Adequate lubrication is essential but often overlooked for achieving optimal productivity in maintaining industrial equipment. Many industries utilize pump systems, from manufacturing to water treatment, and the machinery’s condition directly affects its performance. Among these components, one of the most imported parts is the bearing housing, as it contains the bearings that facilitate load transfer while minimizing friction. This article looks at the lubrication of pump bearings, its effect on efficiency, and the importance of maintenance to save money while optimizing the system’s performance. If these principles are understood, businesses can achieve more excellent reliability and operational efficiency in their systems.

Why is bearing lubrication crucial for pump maintenance?

Understanding the impact of poor lubrication

I cannot stress enough how critical the lack of lubrication is to the effectiveness and lifespan of the pump’s bearings. Increased friction due to insufficient lubrication leads to rapid wear and overheating. In addition to faster deterioration, bearing seizure occurs. Technically, poor lubrication adversely affects temperature, vibrations, and energy consumption, among other things.

Operating Temperature: Inadequate lubrication adds too much friction, which relies on excessive heat that can cause overheating. This can negatively impact the bearing materials and lead to damaging failure.

Vibration Levels: Uneven loading and surface damage due to over-lubrication can raise vibration levels, harming the system’s stability and reliability.

Energy Consumption: Overlubrication creates unnecessary friction, which boosts energy input to maintain functionality, nullifying the entire focus of pumping system efficiency.

Pumps can be expected to perform consistently and at maximum when lubrication issues are solved quickly.

How proper lubrication enhances pump performance

Appropriate lubrication is key to pump upkeep because lubricants impact several characteristics and help to ensure efficient performance. Proper lubrication reduces friction between the pump’s moving parts, minimizing wear and increasing the pump’s life. Reducing friction can reduce the energy consumed, thus improving efficiency. In addition, appropriate lubrication serves to cool the pump parts during operation to help stabilize temperature so that overheating does not happen. Systems overheating may reduce the overall reliability of the system.

Proper lubrication positively affects the following technical characteristics of the pump:

Friction Levels: Constant lubrication allowed the maintenance of lubricants, further reducing mechanical and operational stress and strain.

Energy Efficiency: Eliminated by unnecessary friction and excess power consumption saved by lubrication.

Temperature Control: Preservation of important components by maintaining a temperature range conducive to optimal operations without overheating.

Component Longevity: Increased as prevented lubricants withheld surfaces from degrading and quickly failing materials.

Decreased maintenance requirements enable the pump system to work in much better and more dependable conditions.

The role of pump bearing housing in preventing wear and tear

The pump bears maintain the vital function of inhibiting wear by providing appropriate alignment and support for the rotating parts. B’s housing design and maintenance directly correlate to friction, vibration, and misalignment damages over time.

Friction Control: Proper housing alignment aids in bearing reduced contact points, which results in enhanced energy losses due to excessive friction.

Vibration Levels: A properly fitted bearing housing also protects the surrounding parts of the rotating components, reducing excessive vibration.

Thermal Management: The housing helps prevent excessive heat buildup from poorly aligned or stressed bearings while ensuring proper bearing function.

Load Distribution: The fitted bearing housing distributes operational loads evenly across the components, reducing system stress.

The hydraulics system is a prime example of these factors, highlighting the importance of proper calibration and functionality of the bearing housing in an operating bearing and the pump system.

What are the best practices for lubricating pump bearings?

Determining the correct type of lubrication

When choosing the correct lubricant for a specific pump bearing, I ensure it corresponds to the clearly understood system operating conditions and design specifications. These are load, speed, temperature, and other environmental issues. For example:

Load: Generally, higher loads would mean higher lubricant film strength to avoid wear and tear on the rotating machinery.

Speed: Low-viscosity lubricants are common in high-speed applications due to the ease of wear and tear friction and lower heat levels generated.

Temperature: In cases of too much exposure to a high or too low environment, I select lubricants with appropriate thermal and viscosity properties to keep the bearings functioning correctly.

Contamination: More durable Grease seals are required due to a dust or moisture-containing atmosphere that requires further enhanced sealing.

Based on these criteria, I can substantiate the choice of lubricant because there will be a significant improvement in the performance of the pump bearings, a decreased maintenance frequency, and the entire pump system will likely last longer. Such considerations also safeguard some pump components alongside the bearings and ensure they are useable with the pump system under the prescribed working conditions.

Implementing an economical lubrication management system

In setting up a cost-efficient lubrication management system, I would first analyze the operating conditions of the pump system, such as load, speed, temperature, and moisture or contaminants in the environment. These elements affect the chosen lubricant and its performance during the operational cycle. I can reduce energy expenditure while minimizing wear by selecting a lubricant with the correct additive package and viscosity, which notably impacts the bearing efficiency and the operator’s lifetime.

I would set up a routine maintenance system that is unique and specific to the system’s needs. This system would include monitoring the lubricant amounts, analyzing their condition, and replacing them when necessary to avert breakdowns. These techniques would help ensure that the continuity of the lubrication film is retained in the working machinery, which assists in lowering friction and operational heat.

Moreover, automating lubrication and combining it with monitoring tools is one economical option that reduces human error and waste. These instruments collect and store information in a database, allowing users to alter lubrication parameters accordingly and guarantee performance efficiency with changing workloads. Each of these steps allows for lower operational costs and the optimal use of resources while greatly justifying the expenses incurred from investing in a well-managed lubrication system.

Monitoring the quality of lubrication

I would emphasize routine sampling and analysis of lubricant conditions to ensure adequate lubrication. Some parameters to check include viscosity, contamination levels, or wear debris. Any significant deviation from acceptable ranges can prevent the equipment from performing at optimal levels, such as,

Viscosity: Inadequate justifications for operating temperature or pressure alterations can compromise load-carrying capacity, escalate wear, and cause overheating.

Contamination Levels: The presence of water, dirt, or other contaminants can deteriorate system efficiency by increasing the rate of corrosion and abrasion. Regular filtration techniques, alongside robust contamination control practices, should mitigate these effects.

Wear Debris: An increased concentration of metallic particles found in lubricant is a key indicator of excessive wear, requiring immediate addressing through ranking inspections and preventative maintenance.

Integrating multi-parameter monitoring allows me to shift lubrication targets for optimum uptime and slow component failure rates.

What types of lubrication are used for pump bearings?

The benefits of oil lubrication vs. grease

Both oil lubrication and grease benefit pump bearings, and the final output of my projects determines which one I go with. Oil provides better cooling, making it ideal for high speeds or temperatures lubrication. The oil circulates quite rapidly, reducing friction and dissipation of heat. This helps dissolve the friction, alongside gages having the height required for optimal operation. The technical parameters bearing temperature and friction level are significantly impacted, and having control of these two eliminates overheating, prolonging reliability.

In contrast, grease comes in handy with sealed systems and those that need lower maintenance since its sealing arrangements protect against dirt and moisture, which might damage the pump’s bearings. Grease’s lack of real need for a complex lubrication system eliminates the complex setup. Some technical parameters, such as level of contamination and lubricant grade, need to be controlled as the grease ages. So, these measures allow me to check which measures my lubrication practices accurately are under operational performance.

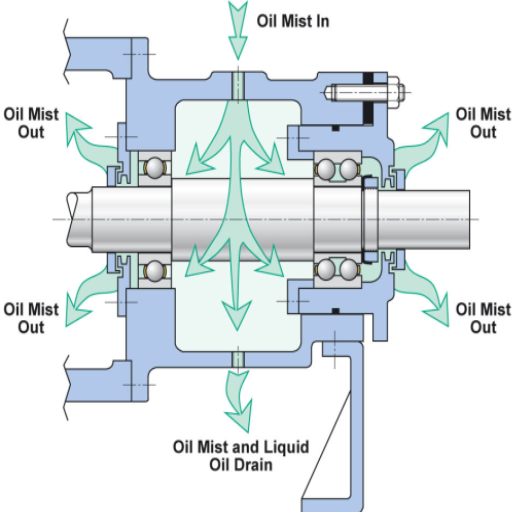

Exploring mist lubrication and its applications

Mist lubrication helps supply a specific amount of lubricant to different parts of high-speed engines and machines. In this method, lubricant is atomized into very tiny droplets, which are blown to the desired location using an air stream. This method provides adequate lubrication while eliminating waste and reducing the chance of contamination.

Mist Consistency/Uniformity—The size distribution of mist particles should be controlled to enable uniform coverage of the components for consistent performance.

Air Pressure and Flow Rate – These determine how well the mist is delivered to its target area and how well lubrication is achieved.

Lubricant Viscosity—The Viscosity should be adequate to interactively atomize a lubricant while reducing the risk of clogging the system.

System Contamination Levels – Any air or lubricant contaminants can negatively affect the machine and lead to wear or failure over time.

I can perform mist lubrication by expertly managing these factors, remarkably enhancing operational accuracy.

The effectiveness of oil splash lubrication

Oil splash lubrication effectively provides reliable lubrication across the internal structures of enclosed systems, such as gears and bearings. This performance can be examined based on a few key technical parameters:

Oil Viscosity—Proper viscosity selection ensures adequate film strength without excessive drag. Depending on the loads and speeds at which gearboxes operate, ISO VG 68 – 220 is typical.

Most Effective Operating Temperature Range – Splash systems work best when there are boundaries on the temperature levels to be maintained generally, between 40 degrees and 90 degrees Celsius. Maximum temperature values beyond this would compromise the oil, leading to the lubricating properties of the oil being reduced.

Speed of Components—The rotational speed of gears and shafts determines how much oil is distributed. A higher rotational speed increases the distribution of oil splash, but there are limits to the foaming and aeration of the oil.

Oil Level – Effective lubrication requires always maintaining the optimal oil level. Underfilling leads to a lack of coverage while overfilling leads to unnecessary churning and increased oil temperature.

Contaminant Management—Routine monitoring and filtration of contaminations (max. dimension of particles of less than five microns for precision applications) must be done to maintain oil quality and prolong component lifetimes.

Optimizing the system’s oil splash lubrication parameters can enhance reliability and efficiency and reduce wear under different working conditions.

How can the correct quantity of lubrication be ensured?

Calculating the oil level for optimal performance

It is essential to assess the unique characteristics of the equipment to determine the ideal oil level. The following parameters are vital for correct oil level determination:

Immersion Depth of Component—The oil level should help maintain the healthy immersion of gears or bearings without causing excessive churning. As a rule of thumb, energy loss is avoided if gears are displaced by 1/3 of their diameter.

Temperature of Operation—Oil expansion must be factored in. Ensure that the reservoir does not overflow or remain underfilled during use.

Splash Lubrication for Everyday Use—The critical elements that need splash contact must be reachable by rotating or moving parts. Confirm the oil level with the lubrication system’s design requirements.

Equipment’s Angle – In static or other active inclined systems, ensure that the oil is evenly dispersed and continues to cover the critical areas.

Industry—and Equipment-Specific Guidelines—The oil level should always be checked according to the recommendations for the specific equipment.

The systems’ wear and failure can be managed through thorough inspection and adjustments of the parameters. Optimal performance is achievable.

Preventing over-lubrication and its consequences

To reduce the likelihood of over-lubrication, I evaluate the needs of the system in question, along with the instructions given by the manufacturer. A complete system or part might fail due to excess pressure or leakage from an excessive temperature or energy loss put forth by over-lubrication. Here is how I make changes to the system while considering the technical details:

Accessibility for Lubrication—Lubricant is applied to various critical parts of the system to ensure that moving components function freely without build-up. When system components are over-lubricated, imbalance and other inefficiencies can occur.

Equipment Inclinations—For inclined systems, I pay close attention to the flow of lubricants at these angles to ensure that overuse does not occur at the choke points. Ineffectively coating critical components can lead to coating failure; worse, overlubricated components can be wasted at some angles.

Manufacturer Provided Guidelines – When analyzing the lubrication requirements of the system, this information is compared with the instructions issued by the manufacturer. Through different means, over-lubrication is something that I pay particular caution towards as it can effectively obstruct flowing channels and over-stimulate bearings, destroying the design intentions.

For the utmost efficiency and sustainable system operations, the above precautions, alongside regular monitoring, will create optimal conditions to ensure that all moving parts are adequately lubricated without compromising the system’s efficiency.

What are the signs of bearing lubrication issues?

Identifying symptoms of improper lubrication

Recognizing signs of inadequate lubrication in a system revolves around performance monitoring and interpretation. Here are the ones I pay attention to:

Loud and Unusual Noises—Operating machinery produces strange sounds, such as squealing or grinding, which suggests poor lubrication. The noise of the bearings means there is too much friction, eventually leading to wear and overheating. This directly impacts the system’s smooth functioning, and the components may be damaged alarmingly.

More Than Expected Operating Temperature—Overulculating or under-lubricating is responsible for higher temperatures. Machinery operating hotter than its baseline expectations indicates that the lubricant is not granting proper flow or failing to cover the surfaces uniformly. This parameter degrades thermal efficiency and might even interfere with the ability to sustain optimal working conditions.

Oil Seepage or Leakage—When checking for oil seepage, I always pay attention to seals or joints that exhibit signs of weakening or damage. Lubricant is overused and poorly used, as leakage points suggest contamination of other parts. This directly impacts proper lubricant distribution and cleanliness of the system.

Unusual Wear Patterns – Scoring or pitting on the bearings directly results from defective lubrication. This aggravates the most critical metric of surface protection, curtailing the bearing’s life expectancy and ultimately leading to system failure.

Higher Amplitude Vibration—Excessive vibration could be a symptom of insufficient bearing lubrication. Excessive turbulence can also affect system stability, compromising operational integrity and causing more severe mechanical problems.

Prompt diagnosis of these symptoms and mapping them to the potential underlying parameters will enable me to take precise remedial measures to restore system controls and thus ensure proper lubrication management to maximize system productivity.

Steps to take when faced with lubrication failure

Check Lubricant Quality: The first thing I do is determine how good the lubricant is. If contamination or degradation occurs, I substitute the lubricant for another that satisfies the system’s requirements. This covers the effectiveness of cleanliness and lubrication, ensuring the system functions effectively and efficiently.

Check Application Procedures: I have to review the lubrication application procedures to ensure that a proper quantity is used. Adding too much or too little lubricant can impact the distribution and cleanliness of the lubricant, leading to inefficiencies. Changing these methods balances these parameters.

Check for Leakage: I observe seals or fittings for any evidence of leakage, an issue with over-lubrication, or wearing out of the equipment. Fixing this contamination helps to control the leakage of surrounding components, rendering adequate lubrication and system reliability.

Check Conditions of Bearings: Improper lubrication can be fixed by monitoring the wear patterns on bearing surfaces. Either adjusting or replacing components in the bearing prevents further degradation of the surfaces and positively impacts the life of the lubrication.

Monitor Shocks: I measure the vibration of poor lubrication to determine whether it destabilizes the system. Attending to this restores system stability minimizes the risks of further mechanical damage, and ensures smooth operations.

When applying corrective actions, I not only address symptoms that arise from lubrication failure, but I also take time to restore the critical technical requirements that are needed for a fully functional system.

Frequently Asked Questions (FAQs)

Q: Why is the lubrication of pump-bearing housing necessary in maintenance work?

A: Lubricating the housing of the pump bearing is critical to maintenance, as it supports the proper operation of the rolling element bearings in process pumps. Economical lubrication minimizes friction, slows wear, and increases bearing life. It also maintains the operational efficiency of centrifugal pumps and other pumping apparatus, reducing downtime and maintenance expenses.

Q: What are the primary methods of lubricating the bearings in process pumps?

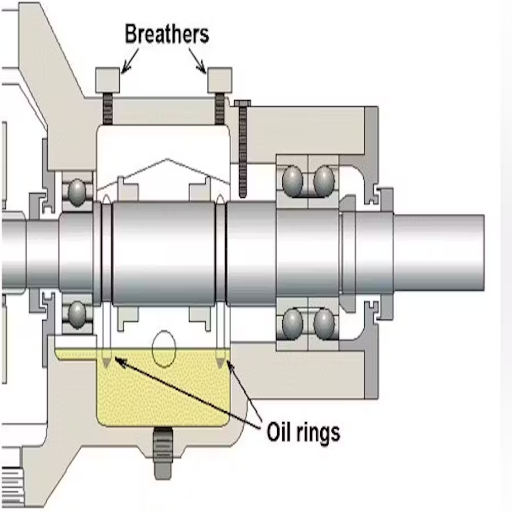

A: The primary methods of lubricating the bearings in process pumps are oil ring lubrication, oil mist lubrication, and grease lubrication. Oil ring lubrication is one of the most popular methods, where an oil ring is mounted loosely around the shaft. When the shaft rotates, it dips into the oil sump to pick up oil carried to the bearings as the shaft rotates. Each method has its benefits based on the pump operating conditions’ criteria and requirements.

Q: How does an oil ring lubrication system work in the context of a pump-bearing housing?

A: In an oil ring lubrication system, an oil ring is mounted on the pump shaft and rests partly in the oil sump positioned within the bearing housing. When the shaft moves, the oil ring rotates and tows oil from the sump, feeding it to the bearings. This simple but efficient technique frequently lubricates the pump’s bearings when it works as the pump operates.

Q: What influences the quantity and quality of lubrication in pump bearings?

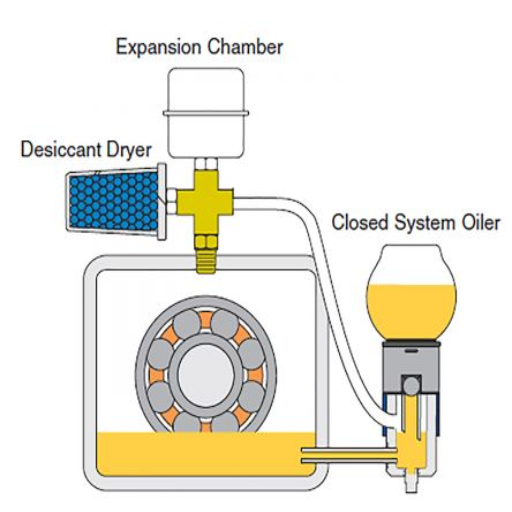

A: Different factors affect the quantity and quality of pump bearings lubrication, such as the condition of the oil, the pump performance, ambient temperature, and the condition of the bearing housing itself. Regularly changing the oil, ensuring proper sealing, and keeping the right sump oil level are all essential to optimal lubrication. Of course, the airflow over the pump and the temperature difference between the equipment housing and the environment will also affect lubrication efficiency.

Q: Why are the bearing protector seals crucial in lubricating the pump bearings?

A: Bearing protector seals are essential for lubricating pump bearings. They prevent coolant from entering the bearing housing and keep the lubricant within. These seals help purify the lubricant, keep out moisture, and prolong the life of the lubricant and the bearings. Proper sealing is required to ensure the reliability and longevity of the pump’s lubrication system.

Q: What other essential aspects of lubrication should pump users appreciate?

A: Users of the pumps should know of few simple aspects of lubrication, which are 1. Knowing the types of oil suitable for the specific pump and its working conditions. 2. Checking and maintaining the oil level in the sump. 3. Carrying out periodical oil Inspections and changes. 4. Checking for seal integrity to prevent contamination. 5. Recognizing signs of insufficient lubrication like noise or vibration. 6. Adjusting maintenance activities to include a lubrication routine.

Q: How can pump users determine if their pump-bearing housing lubrication is adequate?

A: The pump users can tell whether sufficient lubrication is provided to the pump bearing housing by: 1. Observing the operating temperatures of the bearing during working cycles. 2. Regularly check the oil level using the sight glasses or indicators. 3. Assessing the oil for any deterioration or contamination. 4. Noticing strange sounds that may show bearings or other moving parts are not adequately lubricated. 5. Noting vibration increases when the moving parts are poorly lubricated. 6. Performing tests on the oil to find contaminants and evaluate the extent of oil degradation. 7. inspect the bearings’ wear and tear and damage during usual servicing activities.

Q: What role do plugs in the bearing housing play in pump lubrication?

A: Plugs in the bearing housing provide several significant functions in pump lubrication: 1. Filler plugs enable adding fresh oil to the sump. 2. Vent plugs to equalize pressure within the housing, thus preventing oil escape. 3. Thermometers or vibration sensors can be attached to sure plugs to track the condition of the bearings. These plugs, if mismanaged, can cause contaminants in the oil and sump and hinder lubrication effectiveness.