Selecting a bearing oil pump is crucial for the performance and longevity of your machinery systems. The proper selection can ensure that the bearing is operating with the least friction, heat, and, accordingly, the minimum wear, increasing the lifespan of your machinery. This article outlines some pitfalls that should be avoided when selecting a bearing oil pump, the bearing oil pumps’ role in optimal lubrication, and the outcomes of making ill-informed decisions. If your work consists of any industrial applications or simply managing precision machinery, knowing bearing oil pumps can make all the difference about reliability and efficiency.

What is a Bearing Oil Pump and Why is it Essential?

Understanding the Purpose of a Bearing Oil Pump

An oil-bearing pump is an essential component in machines that guarantees the bearings receive the right amount of lubrication, thus enhancing productivity and the life span of the machine. Its crucial function is maintaining a constant oil supply to minimize friction, overheating, and the impact of wear and tear on the bearings. Lack of adequate lubrication in a machine translates to a more significant loss of energy, elevated temperature while operating, and increased chances of damage to the machine parts.

Specific considerations need to be made during an assessment of the technical parameters. The oil’s viscosity grade should match the operational speeds and loads; low-viscosity oils tend to be used at higher speeds. The output pressure capacity of the pump determines the oil delivery to all the bearings,’ and it has to be sufficient to deliver the oil above system resistance. Depending on the bearing size and type, the required lubrication amount also influences another significant characteristic: the flow rate, which must be adequate for the lubrication volume. In addition, the resistance to contamination and high temperatures of the pump’s designed environment also matters. These parameters need to be comprehended and justified to guarantee effectiveness during usage.

How Does a Bearing Oil Pump Work?

An oil-bearing pump transports oil from a tank to the bearings via a pressure system, guaranteeing consistent lubrication and cooling. The pump applies a pressure differential that compels the oil to pass through pipes and nozzles directly toward the bearing surfaces. The following key technical parameters justify its operation:

Flow Rate: The pump needs to deliver oil at a flow rate that is balanced with the lubrication requirements, which are estimated based on the type, speed, and size of the bearing. Flow rates usually differ from 3 to 15 liters every minute, depending on the system.

Pressure: The pump needs to maintain an adequate pressure, which is in the overrunning level, usually between 2 and 10 bar. In multi-complex systems, oil is required to be delivered consistently to each bearing, which is assured by sufficient pump pressure.

Temperature Resistance: To function optimally in heated conditions, the pump needs to tolerate operating temperatures of 100-150 degrees Celsius.

Viscosity Range: Depending on the usage, the design range of the pump application should include oil viscosity, which could differ from 20 cSt to 320 cSt.

Material Compatibility: In extreme conditions, like contamination, corrosion, and wear, the secondary materials provided for the pumps should include asbestos—materials free of the described problems.

With the appropriate choice of parameters and fine-tuning, the bearing oil pump will efficiently provide sufficient lubrication in its use area.

The Role of Bearing Oil Pumps in Various Applications

Bearing oil pumps are useful in various applications due to their unique performance optimization and durability prowess. From my understanding, the foremost goal is maintaining lubrication to reduce friction and wear in critical systems, including turbines, compressors, and heavy industrial machines. For instance, in high-speed turbines, a suitable operating oil pump must be set in place and correlate with high pressures and temperatures, which affect oil intake pulse pressure and flow rate.

In my experience, material compatibility and robust filtration systems are paramount in avoiding system clogging and wear within contaminated environments. Pumps require the use of resistant materials, thus making them more expensive but more beneficial to the targeted endeavors. On the other hand, if the oil viscosity changes due to certain operating temperatures or environmental aspects, a dedicated viscosity range oil pump is a must-have ranging from 20 CST to 320 CST. These decisions always stem from measuring the technical parameters, power consumption, viscosity range, and efficiency rating and using the machine without fearing failure over time.

How to Identify a Faulty Oil Pump?

Signs of a Bad Oil Pump and Bearing Failure

Based on my experience, a particular combination of indicators defines an oil pump or bearing defect. There is a direct correlation between these problems and the relevant technical parameters. First, it is very common to notice low oil pressure, which indicates inadequate lubrication due to a faulty pump. As a result, one’s efficiency rating would deteriorate, and power consumption would increase due to heightened mechanical friction.

Another warning indicator stems from abnormal sounds such as whining and grinding. These can lead to the identification of a worn-out bearing or a pump with a fair amount of cavitation. Such internal damage fundamentally changes the viscosity range and compromises the pump’s overall capability of fluid handling. Another reason could be elevated operating temperatures due to increased friction from nonfunctional bearings, which leads to excessive loss in system efficiency and overheating.

By carefully tracking some of these indicators along with the technical parameters of oil pressure, operating temperatures, and power used, one can get ahead of system faults and achieve optimal sytem performance and longevity.

Common Causes of Oil Pump Malfunctions

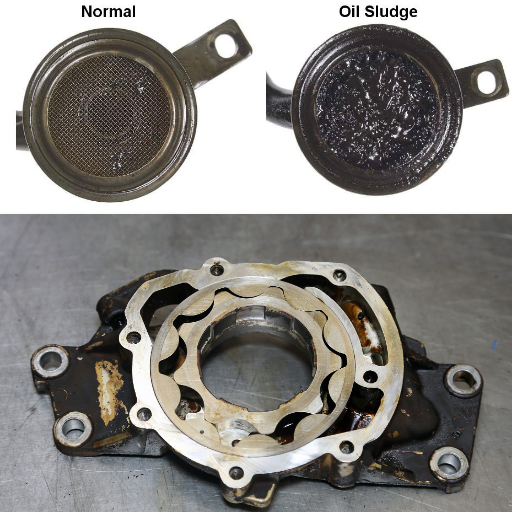

In my personal view, one of the major issues leading to oil pumping malfunctions is oil contamination. When particulate matter, including dirt, dust, and metallic particles, invades the system, it can obstruct or even harm pump mechanisms. This leads to a drop in oil pressure and an increase in friction. These blockages directly impact essential characteristics such as operating temperatures, which are likely to rise because of increased effort on the pumps, and oil pressure, which will most certainly lower.

Another major problem is the overuse of internal parts, including gears and bearings. This automatic deterioration takes place invariably over time. Because of such wear and tear, the pumping mechanisms will gradually become deficient, further aggravating a decrease in oil pressure while increasing power usage as the system struggles to deal with the deficiency.

Finally, any form of air leaks or cavitation bubbles within the machinery system puts much strain on its performance capabilities. When air penetrates the stream of oil, the flow is interrupted, which results in poor lubrication. Such a system typically suffers from unstable power consumption and voltage readings, such as the oil pressure levels, and the pump tries to regulate action. That’s why it is so critical to step in to nip these problems in the bud so that one does not end up destabilizing the operational control.

Diagnosing Faulty Oil Pump Issues in Your System

Systematic and precise decision-making is vital to properly diagnosing oil pump issues. The steps outlined below should be accompanied by specific technical parameters to ensure the process’s effectiveness.

Check Oil Pressure Readings: It’s normal for the oil pressure to range from 10-30 volts per psi when idling and as much as 50-70 voluntarily when the system is under greater demands under speed. Using a qualitative pressure gauge will assist you in monitoring oil pressure continuously. Any deviations from these values may indicate worn-out pump components, blockages, or leaks.

Inspect for Air Leaks or Cavitation: Look out for any cessation in flow, instant sequence flow, and noise, as these could be signs of cavitation. These occur when the system operates below proper suction pressure, which is usually set at -0.5 bar to avoid vapor formation.

Evaluate Power Consumption: Use a wattmeter to gauge the system pump’s electronic power consumption. Internal resistance, a worn-out device, or improper alignment may suggest abnormally high or fluctuating values. The values are usually annotated in kW or HP, depending on the manufacturer.

Assess Oil Viscosity: An improperly viscose system could lead to insufficient lubrication or increased internal wear. Confirm that the oil being used matches the system’s viscosity specifications, such as ISO VG 46 or ISO VG 68.

Check the oil temperature at the inlet and outlet points. Most systems work efficiently within a range of 80 – 120 (or 27-49) degrees Fahrenheit. If the system starts consuming excess heat, it could be a sign of deteriorated flow, issues with the bearing, or excessive friction.

If required, dismantle the assembly carefully and observe the pump for worn-out seals, bearings, gears, or any other wear and tear. With the help of micrometers or calipers, check the tolerances against the specified measurements and ensure they fall within the allowable limits. By methodically adhering to these instructions and evaluating the related parameters, the oil pump system can be diagnosed and promptly repaired.

What Are the Types of Bearings Used in Pumps?

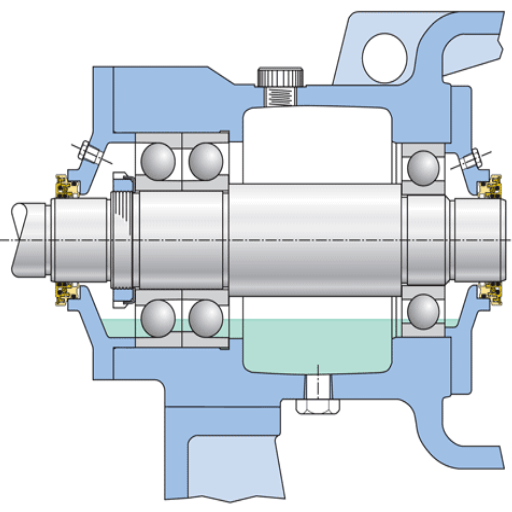

Exploring Ball Bearings and Their Applications

A type of bearing that is universal in application is ball bearings, which serve a primary function in pumps for lowering friction and aiding in rotational movement. They are manufactured specifically to accommodate radial and axial loads, which is essential for different types of pumps. Ball bearings also possess the following key technical features:

Operating Speed: This parameter is predetermined by the material, design, and lubrication of the ball bearings. It is further defined as the maximum revolutions per minute (RPM) the bearing can attain without overheating and excessive wear.

Tolerance and Precision Grade: Ball bearings are further classified according to ISO or ABEC tolerance standards. The tighter the tolerances, the greater the precision and efficiency.

Lubrication Requirements: Proper lubrication is essential for minimizing friction and, therefore, wear. Grease or oil lubrication is typically used, and the type is determined by operating conditions such as speed, temperature, and the load the bearing is under.

Temperature Range: There are known ranges of temperatures in which ball bearings can function, avoiding overheating where the material and lubrication will be subjected to damage.

Ball bearings are not limited to centrifugal pumps. They aid in the smooth operation of the shaft and increase the lifespan of the equipment. Therefore, they are very useful in engineering, considering their high efficiency, compact size, and ability to withstand various operating conditions.

When to Use Thrust Bearings in Pump Systems

Thrust bearings function best in pump systems with large or easily controllable axial loads. For instance, a thrust bearing is primarily employed on a pump during operations that involve high pressures or extensive flows since these factors produce forces along the shaft’s axis. These components enhance the shaft’s alignment, reduce the risk of wearing out, and avert harm to other parts in the system.

Axial Load Capacity: Thrust bearings are additionally classified according to the relevant axial load. For instance, some types of bearings are rated for 500 N, while others, depending on shape and composition, can accommodate up to 10,000 N.

Operating Speed: The rated speed is often targeted for higher-than-normal applications. For instance, a bearing made using certain materials can operate at a rotation per minute speed of up to 10,000 or even higher.

Temperature Range: Most lubricants and materials equipped in certain bearing designs have a normal operating temperature range between -20 degrees Celsius and 200 degrees Celsius.

Material Composition: High-end steel or even ceramics are most commonly used for maximum strength and resistance to wear under harsh conditions.

Lubrication Requirements: Friction and heat in high-stress situations need to be dissipated, and this is only possible through proper lubrication, be it oil or grease.

Recognizing these parameters allows thrust bearings to work efficiently and reliably in pump systems, especially in vertical or multistage pumps where axial forces are important.

Comparing Roller and Journal Bearings

The selection of roller versus journal bearings largely depends upon the application and operating parameters. Based on my experience, the following are some points to consider for both types of bearings:

Load Capacity: Roller bearings are appropriate for high-load applications because they can carry both radial and axial loads. Unlike roller bearings, journal bearings can only carry radial loads, making them best suited for supporting steady and uniform loads.

Speed Considerations: Journal bearings tend to perform better at high speeds due to hydrodynamic lubrication. Roller bearings can perform at moderate to high speeds, but at very high speeds, an increase in wear and heat leads to their usability being effectively limited.

Friction and Efficiency: Roller bearings tend to have greater friction due to the mechanical contact between parts. Using a lubricating film in journal bearings results in a much lower friction level during operation, thus improving efficiency.

Maintenance and Durability: Apart from the roller bearings’ intricate design, these bearings have many moving parts that require consistent maintenance to ensure proper lubrication and reduce wear and tear. Journal bearings are more simplistic, highly durable, and require little maintenance as long as there is lubrication.

Both types of bearings have advantages and disadvantages, which largely depend on the specific technical requirements of the pump or machinery.

How to Maintain Proper Bearing Lubrication?

Best Practices for Bearing Lubrication

To ensure that the bearings are perfectly lubricated, I apply several predetermined steps to verify there is proper lubrication in place as well as protection against mechanical deterioration – these are:

Picking the Correct Lubrication: The lubricant employed must complement the bearing’s operating conditions. This includes the range of temperature, speed, load, and the surrounding environment. For instance, a bearing with high speeds requires a low-viscosity lubricant to help decrease friction, while a heavily loaded bearing would need a viscous lubricant or one with high-pressure extreme additives.

Watch Lubrication Levels: The oil film required to keep elements in the best working conditions should neither be too high nor too low. Too high will span beyond the best oil film, resulting in under lubrication, while too low causes excessive friction, leading to the breakdown of the components. A steady film adjustable to the type of bearing and its application enables a balance between friction and heat dissipation.

Schedule Lubrication: In terms of my operating regimes, I try to ensure lubrication intervals are set for the peed of operations along with temperature and other levels of contamination. For example, if the environment is at high temperatures, oiling more often would keep the lubricant intact and enable it to function.

Remove Unwanted Particles Before Application: Lubricants can lose effectiveness if elements like dirt and moisture are left unremoved, which can also scratch the surface of the bearing negatively. Factors that compromise lubrication quality and other technical aspects such as load capacity and overall life, I ensure particles are removed using clear and proper application tools.

Look For Signs Of Lubricant Degradation: Conducting a standard inspection maintenance check on the lubricant enables me to identify deterioration caused by oxidation and thermal stress shock. The condition of the lubricant determines its viscosity and protective properties, which directly influence the performance of the bearing with respect to load and temperature.

Conducting these procedures enables me to achieve optimal lubrication with enhanced temperature control, low friction levels, and increased bearing life without compromising the technical specifications of the machines.

Understanding Oil Level and Lubrication System Requirements

To answer these questions concisely, I have ensured that the oil level is kept within the permissible range set by the equipment manufacturer. Elevated oil level affects the lubricating efficiency, resulting in excessive oil and heat transfer. If the oil level is insufficiently low, it can lead to insufficient lubrication, which increases friction and overheating, thus accelerating the wear of the components. All of these factors negatively impact load capacity and significantly reduce the life expectancy of the components. Conversely, a lower boundary of high oil will result in increased churning, aeration, and energy usage while also causing poor uneven distribution of lubrication, which decreases operational efficiency.

Concerning these characteristics, affected boundaries include viscosity consistency, load handling ability, and thermal conductivity. These characteristics are proven to exist because suboptimal oil levels loosen the bounds set on the temperature range of the lubricant’s viscosity, which subsequently affects the bearings. Furthermore, the determined oil level serves system requirements, ensuring proper equipment functioning and extending components’ life cycles.

Preventing Contamination in Bearing Lubrication

The incorporation of meticulous cleanliness standards along with effective sealing systems ensures contamination in bearing lubrication is controlled. To answer this question directly, I thoroughly clean the lubricant storage and handling premises so that any loose particles do not compromise the system. Contaminants in the lubricant are removed using appropriate filtration systems before application to prevent further contamination. In addition, periodic inspection and maintenance help identify contamination sources like seal wear or leaks that are controlled on time.

The following technical parameters are affected if contamination persists:

Viscosity Consistency – The lubricant’s ability to perform within different temperatures and loads is disrupted because the lubricant’s viscosity is altered.

Load Bearing Capability—The lubricant’s effectiveness is reduced, causing abrasive particles to impair its ability to support dynamic and static loads.

Thermal Management—Contaminants hinder heat displacement, resulting in an increase in the operating temperature and thermal damage.

Justifying these parameters is vital because residues actively alter the lubricant’s performance, causing uneven wear, reduced efficiency, and destructive machinery failure. I am confident that my proactive measures help maintain reliable functionality within my operating conditions and extend the life of the bearings.

What Factors Affect Oil Pump Performance?

Impact of Oil Pressure and Oil Flow on Pump Efficiency

Oil pumps rely on oil pressure and flow, and I will be meticulous when analyzing these parameters to achieve maximum efficiency for my oil pump. Keeping a high oil pressure is vital for ensuring that lubrication is stable, but too high pressure can cause seal damage and energy losses. On the other side of the spectrum, oil pressure that is too low will fail to lubricate the components, leading to overheating adequately.

Just like above, the oil flow requires balancing as well. Having too low of a flow rate poses risks of not cooling and lubricating the system enough, while having too high of a flow rate can lead to turbulence destroying the pump’s efficiency. The key technical parameters affected include:

Insufficient Pressure Lubrication—Oil’s inability to maintain a stable lubrication layer because of low flow and low-pressure results in a significant increase in wear and friction.

Heat Over Dissipation—Low oil flow leads to oil’s inability to manage thermal energy, which leads to a rapid increase in temperature and thermal degradation.

Longevity Of The Pump—Ideally, the pressure should be between the set ranges, but if the flow is higher, it leads to increased mechanical stress on the pump, resulting in a lower lifespan.

To allow the oil pump to consistently support system durability and efficiency while operating reliably, I monitor and maintain the optimal ranges of oil pressure and oil flow.

Influence of Shaft Rotation and Load on Pump Performance

The rotation of the shaft and the load have an important impact on the pump’s performance and operational efficiency. Shaft rotation out of sync with the optimal speed results in improper oil flow and pressure, leading to poor lubrication and low heat dissipation. An increase in pump load leads to higher mechanical aggravation, which results in inefficiency and lower overall life.

Lubrication Consistency—A reduction in shaft rotation or an increase in load can impede the lubrication layer, rendering it prone to wear and tear.

Heat Dissipation—A shift in shaft rotation, along with an increase in load, reduces the oil’s capacity to absorb heat. This results in overheating and greater inefficiency within the system.

Pump Longevity—Excessive load, along with improper rotation speed, leads to greater pump discomfort and mechanical wear and tear, ultimately lowering overall capabilities.

By consistently monitoring shaft rotation and load, I am able to prevent and safeguard critical parameters, providing the system with durability and efficiency.

How to Optimize Oil Supply and Oil Feed for Better Performance

Using systems monitoring and proper calibration, I optimize the supply and feed of oil to ensure peak performance. First, I ensure that the shaft’s rotation speed is within the manufacturer’s limits. Shaft extremities can limit lubrication, dissipate heat, and affect the pump’s longevity. For instance, maximizing the rate of rotation reduces frictional bearing wear and helps maintain a stable lubricating film. In addition, I balance load capacity to prevent excessive mechanical forces, which impact the pump’s efficiency and longevity.

Shaft Rotation Speed—It must remain stable and within specified operational boundaries for effective heat transfer and lubrication.

Load Capacity – Lower bounds are specified to ensure they are within the threshold of the component’s limits and to avoid rapid degradation of the mechanical parts.

Oil Viscosity – This should be provided to the system internally and externally to allow a smooth temperature variance.

To sustain the standards, I systematically improve the system’s performance. Routine maintenance is another important aspect, along with constant adherence to set standards.

Frequently Asked Questions (FAQs)

Q: What factors should I consider when selecting a pump bearing for my application?

A: When choosing a pump bearing, concentrate on aspects like the speed at which the pump operates, the load conditions, the temperature, and other environmental factors. Also, consider the industry, such as oil and gas, power generation, and others, where the pump applications revolve. One should follow the guidance given by the pump manufacturers, along with API and ISO, to ensure reliable performance through the right bearing selection.

Q: How does other lube oil affect the performance of the pump bearing?

A: Together with some other aspects, lube oil is essential in the performance of pump bearings. It reduces friction during the relative movement of rotating elements, carries away excess heat, and combats wear. Proper lube oil with the appropriate viscosity ensures that the bearings rotate efficiently and without problems. Insufficient lubrication causes overheating, excessive wearing, or complete bearing failure. Therefore, regular oil changes and maintaining the bearing’s oil level are vital for the optimum strength of the bearing.

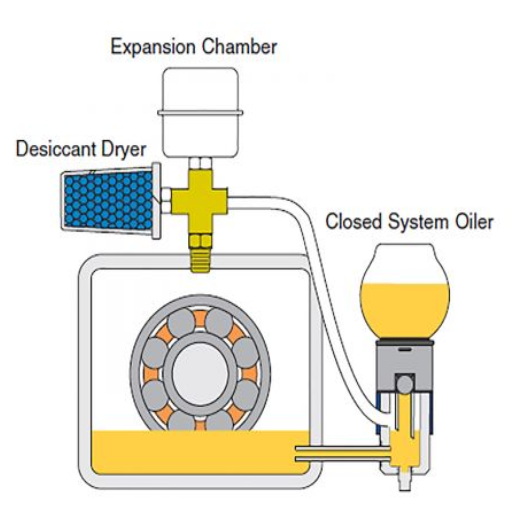

Q: What are the standard lubrication methods for pump bearings?

A: Oil is used to lubricate a bearing through an oil bath, where the bearing is placed within the confines of a sealed casing filled with oil. Other methods include oil rings, which involve an energizing ring riding on the shaft to scatter oil towards the bearing, and forced circulation, which entails pumping oil through the bearing. More inventive methods like oil mist, which sprays oil in tiny water droplets towards the bearing, and grease, which is used in lower speed scenarios, can also be used. The methods that can be implemented are always dictated by the design of the pump and its speed, as well as other operating conditions.

Q: How can I prevent contaminants from entering the bearing in my pump?

A: Based on the pump’s design specifications and expected conditions, it is essential to ensure the pump’s housing is sealed correctly so contaminants can’t seep through. Regular checks on the lubricant and shielding should be performed to avoid introducing new pollutants. It is equally crucial to conduct oil analyses frequently to ensure quality, and that contamination can be caught early. For better results, slightly elevating the pressure within the bearing housing helps keep contaminants out.

Q: How can I recognize a pump has inappropriate lubrication on the bearings?

A: Improper bearing lubrication can be indicated with the following: 1. Elevated noise or vibration. 2. Elevated working temperatures. 3. Increased energy usage. 4. Leaks visible around the seals. 5. Smell discoloration or burning from the lubricant used. 6. Bearing failure or wear too soon. 7. Decreasing efficiency in pumping. Early identification of these troubles can be made with active supervision and maintenance.

Q: How frequently should I replace the oil for the bearings of my pump?

A: As for the interval of oil replacement, this item varies based on several criteria: the use of a pump, its operating conditions, and the kind of oil in the pump. Usually, it is best to stick to the recommendations provided by the pump manufacturer. In most industrial cases, oil replacement is typically done in 6 and 12 months. While regular use or operations are acceptable, more frequent changes are warranted for extremely hostile environments or rapid actions. Regular analysis can be done to determine the most optimal interval for other specific applications.

Q: What is oil mist lubrication, and when is it necessary for pump bearing use?

A: Oil mist lubrication is a technique where oil in vaporized form is sprayed continuously on the bearings. This method is most effective in high-rotation speed pumps, compressors, and similar rotating machinery. It is common practice to alter the lubrication methods of machine parts that move with high velocity to minimize friction and heat sinking. More importantly, it is used when there is a need to improve the reliability of the equipment or when there is a need to reduce maintenance, and dry lubrication is insufficient to meet the reliability goals.

Q: What are the consequences of having excess oil in pump bearings?

A: These are the problems caused by having excess oil in pump bearings: 1. Increased energy losses due to the friction of moving parts 2. Higher temperature levels 3. Seals leaking oil 4. Air may mix with the oil, thus deteriorating its effectiveness for lubrication 5. Over-stressed seals increase the chances of seal breakage 6. In severe situations, hydraulic locking of the bearing Friction is reduced, and oil levels are optimized to avoid these problems.

Q: How do I ensure proper lubrication during pump startup?

A: To ensure lubrication during pump startup: 1. Oil level should be checked before starting the pump. 2. In forced lubrication systems, switch on the lube oil pump ahead of the main pump. 3. Make sure that oil has reached all bearing surfaces. 4. Measure the temperature and vibration of the bearing during startup. 5. Increase the speed of the device gradually so that proper lubricating oil film is achieved to the bearings. 6. Set the mist generated to flow before operating the device. 7. Where the temperature is low, the oil should be heated before setting it. Carrying out these steps during the start-up will minimize the possibility of destroying the bearings’ inner surfaces, which is critical.