Bearings in Europe are essential for many machines, from industry machines to transport systems, as they ensure smooth operation and long-term efficiency. However, monitoring the bearing’s performance is equally important to avoid unexpected failures that can lead to substantial cost problems during the downtime. Bearing temperature monitoring systems provide an excellent solution by supplying crucial real-time data, making it possible to identify issues during operation, like overheating or other problems arising from constant friction. This blog will analyze how such systems work, their role in predictive maintenance, and the technological innovations that increase their efficiency. Engineers, maintenance professionals, and anyone interested in modern technology will find useful information to understand how effective temperature monitoring can best improve performance and lower operational risk.

How Does a Temperature Sensor Work in Bearing Systems?

Understanding the Role of a Temperature Sensor

Overall, there isn’t much information regarding how a temperature sensor influences the optimal wear and failure of components in a system and how it intervenes with the working temperature of a bearing system. Still, it could be noted that a bearing system maintains lubrication and cooling, along with high sensitivity to temperature changes, which indicates that the system will try to guard the components against extreme wear and failure.

When the temperature exceeds acceptable limits, it has a direct effect on these technical features:

Efficiency of lubrication: Heat deteriorates the lubricating substances, which causes thickening beyond what is ideal for optimal lubrication.

Clearance of the bearing: This increase in temperature causes some materials to expand, resulting in an increase in clearance and friction, too.

Speed of rotation: A slower speed is easier, but it is not preferred due to strain and overworking.

Expected life: Continuous overheating significantly reduces the life of the bearings and components/parts nearby.

Hence, these factors should be considered when making a decision on how to use temperature sensors to maintain system performance, maintenance cycles, and overall system performance.

Installation and Measurement Techniques

The correct installation and measurement are crucial to achieving optimal functionality of the bearing and its parts under variable thermal influences. A description of the crucial aspects concerning the matter and the relevant technical details follows:

Best Practices for Bearing Installation

Before installation, ensure surfaces are clean and contaminant-free to prevent excessive wear and heat.

Hydraulic presses and induction heaters are suggested for specific bearing types to prevent mechanical damage.

Technical Parameter: Application preconception must be considered in setting preload restrictions (e.g., 0.01 mm—0.02 mm radial preload for precision bearings).

Techniques for Temperature Monitoring

Sensors like thermocouples and RTDs can be placed on or near the bearing surface to read temperatures immediately.

Using the appropriate bearing material, operational temperatures must be heated or cooled.

Technical Parameter: The expected temperature range for bearing steel is minus twenty to one hundred twenty degrees Celsius, whereas minus twenty to eighty degrees Celsius is accepted for ceramics, as long as their thermal capability is assumed.

Shaft and Alignment Measurement

Tools such as laser alignment systems and shaft and bearing placement can be used with sufficient accuracy.

The shaft measurement can be performed using micrometers and calipers to confirm tolerances accurately.

Technical Parameter: For bearings and shafts in industrial machines, commonly used fits for tolerance H7/g6 or JS7/h5 shafts.

Lubrication Evaluation

Depending on the operational speeds and temperature variation, the correct grade of the lubricant must be applied.

Routine oil checks are necessary to make sure they are still valid.

Technical Parameter: For Heuristic drives going from a few dozen to a few hundred RPM, the viscosity of the lubricants should be between ISO VG 32 and ISO VG 68, depending on the rotational speed.

With these techniques, precision instruments, and steps, system reliability and performance can be maximized while simultaneously reducing the chance of overheating and wear.

Common Temperature Detector Types Used

The abovementioned temperature detectors include Resistance Temperature Detectors, thermocouples, thermistors, and infrared sensors. All of these types have their designated use and appropriate environment.

RTDs are most useful in a wide range of measurements and exact tasks and offer exceptional accuracy. RTDs typically function within the range of -200 C to 600 C. If used, ensure the system can measure temperature in the specified range.

Thermocouples: These are very useful, with great range and versatility. They can measure between -270 C and 1800 C alone, and they require additional configurations like cold-junction compensation to guarantee accuracy. These are fantastic considerations for fast-acting systems seeking to change their temperature.

Thermistors are best for range-confined environments and offer great sensitivity within their effective but narrow range. Operating close to set temperature thresholds may affect lubricant decisions or system tolerances.

Infrared sensors: These allow measuring temperature without contact, which is very useful in many systems that cannot allow physical contact. When remote accurate temperature detection is important, these also alter some construction parameters.

Clearly defined technical parameters must be in place to ensure optimal performance for each type of temperature detector: system sensitivity, operational range, intended precision, and operational temperature ranges must be compatible.

Why is Bearing Temperature Monitoring Essential?

Preventing Bearing Failure Through Monitoring

I can identify problems beforehand by closely monitoring the temperatures of bearings. Overshooting the heat can lead to problems such as inadequate lubrication, misalignment, and wear that can endanger the entire system’s reliability. Resolving these matters helps improve the system’s uptime and prolong the bearings’ life.

If thresholds are high, this affects the following factors:

Lubrication Effectiveness: High temperatures can damage lubricants, making them less efficient.

Material Strength: Overheating over an extended period may weaken bearing materials, leading to structural failure.

System Resolution Sensitivity: Sensors should be able to resolve sufficiently small changes to make the monitoring and detection precise.

Working Load Restrictions: Increased temperatures may cause the load tolerances to exceed, requiring load interventions or further bearing modifications.

Optimizing system efficiency is essential to achieving operational reliability, and so all these factors should be considered in detail and logically.

Impact of Temperature on Bearing Health

While evaluating temperature effects on the bearing, I would check how high degrees can impact lubrication, material strength, and overall performance. For example, if the operating range temperature surpasses the limits for the given lubricant, friction and overall wear and tear would also increase. Similarly, excessive amounts of heat may result in loss of material strength of the bearing, thus potentially initiating deformation or even failure.

The following technical parameters would be affected:

Lubrication Viscosity: Higher temperatures decrease viscosity, which worsens lubrication quality. This means these conditions require high-temperature lubricants or active constant lubrication.

Material Hardness: Certain Levels of Heat might cause a loss of hardness, which reduces overall load-bearing capacity, lifespan, and fatigue resistance. Material strengthening or the use of heat-resistant alloys might be necessitated.

Thermal Expansion: A chronically high-temperature range leads to dimensional change, which results in misalignment and excessive gaps or clearances. Hence, this warrants re-calibrating or the addition of thermal compensation devices.

Every parameter adjustment would take into account the system’s operational needs and reliability characteristics.

Reducing Machinery Downtime with Monitoring

To answer the questions directly and in the first person, here is my approach to monitoring, which minimizes machinery downtime while balancing the other technical aspects:

Monitoring of Temperature: By observing the operating temperatures in real-time, I can identify signs of overheating. If the operating temperatures go beyond the set limits, they may compromise the integrity of the materials used, the effectiveness of lubrication, and the expansion gaps needed. Moreover, there has been an increase in maintenance monitoring activities, which supports the need for heat-resistant materials or improved cooling systems.

Monitoring of Vibration: I utilize vibration monitoring to pinpoint misalignment, wear, or imbalance in the rotating parts. Abnormal vibrations tend to occur when there is a misalignment or an issue with the fatigue life of the system, at which point recalibration or replacement of components is essential to maintain the system’s stability and efficiency.

Use of Pressure and Flow Sensors: These can efficiently enable me to monitor hydraulic or pneumatic systems. Any alterations in the pressure or flow tend to signal leaks, blockages, or pump inefficiency. Adjustments to the technical values of clearances, the valves’ opening conditions, and the seals’ quality need to be made to prevent the performance deterioration from worsening.

Monitoring of Cycle Times: Monitoring overheads in machinery cycle times provides the capability to detect delays and inefficiencies. The slowdowns noticed could originate from problems of system inertia or inadequacy of power supply, which can then justify further examination of the drive systems and power supply channels.

With the help of modern tracking systems, I confirm many shift adjustments utilizing operational data. This confirms that the changes made met the system’s performance and reliability requirements. This method reduces downtime and increases the machine’s life.

Insights into Bearing Temperature Sensors

Exploring RTD and Thermocouple Options

In the past, using RTD (Resistance Temperature Detectors) or Thermocouple technology was driven mainly by the sensitivity, response time, or even the environmental obstacles that had to be overcome. However, so much more goes into effectively adopting these two technologies. For instance, RTDs work best in areas requiring precision measurement and extraordinary stability for extended periods. The performance of RTDs is optimal in moderate and set temperatures due to its narrow working range, which for RTDs maxes out at 600 degrees celcius. It is important to note that RTDs can be mechanically strained by vibrations, compromising functionality. Additionally, RTDs take longer to respond to than Thermocouples.

There are different types of thermocouples, but all of them demonstrate striking performance in harsher environments. This includes extreme temperatures and severe mechanical strain. Furthermore, Thermocouples function perfectly in cold and hot environments and have a much broader operational working range, which can exceed the temperature of 2300 degrees celcius – the maximum temperature that thermocouples can endure. All of this allows for a much simpler and quicker installation, as there is little concern about the conditions surrounding the device. That said, it is essential to remember that environmental extremes take a toll on the device’s other features. Thermocouples do not give as accurate readings as RTDs and tend to drift.

In the modern world, where every second is critical, time is the one resource that no one can compromise on, which is why choosing the right technology matters. Whether it is the inability to perform in accurate and precise conditions or the need to perform excessive calibration and maintenance, all these factors are essential for the sustainability of the device. The most notable consequences are accuracy, response time, temperature range, durability, and system compatibility. Planning Any thermocouple offers greater freedom while adopting a much harsher environment, but calibration has to be done frequently to ensure reliability. While RTDs are perfect in stable environments, they require care and monitoring towards vibrations and additional obstacles.

Advantages of Miniature Sensors

In my opinion, miniature sensors have critical benefits, especially in cases where space and measurement are very important factors. First, the smaller size enables more straightforward incorporation into systems where space is limited, providing more design freedom while still meeting required functionalities. This impacts parameters such as response time and dynamic range as smaller sensors tend to have less thermal mass, which means they can measure more slowly.

Second, the sensor’s weight lessens the total weight of the overall system, which ensures that mechanical stability is not impacted. This quality is of particular benefit for mobile or precision instruments. Smaller sensors are also more sensitive and accurate because they can be placed closer to the target region. This level of accuracy is so important in situations with detailed thermal gradients or quick temperature changes.

Finally, miniature sensors can also expand the possibility of inclusiveness because of the reduced stress they endure under vibration and mechanical forces, assuming they are correctly installed. However, continuous recalibration and other operational requirements must be met to achieve long-term dependability and extreme temperature range compatibility.

Role of PT100 in Temperature Measurement

The PT100 sensor is key in measuring temperatures because it offers accuracy, stability, and a wide range of measurements. From my point of view, a PT100 device is beneficial due to its accuracy and sturdiness, which makes it ideal for industries that require precise and stable temperature readings over long periods. On the other hand, when exposed to harsh environments or high mechanical impact, the sensor’s overall efficacy is influenced.

To explore the consequences of the corresponding technical parameters:

Accuracy: Under standard conditions, PT100 sensors can typically allow an accuracy range of ±0.1°C. As a result, extreme temperatures for sustained periods require a realignment to ensure accuracy is maintained.

Temperature Range: A PT100 device’s capacity ranges from -200°C to 850°C, so temperature ranges outside will tend to deviate from accuracy as the resistance characteristics will alter, leading to erroneous measurements.

Durability: Mechanical impact might prove damaging, as PT100 can be low to moderate. However, excessive vibration and impacts can inflict considerable mechanical strain, which can damage the sensor and, as a result, delay and compromise its reliability and response time.

Response Time: PT100, under ideal installation circumstances, will give optimal response time settings. However, when inverse conditions prevail, timely readouts can be prolonged, or inaccurate temperature detection can occur.

Having established suitable installation parameters and sustained upkeep while considering certain environmental conditions, PT100 can achieve maximum output while remaining within their regulated technical boundaries.

Overview of Temperature Monitoring Systems in Rotating Equipment

Components of a Comprehensive Monitoring System

An efficient temperature monitoring system with rotating equipment usually has specific components essential for its functionality. These are:

Temperature Sensors: PT100 sensors, for instance, are specialized devices that record temperature levels in real-time. Their installation must be done with utmost care to fulfill certain technical requirements, such as response time or reliability. For example, improper installation could make the detection of temperature anomalies too slow, thus affecting the chances of safeguarding the machinery.

Signal Transmitters: These devices transform the electrical resistance data collected from the sensor into a format that can be utilized. The system’s accuracy depends on the transmitters’ proper calibration. Failure to achieve correct calibration could lead to inaccuracies that are detrimental to monitoring.

Data Acquisition Units: These units aggregate data and temperature points together to track them. Technical issues or delays in data acquisition can affect trend analysis and proper decision-making.

Analysis Software: The software checks the temperature data collected for important patterns, insights, or the need for future interventions. The installed software could have issues, such as failing to recognize a configuration problem, which results in a lack of information being processed.

Power Supply Systems: The monitoring system needs a consistent and reliable power source to operate efficiently. Unstable power sources result in disruptions that can cause the system to miss specific data points, thus making the system less reliable.

If each element is consistently preserved in terms of its specific technical requirements, then the monitoring system’s performance and operation can be achieved, and it can effortlessly function and perform to the requirements of a high-stress environment.

Ensuring Bearing Health in Rotating Equipment

When monitoring the health of bearings in rotating equipment, I focus on several important aspects in a stepwise manner. First, I consider using lubrication since using too little or low-quality lubricant will result in more friction and heat, which will impact metrics such as operating temperature and the amount of friction produced. Monitoring ensures continuous performance.

Secondly, vibration readings are taken and analyzed because monitoring excessive vibration is key to detecting misalignment, imbalance, or general wear. This impacts the bearing load and the effective rotation stability of the bearing, which requires timely intervention to mitigate long-term damage.

Lastly, I look at environmental and operational conditions, including contamination, moisture, or debris that could get to the bearings. This assures operational cleanliness and a contamination-free environment without affecting load-bearing materials. If all these steps are taken together with routine maintenance, they enhance the bearing health and the general operational performance of the equipment.

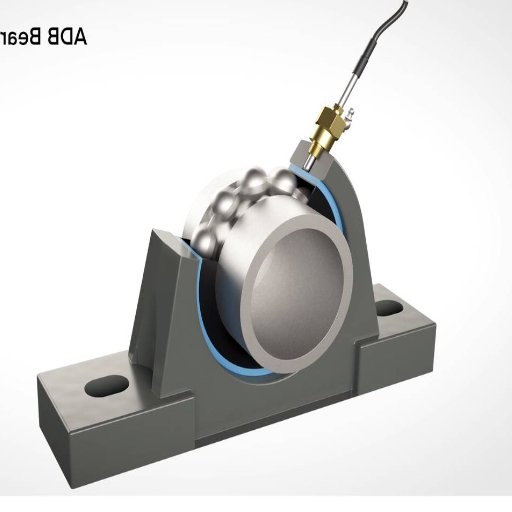

Monitoring System Installation Tips

While setting up a monitoring system, I focus on placing the sensors in positions of the bearing parts that matter most for its functionality. For instance, placing sensors in high friction zones would allow for more precise temperature and operational wear measurements. This information significantly impacts factors such as lubrication effectiveness and material strain. Likewise, I do not install sensors in locations that are likely to experience interference or external sounds that, too, can result in noise in the vibration measurement, which is required to check the load and rotational stability balance.

In the event of improper sensor placement, the accuracy of the advanced multi-function monitoring system’s critical parameters, like bearing life, alignment, and temperature, will likely be outside optimal levels. Therefore, after installation, I conduct calibration checks to determine if the sensor positions are optimal for data collection. As a result, the monitoring system is designed to guarantee efficient and safe operation at all times.

What are the Benefits of Bearing Temperature Detectors?

Enhancing Lubrication Through Accurate Monitoring

Bearing temperature provides the necessary amount of lubrication, so it is important to control it as accurately as possible. With proper temperature readings, I can check whether the lubrication is sufficient or if something needs to be done to maintain high standards and efficient performance. If acceptable temperature values are exceeded, it could suggest poor lubrication, dirt inside bearings, or excessive lubrication, which are detrimental to the system.

Inaccurate monitoring affects technical parameters like lubrication viscosity, bearing surface wear, and friction. Those parameters are critical to the bearing’s performance and system efficiency. With adequate monitoring, I am able to support the limitation of parameters that, without precision, would result in operational setbacks and lessen the reliability of the entire system.

Detecting Misalignment Early

Identifying cases of misalignment not only increases a system’s maximum lifetime but also greatly optimizes its performance. If I identify misalignment early on, I can tend to the problem before it evolves into something worse, such as noise, vibration, or even increased wear on the system. Certain components, such as connected components and bearings, often experience a fair bit of excess stress due to misalignment. This causes a direct and adverse effect on the performance and lifespan of the components.

Some of the key technical cases that are impacted due to misalignment are the following:

Bearing Load Distribution—In efficient bearings, unbalanced loads can cause a great deal of wear and tear, which is known as premature wear.

Vibration Levels—Misalignment causes the primary vibration to increase to a much higher level than normal, resulting in worsened wear and mechanical failure on various system components.

Energy Consumption—Misaligned systems consume more energy, which directly lowers their efficiency.

Surface Wear Patterns- The surface of the bearing has irregular wearing patterns, which is proof of misalignment.

In addition to all the previous statements, if I manage to identify and mitigate any future instances of misalignment, I can sustain the system’s optimal performance, reduce maintenance efforts, and avoid replacing system components.

Improving Efficiency in Pump and Turbine Operations

I focus on specific areas that can be resolved in advance to increase effectiveness in the functions of pumps and turbines. Here’s what I do:

Correct Alignment: I outline the proper positioning of the shafts and other parts so that the bearings will not be unduly loaded, there will be no excessive vibration, energy consumption will not be high, and irregular patterns will not develop on the surfaces of the mechanical components. Proper alignment reduces undue strain on the mechanical systems, enhancing the system’s overall performance.

Vibration Monitoring and Control: By carefully analyzing the levels of vibration, I can tell where disimbalance, misalignment, or other factors exist. Systems under high vibration will lose stability, accelerate wear, and consume energy. These control measures must be taken to remain efficient.

Energy Saving: Effective maintenance procedures correlate with energy savings by increasing system efficiency. For example, systems that are not aligned properly draw on more energy than is necessary and, therefore, need to be corrected. A much more complex energy-saving problem can be solved by directly dealing with operational effectiveness.

Routine Maintenance Scheduling: I perform routine inspections to check for problems like irregular wear or lack of performance. The goal is to rectify smaller problems before they snowball into significant issues that are expensive.

The actions above affect technical parameters: bearing load, vibration, energy usage, and wear of the surface so that the performer of the turbines and the pumps will always be ready to deliver maximum value and efficiency.

Frequently Asked Questions (FAQs)

Q: What are the primary advantages of utilizing pump-bearing temperature monitoring systems?

A: The main advantages an organization can gain include complementing bearing failure diagnostics, mitigating unexpected suspension of work, increasing duration of service, decreasing maintenance expenses, and boosting the overall operational efficiency of pumps. These systems measure and indicate the general condition of bearings, which can reduce the probability of problem occurrence.

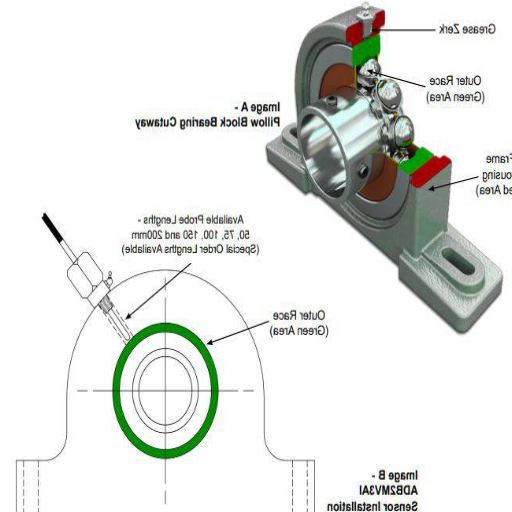

Q: In what way do pump-bearing temperature monitoring systems detect the heat?

A: For temperature measurement, such systems often use RTDs or thermocouples to detect the temperature of a bearing. These units are usually mounted within or adjacent to the protecting case that contains the bearing, so they continuously and precisely record the temperature. Depending on the purpose, the temperature of the insides of the bearing or the surface of the bearing may also be measured.

Q: How important is bearing temperature monitoring for heavy industry machinery?

A: Bearing temperature monitoring is crucial because it is another method for determining the useful life a bearing may have left. Unreasonable heating indicates inadequate lubrication, misalignment, or overload. Failure to pay due attention to the signs will lead to massive failures, expensive repairs, or worse, increased downtime for heavy industry machinery.

Q: Can pump-bearing temperature monitoring systems detect specific issues aside from overheating?

A: Yes, these systems can detect other issues to some extent. As with most equipment, the primary focus is on temperature monitoring. However, unusually high or low readings can signal several problems, such as a breakdown in lubrication, misalignment of the shaft, high vibrations, or even motor overload. Temperature changes encompassing these parameters often occur before destructive symptoms appear, making temperature monitoring an efficient first alert system.

Q: How high or low is the average temperature for these systems to function?

A: The operational range of temperatures of pump bearing monitoring systems is application-dependent and also governed by the type of sensors used for the job. Most systems, however, are capable of monitoring temperatures between -50C and 250C (-58F to 482F). For some extreme applications, where higher temperatures are encountered, specialized sensors are available that can measure even greater temperatures.

Q: What is the general installation process for bearing sensors in pumps?

A: In most cases, bearing sensors are installed through the mounting holes of the pump housing that are closest to the bearing but do not obstruct its movement. In some cases, miniaturized bearing sensors can be placed within the bearing assembly itself. Many factors come into play when deciding on the method of installation, including pump design, the type of sensor, and the specifics of monitoring.

Q: What happens when the bearing temperature exceeds the set threshold?

A: Bearings have preset limits that help prevent them from overheating. Alarms can vary, from visible signals on control panels to hovering sounds. In more advanced types, such systems automatically prevent damage from high temperatures. Such features allow operators to inspect the cause and resolve the matter due to any possible failure of the bearing.

Q: Are these monitoring systems suitable for all types of pumps?

A: Monitoring motorized centrifugal, positive displacement pumps, and numerous other pump types are highly adjustable. Nonetheless, the design and the system’s installation largely depend on the pump type, its size, as well as its operating conditions. Some instruments are made to withstand most demanding environments, such as chemical processing and oil or gas; they are made of sturdy stainless steel for the sensor probes to avoid corrosion.