The temperature of the pump bearing is one of the leading indicators of thorough maintenance and operation of an industrial pump. It often results in costly replacements, repairs, and downtimes. Therefore, it is essential to be aware of the factors that affect temperature fluctuations. In this paper, we will try to cover the characteristics that determine the status of the pump bearing temperature about the operational environment, bearing material, lubrication, and mechanical design of the pump being sought the answer. By looking at those elements, the readers will learn how to maximize the pump’s effectiveness and decrease its thermal stress risks. It doesn’t matter if you are an engineer or a maintenance expert; on the other hand, this paper presents valid points concerning the behavior of bearings and thermal conductivity for someone just curious about how machines operate.

What are the standard temperature limits for pump bearings?

How do SKF-bearing temperature standards compare to national standards?

According to SKF’s established protocols, rotating elements, including rolling bearings, can function optimally and sometimes exceed the minimum requirements outlined by national standards. These specifics are purposefully designed with safety concerns in mind. National or base operating standards, such as ISO or ANSI, usually define the maximum temperature for bearings used in various industries, which may range from 80 degrees to 120 degrees centigrade (176-248 degrees Fahrenheit) for some types of bearings used with specific lubricants.

Regarding bearings, however, technological evolution and professionalism allow SKF to set temperature restrictions however appropriate. This is accomplished by establishing OSs that limit those temperatures and provide ample room to withstand the Merciless harshness of the environment they would withstand during normal operations. To illustrate:

Standard SKF Bearings: Allowable work temperatures are up to 120 centigrade with robust designs to endure within this temperature ceiling.

High-Temperature SKF Bearings: High-performance models can withstand temperatures up to 200 degrees centigrade, although some are designed for lower operating temperatures.

Lubrication compatibility: SKF bearings are compact and advanced in surface engineering and lubrication. They are intended to work with high-performance lubricants and thus maintain their properties while working under severe temperatures to minimize wear.

These designs greatly surpass national guidelines because they have stringent requirements that necessitate a lot of testing and innovativeness, providing a higher safety margin for quite some industrial applications. Always refer to individual SKF material data sheets for upper limits, which may vary as to how such factors as speed, load, and environment can affect the maximum allowable operational temperatures.

What is the maximum temperature a pump bearing should not exceed?

Para saber la temperatura máxima que debe tener un rodamiento de bomba, se debe tener en cuenta el diseño y material del rodamiento. Hablando de SKF, sus rodamientos permiten generalmente una temperatura operativa de 120 °C (248°F) para rodamientos estandarizados. Sin embargo, para los rodamientos que trabajan a mayores temperaturas, permiten temperaturas entre 200 °C (392 °F) y más, dependiendo del material y lubricantes usados. Algunos de los factores que limitan estos parámetros son:

Material: Se toleran mayores temperaturas en rodamientos de aceros de alta calidad o de cerámica.

Lubricación: Es muy importante que se usen lubricantes diseñados para trabajar a altas temperaturas, si se quiere tener operaciones por encima de los 120 °C.

Carga y Velocidad: Se puede generar mayor temperatura en el rodamiento si se aumenta la carga o velocidad.

Ambiente: Las limitaciones de temperatura también dependen de otras condiciones ambientales como temperatura de los alrededores o la cantidad de refrigerante que se disponga.

Verifique siempre estos parámetros en la documentación proporcionada por SKF o acuda a la asistencia técnica para garantizar que, dentro de sus condiciones de temperatura, el rodamiento tiene un rendimiento óptimo.

How does ambient temperature influence bearing temperature limits?

In my opinion, the ambient temperature influences the bearing’s overall insulation. The bearing’s baseline temperature must increase if the surrounding temperature is higher. On the other hand, reducing the operating temperature aids in the bearing’s overall insulation, keeping it within the desired specifications and helping reduce power consumption.

Ambient Temperature Range: According to some specifications, historical documents such as the SKO 02 and fellow certification rollers in certain regions need not exceed 120°C or drop below 30°C to avoid damaging the bearing.

Lubrication Performance: Surrounding temperatures higher than -30°C and +120° might affect the viscosity of lubrication oil and grease, which can directly affect the performance of the bearing if not maintained.

Thermal Expansion: Plastic deformation can occur when materials expand due to excessive heat, limiting movement clearance, or increasing friction.

Cooling Mechanism: Since higher temperatures impact performance, an external cooling system and controlling exposure to higher temperatures are necessary.

Do not forget to double-check the product documentation to ascertain whether the parameters correspond with the environmental conditions.

How does operating temperature impact pump bearing performance?

What is the ideal operating temperature range for pump bearings?

A temperature of between 120 °F to 180 °F (49 °C to 82 °C) is recommended for pump bearings. This temperature range helps degrade excessive wear, lubricating powers, and thermal expansion. Nonetheless, the type of lubricant, the bearing type, and the application environment could impact specific parameters. For example, standard bearings are designed to operate at close to 200 °F (93 °C) for standard lubricants. Anything above this probably would become difficult unless high-temperature bearing varieties are used.

Another critical factor is the type of lubricant used. Standard mineral oils have a high-efficiency rating between 180 °F and 82 °C. In comparison, most synthetic oils work perfectly at over 200 °F (93 °C). Various thrust load bearings can withstand torque load operations without lubrication; however, going above and beyond the rate can cause damage.

The pump and pumpators expansion tolerance is crucial for proper functionality and proper clearances, exceeding the limits can and have cause severe distortion. In cases where the application needs these limits, external cooling systems or high-performance materials are required for maximum integrity. Always crosscheck with industry standards and specifications for precise use cases to prevent application damage.

How does temperature rise affect bearing longevity?

An increase in temperature has quite a profound effect on bearing life as it causes rapid wear, decreases the effectiveness of lubricant, and might even change the material itself. In my experience, high temperatures indeed tend to cause a lubricant to oxidize quickly, limiting its friction-reducing properties, which, in turn, may lead to more wear on the surfaces of the bearing. For example, most common lubricants start breaking down at around 212°F (100°C), while depending on the specific product, high-temperature lubricants may last for as long as 392°F (200°C).

Also, elevated temperatures may result in dimensional alteration of the bearing parts, resulting in loose fits or excessive clearance, which worsens the performance. Bearings with high-durability composite structures, such as ceramics or complex steel alloys designed for high-temperature applications, could reduce these limits to a specific region while remaining fair under operating temperatures not exceeding 572°F (300°C) and more. I always suggest keeping the operating temperature within the manufacturer’s parameters to maximize the bearing lifespan.

What role does lubricant play in controlling bearing temperature?

How does lubricant viscosity change with temperature?

Lubricants are constantly subjected to temperature changes, and it is a fact that with an increase in temperature, the viscosity reduces, and on the other hand, when the temperature goes down, viscosity increases. This phenomenon is characterized by a lubricant’s viscosity index or VI, which determines how much the lubricant’s viscosity will change. For example, using a low-VI lubricant means that a temperature shift will drastically impact its consistency. Still, in the case of high-VI, the temperature shift will not impact its consistency a lot.

This becomes more of an issue for high temperatures as low viscosity can lead to thinner lubricant films, resulting in friction and slow wear as there is an increased chance of metal-to-metal contact. A good example is 212 degrees Fahrenheit, where a standard ISO VG 68 lubricant can go as low as 8-10cSt viscosity, making load lubrication difficult and lacking film thickness. However, at lower temperatures, too high viscosity can cause a choke in the flow of lubrication, which only raises the level of friction where coverage becomes lackluster.

In such cases, the only solution is to use thermally stable lubricants with the proper viscosity grades. Modern lubricant technology usually uses additives to enable lubricants to withstand extreme temperature changes without impacting their viscosity, making them effective functional lubricants. The data sheet must be checked beforehand to ensure that the viscosity range suits the conditions in which the lubricant will be used.

What are the best lubricants for high-temperature pump applications?

Synthetically formulated oil and grease are ideal for high-temperature pump applications. Heating and thermal stress make lubrication more complex. Thus, synthetic oils and lubricants should be employed. Lubricants must have good heat resistance, High stability at high heat exposure, a low vaporization rate, and many other characteristics to ensure good quality performance.

VI: The bigger the number, the better the performance when exposed to different temperatures. A number greater than 120 is ideal for lubricants, and this is the overall range.

Flash Point: When a lubricant’s flash point exceeds 200C (400 Fahrenheit), it experiences vaporization and leads to fires when near other such points of ignition.

Thermal Stability: Lubricants should withstand breaking down even at 150C (300 F) temperatures.

Additives: Antioxidants, anti-wear agents, and corrosion blockers can increase the durability of components and reduce wear and tear.

Base Oil Type: PAOs and Synthetic esters are ideal and highly recommended oils for operations that run at high temperatures.

Before using this oil, one must verify the specific operating temperature range it is best suited for, whether it is compatible with other systems, and always check the manufacturer’s specifications.

How can you accurately measure pump-bearing temperature?

What are the pros and cons of using infrared thermometers?

Pros:

Non-Contact Measurement: These infrared thermometers work well for great temperature and remote measurement applications since hot and difficult-to-reach areas make it physically impossible to take measurements without contact.

Quick Response Time: Performing routine checks dramatically helps in increasing efficiency by providing measurement results virtually instantaneously.

Safety: These free-hand measurements ensure safety when operating in dangerous or extremely hot areas.

Wide Temperature Range: Depending on the model, an infrared thermometer in Ontario can measure a wide range of temperatures, most measuring between -58 F and 3,000 F (-50 C and 1650 C). These thermometers can be used for multiple industrial processes.

High Accuracy: To provide usable data for the operational processes, more advanced models can be accurate to within ±1 to 2 % of the actual value of the thermal measurement.

Cons:

Surface Dependence: The emissivity of the measured surface can hinder the accuracy of the infrared thermometer’s results. Surfaces with poor emissivity, such as shiny metals, might have to be altered or additional products used. For example, emissivity tape may help.

Limited to Surface Temperature: Without infrared thermometers, one cannot measure or gauge internal heat accumulation. Hence, only the surface temperature can be measured.

Environmental Interference: Dust, steam, or grease in the nearby surroundings can limit signal strength, affecting the thermal infrared measurement and resulting in low-accuracy readings.

Field of View (FOV): To get better readings, measurements need to be taken from an appropriate distance with a proper target size; otherwise, if the target is too small and the distance is significant, a thermometer with a higher optical ratio (50:1 or more) will have to be used.

By understanding these factors, you can decide if infrared thermometers meet your operational needs and conform to your technical requirements.

As usual, focus on the terms and provisions of each application and the specifications for the equipment.

Is measuring bearing housing temperature sufficient?

Caution should be exercised when relying solely on measuring the operating temperature of the bearing housing since it does not provide a complete assessment of the bearing or the machine. It does, however, indicate some vital details about the bearing’s operating environment and situations of possible overheating, but it does not indicate other dynamics that affect bearing performance. Furthermore, alongside temperature, other parameters such as vibration, lubrication, and RPM should also be measured to give a more complete picture of bearing health.

Threshold temperature Range: Bearings operate between the temperature of 60 degree Celsius 40 degree Celsius and 082 degree Celsius, temperatures beyond this range stand to show slippage, bearing misalignment or leakage of lubrication fluid.

Vibration Metrics: Using sensors, vibration velocity in different scales (mm/ s or inches/s) shows an abnormality that may indicate wear, disbalance, or unalignment of a part.

Lubricant Condition: Understand the lubricant through its equilibration, contamination, and temperature for optimum efficacy output.

Rotational speed: Bearings have a limit on the speed they can support; otherwise, the temperature will increase, causing the bearing to deteriorate.

Combined with measuring the bearing housing temperature, these parameters provide an in-depth insight into the bearing condition, which can help reduce unplanned downtime and improve planning accuracy.

What factors contribute to excessive pump-bearing temperatures?

How does pump load affect bearing temperature?

A rise in the load on the pump often translates to a proportional rise in the temperature of its bearings. This results from the increased stress, friction, and, eventually, heat. A superior amount of load can be the reason behind the breakdown of the lubrication film, possibly giving way to excess temperature as the lubrication effectiveness would furthermore suffer.

Anyway, the first one is that the bearing’s overall load rating will change for dynamic bearing operating loads—this is a recommended operating change. Also, do not switch to unbalanced or alternately switch to unbalanced.

Dynamic Load Rating: Also known as C, always ensure the bearing’s adequate dynamic load capacity to suit the pump’s operational condition. Avoid overloading.

Frictional Torque: There are bounds to be maintained for friction not to create excess heat.

Lubrication Parameters: It is best to use a good lubricant to hold the required film under load.

Temperature Monitoring: To avoid overload conditions, it is essential to continuously monitor the temperatures of bearing housings with thermal sensors. A temperature over 180°F (82°C) is invariably without a guide temperature.

Essentially, where the pump load is appropriately maintained within the bearing limits, you avoid equipment servicing issues and extend the useful life of the equipment.

Can the temperature of the conveying medium impact the bearing temperature?

Of course, the conveying medium has a temperature and can significantly affect the bearing temperature. A rise in the medium’s temperature tends to increase heat transfer to other elements, such as the bearing casing, which could also raise its operating temperature. This is further aggravated in cases where the thermal insulation separates the bearing, the conveying medium is weak, or the heat dissipation is poor.

Medium Temperature: The range of conveying medium temperature must be controlled so that it is not above a specific value, which can be detrimental to other components. For example, a medium temperature of 93 degrees centigrade or 200 degrees Fahrenheit is relatively high and could lead to the device overheating through the heat exchange increase that takes place.

Thermal Conductivity of Materials: If the thermal conductivity of the pump material and the housing materials is high, it makes it easier to transfer heat to the bearings, which means that the design of these components has to be optimized.

Bearing Operating Temperature Range: Ensure the bearing temperature limits set will exceed the limit the medium can reach. For instance, standard bearings can operate at 121 degrees, but typically, 250 is the general limit for many high-temperature variants.

Cooling Mechanism: Cooling devices such as water jackets or outboard fans to cool down excessive heat.

Lubricant Temperature Tolerance: Choose marine lubricants that can operate at 149 degrees Celsius and 300 degrees Celsius without losing their strength.

The right thermal management and material must be employed to reduce how much a bearing’s performance is affected by temperature. Regular checks are also paramount to identify any particular anomalies that may cause equipment malfunctions at some point in the future.

Frequently Asked Questions (FAQs)

Q: What is the average bearing temperature in the centrifugal pump?

A: The average cranking temperature for a bearing in a centrifugal pump is within the indicated range. For oil bearings, the maximum temperature should not be more than 82 degrees Celsius, whereas 99 degrees Celsius can be manageable in grease bearings. The stated temperature can also differ depending on the centrifugal pump design, daily working conditions, and the lubrication type used.

Q: In your opinion, what effects does a rise in bearing temperature have on a centrifugal pump?

A: In short, a bearing’s temperature raises concerns because of the thrust the pump might require. A general rule is that the thrust the centrifugal pump needs should not exceed 40 degrees Celsius. A temperature rise may also affect lubricant stability and bearing life and can malfunction the entire pump system. Monitoring temperature rises is necessary to maintain the efficiency and endurance of the centrifugal pump.

Q: Are there any specific temperature standards for NDE bearings in the pump?

A: Talking about NDE, the temperature standards for pump bearings are same as for other internal pump bearings, degassed oil bearings should not cross 82 C and degreased bearings should cross 99 C, whereas maximum rise in performance bearing does not cross 40 C.

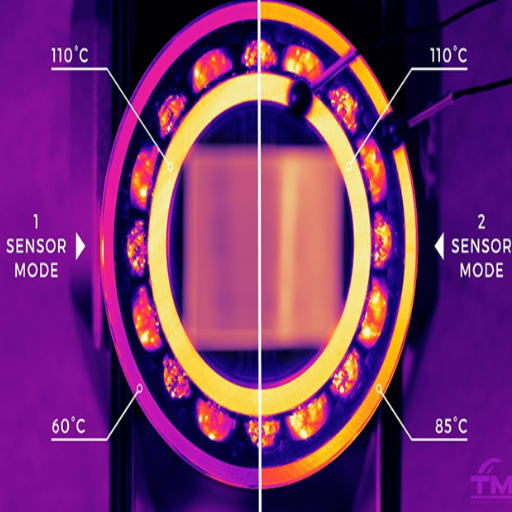

Q: What are the commonly used bearing temperature measurement techniques?

A: There are several ways to measure the temperature of the outer surface of a pump bearing, including the following techniques: 1. Infrared thermometer: This is a fast and non-contact method that makes measurement easy. 2. Contact thermometers: These are accurate temperature measuring instruments that provide the best results with direct contact with the bearing housings. 3. Thermocouples: These can be set up for periodic assessment, although it is not advisable to use them. 4. Thermal imaging camera: This equipment captures pictures indicating temperature differences. It is essential to ensure the pump operates under normal conditions during measurement.

Q: How does the sump temperature affect the ball-bearing performance in pumps?

A: The performance of ball bearings is greatly influenced by the temperature of the oil sump. When it comes to oil-lubricated bearings, it is essential to check the temperature of the oil sump to ensure it does not exceed 82 degrees Celsius. An increased sump temperature may decrease the oil’s viscosity, leading to poor lubrication and more friction. This issue causes the pump and the bearing to experience faster degradation than expected and suffer from reduced pump efficiency.

Q: What must be done if the bearing temperature goes over the recommended bearing temperature?

A: A few steps need to be followed in case the actual bearing gets warmer than the established temperature limit; those include: 1. The pump should be switched off immediately to avoid further damage. 2. Determine what went wrong, such as insufficient lubrication, the pump not aligning correctly, or the fact that it has taken too much weight. 3. Let the pump cool. 4. If needed, check and change the existing lubricant. 5. Check whether the bearing is damaged or not. 6. Resolve any problem found, and only then power on the pump. 7. If the problem is resolved, keep monitoring the temperature of the bearing closely when the pump is turned on.

Q: Regarding temperature control, how do externally mounted bearings compare to internal ones?

A: Externally mounted bearings frequently exhibit unique temperature management considerations compared to internal bearings: They are more exposed to room temperature, which can influence their temperature. 2. The bearing oscillates at a lower temperature owing to heat losses. 3. They are usually less challenging to oversee and operate. 4. As required, external means for cooling can be used much more quickly. Still, the fundamental limits of operational temperature (82 degrees Celsius for oil-bearing and 99 degrees Celsius for grease-bearing) continue to hold for improving the quality of service provided.