size charts often cover a full range of sizes, including both standard and non-standard dimensions. This ensures that users can find the appropriate bearing for various applications.

Q: How can I ensure my water pump runs efficiently with the right bearing?

A: To ensure your water pump runs efficiently, always use the correct bearing size as specified in the size chart, employ improved grease for lubrication, and follow the manufacturer’s maintenance recommendations. Regular inspection and timely replacement of bearings can also help maintain optimal performance.