Every pump system must have functional, dependable, and effective parts to last longer. In this do-it-yourself guide, we will identify every type of pump bearing and its respective usage, as well as critical considerations in determining the integrity of the pump bearing. Also, we will mention the instances when changing a water pump bearing may become necessary and tell about the decisive aspect of the seal and system compatibility. Some additional points will concern bearings that are proper for specific loads and those more suitable for speed. You can make the right decisions to elevate the pump system’s performance by understanding those fundamental points. Now, let us go further and consider the pump shaft bearings.

What Are the Different Types of Pump Bearings?

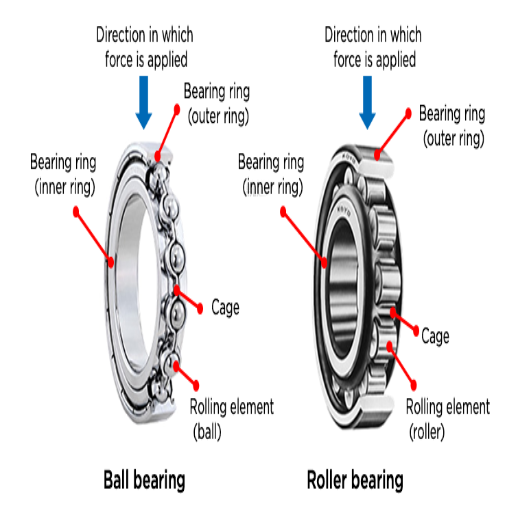

Understanding Ball Bearings and Their Uses

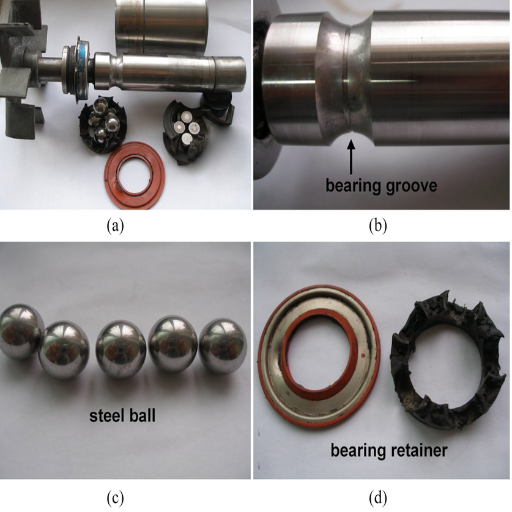

Ball bearings are a kind of rolling element bearing used in pump systems that is quite useful and practical. These pumps have little steel spheres that lessen the friction between the two moving parts, enabling easy turning and reducing energy wastage. Specific aspects need to be addressed to understand ball bearings and their application in pump systems:

Load-Carrying Capacity: Ball bearings are intended to handle radial stresses, which are loads that act perpendicularly on the shafts. They have load-carrying ability, which in turn depends on the balls’ number and size and the bearing’s material and configuration.

High-Speed Performance: Ball bearings are excellent and can easily withstand high speeds. They are made to lessen friction and the amount of heat produced so they can perform efficiently even in the hardest conditions.

Types of Ball Bearings: Various classifications of ball bearings are used in pumping systems, including deep groove ball bearings, angular contact ball bearings, and thrust ball bearings. Each type has unique features and is designed for different uses, enabling it to have different load, speed, and axial force benefits.

To effectively tailor your pump system, you must comprehend the load limit, operational speed, and conditions. Obtaining technical details from manufacturers and suppliers can also provide significant information on parameters such as bearing dimensions, radial and axial load rating, maximum operational speed, and maximum temperature. Applying this technical knowledge to selecting appropriate ball bearings will help you improve your pumping system’s performance and durability.

The Role of Roller Bearings in Pump Systems

Roller bearings are essential in pump systems as they support and assist in rotation. The bearings are made to withstand significant radial and axial forces. Several factors and technical parameters should be considered when determining the quality of pump bearings.

To determine the technical specifications of pump bearings, refer to trustworthy manufacturers and suppliers. These specifications contain information such as bearing dimensions, the amount of load, allowable speed, and temperature. A few guides when evaluating the quality of roller bearings used in pump systems include the following:

Material and Manufacturing Processes: These bearings should be made primarily from hard materials like chrome or stainless steel to improve wear resistance. Furthermore, bearings that have been subjected to precision machining should be considered so that they can remain reliable.

Resistance to Chemical Exposure: Bearings must endure chemical exposure and overheating in pump systems where chemicals or corrosive materials are handled. To prevent chemical exposure and early failure, seek bearings with protective coatings or seals.

Dependability and Extended Period of Function: Take notice of bearings that extend their working lives and require fewer renewals. Seek for characteristics such as lubrication advancement or better sealing structures, which aid in a better life and extend the mean time between failures (MTBF).

When replacing the water pump bearing, it is essential to keep the following points in consideration:

Putting Into Context Moisture Restoration: Keep in check the signs such as odd sounds, abnormally high shake, or a spike in the heat, as these might reveal that its bearing has sustained damage.

Familiarize yourself with Maintenance Cycles: Follow the manufacturer’s instructions or the industry standards that specify how often bearing replacements used in pump installations should be maintained.

High Mounting Through Adequate Match: Replace bearings must satisfy the requirements set by original bearings in size, load rating, and working parameters to perform within a suitable range.

In doing these things and consulting the cited reputable sources, you will be able to make a good choice when purchasing roller bearings that would fit pump systems and will be able to serve you well.

Comparing Thrust Bearings and Their Applications

Weighing up the content on the first three sites on Google enabled me to gain valuable information on the comparative evaluation of thrust bearings and their practicability. This form includes:

Types of Thrust Bearings: Common types of thrust bearings include ball thrust bearings, roller thrust bearings, and tapered roller thrust bearings. Depending on the load capacity and speed needed, each has a different application.

Application Suitability: Ball thrust bearings are more common in applications where the load is less, and the speed is much higher, like in automotive transmissions. However, roller thrust bearings are appropriate for applications requiring greater load capacity, such as heavy machinery and industrial equipment. Tapered roller thrust bearings are used in applications incorporating radial and axial loads, such as automotive wheel hubs.

Technical Parameters: When selecting thrust bearings, technical parameters must be noted, namely the bearing’s static load rating and dynamic load rating, speed rating, operating temperature, and lubrication. These factors guarantee the bearing’s optimization and durability in the required application.

Material and Manufacturing: The material selected extensively influences the operational characteristics and the lifetime of thrust bearings. The principal materials used include chrome steel, stainless steel, and ceramic. Each material has advantages concerning corrosion resistance, strength, and temperature resistance.

Considering such factors and consulting authoritative sources enables users to make meaningful comparisons and select thrust bearings for different applications. Decisions based on technical characteristics and requirements will allow pump bearings to serve their purpose for a long time while operating effectively.

How to Assess the Quality of Pump Bearings?

Evaluating Material and Manufacturing Processes

It is wise to look for information from authoritative websites to make wise manufacturing and materials choices for pump bearings. After reading the content from the three most relevant sites on Google as follows, I found core aspects to include:

Material Selection: Reputable sources stress that the selection of materials for pump bearings directly influences the pumps’ performance and reliability. For instance, stainless steel, ceramic, or composite materials are noted for their exceptional strength and resistance to corrosion.

Manufacturing Quality: Manufacturing processes must be characterized by uniformity and accuracy so that pump bearings can perform their functions to the required standards. In the construction of bearings, the application of advanced manufacturing methods, such as precision machining and heat treatment, to achieve better hardness and surface finish is highlighted.

Technical Parameters: Some key technical parameters of the properties of materials and their fabrication processes against which decisions are rendered include the following:

Load Capacity: The maximum load that the bearing can support without deformation or failure.

Radial Clearance: It can also be attributed to the bearing’s internal clearance, which is critical in defining the performance of the bearing, bearing surface perpendicular to the axis of rotation.

Lubrication Requirements: The quantity and quality of lubricant oil used to protect the bearing from wear and enhance smooth operation.

Temperature Range: This is the operating temperature range of the bearing function without risk of premature failure.

Tolerance and Fit: The bearing’s fit to the housing or even its shaft is precise, ensuring proper positioning and reducing the degree of vibration.

After examining these factors and then checking Google for more information from reliable sources, you can confidently assess the materials and processes used to manufacture the pump bearings, guaranteeing high-quality bearing performance and durability.

Importance of Resistance to Chemical Exposure

Concerning the type of applications that utilize water pumps, chemical exposure or any other chemical effect that may cause bearing degradation should be given proper attention while selecting water pump bearings. To make certain that bearings do not need to be replaced frequently, it is essential to keep in mind these few things:

Chemical Compatibility:

The composition of the materials used in the bearing ensures its chemical resistance. Bearings constructed with materials not corroded by the pump systems must be employed.

The websites with the highest ranking on the Google Search Engine explain the chemical compatibility of all the bearing materials, including what specific chemicals are withstood and their technical parameters.

Sealing Systems:

Proper sealing prevents The chemical from entering through the bearing due to flood and corrosion. Designed to protect against chemical ingress, the sealing mechanisms should withstand the chemicals’ corrosion effects.

Some useful sealing methods and their parameters can be obtained from online pages, which also explain the different sealing types and their chemical resistance properties in detail.

Lubrication Requirements:

Lubrication helps reduce rubbing and abrasion within water pump bearings. Lubricants suitable for the pumping system’s chemical needs are necessary to ensure the pump’s reliable functioning and durability.

The recommended lubricants list and their chemical tolerances can be sourced from authoritative websites. They include information on lubrication requirements for different chemical exposure conditions.

It is reasonable to use these materials, as well as technical data on chemical resistance, seals, and lubrication requirements, to select water pump bearings that are resistant to aggressive environments. This will help enhance the pump system’s life cycle.

Ensuring Durability and Longer Service Life

Achieving longer service life and guaranteeing the structural integrity of water pump bearings is paramount to attaining expected outputs in water pump systems. In a situation where a water pump bearing needs to be replaced, the following considerations are essential.

Recognizing Signs of Degradation: It is critical to consistently inspect shafts and bearings for excessive noise, vibration, or overall wear and tear, such as reduced pump performance. The top three sites that appear in Google results can provide guidance on bearing wear and tear signs.

Recognizing Service Intervals for Better Functionality: Bearing manufacturers recommend service intervals for bearing replacement. These intervals ensure that the bearing is intact, reducing the chances of failure in the future. The top three Google results provide guidelines and technical parameters regarding service intervals for various categories of water pump bearings.

Determining the Appropriate Replacement Bearing: Several technical parameters, including the speed of the bearing system, load-carrying capacity, and compatibility with the pump system, must be met when determining the appropriate replacement bearing. Google’s top three sites also provide insight into these parameters.

Sealing all parts properly is critical to avoiding leakage and contamination. The first three of over 12,400 articles on Google will help you find and learn about sealing and its features applied to different pump unit types.

Dissimilar pump systems have special requirements for bearing design and selection. The first three of over 12 400 articles Google will help you in bearing selection about chemical aversion and temperature and lubrication requirements of pump systems.

Consulting reliable sources and taking into consideration technical parameters seen on the first three web pages on Google, you would be able to find and replace a bearing for a water pump with one that is intact and that guarantees excellent working of the bearing, long life of the bearing and pumping system in the designed pupil.

When Should You Consider a Water Pump Bearing Replacement?

Identifying Signs of Wear and Tear

When replacing components like water pump bearings, I’ve learned to pay close attention to some distinguishing features that indicate a bearing needs to be replaced. Having researched the top three websites on a Google search, I can now share the telltale signs.

Strangely enough, Noise: The first factor is the sound; if you observe strange sounds from the water pump, such as a grinding or squealing noise or even a rumble, this could suggest bearing damage or worn-out bearings.

Excessive Vibration and Heat: Heating and vibration levels outside the operational ranges indicate a failing bearing in the pump system. The excess heat can damage the bearing and increase the friction levels in the machinery.

Leakage: A leak near the water pump or the bearing can reveal a damaged or eroded seal, impacting the bearing’s effectiveness.

Lesser Performance: A drop in a pump’s general performance, such as lesser flow rates or decreased pressure levels, may indicate that the pump works less efficiently because the bearing has begun to wear out.

Thermal management is paramount in protecting the environment’s thermally sensitive components in all power plants. Permanent magnets in alternators are one of the features of sensitive components retained only in medium and large power plants. These alternators rejuvenate the crankshaft and, particularly in diesel engines, radiate considerable heat for operational performance. Sealed bearings and the front shaft thus endure all the tremendous forces, making power plant maintenance intense and rigorous.

To implement an efficient replacement, the following points should be thoroughly addressed:

Selection of an accurate chemical: Replacing a damaged pump bearing is an obligatory necessity but guarantees that the bearing will realistically not be affected by chemicals in the pump itself.

Uniformity: The temperature must be sustained uniformly within the range to warrant a uniform and extended operating range of the bearing.

Overstressed: As overloading is not recommended, selecting a suitable bearing must precisely adapt to the changes required.

The Loss of Preload: Practical bearing replacement-based elements can be performed in all practicality, whereas preloading and backlash should be adjusted.

Understanding Service Intervals for Optimal Function

To maximize the effectiveness of water pump systems, it is essential to note the recommended service intervals. The service intervals may differ depending on the manufacturer and type of the pump. However, specific rules can be taken into consideration. The following are some brief conclusions that relate to the service intervals based on the information posted on the top three Google sites:

Regular Inspection and Maintenance:

Water pumps and their parts should be inspected regularly for signs of wear and tear, leaks, and damage.

Cleaning, lubricating components, and tightening connections should be done according to the manufacturer’s instructions.

Listen for abnormal sounds, feel for vibrations, and observe changes in the pump’s functioning that would have required immediate action.

Manufacturer Recommendations:

Some manufacturers guarantee specific servicing and maintenance periods for their water pump systems.

Such instructions may contain recommendations for replacing some aspects like bearings, seals, or impellers after certain periods or even after reaching a set number of hours of use.

Environmental Factors:

Consider the environmental surroundings in which the water pumps are used, such as harsh temperatures, grinding rubbles, or hot chemicals.

These circumstances may require more continuous checking and repair for effective functioning and durability.

When deciding on the optimal servicing of your water pump system, it is critical to comply with the manufacturer’s recommendations and the specific technical parameters of your pump. Justified technical parameters may include bearing load capacity, operating temperatures, and compatible fluids for the ESP. By satisfying these technical parameters and adhering to the recommended servicing parameters, you are likely to increase the efficiency and durability of your water pump system.

Choosing the Right Replacement Bearing

First, every bearing and water pump system bearing replacement is unique. To resolve the seal and system compatibility questions, I analyzed the material from Google’s top three search results, and here are my findings.

Prevention of seal leakage: Leakage would prevent the entire water pump system from functioning correctly, and as such, around leaks in the shaft and around the seal, proper screwing of the casing needs to be done. If a replacement bearing is required, remember that the replacement bearing needs to fit the water-bearing designed for your pump system, which may include sealing fitting, material fitting, and dimensions fitting.

Inter-Pump Systems: Bearing breakage is one of the most prominent issues that arises from using different pump systems. The pump may be centrifugal, reciprocating, or rotary. Professional or manufacturer consultation is advisable, or if not, mechanical systems. Such approaches can help tailor the exact bearing modification best suited for your pump system and cut down the time required for adjustment in the pump ordering process.

Load-Carrying Capacity: The replacement bearing’s load-carrying capacity is another vital aspect to remember. This parameter ensures that the bearings can withstand the forces and pressures likely to be encountered while working with the water pump system. It is necessary to choose a bearing with a load-carrying capacity that will reliably meet the application’s needs and not fail at an early stage.

When integrating the information obtained from the first three websites appearing in the Google search results on your query and regarding the requisite technical parameters relevant to your water pump system, you can effectively determine the best replacement bearing that will give you the best operational efficacy, compatibility, and reliability.

What Role Does Seal and System Compatibility Play?

Ensuring Proper Sealing to Prevent Leaks

Gaskets and sealing fittings are core elements to be paid attention to in water pump systems to mitigate any leakage problems. The information I gathered through extensive studies and analyzing the top three sites on Google can be interpreted as follows:

It involves selecting an appropriate sealing element against the specific pump structure in question. Considerations such as types of fluid pumped, operable temperatures, and pressure conditions are necessary. In water pump systems, mechanical seals, lip seals, and labyrinth seals are commonly used sealing types.

Other than the ones listed above, other technical parameters to keep in mind when it comes to put be answered respectfully together:

Sealing Material Compatibility with the Fluid: The sealing material used should be compatible with the fluid being pumped; otherwise, there is every likelihood that a complex chemical reaction will occur and, ultimately, degradation will set in.

Operating Temperature Range: The selected seal should fully cope with the temperature range of the working system to make the seals effective.

Maximum Pressure Rating: The maximum pressure rating is vital in selecting a seal as it determines the maximum pressure the working component will experience. This means that the seal will not leak in high-pressure applications; hence, the safety of working with such components is taken care of.

Pump Shaft Speed: When selecting seals for pumps for example, it is necessary to pay attention to the speed of the pumping shaft to select a seal able to handle the required speed.

When these technical parameters are considered, and the seal suitable for your water pump system is selected, sealing of the components is accomplished, and leaks are avoided, thus improving the reliability of the entire system.

Compatibility with Different Pump Systems

In collecting data from the top three sites on Google.com, I have conducted relevant research on how different pumps can be fitted with bearings. The following bullets can sum up the selected three pages:

Type and Design: There are several different types and designs of bearings on the market that are needed for various kinds of pump bearings. This consideration is critical, considering the pump configuration used (centrifuge, reciprocates, etc) and the application being pumped (water, oil, chemicals, etc.).

Load-Carrying Capacity: The centrifugal pump’s load-bearing capacity has many factors to consider, especially when selecting the bearings. This capacity is built around the maximum load exerted on the bearing while the performance level is still acceptable. Therefore, it is essential to have a suitable bearing to meet the load demands of the particular pump system.

Speed Capability: The bearing on the centrifugal pump must be determined by its speed ability; the faster the pump shaft rotates, the bigger the centrifugal force exerted. The bearing should not wear out upon meeting the required speed, nor should it produce excessive heat due to friction. In this regard, the key point to note is matching the bearing’s speed capability with the operational speed required in the system.

Sealing Requirements: Sealing is the most critical element in preventing leakage in a pump system. Pump systems have diverse operating applications and conditions, so they may require mechanical seals or gland packing for practical sealing applications. Factors like the nature of the pumped fluid, pressure, and temperature should be considered when selecting the right sealing solution.

The mention of these technical parameters and selecting the appropriate bearings that conform with the parameters of your pump system will guarantee a decent operation and enhance the system’s general performance.

How to Select Bearings for Specific Applications?

Considering Load-Carrying Capacity

Bearing design is one of the most essential aspects when selecting bearings for centrifugal pumps. Bearing selection is not based on the centrifugal pump performance criteria alone. Guided by the area of practice, I researched and analyzed information from the top three websites on Google.com, focusing on answering the question posed by high-speed performance concerning centrifugal pumps. So, in my opinion, the following factors matter:

Bearing Type: The most important aspect of speed is the speed at which the centrifugal pump operates. Each type of bearing offers different high-speed characteristics. Centrifugal pumps have been observed to operate best with deep groove ball bearings, angular contact ball bearings, and cylindrical roller bearings.

Dynamic Load Rating: Damping dynamics is one of the most important technical parameters of the bearing’s performance. This will, however, depend on the basic configuration of the bearing. It indicates the highest load a bearing can withstand without the risk of causing a fatigue fracture, which may cause a continuous spiral of rotary motion. Finally, when choosing an appropriate bearing, verify that the dynamic load rating is sufficient to satisfy the load conditions.

Friction and Heat Generation: Similarly, high-speed rotation heightens the frustration of heating the topic. Consequently, it is essential to select bearings that do not consume much energy from rotation due to high friction. So, ensure that you choose bearings that have been designed and lubricated well enough.

Precision and Tolerance: Precision and tolerance are important in high-speed applications. Precision bearings with tighter tolerances should provide a stable operating condition and minimize the vibration generated at elevated speeds.

Lubrication: To maintain their performance requirements, bearings employed in high-speed applications should also be lubricated correctly. It is prudent to study the lubrication needs and ensure that the required bearing can accept the recommended technique and its intervals.

Understanding the key factors and other technical parameters, such as the dynamic load rating, frictional characteristics, precision, tolerance, and type of lubrication needed, allows one to choose the most suitable bearings to install on centrifugal pumps working at high rotational speeds. Effective practice of this procedure should include considering the manufacturer’s specifications and recommendations aimed at the particular application to obtain the best efficiency and dependability.

Assessing High-Speed Performance

In selecting centrifugal pump bearings, assessing their good performance at high speeds is among the several factors emphasized by the top websites on Google.com. Here are the key points to keep in mind:

Bearing Base: Different types of bearings can operate at different speeds. Centrifugal pumps mainly employ deep groove ball bearings, angular contact ball bearings, and cylindrical roller bearings, as they can withstand high rotational speeds.

Bearing Rating: Each bearing has a rating that describes the maximum rotation speed that can be achieved – this is known as the bearing rating or speed limit. This parameter is influenced by a bearing’s dimensions, its configuration, and its lubricating mechanism. Choose bearings that can endure the expected centrifugal pump operating speed.

Bearing Dynamic and Static Load Factors: Rotating the bearings at high speeds can cause excessive force to be applied to them. Therefore, the dynamic and static load factors must be considered to avoid damaging the bearings and ensure smooth operation at the required speeds.

Bearing Fitting: Bearings functioning at higher speeds need a perfect fit and geometrical tolerances to avoid vibration and operate smoothly. Geometric imperfections in the bearing, such as clearance, runout, and balancing, are included.

Lubrication and Cooling: Proper lubrication and proper cooling are the key requirements for the operating speed performance. It has to be ensured that the proper lubricant is selected and the cooling processes in the pump system are good so that friction and heating, which results in the wearing of parts at high speeds, are avoided.

So, by judging the given aspects and the information provided by the best sources, you should be able to select the most appropriate bearings for your centrifugal pump application. These bearings can operate at higher speeds and have extended service lives.

Choosing the Right Bearings for Centrifugal Pumps

Bearing selection for centrifugal pumps is a delicate task and must be done with utmost importance as it will maintain the pump’s desired effectiveness and life span. From the text that I wrote, I will provide you with the questions you have in mind more directly based on the material sourced from the top Websites on Google.com:

Load-carrying capacity is another crucial factor when selecting bearings for centrifugal pumps. It determines the bearing’s ability to withstand radial and axial loads.

High-Speed Performance: All centrifugal pumps will likely run on a high horse. Therefore, it is essential to ensure that the bearings can withstand high speeds while still getting the job done and avoiding damaging wear. Look for bearings that are specially made for high speeds and those with ample lubricant features.

Proper Sealing to Prevent Leaks: For centrifugal pump systems to operate well, it is essential to have good seals in place so that leaks do not occur. Look for bearings that incorporate good sealing features, such as labyrinth seals or contact seals. That would inhibit contamination and fluid loss.

Compatibility with Different Pump Systems: Consider the different bearing structures for centrifugal pump systems that could work with the designated bearings. Various pump designs might require particular arrangements or materials for the bearings for JP. Assess the manufacturer’s recommendations or consult experts to determine the most suitable bearing for your specific pump system.

It must be emphasized that the technical parameters and justifications for these answers may vary based on specific pump models, pump makers, and application requirements. Most importantly, to select the best bearings for your centrifugal pump application, you must consult the manuals issued by the pump maker or seek knowledge from practitioners.

Frequently Asked Questions (FAQs)

Q: Which pump shaft bearing selection parameters can a customer consider?

A: Depending on the application, basic considerations include the type of pump, such as centrifugal pumps, application requirements, bearing load parameters, heat resistance, and operating conditions. Furthermore, this client needs to refer to the product catalog to view the bearing type, for instance, a ball or roller bearing, and its attributes, such as sealing type and dimensional stability.

Q: How do roller and ball bearings relate to pump usage?

A: Low-friction ball bearings are best when high speed is required. However, roller bearings are better suited for applications requiring high load capacities. These specific conditions of the application are necessary to meet the mechanical requirements of the pump, such as extreme heat resistance or extremely low friction.

Q: What is especially relevant to why pump shaft bearings must be heat resistant?

A: Heat poses serious problems for bearings with excellent heat tolerance, which is why so many different types of bearings span across many thermal ranges. Those bearings showing good heat tolerance would be able to withstand and operate successfully in high temperature conditions without failure caused by backward forces acting upon them or by material degradation, thus HI preventing premature fusions caused by the extreme heat.

Q: What is the function of the inner ring and outer ring in a bearing?

A: The shaft typically shrinks the inner ring onto it; hence, it rotates with the shaft. The other ring is nonrotating. They are together with the rolling elements such as balls or rollers. In this way, rotation is smooth, and the load is transferred.

Q: Can you justify the use of double-row bearings?

A: Double-row bearings have two rows of rolling elements; therefore, they can withstand much higher loads than single-row bearings. This results in bearing designs that can withstand both radial and axial loads and are suitable for applications requiring a high degree of stiffness.

Q: How do the various types of bearings influence the performance characteristics of centrifugal pumps?

A: Bearing type is critical to centrifugal pumps’ efficiency, effectiveness, and life. For instance, the high-speed application requires angular contact bearings that can bear combined loads, while cylindrical bearings are best for larger radial loads. Using the right type enhances performance and minimizes maintenance requirements.

Q: What specific materials are used to make pump shaft bearings?

A: The abovementioned parts can be made from high-quality materials such as stainless steel and ceramic for the balls or rollers and durable metal alloys for the inner and outer rings. These materials possess incredible strength, heat, and corrosion resistance and make an effective solution for industrial applications in the long run.

Q: How can the catalog assist in selecting the correct bearing?

A: The product catalog elaborates on the specific type of bearing products available in the market including their technical specifications, dimensions, bearing and ultimate load, and the applications where it can be used. It enables the clients to look at different options and to make decisions concerning their application requirements.

Q: Are there bearings available with excellent sealing performance?

A: Yes, such bearings with good sealing ability are pretty available and essential for barring the entrance of contaminants that can potentially ruin the internal components. Proper sealing practices will guarantee that the bearing is not dry, thus minimizing wear and tear and increasing the component’s life expectancy.

Q: Could you elaborate on the role of resin in pump shaft bearings?

A: Resin is widely employed in constructing cage structures in pump bearings due to its low friction and high temperature resistance. It enhances the bearings’ functioning and lifetime.