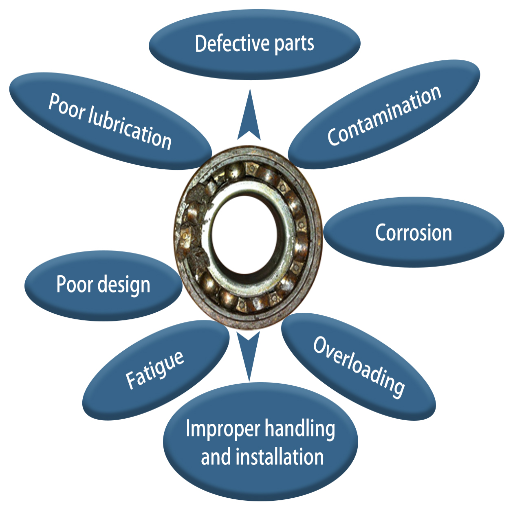

Bearings are essential in pumps, enabling them to function and operate as intended. However, thorough bearing failure is among the common challenges experienced with pump systems, leading to decreases in their reliability, increases in downtimes, and costly repairs. This implies that knowing the reasons behind bearing failure is crucial, especially from a perspective on TPU, durability, and efficiency. The article discusses common causes of bearing failures in pumps, such as low lubricating oil, contamination, improper assembly, and overload conditions. Moreover, we also suggest applicable countermeasures to facilitate competent people’s actions to improve pumps and prolong the bearing life. To this end, our objective is to provide information that will help people manage these systems to be more dependable and have reduced interruptions to the pump systems, whether in use or not.

What are the Common Causes of Bearing Failure in Pumps?

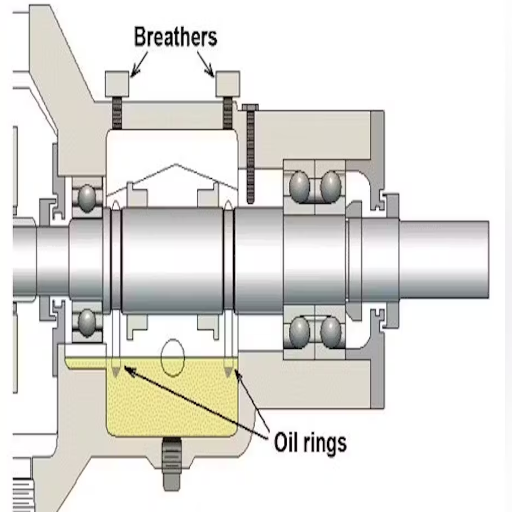

Understanding the Role of Bearing Lubrication

Proper bearing lubrication is essential to ensuring adequate performance and increasing the reliability of pump systems. Lubrication decreases the wear and tear of the moving parts and heat generation during pumping. Without enough lubrication, bearing systems are prone to overheating, wear and tear, or even failure.

Some of the important core attributes when applying the lubricant are listed below.

Viscosity: Based on the pump requirements and functioning, lubricants have a range of viscosity that coincide. For example, low-viscosity oils such as the ISO VG 32 can be used for applications that require higher speed. In contrast, oils with higher viscosity, such as the ISO VG 150, are better suited for usage with slower speeds and heavier loads.

Operating Temperature: While selecting a lubricant, it is advisable to roll with one that can withstand the given temperature range while performing to maximum effectiveness. This often happens with synthetic lubricants built for extreme temperatures from -40 to 300 degrees Fahrenheit.

Lubricant Type: Factors like the type of operations necessary dictate whether oils or glues will be utilized. Greases with a high dropping point and temperatures over 120 degrees Celsius or 250 degrees Fahrenheit are well-suited for high-temperature operations. Continuous use also improves oils fortified with anti-oxidation additives.

Re-lubrication Intervals: Maintenance schedules play an important role. Depending on the product’s makers, if the working conditions are moderate, re-lubrication could be warranted every 2000 to 8,000 hours of operation.

Specialists can prevent most pump failures by utilizing the proper lubricant and constant check-up maintenance of the bearing.

Impact of Contamination on Bearing Lifespan

Contamination is one of the most significant damaging factors to bearings since it can incorporate interference mechanisms such as accelerated wear, surface degeneration, and structural failure. Elements such as dust, dirt, moisture, or any other debris can hinder lubricants, creating abrasive cocktails that increase the rate of erosion and wear. Research has indicated that even unaided particles with dimensions of 10-20 micrometers can substantially impair the structural integrity of the bearing’s surface.

Particle Size Limit: To maintain the desired performance, particles larger than 10 microns should be adequately filtered from the lubricant.

Lubricant Cleanliness Levels (ISO 4406): The level of contamination in the bearings should not be more than 16 on the ISO cleanliness code; otherwise, it will cause more excellent potential wear.

Seal Effectiveness (IP/Ingress Protection Rating): To effectively prevent contamination from mineral fuels, cosmetics, or moisture, the lubricants used in bearings should have an IP rating of IP65 in harsh working environments.

Water Content in Lubricant: The water content of the lubricant or grease should not exceed 200-300 ppm since excessive amounts of this chemical would cause erosion and corrosion.

Integrating strict anti-contamination protocols and controlling these key factors can greatly improve service life and maintenance time, increasing the overall system’s reliability.

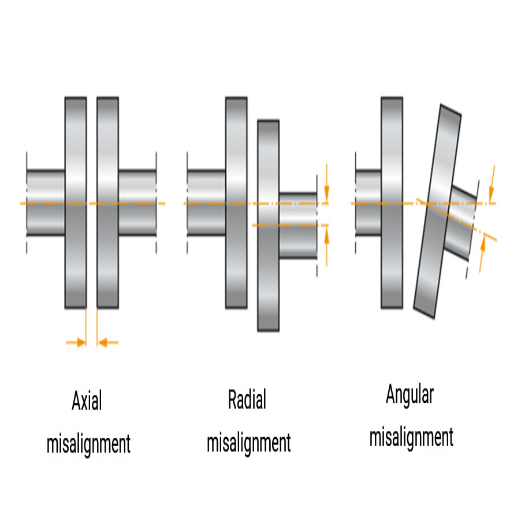

Effects of Improper Installation and Misalignment

Improper installation and misalignment are adverse factors that significantly reduce the performance and life of the bearing. Improper installation practices, such as trying to fit the bearing with excessive force or the wrong tools, can cause structural failures, such as dents or cracked surfaces on the raceways and rolling elements. Such damage undermines the strength of the bearing and diminishes its load-carrying capability, thus increasing the risk of failure.

If the shaft and housing are not appropriately aligned, loads across the bearing are not even. As a result, some spots incur higher friction and heat, leading to early failure of the bearing. Parameters that should be measured are:

Acceptable Alignment Tolerance: The shaft-housing joint must be cylindrical to an accuracy of 0.001 to 0.002 inches to provide equal force throughout the joined elements.

Misalignment Angle: Self-aligning bearers tolerate misaligned angles of between 0.5° to 2°. Beyond these limits, they become significantly less helpful.

Temperature Rise: Abnormal temperature rises are standard with either installation or mechanical alignment defects, so keep operational temperature ranges for the lubricant and the bearing to avoid thermal damage.

Installing the bearings correctly and using precise instruments to check the bearing alignment assists the operators in confronting the three risks, ensuring the bearings operate correctly, and increasing their lifespan.

How Does Lubrication Failure Affect Pump Bearings?

Effects of Employing the Wrong Lubricant

I have seen firsthand that it can significantly influence the pump’s bearings. Whenever the incorrect viscosity is selected, either the film strength is insufficient, or the drag is too much, which would damage the bearings’ surfaces. For instance, the lubricant film does not maintain its integrity when the viscosity is too low, leading to metal-on-metal contact and thereby hastening wear. On the other hand, being too thick of a lubricant has the opposite effect of increasing energy costs and the pump’s temperature, resulting in the lubricant breaking down thermally and losing its structure.

Moreover, the lubricant’s performance can be poorly affected by its additives. Using a lubricant devoid of anti-wear or EP additives, for example, made an entry into the surface only to fatigue and spall under a high load. Another parameter that calls for attention is the temperature range within which the lubricant is supposed to operate. Lubricating fluids that do not have enough strength to withstand the temperatures within the system can cause deposits to form due to early oxidation, making the lubricant less efficient.

So long as the proper viscosity (per ISO VG standards) is selected and employed according to the load conditions and temperature range (say -20F to 250F according to use), I can assist in protecting the pump’s bearings, prolonging their usable age, and ensuring that there are limited instances of faults.

The Potential Risks Of Not Having Proper Lubricating Flow

My research shows that dysfunctional lubricating flow can result in various problems that can be catastrophic to the overall system, which is alarming when unattended. One of the most glaring signs is the operating temperature surge, which is outside of the normal range, for instance, anything exceeding a threshold of 250 degrees Fahrenheit in specific applications. Those who fail to lubricate their equipment are often placed under excessive friction conditions and have a build-up of heat generation.

Additionally, humming or crackling sounds from machinery suggest an internal issue. The vital internal workings aren’t receiving enough lubrication to ensure smooth operation. Issues like clogs, incorrect viscosity, or a faulty pump might result in this.

Further, discolored lubricant or a foamy appearance indicates that flow has not been handled adequately and indicates oxidation and contamination. All of these alterations in lubricant fluid decrease the lifespan of the lubricant fluid itself; when water basics or dust particles infiltrate the substance, it hurts it, too.

In the last transmission, I found abnormal gouges or holes on the surfaces of the bearings, which were an evident hint of reduced tension availability. I keep track of the volume of lubrication, temperature, and temperature subjectively to eliminate the risk of putting all operations at a standstill.

Bearing Lubrication Failure Provisioning

To avoid the failure of lubrication for the rolling elements of the bearings, I adopted some measures and parameters that are to be focused on. First, I ensure the selected lubricant fulfills the application’s requirements, including viscosity grade, operating temperature range, and load support. For viscosity values, I check them against the manufacturers’ recommendations as well as the optimal operating range, where the values are not too low or too high to impact performance negatively.

Second, I keep contamination under control with regular tests for water and particulate levels in the lubricating oil. This is done through the right sealing techniques and regular drawings of oil samples for laboratory tests. It is vital to ensure that water concentration is less than 500 ppm and the number of particles is within the ISO 4406 limits to minimize damage to the lubricant.

Finally, I use Planned Maintenance, for example, checking the working temperature (mostly between 50°C and 90°C for standard applications) and inspecting the debris by engaging in oil analysis. These allow the lubricant to be supplied regularly without interruptions and prevent problems caused by wear, such as scoring or pitting. This increases the life span of the bearings and reduces downtime.

What Role Does Shaft Misalignment Play in Bearing Failures?

Detecting Shaft and Bearing Misalignment

Various methods, including visual inspections and diagnostic tools, can establish shaft and bearing misalignment. Bearing signs of misalignment are identifiable and include bearing wear, excessive vibration, or even an abnormal sound during rotation. Vibration analysis and thermal imaging are two advanced techniques that can be applied. Vibration analysis determines the frequencies of the misalignment, while thermal imaging spots friction hot spots resulting from misalignment.

Parameters to monitor in this regard include:

Axial and Radial Runout: Ranges exceeding 0.05 mm from the most precise applications indicate alignment issues.

Vibration Levels: These frequencies are 1x and 2x the equipment’s rotational speed in Hz.

Temperature Variations: If the operating temperature changes by more than 90 degrees Celsius, it is safe to deduce that the industrial system may be causing some interference.

Lubrication Checks: The alignment is disturbed because components fail to contact uniformly; improper lubrication may cause even contact.

In conclusion, by using these detection techniques and these proofs to monitor if a bearing gets misaligned, such a bearing relief of excessive pressure that could get it to fail could be further delayed.

Methods of Correcting Shaft Misalignment

When correcting the shaft misalignment, I will take a more organized approach involving specialized tools and techniques. Here’s how I would go about it:

Utilizing Laser Alignment Systems: I would use laser alignment tools due to their high precision and simplicity. Furthermore, these systems can provide real-time feedback, simplifying the accurate alignment task. For example, deviations can be measured to the micron, meaning the ending cut will be within the tolerances one chooses, such as ±0.05 mm.

Using Dial Indicator Method: In the absence of the laser system, I would naturally have to seek out other alternatives, in this case, I would use a dial indicator which also provides comparatively reliable results. The actual angular and parallel misalignments could then be adjusted by measuring the difference in angular readings between two shaft locations (for instance, between 12 o’clock and 6 o’clock positions).

Making Shim Adjustments: To shift the misalignments in the vertical plane, I would change the shims located under the mounting points attached to the machinery. The plan is to add or remove shims to correct measured offsets while rigid balances between bursts are maintained.

Conducting Soft Foot Checks: Another significant aspect would be ensuring that all mounting points firmly grasp the machine. I would, therefore, check whether any soft foot conditions are present, such as gaps or uneven surfaces that would have occurred during the machine mounting process, and correct those using a feeler gauge before carrying out any alignment.

Verifying the bolt torque again would be my final step once the alignment has been corrected. Slow slippage of improperly torqued bolts induces a misalignment that gets repeated over time. For the sake of accuracy, I would use the manufacturer-specified torque values.

By applying such methods and verifying the adjustments with the set tolerances provided in the equipment manuals, I would achieve the required shaft alignments, improving system reliability and reducing wear.

Long-term Effects of Misalignment on Bearing Health

It is crucial to understand that misalignment impacts the bearing and the system as a whole. From a perspective, continuous misalignment places an undue constraint on the bearings, which generally leads to uneven load conditions for the bearings. If this situation develops, it may subsequently result in local overheating, Depending vibration and ultimately bearing life fatigue does tarnish the bearing life of the machines.

Load Distribution—Such misaligned shafts tend to impose radial and axial forces on the bearings outside of design tolerances, making them operationally uneconomic.

Temperature Rise – Operating above recommended thresholds typically is related to bearing temperatures 40-80 degrees Celsius of set ranges. All are enabled through frictional losses.

Vibration Levels – Elevated vibration, outside of specified areas of functioning or above-set limits (like ISO 10816 for rotating machinery), exhibits early signs of malfunction, including housing misalignment.

Lubrication Degradation – Stress and heat are known to accelerate lubricant breakdown, weakening its properties, which aids wear.

If these considerations are made and alignment techniques are implemented through routine checks, performance levels and machine life expectancy will be enhanced.

How Can Overload and Overheating Lead to Bearing Damage?

Identifying Signs of Overload in Bearings

Of course. Understanding the signs of impending overload on bearings, I evaluate the performance of some technical parameters likely to show signs of statical strain. The following are a few indicators, along with the reasons for their occurrence:

Abnormal Noise—In most cases of overload, odd sounds like grinding, squealing, or clicking come from bearings. This is because rolling elements and raceways are experiencing heightened contact pressure.

Elevated Operating Temperatures—Excessive load produces incredible friction and heat, raising the temperature beyond the material’s threshold, usually above eighty degrees Celsius for regular bearings.

Premature Wear or Deformation – Surfaces’ breakdown begins faster in high loads, including pitting and flaking and an apparent change in the shape of the rolling elements and raceways.

Reduced Lubrication Effectiveness—In heavier loads, this is greater than the filament, which should have had two components separate from each other instead. This results in contact with two of the metal parts.

Sudden Drop in Performance – In the case of overload, the bearing may observe a drop in R P M or may not work as efficiently. This is because the bearing cannot overcome those conditions.

Careful consideration of the above indicators and relevant parameters recognizes overloading problems that can be remedied in their early stages, thus curtailing damage.

Preventative Measures Against Overheating

When it comes to bearing overheating problems, I prefer to apply a few simple measures that are oriented at controlling the operating and environmental conditions in the system:

Lubricating the Parts—I select lubricants with the required viscosity and thermal stability, such as synthetic oils, for elevated temperatures (up to 150°C where needed). Regularly assessing lubricant consumption and degradation is essential because deficiency in this area is one of the main contributors to the rise in heat.

Keeping An Eye On The Temperature – I employ temperature sensors to control the environment in which the elements are located adequately. Standard use has the limits of bearing use under temperatures of 80-90 °C. Any fluctuations from this measurement are dealt with immediately to zero, and how this affects the machine’s performance.

Controlling Load and Speed Conditions—When excessive RPM or an overload is experienced, friction causes a temperature rise. This can be overcome by employing load monitors and ensuring that speeds are within the manufacturer’s designated level and not exceeding 70-80 % of the rated maximum speed.

Working on Clearances and Fitting—Fitment failure or incorrect clearance can result in excessive heat due to friction. I try to ensure adequate clearance, as the bearing type recommends, as detailed in the technical guidelines, such as ISO or manufacturer specifications.

четвертое предложение в первой части Moreover, By integrating these measures. Remember, I just want your opinion on my work and don’t need any permanent solution. Please feel free to tell me by providing your judgments on how I can improve my work. A professional I am not, So I wanna hear what I can do better; otherwise, you can be assured of my confidentiality with your evaluation. Overheating will have expressed consequences for maintenance frequencies over time.

What Precautions Can Prevent Premature Bearing Failure?

Importance of Proper Bearing Installation

Sound bearing installation is a key factor in extending the lifetime of a bearing and achieving good performance. Paraphrasing, I focus on adherence to clear guidelines during installation because a little blunder can result in displacement, uneven delivery of force, or collapsing of the bearing elements. Key technical aspects I consider encompass:

As per the written document, they are all fundamental aspects of installation practices. However, one of the most important is cleanliness during installation. Extraneous materials such as soil and debris can significantly impact performance. I assume the environment, tools, and components used for installation are cleaned adequately before the installation.

Absence of extraneous materials during the installation—I use the appropriate techniques, such as press fit for cylindrical bearings or thermal contraction during fitting, to avoid altering the structure of the fitting bearing. I also hammer directly or use the wrong tools to destroy the bearing.

Pairs and other factors lead to the correct, lively, and tolerant indication of the proper complement material. I work within the international standards ISO tolerances or the manufacturer’s tolerances for the shaft, and the housing fits according to the clearance or interference wanted. That means I chose details with tolerance pairs H7/g6 for mounting roller bearings with tolerance.

Lubricant must be applied in the right amounts as specified by the manufacturers to respective areas during installation of the bearings along shafts to prevent friction between surfaces during operations where motion is experienced.

By faithfully observing the outlined procedures and technical regulations, I am confident that bearing installation will be error-free, mitigating the possibility of premature failure.

Regular Maintenance and Troubleshooting

My important task in regular maintenance is inspecting the bearing condition so that the signs of wear, contamination, or misalignment can be identified early. I pay attention to parameters such as the operating temperature (generally in the limits prescribed by the manufacturer, say, standard bearings between 70 degrees Celsius and 100 degrees Celsius), and vibration which could indicate misalignment or overload if generated beyond permitted values.

I have implemented a scheduled lubrication program that promotes timely and effective relubrication of the bearings. I use formulated grease or oil with correct thozing viscosity for the required application, such as an ISO VG68. Enhanced lubrication or lubrication deficit is not permitted to allow seal failure or too much friction to occur.

To aid diagnostics of problems, I look for familiar symptoms such as spalling, pitting, or discoloration of the raceways, often linked with insufficient lubrication and poor raceway fitting. But if all goes well, I perform measurements (clearance fits such as H7/g6) while examining working settings that follow the technical requirements. A rigorous level of such execution helps me increase the overall system’s performance while prolonging the bearings’ practical life.

Best Practices for Extending Bearing Life

Monitoring Temperature and Vibration

- Ensure that operational temperatures do not exceed the range recommended by the manufacturer (70 °C to 100 °C for a standard bearing).

- Control the levels of vibration generated and/or transmitted so that they do not increase above the operating conditions through vibration analysis tools to enable timely detection of misalignment or overloading during the operation phase. Extreme vibration levels can also be linked with specific faults – imbalance, looseness, and, in other instances, bearing failure.

Appropriate Lubrication

- Always select the right lubricant with the proper viscosity for a given application (ISO VG68, for general industrial use).

- Adhere to the manufacturer’s recommended relubrication intervals to avoid over- or under-lubrication and minimize problems like damaged seals or friction wear.

- Use Clean, Good-Quality Oil or Grease. This will prevent solid particles’ contamination, resulting in scraping and enhanced wear.

Correct Applications Methods

- Confirm that the fit tolerances are consistent with design requirements – for instance, shaft tolerance H7 and bore tolerance g6 for interference fit.

- Use the correct installation tools for mounting and dismounting the bearings so that installation time minimizes the stress exerted on the bearing components.

- Check that the bearing’s position is well aligned, with distribution loads evenly along its raceways.

Failure Analysis and Preventive Action

- Damage mechanisms such as spalling pitting or discoloration should be inspected and recorded due to overloading or insufficient lubrication.

- Implement the following corrective actions, which include adherence to defined but realistic load limits and lubrication parameters.

- Reassess operational conditions periodically to make sure that all technical conditions are reached.

Such approaches and continuous improvements in servicing, maintenance, and bearing analysis provide measures to extend bearing life and ensure trouble-free operation during all specified system applications.

Frequently Asked Questions (FAQs)

Q: What are the common reasons pump bearings fail?

A: Based on past technological experiences, it can be asserted that multi-selection bearings greatly influence the cause and effect of common folktales on bearing. Among many determinant causes reported for such sag are unessential attention being paid to, unused grease, dirt entry, excess load, wrong alignment, and incorrect fitting of the bearing components. Due to these factors, the bearings can undergo fateful alternating loading, affecting the service life.

Q: How does contamination bear on the life of the bearing?

A: The invasion of contaminants such as dirt or moisture into a bearing results in an abnormal increase in escutcheon wear, which in turn affects the fatigue life of the bearing. The rolling elements and bearing surfaces must come in contact with each other upon sufficient load application. If contaminants are present, the bearing is bound to fail prematurely.

Q: What are the load bearings inside the pump shaft intended for?

A: The load-bearing mechanisms on the pump shaft are meant to bear radial and axial loads, allowing smooth and relatively friction void rotation between the contact parts. They assist in accommodating the transverse position of the pump shaft and decreasing the vibrations caused during its rotation process.

Q: How does improper internal clearance lead to bearing failure?

A: If the internal clearance is not set correctly, excessive temperatures and stresses will be generated in the bearing, leading to fatigue failure or other failures. Ignoring the proper internal clearance will compromise the desirable temperature that the bearing must possess to function adequately.

Q: Why do you think the housing contributes to preventing bearing failure?

A: The bearing housing helps the bearings maintain alignment and be free from dirt. Proper formal housing reduces the possibility of bearing failure from misalignments and the absence of enforcement of the bearings. There are chances where the risk of bearing more vigorous enforcement is low.

Q: What do you think are the reasons excessive preload can damage the bearing?

A: Preloading puts an edition on the bearing, making it undergo a less-than-effective use. This may lead to the deformation of the inner and outer rings or overheating and rubbing, forcing the shifting of the Balor wheel bearings, which are much more effective.

Q: How does lubrication assist in eliminating the most common pump-bearing failures?

A: Lubrication is best achieved using oil or grease as they promote coolness and avoid friction by creating designs of oil where the rolling elements combine. Furthermore, excellent oil cooling averts rust or corrosion from gripping the most used part of the machine, thus prolonging the life expectancy of the machine.

Q: Can you explain how high temperature may contribute to pump bearings wearing out faster than intended?

A: Lubrication is critical to controlling the pump’s temperature and maintaining the gap between the ring and the bearing. Avoiding high temperatures also removes strain on the bearings due to excessive pressure. Maintaining the desired temperature is necessary for a bearing’s good and prolonged expiration.

Q: What measures can be taken to prevent the recurrence of pump bearing failures?

A: To prevent flowering, ensure accurate installation, proper preseason loading and alignment, correct lubricant application, and routine observation for wear or contamination. These measures, if taken, may considerably extend the bearing’s life and reduce downtime.

Q: Does the fatigue life of a bearing suffer due to being misaligned?

A: Misalignment entails uneven load distribution on the bearing surfaces, increasing the stress and the amount of wear. Such a situation can often reduce the bearings’ fatigue life and increase the chances of early failure.