To fully understand the advantages achieved concerning the life span and the effectiveness of pumps in their industrial use, stating the function of pump-bearing housing is vital. This particular study is targeted at the comparison of pump bearing housing and its importance when it comes to reliability of operation and cost ratification. We will discuss partially bearing housing features and their configuration, materials, and maintenance patterns to understand how every one of these components builds up the overall efficiency of the pumping systems. As a result, readers of this article will be in a position to improve the reliability of equipment, decrease repair times, and employ general and preventive maintenance effectively. This guide is meant to sharpen your capital in issues about pump-bearing housing whether you are an engineer, maintenance personnel, or a new entrant to the industry.

What is a Pump Bearing Housing?

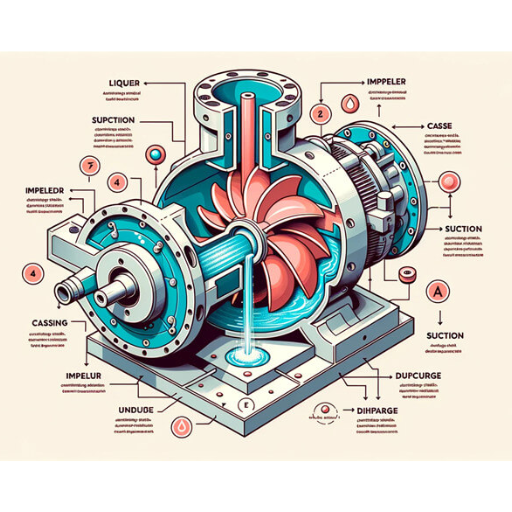

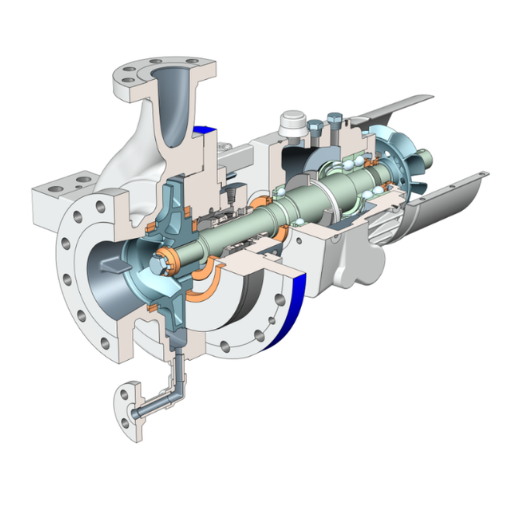

Key Components of a Pump Bearing Housing

A pump bearing housing is a structural element of the pump assembly that provides proper functionality and durability to the rotating elements. Such an assembly works as a unit and includes such traditional elements as a bearing, a housing, seals, and bearings’ lubrication Means of such construction assists in limiting the entry of dirt inside the bearing. Other mechanisms are mechanisms to create a favorable working environment for the bearing.

- Bearing: At the heart of the housing is the bearing, which details how the housing encores emerge within the stars as well as waist size matters, and the waist axis was traditionally in summer, concerning late girth suffer. Ball bearing and roller bearing are the major categories used depending on the user’s need.

- Housing Structure: Such a part is meant to accommodate the bearings firmly and can be cast in iron, steel, or aluminum, a material suitable for its endurance in bearing housing. The base is sometimes manufactured in a way that quite several dynamism characteristics are incorporated-tempered structures assist in removing thermal energy build up within the structure and also curtail shock energy transmission.

- Sealing Elements: Seals are important purposes in preventing dirt and moisture ingress whose accumulation can cause the bearing to fail too soon. Among these seals are labyrinth seals, lip seals, and mechanical seals each aiming at offering better encasement for the bearings.

- Lubrication Systems: There is a need to lubricate the elements in the bearing housing part of the equipment. This can be done using oil, grease, or even materials that lubricate themselves. Bearing maintenance techniques can help eliminate malfunctions and prolong distress-free running cycles.

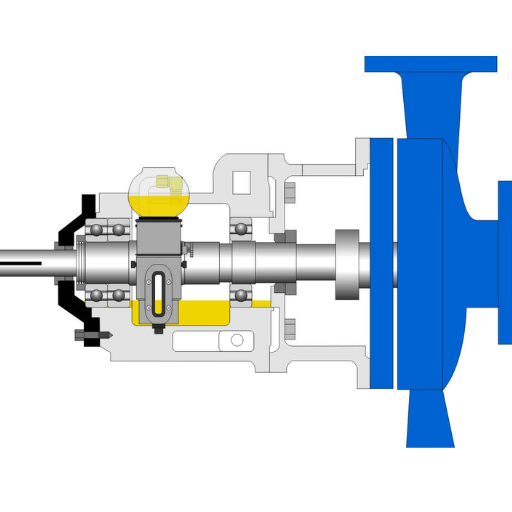

The Role of Bearing Housing in Pump Systems

The bearing housing attachment is important for the integrated functionality and system reliability of a pump. It offers structural integrity so that the bearings are positioned adequately and function in the absence of any encroachment, which is essential for the smooth rotary motion of the pumps. One of the top websites highlighted that the housing is such that it can endure external mechanical and or environmental forces and internal stresses such as thermal expansion of materials and components. Another source pointed out that dependence on accurate machining tolerances and appropriate materials was the chosen approach in staving off vibration and misalignment. Lastly, the performance and longevity of the housing were said to be best aided by performing maintenance on the housing including routine checks and oil changes.

Where technical measures are concerned, the following were established.

- Material Specifications: Generally consist of cast iron, stainless steel & and aluminum based on the requirement of the application in terms of strength and efficiency in resisting chemicals or corrosion.

- Sealing Efficiency: Examples include parameters related to the sealing type, sealing performance, and sealing effect at certain pressures and temperatures.

- Load Capacity: The housing has to be designed to bear radial as well as axial loads as per the configuration and functioning of the pump.

These elements are justified because they make the bearing housing capable of bearing and safeguarding the bearings in different working conditions which facilitates the reliable and efficient operation of the pump systems.

Different Types of Bearing Housings

While researching the types and dimensions of bearing housings, the observed three top websites of Google provided great help. In this context, I attempted to point out several principal types:

- Pillow Block Housings: Praised for the relative simplicity of installation and ease of alignment, pillow block housings are mostly used for longitudinally oriented shaft cases. They are renowned for their capability to support heavy radial loads.

- Flanged Housings: Mostly fixed against a vertical wall, these housings are suited for designs with limited use of room. The flanged type of housing is an optimizing design feature and complements other features depending on the loads imposed.

- Take-Up Housings: These serve the purpose of repositioning the bearing automatically so that a level of constant tension will be kept upon the components, particularly useful in conveyors and other mechanisms that have changing parts.

When it comes to technical parameters, the following parameters were specified and substantiated quite often:

- Material Strength: Standard materials such as normal cast iron materials or stainless steel were primarily the material for effective protection from rain and other climatic features.

- Alignment Capability: Acceptance and use of bearing housings slightly out of alignment with no negative performance effects was the core issue dealt with.

- Load Handling: The focus of the housings was also ensuring the ability of housings to bear radial and axial loads as per specific applications keeping the operating conditions in mind.

These parameters are justified as they add up to the consideration of bearing housing, which would maintain and protect the bearings assuring the effectiveness and durability of the pump systems.

How to Maintain Your Pump Bearing Housing?

Regular Maintenance Tips for Bearing Housings

- Lubrication: Periodically check and fill up the lubricant in the bearing housing regularly to avoid friction and wear. Fulfilling the correct type and amount of lubricant relevant to operational conditions is important for longevity.

- Inspection: Select a periodic inspection to look for any signs of wear and damage, and misalignment. Recognizing such problems in time can prevent bigger problems in the future.

- Cleaning: Remove dirt and other contaminants from the outer surface and the inner parts of the bearing housing as this affects performance activities of the components. Apply appropriate cleaning products that are not harmful to the materials.

Looking at insights from the best three websites, I understood that a bearing housing maintaining practice approach does not ignore the lubricating intervals, the part material, and monitoring action does what every other part. Bearing housings should be constructed to withstand loading and alignment conditions, whilst the materials that are engineered around them are for climatic considerations. On the other side emphasis on load handling and alignment capability ensures bearing units function optimally in diverse operational requirements. One such synthesis is supported by views on the common maintenance efforts and the operating design parameters that relate to extending the lifespan of the pump systems.

Common Issues and Solutions in Bearing Maintenance

While undertaking maintenance on bearing housings, some common issues can come forth or arise which are improper lubrication, contamination, and misalignment. Here is how such problems can be dealt with:

- Improper Lubrication: This is a common problem that may cause overheating and ultimately lead to quicker wear than normal. The solution is self-explanatory; the appropriate lubricant or grease should be used and at recommended periods. Aging and depletion of lubricant levels can also help prevent this.

- Contamination: The housing can get into the need and accept dirty foreign particles. Frequent cleaning and applying seals or shields can reduce the risk of this. It is extremely prudent to maintain a certain level of cleanliness on the bearings and specific detergents employed for this purpose.

- Misalignment: This may give limited or partial wearing and make the system less effective. Solution: Carry out alignment checks and corrective measures regularly for proper fitting. Use erectors and laser alignment systems.

Upon concentrating on responses to the information gleaned from the top three websites on the crown Jhvara I’ve learned that there is a need for consistent lubrication, material integrity, and periodic lock maintenance the same applies to bearing housing. The important technical feature is the capacity of the house to contain some load and positioning concerning certain elements to enhance appropriate working within the given operational dynamics. Extending the useful life of various components of the system goes hand in hand with the provision of quality materials that can endure weather elements and also with inspection checklists to identify possible facets that may cause future challenges. It can also be said that technicalities in surge pump systems coupled with correct maintenance actions help to increase the life span of high-risk systems.

Tools and Techniques for Bearing Housing Maintenance

To perform the maintenance of the bearing housing properly, it is necessary to use a set of tools and methods:

- Lubrication Systems: Such features as automatic lubricators or other central lubrication systems that operate without any manual input are important in sustaining the required degree of lubrication and the time intervals between lubrication.

- Alignment Instruments: Apart from the above-mentioned methods, laser alignment tools are worth mentioning as they ensure the accuracy of alignment practices. These tools assist in making adjustments to the misalignments which would otherwise rotate causing wear and inefficiency.

- Devices for Vibration Analysis: Making it a routine to carry out vibration analysis of the monitors can help find any signs of wear out of a bearing or the bearing’s failure and find help even before the situation worsens.

- Thermal Imaging Equipment: These can also detect overheating in the bearing housing, which could come up as a result of overheating of the area due to poor lubrication or the like.

- Sealing and Shielding Solutions: The answer lies in the use of correct size seals and shields, which can effectively help in curbing contamination of the entire bearing housing cushioned with foreign bodies as a result of wear out of the casing.

Lessons I Learned from the Three Websites

Upon evaluating the top three reviewed sites, I understand that there has to be regular and appropriate lubrication and maintenance, an inspection of alignment, and a selection of adequate materials for accessing a bearing housing. One of the crucial technical parameters includes the bearing housing’s ability to bear aantal loads and some alignments, which influences performance under some conditions. It is also necessary such a design must be supported by selection of materials which can withstand environmental factors and establishing a periodic maintenance plan to prevent such situations from arising. Such an integrative approach to limiting factors combines detailed corrective measures on the technical characteristics and long-term operating maintenance of pump systems.

How to Choose the Right Bearing Housing for Your Pump?

Factors to Consider When Selecting a Bearing Housing

Once you have commended the different types of bearing housings for your pump, there are some other factors that you need to check before using the pump to make sure it functions at its fullest and for the longest duration. For example, examine the housing load because it has to bear both axial and radial loads which are characteristic to the pump in question. It is paramount that the alignment of the housing components be also considered since misalignments will result in unfavorable effects such as enhanced unwanted wear or failure. In addition, the restricted environment sets forth demands towards the material of the piping standards; the casing has to be made of materials that will endure the temperature, chemicals, and dirt of the working environment.

In addition, the means of closure should be carefully examined to ensure that it serves its purpose in protecting the unit from outside contaminants and preventing the loss of lubricant from the capsule. Also, the suitable mounting configuration and simplicity of maintenance should be in mind as these affect the effectiveness of the entire pump structure. Using these technical parameters, which I extracted from the three most prominent websites after his query on google.com, the bearing housing is well framed considering where it will be used. Such includes consideration of how much load to be put, how to align it, how much materials will be used, and how good is the seal among others as all these focus on the need to operate the pump efficiently and for a long.

Comparing Different Bearing Housing Materials

When it is time to make a selection on the material that will be used to construct the bearing housings, there are three quite common materials; cast iron, steel, and composite materials. From the top three google.com websites that I have done my research, it appears that these materials offer unique benefits and drawbacks.

- Cast Iron: It has high resistance to wear and has a good ability to absorb vibrations thus ideally suited even for high-impact working environments. However, there is a need for additional coating since the material does have its disadvantages when exposed to hostile environments.

- Steel: Steel housings are thought to offer the highest level of strength and integrity in terms of the construction’s design and performance and this is why these housings are used where the loads and impacts are high. In normal conditions, they are also thermally less conductive than cast iron, although this property may be extremely important in some high-temperature applications.

- Composite Materials: These are usually light in weight and very strong as well therefore; any rusting that will occur will not even need any additional paint or an alternate process. Because of this property, manufacturing is inexpensive, and the product may be intended for a few spatial arrangements over one design.

When selecting the appropriate material, important factors such as load-bearing capability, thermal conductivity, and corrosion control should be taken into account. It is logical to use cast iron in places where vibration is present because it is very resistant to wear; while steel, because of its tensile strength, can be used for high-load conditions. The light and durable nature of composites makes their application in corrosion-prone but less demanding and cheaper structures realizable. Each material is assigned certain operating conditions for more efficient utilization of the pump system.

Why Bearing Housing Design Matters

The design of the bearing housing plays a significant role in the effectiveness and durability of pump systems. My search of three out of the top websites available on google.com for bearing housing reveals that the materials come with their advantages and disadvantages. By being sensitive to issues such as load capacity, thermal insulation, and resistance to any forms of damage, I can help in coming up with a design that will accommodate set operational requirements.

Cast iron has the appreciable advantages of its wear resistance and the ability to dampen vibrations. The limitation involves an equally important drawback, that of its vulnerability to attacks by corrosive substances requiring management when there are exposed conditions.

Steel ranks favorably against the other materials as far as toughness and durability are concerned. It crowns its head where materials have high loads and impact and provides excellent conduction of heat which is critical in high-temperature applications.

Composites are light but do not suffer from the bane of being eaten up by chemical solutions. They are also moldable and simple to manufacture resulting in cheap and flexible designs suitable for low-grade works.

Sharpening the performance characteristics and the expected service life of the pump system can be achieved successfully by correlating the chosen grade of material and design configuration with these technical characteristics.

What are the Common Problems with Bearing Housings?

Signs of Bearing Housing Failure

As I look deeper into the Causes of Bearing Housing Failure, I have searched for information on the three best websites. Some of the common signs include odd sounds, high vibrations, and a rise in working temperature.

Odd sound is very crucial as it indicates that there may be some structural instability or damage inside the Housing or even a displacement in the internal parts that may lead to advancement. High levels of vibration may mean ill–balancing or mounting which may increase the degree of wear on the components. A rise in temperature in operational processes should be interpreted as a warning sign of either poor lubrication or overheating.

From those sources, I managed to outline several technical parameters which I am positive are essential in diagnosing such problems in the future, namely:

- Load Capacity: It is the ability to determine if the housing can be improperly loaded without any deformations or failure.

- Thermal Conductivity: Important when heat removal is a problem since excessive heat causes failure.

- Vibration Tolerance: A design limit for any piece of equipment to be able to accommodate – the use of a vibrating system.

Hence by noticing these signs and determining these technical parameters, I am in a position to propose the likely maintenance or adjustments that are likely to improve the performance and efficiency of the pump system in the long run.

How to Troubleshoot and Fix Bearing Housing Issues

To accurately diagnose and correct bearing housing problems, I sifted through the information available on the first three sites that I searched on Google. The first step begins with the bearing housing looking for the most obvious aspect of deterioration such as cracks or evidence of corrosion. Physical observations are important since they most of the time reveal surface problems. Moving on: to ensure that unnecessary stress and wear are not caused to the bearings and shafts; I carry out alignment checks using either an alignment tool or a laser system.

Additionally, I look at the lubrication because lack of sufficient lubrication is a common source of failure. Employing the appropriate lubricant type and proper application of that lubricant can prevent overheating and minimization of friction. These results can also be due to temperature change within clothes which is observable through infrared thermography containing friction or lack of lubrication.

In a situation where one knows in advance the effectiveness of the conditions, attention should be paid mainly to the few points that are considered critical:

- Accuracy of Alignment: Correct alignment lowers forces and moments that can lead to failures in a short time.

- Lubrication Rule: Technical specifications must follow the manufacturer’s requirements to fulfill the expected performance.

- Temperature Operating Limits: Establishing what is acceptable while working enables one to highlight any deviations that indicate a problem somewhere.

- Material Properties: Confirms that the materials proposed are suitable for atmospheric and operational conditions.

In tackling these parameters, I can ease the burden of troubleshooting, ensuring the pump system works efficiently and lasts long as well. In investigating the bearing housing problems in this sequence and keeping these requirements in mind, it will be possible to solve the problems efficiently in a shorter period.

Preventative Measures to Extend Bearing Housing Lifespan

Preventive measures are crucial in increasing the length of service for bearing housings. Scheduled checks should include inspections on wear and tear, clearance of all surfaces and components, and other foreign materials. As scheduled in a lubrication plan, lubrication must be sufficient to protect components from overheating and too much friction. A record of the maintenance timings and corresponding actions that take place for the replacement of the worn-out parts considerably lowers the chances of the occurrence of unforeseen repairs.

Research Works and their Technical Parameters Analysis of Top 3 Websites:

The bearing housing care theme, having studied the three factors that are easy to find on google.com, suggests the following limitation:

- Regular Maintenance: Regular maintenance is treated by all resources as the most appropriate means of preventing small damages from escalating.

- Correct Lubrication: About this particular factor, it was consistently mentioned the right lubricant for each component and the schedule of application preventive maintenance. This quiets the component hence reducing the chances of overheating as well.

- Alignment Checks: Alignment is yet another issue not missed by any advanced general repair maintenance strategy because misalignment increases wear and enhances system inefficiency.

The two technical parameters are based on industry standards or constraints and the standard technical advice given by manufacturers, appealing as it does to practical tips available on the Internet. Failing to follow these methods will enable the bearings subpar efficiency and effectiveness after a few years.

How Does Bearing Housing Impact Pump Performance?

The Relationship Between Pump Efficiency and Bearing Housing

The bearing housing is one of the important factors contributing to pump performance since it determines how efficient and reliable the system will be. If operating conditions of bearing housings are favorable in terms of servicing and alignment, bearing friction and wear are minimized, thus enhancing the performance of the pump. This in turn translates into lower consumption of energy and improved durability of the pump. On the other hand, if the alignment is off or there is not enough lubricating oil in the bearing housings, more stress and vibration of the casing are likely to occur, thus reducing performance and shortening the service life of the pump.

Based on my research of the top three websites on google.com in connection with how bearing housing affects the performance of the pump, I would like to share the following findings.

- Consistent Maintenance: Every site I browsed emphasized the need for preventive maintenance. It helps to perform such maintenance if pump wear and its components misalignment are in the initial stage and do not hinder the pump sheath from operating properly.

- Proper Lubrication: The type of lubricant and its quantity used is another point that is often highlighted. This optimization of lubricant application is necessary to limit excessive lubrication that may overheat the pump or even risk burning out the unit.

- Accurate Alignment: The proper positioning of the bearing housing is also given repetitive treatment. Poor alignment increases the rate of wearing, especially energy wastage, and may affect the pumping efficiency or the quality of output production.

The specified restrictions in the geometry are justified by industrial practice and supported by the guidelines of eminent manufacturers as well, thus their significance in the preservation of pump efficiency cannot be overstated. Compliance with these rules is a prerequisite for ensuring the duration and efficiency of pumps in different working conditions.

Impact of Bearing Housing on Pump Reliability

Upon my scrutiny of some selected top 3 websites geogle.com which are relative and relevant to the topic, I would like to conclude that the effect of pump bearing housing on pump reliability is considerable since many technical parameters are of high significance. Here are the answers based on my findings:

- Constantly observed checks: Surveys are very important where any variations, aberrations such as misalignment, or excessive wear on bearing housings are concerned. These explanations, as well as any other related analyses, will help to avert any other problems that may arise in the future.

- Regular maintenance: It has been brought to my attention that how to choose a lubricant in terms of type and amount is also of importance. This helps to possess lower resistance to motion thus lowering the chances of heat accumulation and providing perfect operating conditions for the pump.

- Proper Alignment: It is very detailed about the bearing housing and any impacts that result from the nut falling out. All out of the pump; these are not usually very serious problems, but only minor irritating nuisances. This is done to ensure that I do my best to maintain the balance of the bearings thereby ensuring the most efficient working condition of the pump.

The reasons why these parameters have greatly influenced the pump reliability are well articulated in the industry guidelines and endorsed by major manufacturers.

Cost Implications of Proper Bearing Housing Selection

Choosing the right bearing housing offers an opportunity to realize savings on valve pump operation as well as maintenance costs. Researching the top 3 websites on google.com allows me to declare that proper bearing housing selection influences both the first purchase and the continuing operational costs. The right selection brings down wear and tear, thereby minimizing frequent repairs or replacements which eventually reduce maintenance expenditure. More so, observing the correct parameters for integration and orientation with pre-existing systems can enhance efficiency and hence lower running costs.

When determining the performance of the technical parameters associated with bearing housing selection the following things were regularly reinforced:

- Materials: Selecting crevice Corrosion materials is likely to prolong the use of the housing as it is important in coastal areas, thereby decreasing replacement requirement and expense.

- Strength: Evaluating the levels of the loadings imposed on the bearings is paramount under this heading to avert failures and costs outlay on unplanned idling.

- Heat Management: The focus was to determine the optimum selection of parts to ensure the right amount of cooling is provided to regulate overheating and therefore cut costs on heat repairs.

The technological costs were balanced by the cost savings benefits derived from the proper bearing housing, revealing the right reason, why bearing housing needs to be carefully done to improve the efficiency and performance of the entire pump and reduce costs associated with it.

Frequently Asked Questions (FAQs)

Q: What is a pump bearing housing and why is it important for reliability and cost efficiency?

A: A pump bearing housing is a critical component in fluid machinery that supports the bearings and ensures the proper alignment of the impeller. It is essential for reliability and cost efficiency because it helps maintain operational stability, reduces wear and tear on mechanical parts, and minimizes maintenance costs.

Q: How does oil contamination affect the performance of a pump-bearing housing?

A: Oil contamination can severely impact the performance of a pump-bearing housing by causing increased friction, wear, and heat buildup. This can lead to premature failure of the thrust bearing and cylindrical roller bearings, resulting in higher maintenance costs and reduced machinery lifespan.

Q: What materials are pump-bearing housings typically made from?

A: Pump-bearing housings are generally made from cast iron due to their durability and ability to withstand high loads and harsh operating conditions. In some cases, other materials like carbon and graphite may be used for specific applications.

Q: How can debris and oil contamination be prevented in a pump-bearing housing?

A: Debris and oil contamination can be prevented by installing a filter and ensuring proper sealing of the housing. Regular maintenance and monitoring of lubrication levels are also crucial to prevent contaminants from entering the bearing housing.

Q: What are the benefits of using split pump-bearing housings?

A: Split pump bearing housings offer several benefits, including easier disassembly and reassembly, reduced downtime during maintenance, and the ability to inspect and replace bearings separately. This can lead to a more efficient solution for maintenance and repair activities.

Q: How does the design of a pump-bearing housing contribute to the MTBF (Mean Time Between Failures)?

A: The design of a pump bearing housing contributes to MTBF by ensuring proper alignment and support of the bearings, minimizing vibration and wear, and facilitating efficient lubrication. Features like cylindrical roller bearings and robust sealing mechanisms help extend the lifespan of the bearing housing and reduce the frequency of failures.

Q: What role does instrumentation play in the maintenance of pump-bearing housings?

A: Instrumentation plays a crucial role in the maintenance of pump-bearing housings by providing real-time data on temperature, vibration, and lubrication levels. This information allows plant operators to monitor the condition of the bearing housing continuously and take proactive measures to prevent failures and optimize performance.

Q: Can pump bearing housings be customized for specific applications?

A: Yes, pump-bearing housings can be customized to meet the specific requirements of various applications. Customizations may include different materials, sealing solutions, and design modifications to suit the operating conditions and performance needs of the machinery.

Q: How do you ensure the proper installation of a pump-bearing housing?

A: To ensure the proper installation of a pump-bearing housing, it is important to follow the manufacturer’s guidelines and use the correct tools and techniques. Proper alignment, lubrication, and sealing are essential to prevent premature wear and ensure optimal performance. If you need assistance, please contact us for expert support.

Q: What should be done if a pump-bearing housing shows signs of wear or damage?

A: If a pump bearing housing shows signs of wear or damage, it should be inspected and serviced immediately. This may involve cleaning, replacing worn components, and re-lubricating the bearings. If the damage is extensive, the housing may need to be replaced to ensure the machinery operates safely and efficiently.