Choosing the correct pump bearing manufacturer is arguably one of the most critical prongs that impact industrial equipment’s degree of performance, reliability, and lifespan. You likely feel bombarded by the enormous number of manufacturers as understanding their capabilities and determining which fits your requirements is a meticulous task. This guide aims to simplify the process by providing a detailed outline of primary quality criteria such as quality standards, material choice, technological level, customer care, and cost efficacy. From sourcing bearings for heavy duty and equipment to precision machinery, this article strives to arm you with adequate information to successfully select suitable manufacturers and forge relationships that meet your expectations.

What factors should I consider when choosing a pump-bearing company?

How important is the manufacturer’s reputation in the bearing industry?

A manufacturer’s reputation significantly matters in the bearing field since it indicates dependability, skills, and quality of work. A reputable manufacturer will tend to meet high-quality expectations and provide bearings that possess specific technical conditions such as load, tolerance, and material strength. Some of the crucial factors of technology that need to be addressed are as follows:

Dynamic Load Rating (C): The highest load value that a bearing may carry and remain functioning.

Static Load Rating (C₀): The highest static load value that a bearing may carry without deformation.

Material Quality: The use of top-grade chrome steel or stainless steel as the construction material guarantees sufficient durability and resistance to wear under extreme conditions.

Precision Class (e.g., ABEC/ISO): The system used to classify particular bearings based on their dimensional and rotational accuracy, which is crucial to precision machinery.

Lifespan (L10 Life): The anticipated working life at a particular load and rotational speed requirements that the bearing should be able to meet.

Considered together, it aids in making appropriate decisions that minimize the cost incurred as a result of bearing malfunction failures in trying to achieve company reputation maintenance.

What role does product quality play in selecting a bearing supplier?

Selecting a supplier of bearings should be done critically, with the utmost concern placed on product quality. This is because it plays a significant role in determining different machines’ durability, effectiveness, and reliability. Bearings of higher grade significantly lower the number of breakdowns that occur unexpectedly. This not only guarantees that there is smooth functioning but also helps in reducing maintenance costs. Low maintenance costs can also be achieved with high-quality products by eliminating ineffective operations. The quality of the product can be determined using the following technical features:

Material Composition: Stainless steel or ceramics are ideal components for use since they ensure lower obsolescence and enhanced durability of the product.

Load Ratings (Dynamic and Static): It is essential to confirm the proper load ratings on the bearing, which must withstand operational forces without deformation or fatigue.

Tolerances (ABEC/ISO Standards): A tolerance set on the precision grade indicates a bearing’s capability to retain accuracy in terms of rotational and dimensional performance.

Lubrication Capabilities: Well-built systems of lubrication improve performance and help reduce friction while enhancing durability.

Noise and Vibration Levels: The reduction of life span and the level of noise produced together with the submersion vibration of the bearings is considered in manufacturing such noise and vibration products, as it greatly affects precision applications.

The ideal procedure for selecting a supplier is one that possesses strong control over quality and allocation through the use of strong predefined performance criteria. This guarantees the procurement of reliable bearings, which is essential due to the sophisticated specifications set forth for modern automatic machinery.

How does a company’s range of bearing types influence your decision?

The variety of bearing types in stock determines a firm’s precision and accuracy while making choices, as it guarantees that all available types can function in various industries and fulfill all business needs. A vendor manifesting a broad selection reduces the vendor’s need to use multiple suppliers, which increases operational efficiency within the company. The focus should be on some key technical parameters such as:

Load Capacity: It is important to select the correct bearing for the normal and axial loads that will be placed on these parts. For example, high-load-capacity bearings are crucial for lifting machinery.

Speed Rating: It is necessary to ascertain whether the bearing may be rotated at the required speed for a length of time without overheating or being excessively worn out. In some cases, such as in high-rotation applications, precision-grade bearings are needed.

Material Composition: Durability and performance depend on the composition of the materials used for construction, such as stainless steel and ceramic, which are harsh environment-resistant materials with high extremes of temperatures and corrosion.

Seal Design and Lubrication: Sophisticated sealing and lubrication can improve longevity and maintenance-free operations.

Dimensional Tolerances: Standardized tolerance classes, such as ISO and ABEC ratings, help provide dimensional accuracy for tighter assembly precision and reliability.

Effective application-specific solutions to the problem are owing to the scientific and detailed analysis of a group of technical specifications that bases the design on a broad and diverse type of bearing. This enhances the performance of the system as a whole.

Which are the top pump-bearing manufacturers in the market?

What makes SKF a leading choice for pump bearings?

Because of its strategic focus on technology and engineering, SKF pumps stand out for their commitment to innovation and exceptional service. SKF bearings are built to ensure remarkable reliability, efficiency, and durability, even in the most challenging operational environments. Some of the most notable technical parameters and features include the following:

Robust Material Quality: SKF bearings are highly resistant to wear, corrosion, and fatigue owing to proprietary heat treatments and the use of high-grade steel.

Enhanced Load Capacity: Optimized internal geometries allow for the optimal distribution of both radial and axial loads, thus enhancing overall load capacity.

Precision Manufacturing: Following strict dimensional tolerances, e.g. classes ISO P5 or P6, SKF guarantees excellent performance in the most critical applications.

Energy Efficiency: Designs developed with low friction features contribute to the smooth operation of devices while minimizing energy loss.

Sealing Solutions: Low-friction seals and other advanced sealing technologies are integrated into SKF bearings to reduce contamination and wear while increasing protection.

Temperature Range: -40°F to 300°F is the temperature range in which SKF bearings are known to operate under different environments.

Because of its tailored solutions, wide-ranging technical support, and trusted product portfolio, SKF has solidified its reputation as a reliable choice for pump systems used in oil and gas, water management, and chemical processing industries.

How does Timken compare to other bearing manufacturers?

Compared to other bearing manufacturers, Timken is well-known for its emphasis on durability, performance, and innovation in more specialized areas of design. As other bearing manufacturers may not share this feature with Timken, Timken bearings, for example, are highly regarded for their precise engineering, ensuring an exceptionally high load-carrying capacity and an unmatched ability for wear and tear resistance, making them highly reliable in demanding environments. For instance, the Timken tapered roller bearings are well-known for their capability to work with both radial and axial loads simultaneously and consistently perform well under extreme stress.

From a technical perspective, Timken bearings often lead the industry in load ratings, temperature, and material tolerance. Moreover, Timken uses high-alloy steels for slope-protected purposes, significantly increasing the service life of a bearing while increasing performance in harsh conditions. Typically, their bearings can conveniently work under a vast range of temperatures, e.g., between -65 to 350 degrees Fahrenheit, making them highly acceptable to extreme environments. Furthermore, Timken is well-known for its industry-leading innovations in wear-resistant coatings or other precision-based engineering designs, which decrease friction or energy loss.

All in all, with regard to application-specific solutions alongside a robust product portfolio matched with strong technical support, it is no wonder that Timken has become a leading competitor against the well-known companies SKF and NSK in terms of reliability, efficiency, and longevity.

Are there other notable players in the pump-bearing industry?

Other key actors within the pump-bearing sector enjoy recognition. SKF and NSK, for instance, are well known for their innovative engineering and wide-ranging product portfolios for different sectors. SKF sells highly advanced bearings with features including improved seal technology and enhanced materials that can withstand high loads and extreme temperatures. NSK is equally well known for its advanced bearings, high speed, low friction, and long life due to integrated proprietary materials and lubrication systems.

When comparing bearings, SKF is noted for its outstanding load-carrying capacity and heat management, courtesy of distinct sealing technologies such as the LS or RS series. Conversely, NSK excels with precision parts and advanced internal structures designed to reduce operational vibration and improve energy efficiency. Both companies, however, provide industry-endorsed certifications and rigorous compatibility testing of the equipment and environments they are used within, thus serving as strong candidates for pump-bearing solutions.

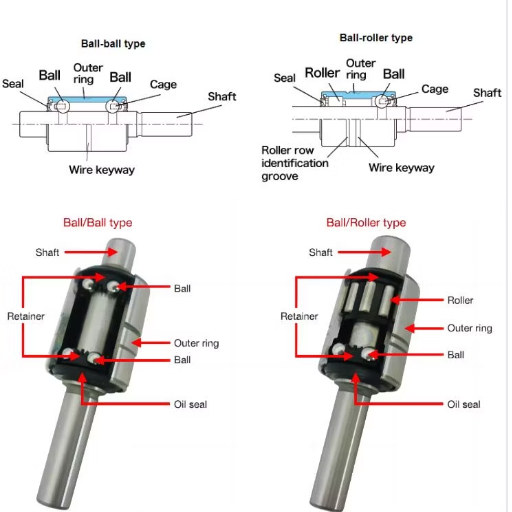

What types of bearings are commonly used in pumps?

How do ball bearings perform in pump applications?

In virtue of the radial and axial load capabilities of ball bearings, they work exceptionally well in pumps. Their versatility is invaluable in some pumps that operate at high speeds. The following justification performs justify their parameter efficiency:

Load Handling Capability: Ball bearings can support radial loads (perpendicular to the shaft) and axial loads (parallel to the shaft), making them suitable for a range of mixed-load conditions encountered in pumps.

Speed Ratings: Ball bearings greatly increase the efficiency of pumps with high operating speeds because their design poses little resistance to high rotational speeds.

Low Friction Coefficients: Ball bearings support energy-efficient operations. Energy loss is highly reduced, with a typical range of 0.001 to 0.002.

Service Life: Properly lubricated ball bearings could provide pumps with extraordinary longevity, which is suitable for equipment reliability and maintenance.

Versatility: Pump systems are perfectly catered for with the single-row, double-row, or angular contact designed for ball bearings.

In conclusion, ball bearings are the optimal choice for most pumps due to their reliability and versatility, which are needed in high-performance applications.

What are the advantages of roller bearings in pumps?

The roller bearings in pumps provide several advantages that enhance their effectiveness and dependability. Firstly, pumps are highly efficient because of the roller bearing design, as they boast excellent load shocks. For instance, cylindrical roller bearings are best designed to support high reindeer scope, while angular roller bearings can simultaneously deal with both radial and axial forces. The lower frictional resistance also improves energy conservation, unlocking operational speeds of over 5,000 RMP in some designs, depending on the bearing configuration and lubrication.

The bearings’ maintenance requirement is minimal, making them more appealing than traditional lubricated designs. Fewer maintenance dead times are further ensured when these roller bearings are used with high-quality synthetic oils with an achieved viscosity index of around ISO 32-68. Moreover, roller bearings are flexible and manufactured in spherical, tapered, or needle roller designs to satisfy the particular requirements of different types of pumps. Those properties make any type of roller bearings a great design To piece together any guides intended for ease of pump operation alongside precision and service life.

When are angular contact ball bearings preferred for pumps?

Angular contact ball bearings are ideal for pumps that need to support combined radial and axial loads at high speeds. Their angular contact provides increased alignment and rigidity. I would primarily suggest these applications with dominant axial load-bearing requirements, for example, in single-stage or multi-stage centrifugal pumps.

Contact Angle (typically 15°, 25°, or 40°): The larger the angle, the greater the bearing’s capacity to carry axial loads.

Speed Rating: These bearings allow for high rotor speeds and are helpful for powerful equipment.

Material and Cage Design (steel, brass, or polyamide): The selection is based on the particular pump conditions and lubrication quality.

Preloading Requirements: The right preloading guarantees perfect rigidity, low vibration, and increased pump control accuracy.

Combining all the above-mentioned aspects allows angular contact ball bearings to perform very effectively in intricate and challenging pump systems.

How do I determine the correct bearing specifications for my pump?

What is the significance of outside diameter in pump bearing selection?

The outer diameter of the bearing is crucial because it dictates its compatibility with the pump housing and the design of the entire system. The outer diameter of the bearing determines whether the bearing fits and whether the system functions stably and effectively. The technical parameters that I analyze while purchasing a bearing are as follows:

Pump Housing Dimensions: The first consideration in this parameter is that the outer diameter must be equal to or greater than the pump housing dimensions so that it can fit and does not require alterations.

Load Tolerance and Distribution: The second parameter is that the outer diameter should be such that it can distribute the load efficiently in high-capacity systems, effectively increasing durability.

System Constraints: This dimension controls the compatibility of a seal or a spacer when assembled with other components, thus delineating integration restrictions.

One can meet operational and design requirements by thoroughly analyzing the factors mentioned earlier, guaranteeing the system’s optimal efficiency and increased lifespan.

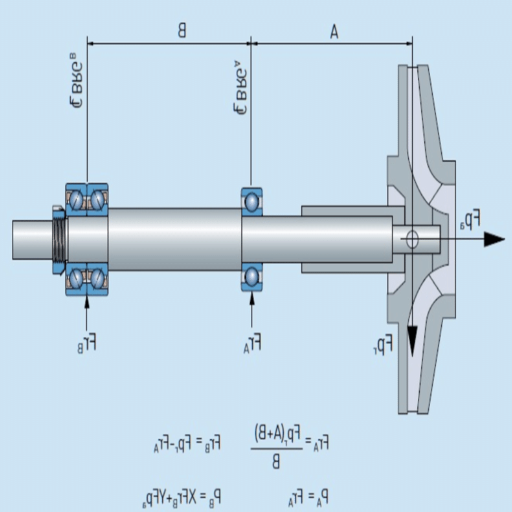

How do radial and axial loads affect bearing choice?

Radial and axial loads greatly influence the selection of a specific bearing for more advanced applications. A bearing is manufactured for optimal combinations of these forces, and any imbalance between what a bearing is ‘capable’ of and what loads are actually applied will invariably result in wear and tear or even catastrophic failure.

Radial Loads: Roller and deep groove ball bearings are appropriate for radial loads perpendicular to the shaft. The axial load capacity is often specified with the bearing’s radial dynamic load rating (C) to ensure it does not deform under operational forces.

Axial Loads: Like screw bearings, tapered roller bearings, and angular contact ball bearings are designed to carry parallel loads acting on the shaft. The axial load capacity is determined by the static rating (C₀) and time dependency of the forces applied.

Combined Loads: Angular contact ball bearings and spherical roller bearings are most appropriate for designs of combined loads, that is, radial and axial components. The angle at which the load has to be taken alters the ability and parameters of the structure to bear the applied force, which has the effect of changing the contact angle (α).

Bearing selection according to the directions and magnitudes of loads while observing technical parameters like load ratings and contact angles will improve the system’s performance and reliability.

Why is precision necessary in pump bearings?

In the performance of pumps, their service life, and the prevention of system breakdowns, the precision attribute of pump bearings is paramount. High-precision pump bearings assist in the reduction of friction and energy losses, which directly aid in the efficiency of the pump’s operations. The following technical details highlight the precision attributes that require attention:

Dimensional Tolerance: This permits the subassembly alignment of the bearing to the shaft and housing, which mitigates the possibility of encountering uncontrolled wear and imbalance.

Runout: Maintains uniformity of linear and angular position of the rotors and assumes low values of radial and axial runout. This translates to accurate rotation, regardless of high speed.

Load Distribution: A provision made in considering the angle of contact (α) results in precision using load ratings (C and C₀), which distribute forces evenly and hence lower the stress concentration and wear.

Lubrication Efficiency: High clarity guarantees better control over internal shims, aiding upward gearing of lubrication and downplaying overheated sections. This results in enhanced lubrication flow, which mitigates heat generation.

All these parameters help to achieve increased stability, reliability, and efficiency of pump bearings in industrial setups, which are certainly parameter-sensitive.

How can I ensure proper maintenance of pump bearings?

What are the best practices for pump-bearing lubrication?

To appropriately lubricate the pump bearing, the lubricant selection is guided by the operating conditions, which include temperature, speed, and load. The adequate selection of lubricants also helps to lower the friction and wear that directly affects viscosity and bears to Euler’s oil film lubrication. Regularly monitoring and adjusting the lubricant level also mitigates the risks of over-lubrication and under-lubrication. Excessive lubrication above the ideal quantity can elevate the heat generated beyond the compensating levels, thereby inducing negative consequences of radial and axial runout. In contrast, extreme lubrication leads to increased friction and wear.

The best practices for relubrication require compliance with the manufacturer’s instructions while also ensuring a clean environment, free from contamination that would impede the effective flow of lubricants and disperse the load. Ultimately, ensuring high bearing operational reliability is possible through the combination of modern automated lubricators or condition monitoring systems along with bearing high-set technical parameters.

When should I consider bearing repair or replacement?

The criteria defining operational steps and when to consider repairing or replacing both bearings are marked by signs such as abnormal temperature rise, noise, and vibration. Some key indicators include unusual noise, excessive vibration, or relatively elevated temperature. These signs are clear at an advanced state of wear or, in reality, more serious damage than expected. Also, suppose cracks, spalls, or any deformities are visible on the bearing surfaces. In that case, action must be taken swiftly to prevent overt damage to the equipment and cuts in productivity.

Operating temperature: Once the bearings exceed 200 f (93c), they often feel the loss of lubrication or too much friction.

Vibration levels: An increase in vibration amplitude, typically anything above 12 mm/s RMS, can indicate problems with the bearings.

Clearance or alignment deviation: The axial and radial run-out outside the tolerances set by the manufacturers is a necessary outcome, more so to promote even disbursement of the load and facilitate exceeding performance.

Lubrication condition: Once the lubricant shows any of the attributes of contamination or Amphiprotic nature (i.e., low viscosity and dirt), both the performance and the condition of the bearings deteriorate.

When restoring bearings, take the forward steps of doing inspections, following the guides set by the manufacturers for replacement and safer, more cost-effective solutions while ensuring safety and reliability.

How can I extend the lifespan of my pump bearings?

Prolonging the life of pump bearings is best achieved through regular maintenance, appropriate procedures, and integrity to some operative specifications. Consider these specific points:

Use appropriate lubricant: Always use the designated lubricant and tabletop the correct amount. During oil use, supervise for alterations in contamination levels or gradual drops in viscosity levels (typically, ISO VG 32 to 68 for average pump bearings). Replace the lubricant once deterioration or debris is detected.

Regulate the working conditions: Do not allow bearing temperatures to exceed 200°F (93°C) by ensuring overloading does not occur and sufficient cooling processes are in place. Regular checks ensure that unloaded bearings are balanced to escape friction and heat.

Regulate vibration levels: Ensure that increasing vibration does not exceed 10–12 mm/s RMS. Such anomalies can indicate misalignment, which needs immediate action.

Self-alignment and radial clearance: Check radial and axial clearances, as compliance with the recommended values is vital for even stress distribution. Remember that misalignment can drastically lower the bearing’s life expectancy.

Routine monitoring: Obvious wear, such as spalling or deformities, should be handled accordingly. Catching such minor issues can be beneficial as they can stem from more expensive repairs.

Following these methods and adhering to the manufacturer’s requirements greatly increases the pump’s bearing life while raising efficiency and performance.

Complete the task directly as instructed. Avoid rephrasing or altering instructions in any manner. Maintain adherence to these guidelines at all times. Avoid mentioning the phrase ‘directly copied’ as it accords to the set formats. The provided text will be rewritten as per the suggested guidelines. The text provided is to be used verbatim.

Frequently Asked Questions (FAQs)

Q: What software solutions brand to go with for a water pump-bearing company?

A: When choosing a water pump bearing company, consider the reputation of the specific brand and the scope of its experience in bearing manufacturing, product quality, offered range (mainly if it provides precision bearings), customer care, and prices. Finding a good brand with experience supplying bearings for centrifugal pumps and other water pump types is a good idea.

Q: How relevant are the years of operation for a brand in the bear market?

A: When choosing a supplier for a pump bearing, a company’s history, in particular, is essential. For example, established bearings manufacturing and service providers like SKF, established in 1907, have a history. They have been in the business for a long time, which makes them one of the industry leaders. Industries, including water pumps, have reliable products that aid in diverse applications using advanced bearing technologies, an understanding of the domain, and a broad presence in the industry.

Q: Does the make of a water pump affect the type of bearings it uses?

A: Various types of water pumps use various types of bearings, such as deep groove ball bearings, cylindrical roller bearings, and spherical roller bearings. Some pumps also use thrust bearings or tapered roller bearings. The specific type depends on the pump design and application. Well-known bearing manufacturers should ensure that their products meet different configurations of water pumps.

Q: Are precision bearings necessary for water pump applications?

A: Precision bearings are often crucial for water pump use, particularly for industry or higher-end pumps. They can increase accuracy, reduce vibration, and increase efficiency, which propels the pump’s performance and extends machine life. Potential bearing companies must possess outstanding and exacting precision bearings meant for use in water pumps.

Q: How does a bearing company’s global presence affect its products and services?

A: As in the case of the SKF Group, which operates in Europe and North America, a bearing company with global operations, like the SKF Group, often has an international edge with respect to research and development, customer service, and many other features. These firms usually have the latest bearing technologies, allowing them to offer and maintain the desired level of service and quality around the globe. This helps foreign and multi-national companies operate more seamlessly.

Q: What role does bearing steel quality play in pump performance?

A: Steel bearing quality is vital for a pump’s overall performance and service life. Quality-bearing steel ensures good resistance to wear, improved load-bearing capabilities, and a greater lifetime. Ask prospective pump bearing manufacturers about their bearing steel quality and processes. Well-known companies use advanced bearing materials, and the company’s reputation rests on the bearing’s performance under severe pump conditions. These companies have treated and enhanced their products.

Q: How would I know that a bearing company is involved in water pump applications?

A: Search for bearing manufacturers with pumps in their product range and check if they have supporting technical literature. Determine if they specialize in bearings suitable for centrifugal and other types of water pumps. Also, check for in-house developed case studies, application guides, or other technical support relevant to pump bearings. Usual companies will focus on single products, whereas those focusing on pumping applications will try to specialize in the broader product range and provide comprehensive services related to them.

Q: What certifications or standards should I seek in a pump-bearing company?

A: During your selection process for a pump-bearing company, ensure its certifications include ISO 9001, ISO 14001, and other water pump-specific certifications. Furthermore, confirm that the company’s products are at par with or exceed the expected industry standards for power transmission and pump systems bearings. Many reputable companies are active in establishing industry standards and will have their quality control measures.