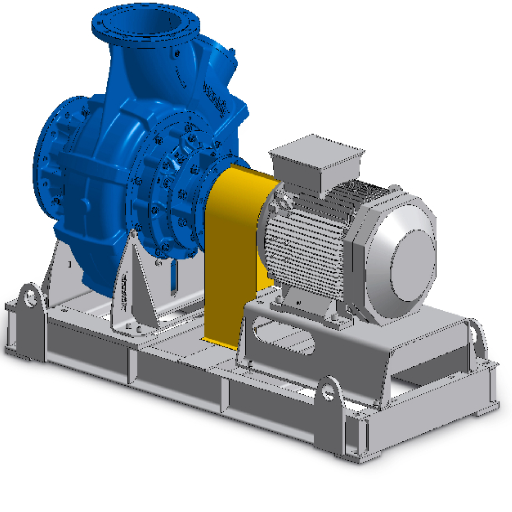

The significance of accurate industrial system processes cannot be achieved without a reliable bearing frame pump. These pumps are vital to various sectors, from chemical manufacturing to water purification. The design features, functional capabilities, and construction quality of a bearing frame pump dictate its serviceability and valuable life. Therefore, it is worth knowing the essential characteristics of high pump quality. In this article, we will break down the most critical elements of a quality frame pump and delve deeper into how these components form the backbone of numerous functions.

What is a Bearing Frame in a Pump?

Components of a Bearing Frame

Based on my knowledge, a typical bearing frame contains the housing, bearings, shaft, seals, and lubrication system. Each has a specific function that helps improve the pump’s effectiveness. The housing serves as a support element that maintains the position of the internal parts and withstanding some stress. Bearings help reduce force and support the rotating shaft, which directly affects the pump’s efficiency in balancing and accommodating axial and radial loads.

The shaft is the system’s central rotating element, and its configuration determines the speed and torque characteristics of the pump. Contamination and leakage regarding the pump also depend on the seal’s ability to do its job, which, when performed poorly, can compromise the pump’s reliability and durability. The lubrication system, on the other hand, serves a different function as it restricts the amount of wear and tear and maintains smooth flowing motion, greatly influencing the overall effectiveness of the pump.

If these components are not functioning optimally, they can significantly impact several technical parameters. For example, low-standard bearings can increase vibration which disturbs balance and stability, in addition, energy consumption will be greater than normal. In another scenario, poor lubrication or sealing can lead to the pump’s excessive wear, and its lifespan will also significantly decrease, forcing more significant maintenance costs. Irrefutably, each component’s design and quality determine the system’s life, effectiveness, and reliability.

Functionality of Bearing Frames in Pumps

The bearing frames in the pumps are essential for the system’s functionality, structural integration, and performance. In my opinion, their primary purpose is to carry the weight of the rotating parts, maintain their position, and minimize the vibrations experienced. If the bearing frame is not constructed correctly, all the crucial technical parameters will likely change drastically. Some of these include:

Vibration Levels: Poor alignment or lack of adequate stiffness causes increased instability of the pump and a reduction in efficacy, which subsequently disturbs the bearing frame.

Wear and Tear: Inadequate stiffness does not support the load balance on the bearings, leading to accelerated wear that subsequently negatively affects the pump’s overall life.

Energy Consumption: Excessive misalignment or oscillation of the pump leads to massive operational inefficiency, which exacerbates the energy needed to power the pump, increasing energy consumption.

Maintenance Requirements: Inaccurate design coupled with weak bearing frame parts could increase the susceptibility of pump breakage, increasing the need for costly replacements and maintenance services.

The impact from these adversities at the end of the day reiterates the necessity of effective bearing frame design, which tackles the challenges of robust and proficient pump functionality over long periods. Adequate design and optimal selections of materials focus on increased effectiveness and pump life.

Materials Used in Bearing Frame Construction

While selecting the materials for the bearing frame construction, I pay particular attention to their strength, corrosion resistance, and endurance, as they have a direct impact on the pump’s performance and service life. Due to their different properties, cast iron, carbon steel, and stainless steel are generally accepted as the materials for manufacturing parts.

Cast Iron is often selected due to its relatively low cost and reasonable machinability. However, it tends to corrode in severely corrosive environments, which can shorten the machinery’s life span and increase maintenance frequency. This will certainly affect the pump’s reliability and MTBF.

Carbon Steel: Powerful and tough; suitable for high-load applications. Its tensile strength is higher than that of cast iron but its corrosion resistance is poorer than that of cast iron. Hence, to avoid material deterioration due to corrosion, it must be protected by coatings or other surface treatments.

Stainless Steel: This material is used in industries where it has to withstand corrosion. It is durable and performs reliably for a long time; thus, it is expensive. In applications dealing with aggressive chemicals or moisture, these materials are warranted because they preserve the structural integrity needed for operational efficiency.

The choice of material affects essential aspects, including the amount of load the pump can withstand, productivity, and maintenance frequency. To attain maximum performance, the material must comply with certain working conditions and the pump’s design.

How Does Bearing Failure Affect Pump Performance?

Common Causes of Bearing Failure

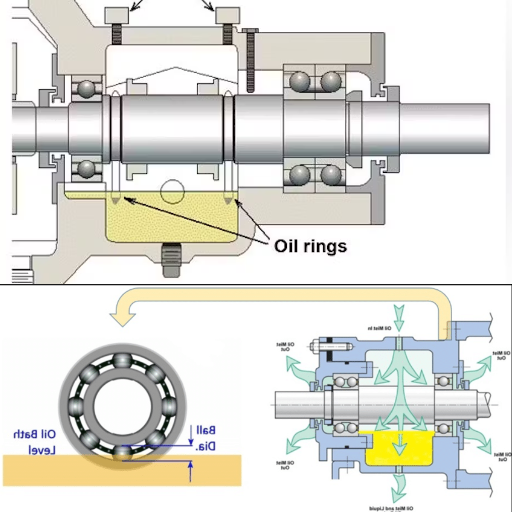

In my observation, the reasons for bearing failure are multifaceted, such as poor lubrication, overloading, usage of undue contamination, and inappropriate lubricant. This practice singularly fractures critical operational parameters, accelerating wear and tear and raising maintenance intervals. It is relevant to add over lubrication is also harmful as pour lubrication is.

Another important reason is the lack of alignment or other parallel changes that cause more strain and stress on the bearing, decreasing load-bearing potential and leading to premature failure. This is prevalent with overstrained conditions due to wrong system design and system not being used as intended. Not only is the load-bearing capacity jeopardized, but the entire integrity of the pump is put at risk.

Finally, ingress contaminants and harsh chemicals harm the bearing and supporting structures. This increases operational inefficiency and frequent maintenance cycles to preserve efficiency. Rationally addressing these problems is paramount to achieving convenience and efficiency within the intended life span of the pump.

Signs and Symptoms of Bearing Failure

In the course of manipulation, I would track the noise level that indicates a problem with the parts of the machine or a problem with the machine itself. In the case of bearings, deviation from the usual noise level is one of the many signs that indicate failure in operations and may be caused by misalignment, wear, or contamination of the bearing, shaft, or housing. Generally, apart from the noise level, vibration level, or movement, which are also measured in g-force or mm/s, serve as indicators to signal reduction in robotic parts’ mechanical stability.

Operating at an increased temperature is equally alarming and can be abnormal when the constitutional machinery is subjected to higher-than-required temperature levels. This further indicates severe heat, which points to malfunction due to poor lubrication or an increased level of friction within the system. All these interconnect to the set operating temperature limits that differ from one machine to another and the type of lubricant oil that is used, although the standard ranges between -20 degrees Celsius and 120 degrees for regular machines of beaters.

Even further examples by which the bearing corrosion, pitting, and other types of surface damage get taken as issues alongside the ingression of water and destructive chemicals to the other side of the bearing. All of these lessen the roughness of the surface and greatly hinder the anticipated load-carrying strength of the entire system due to the fatigue of the material.

While all the abovementioned problems seem unresolvable and put maximum stress on the issued mechanical components, monitoring them keeps me from the significant bearing failures that perform an older pump and prolong his life.

Preventing Bearing Failure in Pumps

Since pump bearing failure can be catastrophic, a carefully planned maintenance program must accompany frequent attention to technical parameter monitoring. Here are some key areas of concern:

Lubricant Application: Proper lubrication benefits bearings by reducing friction and wear. As is common practice, the lubricant type recommended by the manufacturer should be used, and the appropriate viscosity, usually between 10-40 mm²/s at the operating temperature, should be met based on the bearing type and load conditions. Regular inspections must ensure moisture and debris are not introduced into the system.

Shifting Load: Bearings have a service life that may be exceeded if shafts are misaligned or if excessive loads are applied. Shifting loads should be kept within defined tolerances, like lower radial and axial alignment tolerances, with tools such as laser alignment systems. Using specified loads to operate the pumps ensures, to a reasonable extent, that working material does not fatigue.

Temperature Control: With proper monitoring, bearing operational temperatures can be set while avoiding overheating conditions (generally 20 – 50°C), depending on the particular pump system. Temperature sensors should be used to detect overheating, which often indicates lubrication failure or increased friction, provided there is no significant mechanical stress.

Condition Monitoring: Vibration analysis and measurement are essential monitoring and controlling tools. Excessive vibrations, usually measured and represented in velocity with units of mm/s RMS, could indicate misalignment or imbalance of the rotating systems, as well as incipient failure of the bearing and excessive vibrations where well-controlled conditions are from 1-3 mm/s RMS.

Seal Maintenance: Seals guard against dirt, water, or harsh chemical substances infiltrating the bearings. During maintenance intervals, check and replace seals with new ones when required, ensuring an effective barrier is attained. If sealing fluids that can cause corrosion are being used, examine the seal compatibility ratings.

Regular inspection is an ongoing requirement: Set up a calendar for regular inspection and maintenance, in which visually inspecting the bearings for any signs of opening, corroding, or discoloration should be done at a minimum. Diagnostic predictive maintenance, such as infrared thermography or oil analysis, should also be performed to mitigate problems before they materialize.

With these precautions in place and continuous control of the technical parameters, the system can achieve optimal operational performance and greatly minimize the chances of pump bearing deterioration.

What are the Different Types of Pump Bearing Frames?

Characteristics of Horizontal Pump Bearing Frames

Horizontal pump bearing frames are crafted to offer pump shafts dependable alignment support and handle radial and axial loads. These frame types have advanced features that retain stability while working in their set conditions.

Load handling capacity: These frames type vertical and rotational movements with minimalistic friction, with cross-sectionally industrial deploying multidirectional forces.

Alignment and Stability: They provide shafts with perfect alignment when operated on flames, which significantly reduces vibrations and slash shakes.

Lubrication and Cooling: Collier centrifugal pumps provide centralized lubrication and multi-shaft breaks to reduce the risk of overheating.

Ease of Maintenance: Most components of these frames are clad line advanced technologies, so maintenance and examination of all frame types are quick and easy.

These frames work best with horizontal pumps of any caliber, particularly those requiring high precision and integrating machines that last longer.

Advantages of Vertical Pump Bearing Frames

Space-Saving Design: Vertical bearing frames are space-efficient and do not cover a large area of the floor, making them suitable for vertical facilities with smaller footprints. This is really useful in cities or industrial areas with less open space.

Improved Hydraulics: The device’s efficiency is preserved vertically, especially in high-head or low-flow applications. This arrangement is effective in reducing axial loads and controlling the flow patterns.

Better Sealing Systems: Features like streamlined sealing systems are built into various vertical frames to control internal leakage and keep out contaminants, extending the service life of internal parts.

Simplified Mounting: Vertical frames may make aligning the pump and motor easier, which facilitates sealing and quickens the installation process.

Technical Parameters: Some of the common vertical pump bearing frame specifications improve thrust and load balancing, enabling effective management of radial and axial forces with pressure in system elements up to 15 bars or more, depending on designs. These parameters make vertical frames best for indisputable industrial operations.

Choosing Between Horizontal and Vertical Designs

While selecting the optimal horizontal or vertical bearings design for the pump frame, some considerations must be considered for maximum application effectiveness. The primary considerations and their relevant technical parameters are as follows:

Space Limitations:

Vertical Design is best suited for locations with a floor area restriction since it has a lower spatial requirement.

Horizontal Design: More space-consuming but easier to maintain in places that are not easily accessible.

Load Accommodation:

Vertical Design: Designed to include an angular contact ball bearing, which increases overall thrust capacity to critical levels, paramount for systems operating on high pressure or any system that goes beyond 15 bars.

Horizontal Design: Fitted with roller or ball-bearing systems to increase efficiency in handling moderate radial and axial loads in low to medium-pressure systems.

Maintenance Ease:

Vertical Design: Servicing for these can be complex in tight areas due to their design.

Horizontal Design: These are easy to maintain since the repair or replacement of components is not obstructed.

Operational Setting:

Vertical Design: Appropriate for fulfilling robust load balancing requisites in most industrial environments, such as chemical or water treatment plants.

Horizontal Design: Performs well in less demanding industrial or residential systems with stable operating conditions.

These parameters highlight the importance of matching the design to the application’s requirements to ensure reliable operation and desirable efficiency levels.

How to Inspect and Maintain a Bearing Frame?

Routine Inspection Procedures

While conducting regular checks on column support, I make a point of being detailed and organized so that the piece remains valid for a long time. My methodology usually consists of these steps.

Visual Examination: I inspect the frame for cracks, corrosion, or other indications of wear and tear. These factors can undermine the design of both vertical and horizontal geometries, their load-bearing capabilities, and maintenance ease.

Lubrication Check: I ensure all the lubrication points are suitably greased and operational. If lubrication is insufficient, overheating and excessive friction may occur, which is problematic in an industrial vertical system application.

Alignment and Balance: I check to see if the shafts and other elements are aligned. Horizontal configurations with misconstrued alignment usually result in low efficacy, while vertical ones increase the degree of load imbalance.

Fastener Tightness: I check the tightness of the bolts and fasteners that affect the structure stability during operational tractability. Loose fasteners cause vibration while operating under low set conditions, which is particularly detrimental for horizontal designs.

Performance Assessment: I analyze mechanical noise and operational smoothness. Grinding and rattling noises indicate issues with bearings and the frame structure, which is bound to negatively affect the tolerance for vibrations and heat distribution.

Following these steps allows me to operate the bearing frame within its technical parameters, thus enhancing its durability and minimizing unscheduled maintenance. Any fluctuations in productivity relate to lubrication, alignment, or structural defects within the parts of the frame and will tend to diminish the efficiency of the applications, if any.

Maintenance Tips for Longer Bearing Life

Lubrication: Proper lubrication is fundamental to increasing the service life of bearings. I make certain to apply the exact type and recommended amount of lubricant specified by the manufacturer. Insufficient or excessive lubrication can also lead to overheating or, in the worst case, increased friction, which is bound to affect vibration tolerance and thermal distribution.

Alignment: The alignment of the bearing frame is as important as the bearing itself. Proper alignment must be ensured so that uniform load bearing is achieved. Misalignment reduces overall vibration tolerances, which affects structural integrity and impacts performance reliability.

Operating Conditions: I keep checking the sustained load and speed limits because they have a designed tolerance that should not be crossed. If the set parameters are exceeded, the rotating shaft is bound to apply excessive stress on the bearings, and smooth operation will be severely disrupted with an accelerated degradation of dynamic load capacity.

Contamination Control: Dust, dirt, and other forms of contaminants, when allowed to compromise the system, inadvertently damage the bearing surfaces. Contamination always acts after altering lubrication effectiveness and friction levels, resulting in abnormal thermal distribution.

Routine Inspections: I regularly conduct inspections to locate early signs of wear, corrosion, or damage. If these problems are not dealt with proactively, operational smoothness will be hampered, as vibration tolerance will be compromised.

I can confidently say that by following these steps, I am able to extend the bearings’ life while maintaining all core technical parameters.

Tools Required for Bearing Frame Maintenance

My bearing frame maintenance is on point thanks to the tools I am about to describe, which help impact the corresponding technical parameters.

Torque Wrench: This tool guarantees that bolts and fasteners maintain their position undisturbed, thus preventing misalignment and over-tightening. This helps compromise dynamic load capacity while increasing internal stresses.

Precision Measuring Instruments: Calipers, micrometers, and dial indicators are vital for measuring dimensional tolerances and alignment. Measurements help maintain radial and axial clearance, directly affecting vibration control and operational efficiency.

Lubrication Equipment: With high-quality grease guns or automatic lubrication systems, I can apply the terms of the appropriate quantity and type of lubricant. This helps ensure optimal thermal distribution, thus maintaining constant rotational performance.

Cleaning Supplies: Lint-free cloths, brushes, and other solvents help prevent contamination during maintenance. Hygiene ensures lubricant potency and diminishes wear, which supports smoother motion and prolongs the life of the bearing.

Portable Heating Device: Induction heaters or oil baths are some of the most valuable devices. They are essential when mounting or dismounting bearings, helping reduce mechanical force. Proper handling ensures the bearing’s structural integrity and load-handling capabilities remain consistent.

Through the careful and precise use of these tools, I can confidently protect the bearings and essential parameters, like alignment, lubrication, vibration tolerance, and load limits. This, in turn, enables the equipment to function correctly and effectively over long periods.

What is the Role of Lubrication in Bearing Frame Pumps?

Types of Lubricants Used in Pumps

Based on my past experience, the lubricants found in the bearing frame pumps’ sets are mineral oils, synthetic oils, and grease. The specific type for use is picked according to the pump’s conditions, such as temperature, speed, and load.

Mineral Oils are widely used due to their cost-effectiveness and availability. They provide lubrication and friction reduction under standard operational temperatures and conditions. They also help mitigate wear reduction. However, their viscosity may change significantly with temperature, affecting parameters like lubricant film thickness and load-bearing capacity.

Synthetic Oils are preferable in extreme conditions because their performance is well supported in broader temperatures. It is the stable viscosity that does the magic. Lubrication is maintained, and vibration, along with axial alignment, is improved, which enhances overall efficiency and protects the pump from excess stress.

Grease: Most frequently used in lower-speed tasks, grease provides both lubrication and a barrier protecting the inner components from external contaminants. It is well suited to sealing out dirt and moisture. However, excessive grease application will increase the operating temperature, reducing the vibration tolerance.

Adhering to accurate lubricant selection and dosing is of the utmost importance as it affects friction reduction, operating temperature, load-bearing capacity, and the system’s stability against vibrations. Proper selection and upkeep of these lubricants improve the pump’s life and working conditions.

Importance of Proper Lubrication

Lubrication is an important consideration when aiming to achieve optimal performance from any pump system, and I can answer all of the questions posed to me on a practical basis. Adapting a lubricant, be it oil, synthetic oil, or grease, impacts a couple of essential technical aspects ,as outlined below:

Reduction of Friction—The proper lubricant selected lowers friction between the system’s moving parts, thus reducing wear and increasing the pump’s operational efficiency.

Operating Temperature—Insufficient or excessive lubrication can cause undesirable temperature changes. An excess of grease could increase operating temperatures, and insufficient oil could cause overheating coupled with component breakdown.

Load Capacity – The viscosity and the properties of the lubricant in question directly relate to the system’s efficiency under load stress. For example, synthetic oils have the viscosity retention needed to perform well at an origin high load.

Vibration Stability – Lubrication dampens mechanical vibrations, ensuring smooth operations. Poor lubrication, on the other hand, leads to misalignment, which increases vibrations while reducing the accuracy and life of the pump.

Considering these relationships enables me to defend the assertion that proper lubricant maintenance is not only a matter of best practice but also a prerequisite to achieving optimal performance, reliability, and longevity in pump systems.

Effects of Poor Lubrication on Bearing Life

I do not doubt that insufficient lubrication significantly damages a bearing’s lifespan and allows me to elaborate on its consequences and its associated factors. Bearings are subjected to friction and heat when insufficient lubrication causes increased wear and fatigue. Allowance of excessive lubrication, in turn, results in churning, which increases the temperature of the bearing. The extremes in these formulations are bound to impact the bearing’s accuracy and life, hence making it essential that the lubrication is performed correctly.

Temperature Limits: Under and over-lubrication not only modifies temperature but also damages the bearing surfaces, reducing efficiency. A lack of lubrication gives rise to overheating, which causes the deformation of materials or failure.

Load Handling Capability: Improperly lubricated bearings give rise to load discrimination, so evenly distributed loads never reach the bearing as intended. This leads to stress concentration, wear, and more significant imbalances for high load.

Vibration and Noise Levels: Inadequate lubrication dramatically reduces the adjustment of mechanical components. Therefore, everything turns imbalanced, and much more noise is produced, which is an indication of potential failure.

Specific parameters must be suspended to fulfill optimal lubrication for the bearing. These stake a great deal in prolonging the expected lifespan of the bearing.

Frequently Asked Questions (FAQs)

Q: What sets a bearing frame pump apart from an end suction pump?

A: A bearing frame pump is a category of centrifugal pump with a robust bearing frame capable of supporting the shaft and impeller. Furthermore, unlike a standard end suction pump, a bearing frame pump’s construction includes a separate bearing unit that can handle greater radial and axial forces. Therefore, it is appropriate for more demanding applications with heavy workloads and rugged working conditions.

Q: What components must a reliable bearing frame pump contain to ensure effectiveness?

A: The distinguishing features of a dependable bearing frame pump are its robust bearing housing, shaft, seals, impeller, bearings such as ball or roller bearings, and motor. In addition, it is also provided with a coupling and other optional components such as lubrication devices and monitoring systems.

Q: In what ways does the bearing housing contribute to the pump’s reliability?

A: Bearing housing plays a crucial part in reliability because its design provides an appropriate mount for the bearings and shaft. A suitable pump housing will enable the correct position of the turbine, lower vibration, shield the bearings from dirt, and assist with maintenance. Cast iron and stainless steel are highly robust materials, significantly increasing the range of applications for this design.

Q: What types of bearings are popular in bearing frame pumps?

A: Most bearing frame pumps operate with a mix of radial and thrust bearings. Deep groove ball bearings, which are used for radial movements, are one of the most used. There are also angular contact ball bearings, which take care of radial as well as axial movements. Cylindrical roller bearings are for maximum radial forces, while a few designs may also contain self-aligning bearings to suit minor alignment errors.

Q: What fluids and applications are bearing frame pumps compatible with?

A: Bearing frame pumps are multifaceted devices suited for various liquids and applications. The specifications of the pumps, the type of materials used, and the sealing arrangements can be made to fit particular process needs. They find applications in various industries like water treatment, chemical processing, and general manufacturing industries where the reliability and strength of the products are of significant concern.

Q: What are the benefits of bearing frame pumps with back pull-out designs?

A: For service and overhaul activities, a back pull-out design enables greater access to the pump. It allows rotation of the assembly, including the impeller, shaft, and pump bearings, with the casing still attached to the pipes. Therefore, maintenance becomes easier as the pump does not need to be physically removed from any installation, leading to less downtime and ensuring ease of maintenance.

Q: Which techniques ensure that bearing frame pumps are adequately lubricated?

A: To attain optimal lubrication oil supply, it is of utmost importance to take good care of the bearings and the pump’s efficiency. Frame pumps can be classified into grease- or oil-bearing frame pumps. In smaller pumps, grease-lubricated bearings are easily found, but they must be maintained by regular greasing. Larger pumps utilize oil-lubricated systems and include oil rings or other means of forced lubrication to suit higher pump speed requirements.

Q: What methods can be utilized to maximize the reliability of a bearing frame pump?

A: Adopting methods such as ensuring correct installation, establishing schedules for routine maintenance, and executing standard operating procedures can significantly improve a bearing frame pump’s reliability. These methods include monitoring vibration and temperature, the correct alignment and periodic lubrication of rotating components, the customary diagnosis of lubricant viscosity, and timely replacement of orthotropic. Selecting a suitable pump for the job or refraining from operating beyond the set parameters also contributes to achieving enhanced reliability.