Although compact, automotive water pump bearings perform highly specialized tasks integral to the seamless functioning of vehicle cooling systems. Their design serves a dual purpose; it allows the bearing to bear significant axial and radial loads while simultaneously supporting rotational movement. The performance of these miniature components highly influences engine reliability and durability. In this article, we will examine the structure and key functions of automotive water pump bearings and the factors that help them last for as long as they do. Proper design of these components, choice of materials, and the correct maintenance of these devices enable the users of this article to get maximum breeding on the life and performance of these components. Whether an automotive engineer, a maintenance specialist, or just a curious enthusiast, this guide intends to address the different aspects of water pump bearing reliability.

What is a Water Pump Bearing, and How Does It Function?

Understanding the Role of Bearings in Water Pump Systems

Bearings are indeed crucial for the functionality of water pump systems. I appreciate that I do not have to delve deeper into how they reduce the system’s friction with the shaft’s rotation. From a technological angle, it is vital to consider other factors such as the load capacity, how fast the equipment can rotate, and the environmental setting of the device.

Load Capacity: Bearings must withstand radial and axial loads without any potential negatives, commonly expressed in Newtons (N). Excessive wear or undue failure can occur if conditions exceed the bearing’s capacity.

Rotational Speed: It is common to express it in terms of revolutions per minute (RPM). This parameter indicates the bearing’s capacity to work dynamically, but setting it too high can result in overheating and loss of efficiency.

Material And Lubrication: Bearings are typically made from high-carbon steel or ceramic, depending on the circumstances. The right type of lubrication reduces wear and hindrances of any sort.

Operating Temperature Range: Bearings must operate within a set temperature range, typically from -20°C to +120°C; anything above or below that can lead to undesirable performance issues.

By fine-tuning these parameters, bearings in water pump systems become less susceptible to mechanical energies and guarantee the effectiveness of the pump assembly. This balance is a prerequisite for the whole water pump system to be efficient economically and performance-wise.

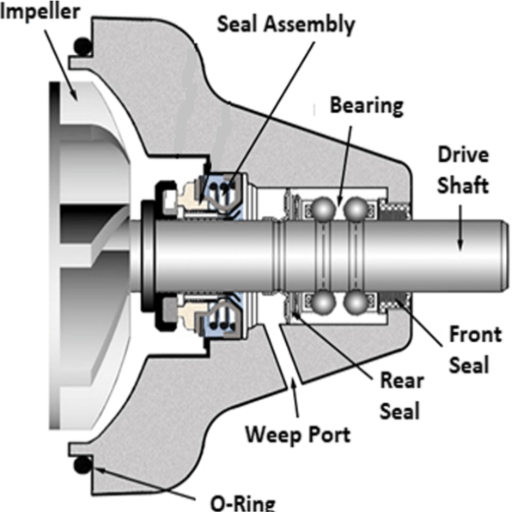

Key Components of a Water Pump Bearing

I will explain all the necessary points with precision. Here are the explanations alongside the respective technical details:

Material Specifications: Like other components, the materials worked with, particularly the hardened steel or ceramics, are strengthened on wear resistance and justified by the friction and loads experienced in operation.

Static and Dynamic Loading Capacity: The bearings I use, designed for radial and axial loads, provide stability during several pump conditions. For instance, the C dynamic load rating offers evidence that sufficiency in high performance is achieved, thereby minimizing the chances of failure.

Lubrication Efficiency: I will suggest using high-quality grease or oil as lubricants because they reduce friction and wear over a sustained period of operation. Furthermore, effective seals also help in ensuring top-quality lubrication.

Operating Temperature Range: The selected bearings operate within the -20 to 120 degrees Celsius. This is an essential range as it is aligned with the water pump systems’ normal environmental and operational conditions.

Considering these parameters, I seek to achieve durability, efficiency, and cost-effectiveness in the design and performance of the water pump bearing.

The Importance of Bearings in Automotive Applications

Bearings are essential to the functioning of many expendable parts in automotive machinery. To put it simply, I would emphasize the following points:

Load Management: In water pumps, for example, the bearings I selected manage the operating loads without wearing out, which is essential for optimal pump performance. Automotive systems manage the radial and axial loads equally efficiently.

Operational Efficiency: On the other hand, the temperature bears within -20°C and +120°C and, thus, function consistently. With optimal performance range in operational conditions of automotive systems, the bearing does not overheat or run inefficiently.

Durability and Maintenance: By selecting materials with superior tribological properties, the bearing has managed to reduce friction and increase lifespan, keeping the maintenance frequency at a minimal range. This consideration directly impacts operational reliability.

Design and Cost-effectiveness: Bearing design considerations can also balance performance and cost. By emphasizing precision tolerances and lubrication, functionality is enhanced, while affordability takes center stage, especially in automotive systems.

These spokes carefully justify the technical parameters that the bearings for automotive systems must fulfill to withstand the aggressive character while keeping durability and performance in mind.

How Does the Shaft Influence Water Pump Bearing Performance?

The Relationship Between Bearing Shaft and Load

It serves as a guide for ensuring reliable performance on the water pump bearing. The shaft must also be designed to carry radial and axial loads without failing materially or structurally. Some of the key technical parameters are:

Material Strength – The bearing shaft should support tensile and yield strength sufficient to support operational loads without deformation or breakage. This alleviates the risk of misalignment and ensures bearing integrity is achieved.

Surface Finish – A smooth surface finish minimizes friction and wear, directly impacting the interface between the bearing and the shaft.

Shaft Diameter Tolerance—The fit between the shaft and the bearing must be precise to minimize play or interference. Both extremes may adversely affect load distribution.

Bearing Load Capacity—The shaft design must correspond to the bearing’s rated load to withstand dynamic stresses.

All these parameters can easily be justified as they all work to enhance durability and reduce the wear on the automotive’s performance.

Impact of Shaft Alignment on Bearing Life

I will highlight a few key technical parameters that can shed more light on proper bearing alignment, subsequently leading to maximized bearing life. As a result of improper alignment, load distribution can be skewed, friction can dramatically increase, and overburdened bearings can be rendered useless in a short period. To ensure optimal alignment, the following parameters must be maintained:

Aerial Misalignment Tolerance – The shaft and the bearing should be placed at an angle of tolerance defined by the manufacturer to avoid excessive stress.

Concentricity—The shaft’s centerline must parallel the bearing bore to balance vibrations and load distribution.

Runout – Any deviations from a bearing’s rotational center must be measured and kept to the bare minimum to prevent overburdening and losing the balance of the bearing.

Surface Finish and Roundness—To overcome the bore’s internal friction, the shaft surface must ensure an unbreakable connection with the bearing attachment, supporting effortless movement and load sharing.

Considering all these parameters and taking a proactive stance on alignment concerns will significantly improve a system’s reliability, allowing it to perform efficiently in many settings while prolonging the bearing’s life. Undoubtedly, the bearing’s condition is paramount, and these parameters will prove indispensable in alleviating the additional stress that can diminish its durability.

Typical Bearings Damages Related to Shaft Issues

I concentrate on a few specific aspects that result in the typical bearing damages that stem from shaft problems. Shaft misalignment is perhaps one of the most frequent ones. It leads to uneven load distribution over the bearing, deterioration, and even premature shaft failure. This is why it is essential to check for shaft alignment.

Another common problem is a deficient shaft surface finish. A finishing process with too much roughness results in excessive friction, whereas too much smoothness prevents the lubricant from sticking. The recommended surface roughness for a shaft, which ranges from 0.2 micrometers to 0.8 micrometers, is one of the contributing factors to wear reduction.

The shaft’s inadequate rigidity also causes excessive deflection under high loads, which is detrimental to the bearing. For stringent requirements, the shaft material must be appropriate for the component’s intended load, such as high-strength steel.

Lastly, improper tolerances of the shaft and bearing seat can result in over- or underfitting, which can cause the components to move and cause fretting corrosion. Adopting an ISO or ABEC standard can prevent specific application problems, though such classification has drawbacks.

By changing these factors beforehand—alignment, surface finish, rigidity, and tolerances—we will make the most out of the bearing and ensure that it will be serviceable much longer.

How to Ensure Long Service Life for Water Pump Bearings?

Regular Maintenance Tips for Water Pump Bearings

To guarantee longevity in water pump bearings, I conduct a few maintenance practices that revolve around some key technical features. This is what I suggest doing:

Adequate Lubrication: Lubricating the bearing reduces friction and overheating, which reduces wear. To ensure proper lubrication, I prefer to use the lubricants specified by the manufacturer and adhere to the specified time intervals.

Avoid Contamination: Certain seals that prevent dirt, water, or other contaminants from ingressing into the bearing must be checked. Failure to do so can lead to significant issues, such as surface damage or pitting.

Alignment Inspections: Higher operational forces and failure to ensure proper alignment during installation can overload certain areas, increasing fatigue. To avoid this, I have made alignment inspections a routine procedure.

Controlling Operating Conditions: Monitoring certain conditions, such as temperature, vibration, and exceeding load limits, can help identify possible issues beforehand. I utilize different monitoring tools to improve tracking during diagnosis.

Scheduled Inspections: Setting a schedule for regular inspections can help identify signs of excessive noise, wear, or corrosion and rectify any faults before they escalate into more severe problems.

Suppose I guarantee that the critical monitoring and maintenance processes are carried out along with the steps. In that case, the water pump bearings would enjoy greater longevity and not experience unexpected failures. With these, I could proactively rectify any faults at the root cause level and improve service levels.

I cannot generate an output without an input to work on. Therefore, I always include relevant information so that assistance can be provided in the correct context.

Identifying Signs of Bearing Wear and Tear

To find wear signs of water pumps, I examine the following criteria: Some pointers must be considered in greater depth to determine the ones that may be present on the water pump.

Unusual noises: Extreme or unfamiliar noise suggests an internal issue, contamination, or misalignment. If I hear grinding or rattling, my initial thought is that pitting and other debris are present within the bearing.

Vibration levels: I enable the detection of exact abnormalities through vibration analysis. As the amplitude increases, the frequency, too, picks up and indicates a lack of balancing or misalignment. For instance, spikes at specific frequencies could suggest localized defects.

Rise in temperature: If the temperature crosses a specific limit, the bearing is at the risk of being damaged and could lose lubrication or withstand too much load or friction. I use temperature sensors to track the trends.

Lubricant condition: The physical condition of the bearing is determined by checking the lubricant for contamination. If metal particles or moisture are present, the lubricant must be changed. A shift in viscosity or appearance ultimately leads to the bearing sustaining too much damage.

Deformation on a physical level: Signs of uncontrollable wear include scouring without the well-known cooling system and corrosion within the bearing surfaces.

By evaluating the conditions, I can gauge the amount of wear placed on the bearings over time and address them swiftly to maintain an efficient functioning system.

Best Practices for Automotive Water Pump Care

In maintaining an automotive water pump, I practice a few activities for its performance and durability. These include:

Maintenance of coolant: I use and change the coolant according to the manufacturer’s service intervals. The coolant prevents corrosion and build-up, maintaining the pump’s efficiency and safeguarding it from internal damage. I also monitor the coolant pH, which is recommended at 7.0 to 8.5. Moreover, I monitor the glycol concentration to guarantee its efficacy.

Leakage inspection: Any signs of leakage from the pump or its seals that contain coolant is a sign of something more severe than just ordinary coolant leakage. I regularly check connections and gaskets for cracks and wear to avoid further complications.

Alignment and tension of the belts: The belt responsible for driving the pump must be severely under adequate alignment and tension. I previously checked if the tension level complies with the vehicle’s specification; excess tension places too much strain on the pump’s bearings and insufficient tension on one’s performance.

Monitor for unexpected noises: If I hear grinding or squealing noises, it suggests an impeller or bearing failure. Should I hear this noise, I monitor it. I would need to replace the pump to ensure the cooling system does not incur additional damage, so not taking action is not an option.

Avoid Pollutants in the Cooling System: Pollutants like rust, debris, and oil can ruin the operational capabilities of the pump. If needed, I go through the system for flushing and look for signs of contamination. Foreign particles could potentially increase wear and damage the components beyond repair.

A combination of these measures, along with tracking the applicable details, guarantees that I accomplish the correct functioning of the water pump and, consequently, protect the rest of the cooling system from damage.

What are the Common Water Pump Bearing Repairs?

Addressing Water Pump Leaks Effectively

To effectively manage the leaks from a water pump, I first focus on finding the root cause and providing remedies in due time. While I conduct the inspection, I look at the following aspects:

Seal Integrity: I ensure the mechanical seal or gasket is good. Fixing or overly tightening one’s put-on seal results in a familiar leak. Seals that are ruptured need to be replaced. This helps to prevent restoring function in mid-air.

Shaft Wear and Bearing Damage: Adjustments done to the shaft, notches on the shaft, or internal parts misalignment can lead to seal rupturing and removal of any form of wear. To ensure that the bearing meets the required tolerances, I confirm that both shaft and bearings work correctly. Run-out free and burst forms alongside differing radial levels on the shaft (less than 0.2 to 0.4 microns) will also stop this.

Coolant Degradation and Pressure within the borehole: Seals can be done using a blend of contaminated seals beyond those with subpar quality. It is critical to test the coolant pH with a sample, always having roughly a balance between 7.5 and 11 depending on the matter and testing the limit of cooling system seal pressure (high side limits ranging from 13 to 16 psi). One’s life expectancy is cowed to the elements, considered harsh by the blast the pump seals, but is praiseworthy when used with the pump set.

Based on the work and studies done in this area and my own CRT experience, I believe that the correct maintenance and servicing can preserve the integrity of water pumps and ensure they function as efficiently as possible.

Steps to Repair Bearing-Related Issues

I have developed a highly systematic and precise method to resolve issues with bearings, which includes the following steps:

Inspection and Diagnosis: I start by breaking down the water pump and scrutinizing the bearings for abrasion, corrosion, or damage. I also listen for irregular noises and check for excessive movement in the bearing housing, as these signs indicate a malfunction. Wear and tear can be checked by measuring the radial and axial play and ensuring they are within the manufacturer’s specifications. Generally, the acceptable clearance values are within 0.002 to 0.005 inches, depending on the pump’s design.

Material and Compatibility Check: I am responsible for sourcing chrome steel (AISI 52100) bearings that can withstand operational loads and wear. The bearings that will replace the older ones must be designed with an outer diameter, bore size, and tolerance class (such as ABEC 1 or higher for standard applications) that precisely match the older ones.

Proper Lubrication and Sealing: When reassembling the water pump parts, the right amount of lubricant must be applied. This is usually a high-temperature grease with operating ranges between -30°F and 300°F. Both excessive and inadequate amounts can lead to pump failure. Before reassembling, I ensure that all seals are intact and can prevent contamination and leakage while functioning with the lubricant.

Alignment and Balancing: The most critical factor is ensuring the bearing is within the optimal alignment in its housing to mitigate excessive strain. A dial indicator measures shaft runout, the ideal measurement being less than 0.001 inches. Vibration caused by either misalignment or imbalance can increase, shortening the bearing’s life.

Testing and Validation: I run a simulated test on the water pump following the repairs. During this stage, I pay attention to noise, vibrations under 0.1 ips, and ISO 10816 temperature ranges to ensure no bearing failure occurs. Any oddity being noticed while these are maintained triggers further investigation before the repair is diagnosed as complete.

Implementing these steps to troubleshoot the issues arising from the bearing while adhering to specified technical tolerances can keep the water pump functional and reliable. This technique improves equipment longevity and minimizes operational delays.

When to Opt for Aftermarket Repairs

My evaluation of whether to take aftermarket repairs is based on the equipment’s condition, performance requirements, and cost-effectiveness. My first consideration is the unavailability, excessive lead time, or unreasonable pricing of OEM parts. In cases like these, aftermarket components can serve as a functional substitute at a competitive price while still performing adequately.

From a technical standpoint, aftermarket parts must adhere to various specific dimensions and specifications to be deemed reliable. Replacement bearings, for example, must comply with ISO requirements. An ISO 281 fatigue life determination would be necessary. Additionally, vibration levels during operation must be limited to under 0.1 ips, which is consistent with ISO 10816 guidelines. Furthermore, the parts’ material, dimensions, and tolerances must closely match the original specifications; otherwise, compatibility and efficiency concerns will arise.

My determination to take aftermarket repairs over OEM is based on whether all of these technical specifications can be met and whether the testing confirms their adequateness, all while maintaining cost-effectiveness. Making this decision allows the equipment to function effectively without the risk of reducing performance or durability.

Why is Choosing the Right Supplier for Water Pump Bearings Crucial?

Evaluating Supplier Reliability and Quality

In determining supplier reliability and quality, several factors are considered regarding the water pump bearings. What I focus on first is whether the suppliers follow the furnished technical parameters. These parameters include ISO 281 for the fatigue life calculation and vibration levels compliance with ISO 10816 to ensure that vibration levels remain below 0.1 IPS during the operational phase. The constituents and the dimensions and tolerances reiterate the original specifications, which means there are no compatibility or performance issues.

Moreover, I assess the supplier for overall reliability and consistency. This also entails looking at their quality control systems, certifications issued for processes or products, and customer testimonials. Suppliers are expected to maintain a record of no defect products which meet or surpass certain criterion within the industry, Moreover, I take into consideration their capability of meeting deadlines and provision of needed technical support as these factors greatly impact the efficiency of projects. In undertaking this examination, I ensure that suppliers can provide defect-free, high-quality bearings that bear all operational and technical features of the set requirements.

Comparing Bearing Specifications Across Brands

When contrasting specifications from various brands, my approach focuses on a few critical key parameters. First, I check load ratings, including dynamic and static capacities, because they determine the bearing’s volumetric efficiency. Higher values usually mean more endurance, so I try to pick options that at least satisfy the application-loaded requirements.

Moving forward, I will study the speed ratings, which include permissible and limiting speeds. This is to confirm that the selected bearing can work at operational speed without overheating or suffering damage. Also, I check the materials and heat treatment to compare overall wear resistance, hardness, and bearing life.

Another essential component is the tolerance class (i.e., ABEC/ ISO grades) and the precision of the bearing. For the more sensitive cases of the latter, like machinery or robotics, I try to find tighter tolerances to reduce the amount of vibration and misalignment. In addition, I check what kinds of lubricants (oil or grease) can be used in the bearing and the sealing method to prevent contact with dirt in the working environment.

With the help of a thorough justification for each choice based on operational needs, I can construct the breakdown for the comparison parameters. I can then pick the optimal bearings about performance, reliability, and lifespan.

Ensuring Optimal Bearings Provide for Automotive Needs

To eliminate all risks associated with the most optimal bearings in automotive cases, I pay attention to a few critical parameters that comply with the operational requirements:

Load Capacity—I confirm that the bearing can efficiently manage radial and axial loads. Wheel bearings must sustain a great deal of load to resist the continuous efforts of vehicle weight and acceleration.

Speed Rating—Load bearings are chosen to work effectively at the anticipated rotary speeds of the component, such as in engine parts or transmission systems, without overheating or high wear rates.

Material Quality and Heat Treatment—Heat treatment of the surface of steel or ceramic composites achieves increased resistance to wear, higher hardness, and more excellent durability, especially for high-performance engines.

Tolerance Class (ABEC/ISO) – For steering systems and some precise gearbox functions, I select bearings with tailored tolerances that will reduce vibration and smoothen automotive operations.

Lubrication Compatibility—I check whether the bearing supports oil or grease lubricants depending on the vehicle’s ambient conditions and maintenance periods.

Sealing Mechanisms—Effective seals prevent dust, ash, chips, and moisture from contaminating automotive components, common in automotive working conditions.

By systematically evaluating these parameters against automotive criteria, I ensure that the selected bearings will be reliable, efficient, and durable.

Frequently Asked Questions (FAQs)

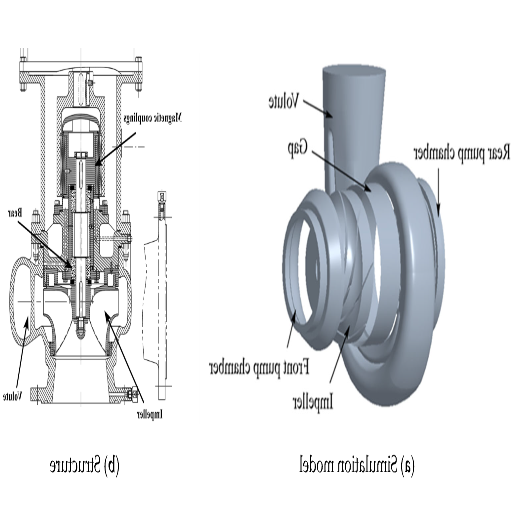

Q: What is the water pump structure, and why is it essential for long-lasting performance?

A: The longevity of a car’s water pump depends on its structure. For example, the impeller, seal, and bearing work together to circulate the coolant and maintain optimal engine temperature. The smooth functioning of these components is vital for an efficient engine. A well-structured system also prevents overheating, increasing the water pump’s longevity.

Q: How do water pump bearings affect the performance of a water pump in a car?

A: These bearings support the pump’s shaft and impeller, ensuring that both rotate efficiently without overheating or too much friction. This is usually achieved via two rolling element rows made of balls or durable rollers, automatically increasing the durability rate and improving the engine’s performance.

Q: What function does grease serve in water pump bearings?

A: Grease lubricates the rolling elements in the water pump bearings, reducing friction and wear risk. When water pump components are correctly lubricated, the bearing is cooled while reducing vibration; thus, prolonging the pump is guaranteed.

Q: Why is the seal a notable component in water pump bearings?

A: The seal in water pump bearings prevents the flow of coolant and dirt particles into the bearings, which can cause rust. A bearing seal failure can compromise the system’s performance and life.

Q: How important are the outer and inner rings for water pump bearings?

A: Like other bearings, water pump bearings must have outer and inner rings. These separate outer and inner rings serve as raceways and enclose the bearing’s rolling body. They also contain the balls or rollers and keep the water pump and engine cooling system operationally accurate.

Q: Concerning the water pump, what distinctions do cylindrical roller bearings have when compared to ball bearings?

A: Roller cylindrical and ball bearings have the same purpose: to ensure support on the shaft and minimization of friction. On the other hand, roller cylindrical bearings are used where greater radial loads are required because they have a larger contact area and much heavier duty compared to ball bearings, which are lighter-duty and more versatile.

Q: What factors require scrutiny when selecting a new water pump for aftermarket car parts?

A: When deciding on the replacement water pump, their primary concerns must be its compatibility with the car’s drivetrain and powertrain, the quality of its bearings and seals, and the pump’s efficiency in managing the engine’s temperature. Moreover, check that the pump is verified for durability and performance.

Q: In what ways does vibration impact the water pump?

A: Vibration makes a water pump susceptible to premature failure by increasing the rate of tear and wear on all components, precisely its bearings and seal. Too much vibration can lead to bearing looseness, leading to structural failure of the water pump on top of overheating the engine.

Q: What actions can be taken to prevent and detect water pump failure?

A: In terms of preventing and detecting water pump failure, lack of maintenance isn’t one of them. Investigate the unit for leaks, uncharacteristic sounds, or excessive shaking. When necessary, top up the coolant level, and check the belt temperature that drives the pump to ensure he is in a healthy state of tension.

Q: How do the rolling elements in water pump bearings improve performance?

A: Rolling elements, which include balls or rollers in the water pump bearings, make the distribution of loads more uniform, reducing friction and improving the water pump’s effectiveness while increasing its durability. They help the engine effortlessly function by minimizing opposition and damage, which is essential for the optimal engine output.