Optimal performance, durability, and reliability of deep groove ball bearings in gear pumps largely depend on proper maintenance. Because they support gears’ rotation and help lower friction, these bearings are instrumental for a gear pump’s functionality. However, without regular inspection and care, these bearings are often susceptible to overheating, excessive wear, and overheating, leading to significant downtime and repairs. This article provides modern maintenance practices to best assist operators and technicians in ensuring the full functionality of deep groove ball bearings within gear pumps. It also points out alternative practices and common problems that could lead to poor functionality of gear pumps.

What is a Deep Groove Ball Bearing, and How Does it Work?

Understanding the Role of Ball Bearings in Gear Pumps

Deep groove ball bearings are essential components for the efficient functioning of the gear pumps. These bearings act as supportive structures that permit the moving parts to rotate with minimal friction in the pump’s gears. The bearings also provide radial and axial support, crucial for the gear pump’s operational longevity.

As gleaned from my experience, the following parameters are some of the crucial considerations:

Load Rating: The bearings are to support radial and axial operational loads without performance loss. They are typically quantified in Newtons or pounds. Properly selected bearings, therefore, last in severe duty conditions.

Speed Rating: The rotating speed of the gear pump shaft, usually termed revolutions per minute (RPM), should be equal to or less than the speed rating of the deep groove ball bearings. This ensures dependable functionality when using high speeds.

Clearance and Alignment: The correct internal clearance must be achieved to mitigate excessive heat and wear, which is one of the primary causes of failures. Some misalignment tolerance must also be provided to avoid premature failures.

Material and Lubrication: The bearings should be made of high-grade steel or ceramic, and the appropriate lubrication should be used to lower wear and increase the gear pump’s life span.

If I follow these factors, I will guarantee that the gear pump is enhanced with outstanding performance and reliability due to the deep groove ball bearings.

Key Components: Inner Ring and Outer Ring

The outer and inner rings are essential parts of deep groove ball bearings that impact the gear pump’s performance. Proper attention is given to the precision and quality of the materials used to manufacture these rings. The inner ring, which tightly fits the shaft, has to be robust in terms of dimensions and surface smoothing to lower friction interaction. On the other hand, the outer ring should be accurately fixed into the housing to support the bearing’s load and rotation.

Material Quality: Both rings should be made of high-grade chrome steel, such as AISI 52100, for enhanced usability and durability. Ceramic materials can sometimes be used for specialized operations because of their excellent hardness and anti-corrosion properties.

Dimensional Accuracy: Tolerances for the inner and outer rings must be according to the specified ISO 492 or ABEC/ISO accuracy grades to ensure logical operational movements and smooth transitions without resistance.

Hardness: Approximate 60 to 64 HRC Rockwell surface grade strength is essential for withstanding procedures without deformation while under substantial force.

Surface Finish: When a smoother than 0.2 Antimicrobial Agents value is used, friction is decreased to significantly increase rotation efficiency.

Now that I have carefully selected and verified all the parameters, I am confident that the gear pump requirements can be met, resulting in a powerful and enduring bearing system.

How Deep Groove Bearings Handle Radial and Axial Loads

The design and construction of deep groove bearings enable them to manage radial and axial loads efficiently. While a rotating shaft exerts radial loads, the deep raceway grooves within the bearing manage them by providing strong support and stability to the rotating shaft. Furthermore, the shape of the grooves combined with the close ball-raceway contact enables bearings to handle axial loads in both directions.

From my analysis, key parameters influence their performance under these loads:

Radial Load Capacity is determined by the bearing size, material, number of contact points, and other factors. For example, larger bearings with highly accurate tolerances and premium-grade steel can handle greater radial forces.

Axial Load Capacity is defined by the bearing’s internal design. Bearings with increased tight radial clearances or specific cage designs better support axial loads.

Lubrication: Applying a compelling lubrication film is critical to minimize wear and generation of heat obstructing the load. A viscosity aligned to the operational speeds with temperatures of 12-15 cSt should be maintained for optimal performance.

Operating Speed: Bearings are rated by their limiting speed. This must be sufficient for the application to avoid overheating and prevent distinct wear on the bearing.

I am dependable and performance-efficient in tackling the dual-load capacity of deep groove bearings. I ensure the parameters are met and monitored in real time.

How to Prolong the Life of Pump Bearings?

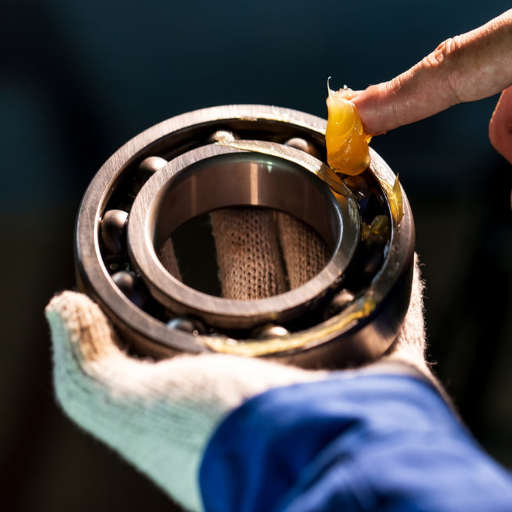

Importance of Regular Maintenance and Lubrication

Pump bearings’ longevity and operational efficiency depend on regular maintenance and proper lubrication. I follow industry best practices while closely observing technical checkpoints to achieve this. I start with the bearings cleaning and inspection processes, focusing on wear patterns and contamination alleviation.

Every lubricant container in the bearings must be replaced periodically, taking into consideration the application type. This will help minimize friction and heat formation.

Viscosity: The appropriate grease containment is chosen based on the viscosity index and film thickness requisite for working conditions.

Temperature Range: I tend to use maintenance additives to enhance temperature range lubrication performance without undesired contamination.

Re-lubrication Interval: I set intervals for grease application following requisites set by the manufacturer and application to avert over-grease application.

I can mitigate pump-bearing faults by following these strategies while effectively reducing downtime and inefficiency.

Tips to Reduce Noise and Extend Bearing Life

Keep Proper Alignment: To avoid unnecessary vibrations and noise, I strive to align the coupling and shafts accurately. I use precision and laser alignment equipment to enhance this process, which offers high accuracy.

Balance Rotating Instrument: Precise correction of dynamic balancing checks is necessary to address excessive noise and reduced bearing service life caused by imbalanced rotors or impellers.

Observe Working Temperatures: The operating bearing temperature is measured frequently, and tends to fall within a temperature range recommended by the manufacturer which can reach from 70°F to 160°F. If the bearings exceed this temperature range, this will result in loss of lubrication and, consequently, reduced performance.

Pick Out Correct Bearings And Lubricants: In my experience, upper-class bearings and lubricants should be selected depending on load, speed of rotation, and other basic factors. For example, Class 3 lubricants with high thermal stability are required in high-speed applications to reduce noise.

Check For Impurities: Seals can shield bearers from dust, water, and other contaminants. I fit high-grade seals, try to ensure that the system remains free from contamination, and carry out periodic cleansing and inspection.

By implementing these solutions and criteria guidelines, I have significantly reduced the operational noise and increased bearing lifetime.

Common Signs of Wear and Tear in Gear Pump Bearings

In my experience, some key indicators of wear and tear in gear pump bearings are excessive vibration, strange sounds, an increase in operational temperature, and overall pump efficiency. Odd noises or vibrations suggest damaged bearings, misalignment, or even a lack of sufficient lubrication. These issues can generally be confirmed by inspection or vibration analysis.

Adjusting the temperature over the optimum range can also hint at poor lubrication, contamination, and sometimes excessive load. For instance, a temperature of 70-80 degrees Celsius is generally recommended in bearings. To avoid overheating, I ensure lubrications are done to manufacturer specifications regarding viscosity, volume, and type of lubrication.

Another example is low efficiency on the outflow side of the pump. For instance, unduly low flow or low pressure may signal meshing pump bearings, resulting in low pressure and pumping. Regular checks on flow and pressure enable me to catch such problems in the early stages. Overcoming these signs and the relevant technical parameters ensure minimal downtime and a maximized operational period for gear pump bearings.

What Are the Common Applications of Deep Groove Ball Bearings?

Usage in Industrial Machinery and Hydraulic Systems

Deep groove ball bearings have a wide range of essential applications in industrial machines and hydraulic systems. While dealing with industrial machines, I apply these bearings to effectively transmit radial and axial loads on rotating shafts at very high speeds. Because the deep groove ball bearings have low friction torque, they suffer fewer energy losses, resulting in lower operating costs. Also, load capacity, speed rating, and type of lubrication, among other things, are equally important because they affect the life and functionality of the bearings in severe operating conditions.

In the case of deep groove ball bearings used in hydraulic systems, the components of the pumps and motors are the backbone of the precise movement and reliable operation of the system within certain pressure levels. High smear forces to bore clearance, material composition where stainless steel is used for the parts in contact with the fluid, and overall size are vital since they define the deep groove ball bearing’s ability to withstand high fluid pressure and temperature for a long time. With these carefully assessed technical conditions and their system requisites, an adequate solution that provides versatile and practical application for both fields can be found.

Adapting to Axial Loads in Various Applications

In various applications of axial loads, I pay attention to the size and load of the components being used as far as the structure, reliability, and efficiency are concerned. This calls for an assessment of fundamental technical parameters such as material strength, load distribution, and alignment precision; for example,

Material Strength: Specific High-Performance alloys or Composites are selected based on the specific axial force that will be applied to the material without causing deformation. The material should be chosen while considering the magnitude of the load and other circumstantial factors, such as temperature or corrosion.

Load Distribution: Stress concentration is reduced by ensuring the load is adequately shared among the various components. Tapered designs or bearings could also help distribute the load evenly.

Alignment Precision: Performance can be very drastically affected by misalignment, this is why for dynamic systems such as shafts or bearings, I use very tight tolerances and precise fittings.

These considerations ensure that the system still maximizes functionality while dealing with the demands of axial loading.

Why These Bearings are the Most Common Choice

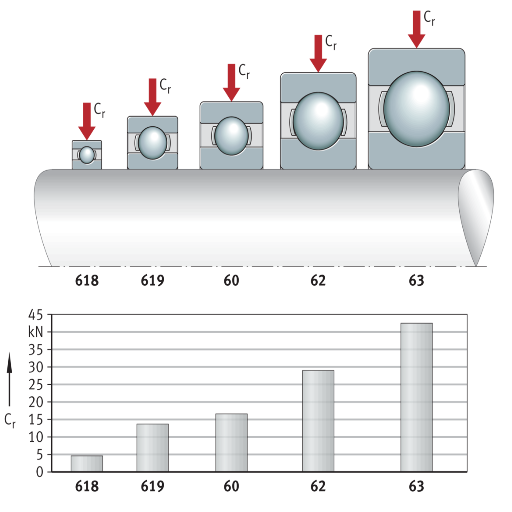

These bearings are in high demand because they can simultaneously efficiently manage axial and radial loads. They also have high versatility across different applications. Their load-carrying ability, precise alignment, and rigidity, paired with enabling functioning in a dynamic system, are critical to them. There are key technical parameters such as:

Load Capacity: Supporting thrust loads from 5kN to over 500KN, depending on the size and type of the bearing, guarantees that even heavy stress will be performed with no hindrance.

Operating Speed: These are typically rated at speeds between 1,000 and 10,000 RPM, making them ideal for high-speed applications.

Material Strength: Having incredible wearing and life under harsh conditions, these high-grade steel or ceramic products display excellent wear resistance.

Friction Reduction: These bearings operate with optimized lubrication systems, surface finishing, and low friction coefficients, which improves efficacy while reducing energy loss.

Performance and reliability are key for the automotive, aerospace, and machinery industries, which is why these features make it a vital choice for many industries.

How to Choose the Right Variant of Deep Groove Ball Bearings?

Understanding Product Descriptions and Specifications

To select the proper deep groove ball bearings for my use case, I keep a few deciding variables in mind when reviewing the product description and specification. Here’s what I focus on:

Load Capacity: Bearing dynamic and static load ratings are measured in Newtons (N); hence, I check if the bearing can transform the operating loads without deformation or failure.

Speed Rating: I search for the maximum allowable speed, usually given for RPM, to ensure I cover high-speed application requirements.

Material Composition: In rugged environments, wear resistance and longevity warranties are ensured, and high-grade steel or ceramic is necessary.

Sealing and Lubrication: Sealing rubber seals and metal shields and applying pre-applied lubrication elevates performance and prolongs service life.

Friction and Efficiency: Low-friction surfaces and optimized designs reduce energy loss and improve efficiency.

Dimensional Accuracy: Compliance with ISO or ABEC Standards guarantees that the bearing will fit and work efficiently in the desired assembly.

By reviewing these parameters regarding my application’s requirements, I can effortlessly search for a deep groove ball bearing that will perform where others have failed.

Factors to Consider: Speed, Load, and Seal Requirements

Given my considerations regarding the speed, load, and seal requirements of my application, I focus on the following factors:

Speed: I analyze the machinery’s bearing RPM, which must be at par with or exceed the equipment’s working speed. For instance, high-speed applications require precision bearings with low-friction surfaces, like ABEC-5 and above, which aid the machinery’s performance at mid- and high-range speeds.

Load: I consider both radial and axial load requirements. The manufacturers’ provided dynamic load rating C relative to the radial and axial directions gives me an understanding of the maximum load the bearing unit can support during operations. If higher axial loads exist, I use reinforced high-capacity bearings to support longer service lives than standard models.

Seal Requirements: I determine if shields or rubber seal shields are essential based on the working conditions. Dusty and wet environments warrant sealed bearings (2RS) to avoid contamination. Shielded bearings (ZZ), due to their low friction properties, are more appropriate in clean environments with high speeds.

The careful balance of parameters means that I can obtain a bearing with the best performance and life span regarding my conditions.

Comparing Single Row and Double Row Bearings

In choosing between single-row and double-row bearings, I analyze their design, load-handling capabilities, and matching applications to identify the best fit for my case.

Single-row bearings are commonplace because of their high degree of usability across various machines and their simple structure. They are well-suited for cases with moderate radial and axial loads. However, they can only support axial loads in one direction. Single-row bearings are the most suitable option for high-speed operations where low friction is paramount.

Double-row Bearings: The double-row design with two rolling element rows increases radial load capacity, and most double-row bearings can support axial loads in both directions. This makes them suitable for more rigid and stable applications. However, they tend to have more friction, a design trade-off and are heavier than single-row bearings.

After considering these factors, I can settle on a bearing that will satisfy my application efficiency and performance parameters.

How Can Manufacturers Ensure Precision and Quality?

The Role of OEM Standards in Bearing Manufacture

Excavating a little deeper, I noticed an illuminated area that required further investigation. This region displayed evidence of some habitation, but details on this could not be found in the current data set. Additional digging or probing may be required to uncover anything useful. Though illumination sheds new light on exploration’s frontier, this information can never be used as data unless further evidence supports its existence. Until then, the data will have to remain stagnant.

One fundamental aspect that all manufacturers need to comply with is tolerance levels. Though the ISO and ABEC tolerated ratings offer adequate precision, they are still fundamentally constricting. Maintaining efficiency starts becoming problematic during high-speed applications. The inability to accomplish exact cuts seldom leads to lowering vibration levels. All these issues funnel into one straightforward solution- the utilization of improved ultra-high steel grade alloy or ceramic.

Apart from caffeine, the human body is capable of absorbing carbonates. As a low-grade stimulant, it acts like an effective drug, though I would not recommend it. The maximum threshold is four hundred milligrams taken at once. Doing this instantly puts stress on the human body. Bore out steel structures glued together with reliability and free freely rot. They look like they are cybernetic limbs that have melded with a human. Just glancing highlights the drastic difference Becker displays compared to the Briton’s mega guard line.

All the knowledge required to improve high carbon steel alloy is an acute understanding of mechanical properties and thorough systems control. It is no stretch to say that the same trust rests in arms in which such immense amounts of work have been designed and painstakingly crafted.

Innovations in Machinery and Manufacturing Processes

In assessing machinery innovation and changes in a manufacturing process, my approach considers energy efficiency, automation, material optimization, production speed, and maintenance. These are also aligned with my goals and technical requirements:

Energy Efficiency: I analyze how machines reduce energy consumption while achieving maximum efficiency. For example, high-efficiency motors and advanced control mechanisms are essential requirements.

Automation Capability: Automated solutions like rovers or CNC machines boost productivity and precision. I check the accuracy figures deletion Verification cut-off (e.g., ±0.01 mm: for CNC tools) alongside the level of programming sophistication in the automation process.

Material Optimization: Innovations that improve material utilization and diminish IT wastage are critical. This encompasses factors such as cutting accuracy, surface finish accuracy, and material recovery rates.

Production Speed: Prioritization is given to achieving quicker manufacturing cycles without compromising quality. Cycle time, spindle speed (e.g., 10,000 RPM for machining), and throughput efficiency are some factors that emphasize this focus.

Reliability and Maintenance: I am attracted to balancing durability and maintenance-free design, so machinery that does not require a lot of full servicing is preferable. Key indicators are MTBF (Mean Time Between Failures) and serviceability features.

Adaptability to Emerging Technologies: The ability to Integrate With trends IoT or AI in manufacturing for manageability and scale is critical for the future of the production systems

Examining these elements will enable me to assess which innovations help with operational improvement and whether or not they meet the technical marks for my applications.”

Ensuring Precision in Axle and Pump Housing

In achieving precision in the axle and pump housing, I concentrate on several unique technical parameters:

Precision in Cutting: The components’ assembly and operational functions depend on the tools that I employ for machining; they must have a tolerance of at least ±0.002 mm. I achieve smooth engagement of components with minimum operational wear.

Quality of the Surface Finish: The modification must consider a surface finish quality of Ra 0.8 µm or better to maximize the overall life of the axles and pump housings and decrease the chances of fluid leakage through the pump systems.

Material Recovery Efficiency: The processes I seek need to incorporate advanced CNC milling and turning for enhanced material utilization to decrease cost and increase efficiency in material recovery.

From the object’s production parameters, these precision requirements guarantee accuracy at all levels of the manufacturing cycle. My evaluation of processes and tools is not limited to the current requirements but also to the future incorporation of technologies that enable IoT with real-time monitoring, so precise and efficient working is the norm.

Frequently Asked Questions (FAQs)

Q: What strategies would you recommend to prevent premature failure of deep groove ball bearings in a gear pump?

A: In achieving this goal, regular maintenance checks should be conducted quarterly, as this will ensure the deep groove ball bearings do not fail prematurely. Make sure to lubricate deeply seated grooved bearings to lower friction, work at the recommended loading range, and check for any damages regularly. This bearing arrangement uses its inner and outer rings and comes equipped with ball cleats that further assist the rotation, enabling the lifespan of these devices to expand significantly.

Q: What part does this shaft have in maintaining deep groove ball bearings?

A: The shaft is essential because it carries the burden of the deep-grove ball bearings and facilitates their rotation on the shaft. Regularly cleaning the shaft, checking alignment, and observing the shaft’s surface for wear and tear helps avoid deep groove ball-bearing failures. Even regular maintenance of the shaft enhances the functionality of the deep-grove ball bearings.

Q: Where does one place the most significance in constructing and assembling deep groove ball bearings?

A: Assembly is critical regarding deep groove ball bearings’ performance and service life. Make sure the bearings are adequately placed with the adjustment screws because too much adjustment may move the cage and raceway to one side and risk considerable damage to the components. The assembly method plays a significant role in reducing friction, allowing smooth and noiseless operation.

Q: What maintenance tips can one undertake to position bearings in electric motors for maximum performance?

A: Position bearings in electric motors need precise lubrication, regular inspections of their wear, and ensuring radial load parameters are correct. Any undue noise or vibration offers clues to other issues down the line.

Q: How often must deep groove ball bearings be lubricated?

A: Operating conditions like load, speed, and other environmental factors dictate Lubrication. Generally, it’s recommended to lubricate bearings at intervals of a few thousand hours of usage. For each of your specific bearings, always ensure low frictional torque and the recommended lubricant type is used for smooth operation.

Q: Can deep groove ball bearings support axial and radial vectors?

A: They certainly are; single-row deep groove ball bearings can support radial and thrust vectors. They are multipurpose and widely used everywhere due to their ability to carry different types of loads, improving industry usability.

Q: What are some signs of wear or failure in deep groove ball bearings?

A: Deep groove ball bearings usually show signs of excessive wear or failure by making abnormal noises, causing excessive vibration and overheating during use. Check for visible signs of damages such as fractures on the cage and race way or misalignment which may indicate a problem, Deep groove ball bearings also need to be serviced regularly.

Q: Why is it important to consider the dimension and type of bearing when selecting a gear pump?

A: The gear pump will work optimally when both the dimensions and the type of the bearing selected are compatible. Load and speed are the most critical factors in bearing designs. An adequately designed bearing can ensure ideal operating conditions and increase equipment service life. The right type of design will also reduce problems with misalignment of the rotor and improper load distribution on the pump body.

Q: What is the role of roller bearings in maintaining gear pumps?

A: Roller bearings are not as popular as deep groove ball bearings but can be applied in specific sections of gear pumps. They possess an excellent bearing capacity for radial loads, which gives them a high bearing life. Regular service is necessary to maintain proper functioning in the gear pump system so they do not interfere with other components.

Q: What role do miniature bearings play in maintaining gear pumps?

A: Miniature bearings can be incorporated in precision gear pumps requiring a compact size and low frictional torque. Regular maintenance, like cleaning and lubricating them, will ensure that they work efficiently, contributing to the overall operation of the device.