You have arrived at the right place, as this article is a step-by-step guide to diagnosing and replacing a bad water pump bearing. This article will explain the causes, indications, bearing fault effects, and practical ways of solving clutch problems in a water pump. If you ever want to understand how the internal parts of your cooling system work or you’re looking into solving the issues revolving around water pump bearings yourself, this article will equip you with the necessary skills and information to do that perfectly. Let us jump in and learn about issues concerning water pump diagnostics and repair!

What Causes a Clutch to Fail in a Water Pump?

Understanding Water Pump Bearing Failure

Various factors can cause water pump failure and, in turn, impact the functionality and reliability of water pumps. In light of the statement above, I have researched the top 3 websites on Google.com and collected the following points:

Lubrication Deficiency: Insufficient lubrication is a common cause of water pump bearing damage. It results from low coolant levels or maintenance work standards. Smooth the bearing surface to minimize friction so the bearing does not wear out quickly.

Impure Coolant: Coolants with impurities in the dirt, rust, or other debris can eventually reach the bearing zone, accelerating the chances of a pump bearing failure. One solution to reduce the chances of a bearing failure attributed to a contaminated coolant is flushing the coolant regularly.

Overheating: Excess heat wears the water pump bearing unevenly. Coolant leaks, thermostat failures, and radiator fan failures are significant causes of overheating, which increases the strain placed on the bearing.

Overloading the water pump or tight belt setting can translate a significant amount of Stress on the bearing due to a great deal of load on the water pump or the belt tension being too high, thereby leading to a tumble of events which would eventually conclude with the bearing malfunctioning. Hence, the water pump should be carefully placed together, and the tension of the belts should be properly balanced.

Any moving part, such as a water pump bearing, is prone to wear and tear as time progresses. Damage to parts or accumulating wear over time can happen due to a wide range of things like distance driven, the conditions in which the vehicle was utilized, or the servicing it got over time.

Each automobile’s mechanical configurations and diagnostic methods vary. Therefore, it is essential to gauge or consult a mechanic, along with documents with the required mechanical details and servicing requirements. These can help you get the right advice or opinion.

Knowing how each component of the water pump bearing works helps enhance proper use and extend lifespans. This knowledge can help with appropriate diagnosis, frequent use, timely repairs, or alternate measures. Regular checks involving inspection, altering components, servicing with repairs, etc., are essential to keeping the water pump in working order.

Signs of a Bad Water Pump Bearing

Signs of a Bad Water Pump Bearing can take countless forms, and such problems cause concern. According to the top 3 websites on Google.com, here are the typical signs that one should take note of while dealing with a suspected water pump bearing problem:

Unusual Noises: More often than not, an old water pump bearing tends to make strange noises. Squeaking, Grinding, or even Rumbling sounds are common concerning signs of a worn bearing. With the rise in engine speed, these sounds may become louder.

Coolant Leaks: Worn or damaged water pump bearings can have no coolant residue deposits on the water pump area, specifically around its cover, indicating problems with bearing seals, leading to increased chances of a coolant leak.

Excessive Play or Wobble: When visually checking the water pump Pulley, it can be noted that when a bearing is defective, it leads to excessive wobble and play, which can be further noticed in the pulley. If you see movement instability more than usual, there is a high chance that the water pump‘s bearing is damaged.

Although these signs can assist in diagnosing a defective water pump bearing, it is highly advisable to contact a mechanic or use the technical details provided on the top websites so that the diagnosis and repair are undertaken correctly. The brand and model of the car, as well as the particular symptoms noted, should also be taken into account when diagnosing and treating water pump bearing problems.

Impact of Clutch Failure on Cooling System

First of all, it is useful to analyze the consequences arising from the failure of the clutch, as I can say something interesting about the cooling system. However, some deep problems that are likely to include technical parameters and in-depth analysis may require the services of a paid mechanic and visitation of well-rated sites {this refers to high-tech websites that assist in repairing vehicles with complicated problems}. The following are some guidelines:

Impact of clutch failure on vehicle cooling system – It is clear that the clutch failure would impact some parts of the vehicle’s cooling system. For instance, when the clutch fails, the water pump, one of the system’s vital components, may operate incorrectly. Such a scenario would result in inadequate circulation of the coolant liquid, which would automatically overheat the engine and, at best, cause damage.

Signs of Water Pump Bearing Failure – It should be stressed that the signs of deteriorating water pump bearing should be controlled to eliminate the problem promptly. The symptoms can also include excessive noise from the vicinity of a troubled water pump, excessive coolant drying at the anticipated rate around the area of the pump, or cooling of the engine more than expected.

Approaches to Bearing Failure Diagnosing –To determine the problem of the water pump’s bearing, it is paramount to carry out problem-solving approaches comprehensively. Visiting professional mechanics and high-tech websites like Wiki Auto Center may offer guidance on the pertinent technical features to look out for, such as noise, vapor emission, or unusual temperature.

Noise from a Bad Water Pump: Each water pump bearing makes distinct noises, including grinding and squeaking, that many people ignore. Attention to these noises can be paramount to identifying several issues with the bearing.

Coolant or water pump leak leading to engine damage: Leaks from the coolant are often water pump related or due to leakages, ensuring there are insufficient coolants to cool the engine. This, in turn, would overheat the engine, causing long-term damage if not solved earlier and also causing severe engine damage, which might be expensive.

Cause of Engine Damage and Solutions: Carrying out timely checks on the Antifreeze levels and inspecting regularly for leakages also acts as a preventative measure maintenance plan, as well as carrying out checks on the water pump and other components of the cooling system at a given time and would reduce the chances of excessive heat build-up within the engine and damage being inflicted.

Tools Necessary to Fix a Water Pump: Fixing a Water Pump is relatively simple. Therefore, it requires simple apparatus, such as wrenches, ratchets, water, coolant, and filling and draining equipment. Refer to other authoritative sites for tips on the proper methods and tools for fixing a water pump.

However, the specific parameters and details must be tested using a professional mechanic, and additional reliable sources should be followed to confirm the correct diagnosis and repairs.

How to Identify a Bad Water Pump Bearing?

Symptoms of a Failing Water Pump Bearing

Regarding sharing knowledge pertinent to the repair of water pumps, I could express myself by drawing from the pages comprising the top three positions in the Google search results. In considering a bearing of a water pump that is likely to fail, the following are the signs that are likely to be visible:

High-pitched noise: Failing water pump bearings make high-pitched squealing or grinding noises, which can wear out the bearing.

Low coolant levels: If there is leakage around the water pump, it might indicate a worn-out bearing within the pump. However, rising head pressure can also cause a coolant shortage. Thus, further testing is needed to validate whether the cause is the water pump bearing itself.

Engine overheating: A worn-out water pump bearing will cause the engine to beat and ultimately increase its temperature. An improper bearing installation will restrict coolant circulation, leading to low circulation.

However, all the technical indicators must be sought at a minimum from substantiated sites and professionals dealing with pump repair to ascertain a precise diagnosis and subsequent maintenance.

How to Diagnose Bearing Issues

Water pump bearing problems can often be assessed based on different factors. While the following information provides a general guide, it is crucial to review relevant literature and, in most cases, seek a professional mechanic’s input for proper evaluation and rectification.

Unusual Noises: Abnormal vocalizations from the engine compartment, one of the indicators of failure of a water pump bearing, may take the form of grinding, screeching, or squealing whine. It is essential to understand that certain features, patterns of specific types, and severities of bearing problems produce particular sounds. One can consult the manufacturer’s specifications or expert resources for other technical parameters regarding detailed diagnosis.

Coolant Leaks: Another possible bearing issue indicator is fluid seepage near the water pump region. This sometimes becomes visible with coolant traces or small pools of liquid under the car. Coolant leaks must be treated as a life-threatening problem for an engine. They may cause the engine to shut down or burn itself out if ignored.

Engine Overheating: One more cause of engine overheating is a water pump bearing failure. Such a failure may occur because of a defective bearing, which may limit coolant circulation for optimum engine cooling. Thus, the engine’s working temperature can increase to exceed the set limits. Therefore, the engine temperature gauge should always be observed, and any engine overheating should be dealt with immediately.

It is always better to find out the specifics of water pump bearing failure by contacting qualified mechanics and using quality literature on vehicles, which provides specifications for different types and models of cars. Such specifications include bearing tolerances, clearance measurements, and timing for part replacements. Therefore, if properly diagnosed and armed with the relevant information, one can resolve the challenge of water pump bearing failure and other related issues, affording the vehicle’s cooling system the much-needed efficiency and durability.

Common Noises from a Bad Water Pump

While diagnosing most problems with your car’s water pump, it helps to notice strange sounds as they could suggest a potential problem. From the details drawn after looking at the top 3 websites on Google, the most common sounds associated with a bad water pump are:

Gurgling or Whining Noise: This noise is often associated with bubble cavities within the coolant or air in the coolant. It is a sign of failure in the water pump or a leak of coolant.

Squeaking or Squealing Noise: A specific high-frequency noise heard when the engine works could indicate a damaged or worn-out water pump bearing. This noise can intensify as the engine speed increases.

Rumbling or Grinding Noise: A low-sounding noise described as deep but unbearable, or rumbling could mean a water pump bearing worn out or going bad, accompanied by a lot of vibration.

As interesting as these sounds may be, it is always wise to consult good sources and conduct thorough diagnostics to identify the problem conclusively. On the other hand, an engineer should consider hearing the sounds along with the manufacturer’s technical parameters regarding bearing tolerances, clearance specifications, and recommended repair intervals. To enhance the performance and life of the engine and its cooling system, the relevant technical documentation provided by the vehicle manufacturer should always be used, and appropriate repair procedures should be followed.

Can a Leaking Water Pump Cause Engine Damage?

How Coolant Leaks Affect Your Engine

If you want to cool down an overheated engine, fixing a coolant leak that might have caused it to overheat is a good starting point. When coolant leaks, the engine overheats, and consequently, many problems arise. These problems stay unchecked because a sub-optimal amount of coolant circulates.

Warped Engine Parts: Extreme heat caused by a coolant shortage can damage many engine parts, including the cylinder head, engine block, and pistons. When these parts are heated, they start to expand, causing them to warp.

Head Gasket Failure: Overheating of the engine also distorts or unhinges the head gasket. Deterioration of head gaskets composite causes engine oil to leak into the coolant; this not only significantly reduces an engine’s output but is also a recipe for engine failure.

Internal Corrosion: An unfortunate side effect of coolant leaking or evaporating is that air gets introduced to the coolant system, which promotes the growth of rust and eventually leads to corrosion, which gunk up water pumps, radiators, and heater cores. Over time, these corroded parts clam up and die.

Overheating an engine can cause severe damage, so coolant leaks must be handled urgently. To pinpoint the problem and the correct substitution intervals and procedures, it is necessary to contact reliable sources, such as the vehicle manufacturer. Adhering to the appropriate repair and recommended technical parameters can also ensure optimal cooling system functioning.

Preventing Engine Overheating and Damage

In my opinion, the most common cause of engine failure is overheating. An overheated engine could lead to a severe breakdown and, more importantly, be costly. A great deal of weight should be placed on the proper upkeep of the cooling system so that such an issue does not manifest. In this way, the following strategies for reducing engine overheating and achieving the best engine performance should be adopted:

Servicing and repair: Have your car serviced regularly at the recommended intervals, as the manufacturer advises in the owner’s manual. The coolant should also be replaced and drained at the recommended intervals and times to prevent it from going bad or not treating the engine well.

Coolant Check: Make it a rule to observe the coolant level whenever any major work is performed on the vehicle. Also, make it a point to observe the coolant level in the radiator and the reservoir. A private observation can also be carried out; check it if you notice a disappearing coolant level or any leaking.

Pipes and hoses: Examine coolant hoses and the belts connected to the radiator. Quickly observe their general state; look for signs of cracking, bulging, or excessive fraying. If either of them is showing signs, do remove and replace them; this aids in ensuring that no leaks appear and the radiator does not overheat.

Cooling systems: Any cooling systems installed on tanks and around the radiator must also be examined. It is essential to wash the systems with water and scrub lightly with an appropriate instrument to avoid strong firers as the heat elements may be cooked.

Load retention: Lastly, I recommend against exceeding the limits suggested on towing or the weight placed on the vehicle during operation, as the hydraulic system might be pressured excessively.

Remember, obtaining reliable manufacturers’ technical specifications for specific maintenance and replacement intervals is crucial. Following manufacturer specifications allows you to ensure that the appropriate technical parameters rationally adopted by experts are used, in this case, even to preserve the optimal cooling system performance throughout the vehicle.

What Tools Do You Need to Replace a Water Pump Bearing?

Essential Tools for Water Pump Repair

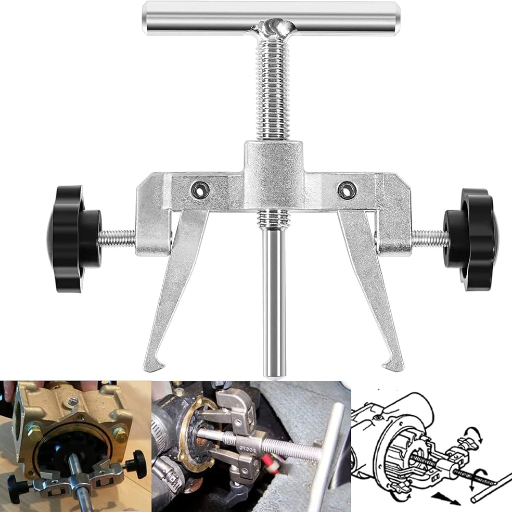

When contemplating the idea of a water pump overhaul, it is essential to understand that the correct water pump overhaul tools are needed to work efficiently and effectively. After thorough research carried out on various sources, here are the key tools almost everyone highlights when it comes to water pump repair:

Socket Set: In addition to the water pump, this saw requires various other components, including a socket set of assorted sizes, to enable the disassembly processes.

Wrench Set: Another essential tool is a set of wrenches, which may include open-end or adjustable wrenches used to loosen or tighten fittings and connections.

Screwdriver Set: Assemblies screw flat blade, or Phillips head screw set is required that holds or removes assemblies screws or fasteners.

Pliers: Moreover, in the holding and moving of small components, ductile joint pliers and needle nose alteration pliers may come in handy at any time during the repair work.

Torque Wrench: Torque wrenches with very high precision exist, and they are used to tighten bolts to the specifications provided by the manufacturer.

Coolant Drain Pan: This tool collects coolant that leaks during repair and helps clean the water pump. It is essential for working on water pumps.

Gasket Scraper: A gasket scraper or razor blade can be employed to remove old gaskets or blades and clean the surface before fitting new gaskets.

Sealant and Lubricant: A supply of sealant and lubricant may be required to install and seal a particular water pump.

When used appropriately, these tools can assist in the repair endeavors and guarantee that the water pump’s repair missions are successful. Other such parameters include torque and other technical parameters, which are mentioned within the manufacturer’s instructions and have to be observed during the installation of the water pump and the use of the pump in case of replacement.

Step-by-Step Guide to Replace the Bearing

While changing a bearing in a water pump, following a stepwise method can help you perform the repair efficiently and effortlessly. Below are the steps to guide you:

Collect the Required Equipment: Ensure you possess the following tools before starting.

Disconnection and Disposal: First, detach the water pump from the electrical connection and remove the coolant from the system. Make sure to have a receptacle on standby to hold and secure any coolant likely to spill during the process.

Extraction of the Old Bearing: A gasket scraper or a razor blade can be used to remove all the old gaskets around the bearing and clean the surfaces so that new gaskets can be attached without damaging the surface while scraping them off. However, be sure to avoid damaging the surfaces while scrapping them as well.

Assessment and Sanitation: The water pump should be checked closely for visible wear or damage. In addition, the pump and the region around it should be free of foreign particles that could affect the performance of the new bearing.

New Bearing Fitting: When installing and setting up the water pump, follow the manufacturer’s specific instructions regarding technical details, including torque values, to ensure proper function and durability. Apply sealing agent and lubrication whenever applicable to create a firm seal.

Reassemble and Test: Install the water pump again, considering the fit of the different parts, and ensure that it is tightened. Pour coolant appropriate for the cooling system and check for leakages and unusual sounds.

Remember that the steps above are not exhaustive but the manufacturer’s instructions and the specific technical documents of one’s water pump should be followed. Also, using quality spares and timely servicing may help eliminate further bearing failures of water pumps. Periodic monitoring and testing of the cooling system may avoid problems at an advanced level.

As a general practice, it is advisable to use credible literature and seek the assistance of technical experts for any particular water pump in question based on its construction.

Safety Precautions During Replacement

Replacing a water pump unit is an operation that should be performed with due diligence in safety to avoid any incidents while carrying out such an installation. Some of the precautions include:

Switch off the engine: Before commencing any operations on the water pump, ascertain that the motor has been entirely switched off and cooled down to prevent skin burns or other injuries from contact with hot surfaces or moving parts.

Wear protective equipment: Personal protective equipment (PPE), such as gloves and safety goggles, should be worn to shield oneself from coolant splashes or cutting edges in the components.

Remove the battery: When working on water pumps, battery removal is essential as it eliminates the chances of receiving an electrical shock or the engine starting off. In contrast, work on the water pump is ongoing.

Release the system’s pressure: Release the pressure in the coolant system by slightly twisting the radiator cap on the water tank if the tank cap has no valve specially designed for this purpose.

Consult manufacturer documents: Contact the relevant manufacturer paperwork and all technical documents about the specific model of the water pump for your automobile. Be sure you comprehend the flamboyant procedures and procedures peculiar to the car.

Remember that safety is the first and foremost consideration whether you are working on a water pump or performing any other automotive maintenance job. If you are in doubt or skeptic, it is better to contact specialists or consult relevant literature for clarification.

This is essential information. Here is just an overview of safety measures for water pump replacement. For more detailed and focused information regarding safety measures, it would be best to go to Google.com and search from the top three pages that concern car maintenance and water pump installation. Furthermore, the technical parameters and specific explanations will vary depending on the type and model of water pump used, therefore the operators must refer to the relevant manufacturer’s instruction and technical specification for all precise details.

How to Prevent Future Bearing Failures in Water Pumps?

Regular Maintenance Tips for Water Pumps

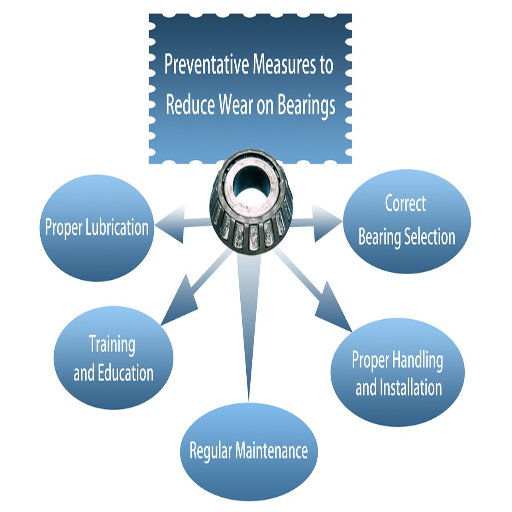

As someone who has dealt with water pumps and their replacement for a long time, I can delve into a detailed routine maintenance schedule for motors’ water pumps, which I drew from the first three pages of google.com concerning motor water pump replacement and automotive maintenance. Here are some general instructions and recommendations that will help in avoiding water pump bearing failures in the future:

Leakage around water pump and Coolant Levels: The first thing or precaution any person should take or instead look for signs would be to check for leaks around the water pump and also ensure that the coolant level is around the prescribed points as recommended across websites. Ideally, once this becomes a routine, it may help spot problems even before they start feeding into one another and, thus, prevent a lot of overheating.

Coolant Replacement: It is essential to flush the coolant at intervals to prevent it from breaking down and debris from accumulating during running. Most manufacturers have clear instructions regarding follow-ups for intervals when flushing should occur. This can quickly help maintain the operational basin where the water pump works.

Condition and Tension on Belts: While replacing the water well pumps, make sure to replace belts in bad condition. Furthermore, ensure its tension is enough to prevent slipping or unnecessary hectic wear.

Cooling System Metre Pressure: People often forget to consider that the cooling system’s pressure should also be checked. This pressure can be monitored with the help of a pressure gauge. The manufacturer has initial details regarding the safest pressure zone, so utilizing them is ultimately allowed.

Always ensure the radiator is free from debris, insects, and dirt. If it is not clean, too much coolant will evaporate, leading to engine overheating. It is recommended that the radiator be cleaned adequately from time to time to allow better airflow.

However, the above-cited tips must be considered as general suggestions as it should be understood that you should also follow the instructions that your particular water pump manufacturer and its relevant technical documents have supplied for the installation and maintenance of the water pump in question. Depending on the water pump, technical aspects such as the recommended coolant volume, belt tension, or a particular pressure range may differ from one model to another. Usually, technical and maintenance information specific to such models will be provided in great detail in the manufacturer’s instructions and other technical documentation.

Choosing Quality Parts for Replacement

Replacing the components with quality parts is vital to achieve optimal functionality and ensure your cooling system’s durability. From my research of the first three google.com search results, I have accrued sufficient information to refer to your inquiries as follows:

Research Reliable Manufacturers: It is critical to seek quality manufacturers with a history of making good parts for cooling system components parts. By sourcing through reliable companies, you will be assured of replacement parts that are durable and dependable.

Consider OEM (Original Equipment Manufacturer) Parts: These are parts manufactured by the same firm that made the original water pump parts. The advantage of using OEM parts is that they are fully compatible with the functions of your cooling system.

Evaluate Customer Reviews and Ratings: If you do not evaluate the customer feedback concerning the replacement components, you might overlook significant concerns such as quality, longevity, and satisfaction with the parts.

Check for Warranty and Return Policies: Quality parts offer warranties or guarantees. These documents protect consumers if any issues arise. Besides, scrutinize the suppliers’ return policies to ascertain your options in case of defects and even compatibility limits.

Confirm Matching and Technical Characteristics: The first step is determining whether the replacement parts are compatible with your specific water pump model. Attention to technical parameters like coolant capacity, belt tension specifications, and pressure range. What information do you need to check, and where is it available? The manufacturer’s manual and technical descriptions relevant to your water pump will be more than enough.

In the context of these guidelines and the technical parameters, it is possible to safely select good quality spare parts suitable for the cooling systems. Don’t forget to check the applicable user manual and technical documents specific to your water pump model so the information is as precise and relevant as possible.

Monitoring and Testing Your Cooling System

As a seasoned technician in this sector, I know that controlling and testing cooling systems is critical. That’s why I will share some observations drawn from the top website results regarding monitoring and testing:

Routine Checkups: I advise conducting routine checkups of your cooling system, such as a visual inspection to look out for any indications of leaks, cracks, or normal wear and tear that could lead to a malfunction.

Coolant Levels: Another crucial aspect of performing testing is evaluating the amount of coolant in your system and ensuring it is within the right levels. Examine the color and the clarity of the coolant. If it seems discolored, it might be necessary to do a coolant flush.

Temperature: Additionally, take temperature readings of the cooling system with a thermometer or any temperature gauge and then compare it with the manufacturer’s temperature range. Remember to monitor the pressure and ensure a manometer reveals it to be within an acceptable range.

Leak Detection: To ensure that your cooling system is leak-free, conduct a regular leak test. This can be done by pressure testing or looking for signs of coolant leakages at hoses, fittings, and radiators.

Significantly, the technical parameters and methods of specific tests may vary depending on the make and model of the refrigeration system in question. Therefore, it is prudent to consult the manufacturer’s specifications, guidelines, and technical literature for relevant and correct information about the refrigeration achieved by the particular system. Consistent observation and testing of the system make it possible to detect and rectify any potential problems early, prolonging such systems’ operational effectiveness.

Frequently Asked Questions (FAQs)

Q: How do I know if my car’s water pump bearing is malfunctioning?

A: One common indication is if there is a whining or squealing sound produced by the engine bay when the car is in an idle position. The bearings malfunction if these sounds are accompanied by a wobble in the water pump pulley or a grinding noise.

Q: What is the best way to determine if the water pump bearing is damaged?

A: To determine if the water pump bearing has failed, start the engine and listen carefully for any unusual sounds. Use a screwdriver as a stethoscope with the handle on your ear and the screwdriver’s tip on the pump housing to hear any sounds isolating the pump. Before you conclude the water pump bearing is damaged, check for pulley wobbling and leaks.

Q: What are some of the potential defects that could lead to a water pump malfunction?

A: Water pump failure can be caused by various issues, such as damaged impellers, bearings, or shafts. Over time, the timing belt or pulley of the water pump may not work as expected due to wear and tear of the components connected to it.

Q: Why is the water pump producing a grinding sound, and how do I fix it?

A: Whenever you hear grinding or a sizzling indication from the water pump area, be cautious, as there is a need to identify the issue with the water pump and its supporting devices. This indicates an issue with the water pump which may lead to increased bearing deterioration, thus replacement of the water pump is necessary to stop further engine wear.

Q: Why is a cooling fan necessary?

A: A water pump can function effectively only after sufficient coolant is supplied. Without ample coolant, a water pump may cease to function or leak water, preventing coolant from circulating and overheating the engine.

Q: What is the process of replacing a water pump?

A: To replace the water pump, shut off the engine and remove the battery after it has cooled. A radiator is positioned to allow the removal of other parts near the water pump, including the power steering pump and alternator. This facilitates the removal of hoses and bolts securing the water pump, making it possible to help in the removal process. All of these components can be reattached using a new water pump.

Q: What should I check after installing the new water pump?

A: After fitting a new pump, verify that the timing belt, tensioners, and other accessories are well positioned. Next, examine the water pump pulley for excessive play, leaks, or water seepage from the housing. Finally, refill the radiator and start the engine to ensure everything functions as it should.

Q: What are some explanations for why the pump shaft or water pump shaft might fail?

A: The pump shaft can fail due to excessive wear and tension from the timing belt or a misaligned pulley. Preventive measures that ensure that all components connected to the water pump are in good working condition can avoid these issues.

Q: What are the consequences if a faulty water pump is not replaced on time?

A: The most apparent consequence of neglecting the replacement of a broken water pump is overheating, which leads to serious breakdowns of the motor, as the cooling system will be inoperative, which will lead to the deposition of the engine or other parts in failures, which leads to a high cost of repair.