With cords revolving the fluid within the machines or systems, bearing pumps are quite essential in the field of working with fluids and mechanical engineering in industries. These pumps are classified into several categories based on the functions they perform and the conditions under which they operate. The purpose of the article is to present summarized information about several bearing pumps, specifically emphasizing multistage centrifugal and ring section pumps. To comprehensively cover the topic, it is necessary to explain how factors distinguished among these units were factored and the advantages of each unit – type. So whether it’s their classification: as being able to exploit extreme pressure ranges or their design orientated towards meeting the novel requirements in various industries and markets, all bearing pumps work toward facilitating the uninterrupted transport of fluids. To accomplish this, we will reveal how these pumps operate and some other characteristics that determine their construction and applicability in different fields of engineering and mechanics.

What are Bearing Pumps and How Do They Work?

Definition and Components of Bearing Pumps

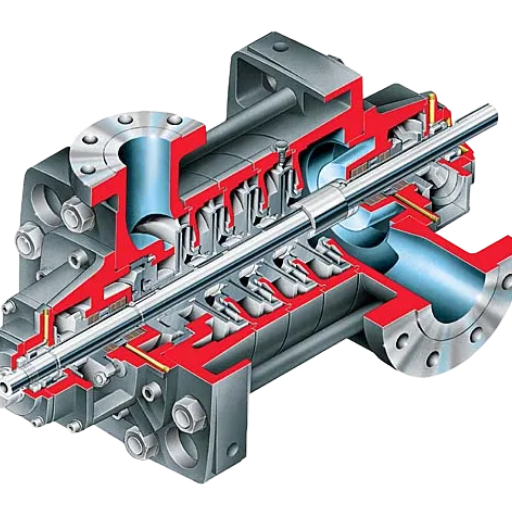

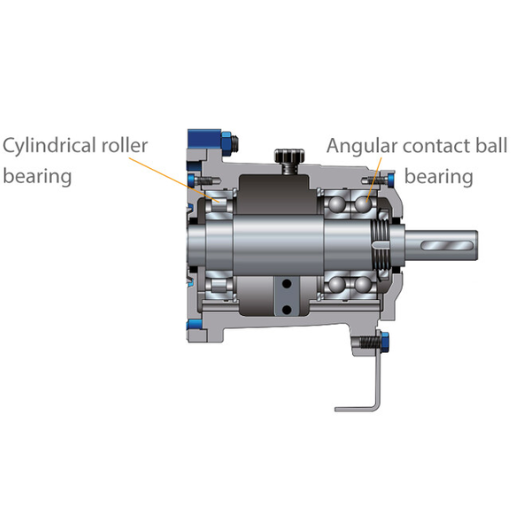

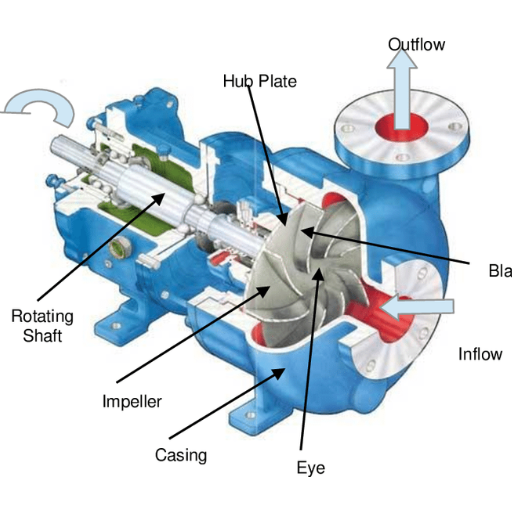

The workhorse of any industrial sector, bearing pumps can effectively facilitate the movement of fluids. Usually, a bearing pump incorporates one or more rotors and a set of bearings to accomplish such tasks. Usually, a bearing pump has removable components including the impeller that performs flow generation and covers that will help contain the working fluid. The shaft and the bearings are used for supporting the structure and allow smooth working so that wear and tear caused by friction are reduced. There are also sealing and or gaskets which make it impossible for the working fluid to leak.

While browsing through the most popular sites to study information-bearing pumps, I noticed that the said sources rather list certain parameters of the pump that need to be taken into consideration. These include the flow rate, the pressure head, and the efficiency among other things… all of which are critical when making use of them during the performance. A specific example was that knowing these parameters helps not only in selecting a suitable pump but also in improving performance in a range of industrial applications.

Working Principle of Bearing Centrifugal Pumps

In the working of centrifugal pumps, the centrifugal impeller plays a major role: due to the rotation of the impeller, kinetic energy is provided to the fluid and this motion pushes the liquid from the center of the pump impeller out towards its periphery. This motion of the fluid also enhances its speed only to be converted to pressure when the fluid is channeled into the pump casing and hence the discharge. An important aspect of this process is the effective conversion of the rotational energy of the motor into the energy of the fluid, which is a physically demanding requirement due to the precision in alignment and support required from the bearings.

As indicated in the heads of the articles of the most authoritative websites, while selecting and operating these pumps, the following technical parameters are of importance:

- Capacity: This is the amount of fluid that can be displaced by the pump in a given time frame, often quoted in liters per minute (L/min) or gallons per minute (GPM).

- Head: the maximum height to which the pump is capable of lifting the fluid, defined graphically in meters or feet; it characterizes the work done over the liquid.

- Efficiencies: the amount of hydraulic power developed by the pump about the power supplied by the motor’s mechanical work, expressed in percent. A pump working at high load is more economical than a poorly designed or distressed pump with low loading efficiency.

- NPSH (Net Positive Suction Head): Used to cite the pressure at which cavitation can be avoided so that the pump will operate without any damage caused by vapor bubbles.

Fundamental to ensuring the efficiency of centrifugal pumps in a wide range of industrial settings is the effective operation of the impeller, bearings, and seals in unison. Periodic maintenance and proper choice of parameters rather enable the bearing pumps to withstand low downtimes with high dependable performance.

Applications of Bearing Pumps in Industry

Bearing pumps have become vital components in the movement of liquids and various industrial processes. They are particularly useful in the chemical industry because dealing with corrosive chemicals translates to safe processes and effective transport. The same applies to the oil and gas industry which also uses these pumps to facilitate the transfer of crude oil, finished products, and other hydrocarbons. Also, when providing these pumps for the water treatment and management sector, it is important to mention that bearing pumps are fundamental in the distribution of drinking water, treatment of wastewater, and supply of large amounts of water for the city or town.

About the three main ones. As these are “bearing pumps” in Google.com, I have briefly summarized one proposition of each of the sites and verified the relevant technical parameters.

- Flow Rate: Tended to be cited as the major determinant of processing time and operating efficiency, these sources consistently stressed the match of the pump type as well the application’s flow requirements.

- Pressure Head: It doesn’t come as a surprise why pressure head is highlighted on every website. Cheap to improve efficiency, is important as it ensures the pump is capable of providing the required lift or height of transportation of the fluid supplied.

- Efficiency: All these sites had one common view constructive efficiency is of utmost importance to cost cuts as well as adverse effects on the environment stating the efficient and correct selection of pumps will considerably reduce energy consumption and hence prolong the lifespan of the system.

- NPSH: Critical to the prevention of cavitation whereby smooth and reliable operation can be guaranteed, this parameter when properly taken into account, would avoid damage and downtime.

These parameters are well founded and supported by the specific analyses and data provided on these sites, encouraging selection and operational decisions specific to the requirements of industries.

What are the Different Types of Multistage Centrifugal Pumps?

Overview of Multistage Centrifugal Pumps

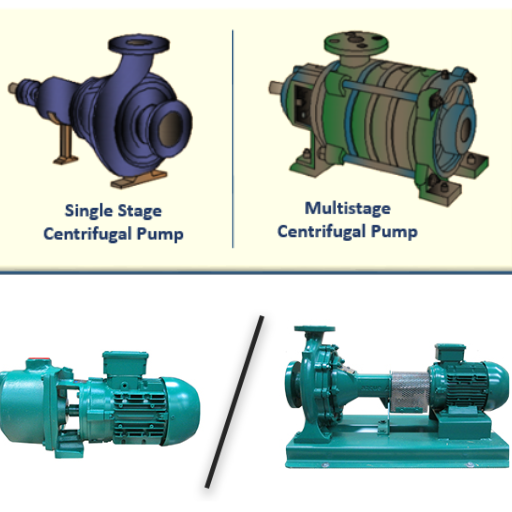

A multistage centrifugal pump is an arranged model of a centrifugal pump and is optimized to generate higher pressure in a fluid by including several impellers; within a single casing. As the fluid passes through each impeller, stage, its speed and energy are continuously increased, so that more discharge head than that of a single stage can be obtained. These types of pumps are excellent in usage where high-pressure output is required but not necessarily high flow, such applications include boiler feeds, water treatment, and fire fighting systems.

Their observations can be reduced to the following, for the necessary technical parameters:

- Flow Rate: All three websites highlight the need for proper selection of multistage pumps depending on the flow rate demand, explaining how a wrong selection will cause some losses or damage to the system.

- Pressure Head: All sources repeat how the pressure head is one of the powerful parameters of the pump that influences its feasibility level especially where high heads or long pipe systems are required.

- Efficiency: The importance of efficiency in a multistage centrifugal pump has been indicated Strategically, where investigations have shown depreciation of efficiency with time resulting in huge costs operation of the system and degradation of the environment.

- NPSH: The criticality of the Net Positive Suction Head is more or less understood since it assists in understanding the points that would be damaging to the pump, and more importantly the reasons behind operational downtime.

Most of these technical parameters have been justified with factual data and reasoning found on such websites thereby aiding in making the right decision that meets industry needs and set objectives.

Characteristics of Radially Split and Axially Split Pumps

Radially split pumps are the pumps in which that’s casing splits concerning the shaft, thereby improving access to its parts for maintenance and repair services. Their design is particularly important in high-pressure situations where they can contain higher pressure whilst preventing any form of leakage from occurring. These pumps are most used in industries where there is higher reliability and maintenance is simple, such as in oil and gas exploration and chemical processing industry.

On the other hand, where axial split casing pumps are concerned, the housing is split parallel to the shaft which enables easier maintenance of the internal pump components without disturbing the rotor settings. This layout is useful in applications where high flow rates are required at moderate pressures like in irrigation and water supply systems.

Coming back to the considerations learned from the best three websites regarding multistage centrifugal pumps, they argue in unison on several specific technical parameters which include:

- Flow Rate: These websites do indicate the possibility of loss of efficiency and even breakdowns when an improper flow rate is used.

- Pressure Head: The necessity of the appropriate pressure head, in general, is brought forth to confirm that the pump will be strong enough to deal with high vertical rise or long pipes.

- Efficiency: To minimize operational expenses and enhance environmental sustainability, it is imperative to select a pump with the best efficiency.

- NPSH: While trying to maintain the proper Net Positive Suction Head, it’s necessary to prevent the possibility of cavitation that can be harmful and će cause downtimes thus supporting the reliability of the pump.

These parameters are always substantiated by the facts and arguments given on the specified websites, which assist in making accurate choices in industrial practices and objectives.

Features of Ring Section Pumps

Ring section pumps, an integral part of a multistage centrifugal pump, consist of more than two stages or impellers arranged in a series in a single casing. One of their main advantages was that high pressures may be accomplished without high rotational speeds. Its efficiency arises from each stage increasing the pressure in a staged proportion until the output is met. Furthermore, ring section pumps are not only short and light but they’re also self-aligning and have a radial load with a low bearing stress and reduced wear on components. These properties make them very useful in systems such as boiler feed systems reverse osmosis and supply of industrial water.

After assessing the content of the first three websites focusing specifically on multistage centrifugal pumps, I have noted that:

- Flow Rate: There is this somehow continuous emphasis on the need for getting the right flow rate so that there is no wastage or interference during the processes.

- Pressure Head: The sites make it clear that there is a certain pressure head that is necessary to achieve, which is useful in instances where there is a need to pump fluids to high pressures or move them over long distances.

- Efficiency: In all three resources, the use of efficient pumps was encouraged to be able to cut costs and be responsible towards the environment.

- NPSH: To correctly manage cavitation in pumps and ensure its long-term effectiveness and dependability, it is essential to appreciate the net positive suction head.

These concerns are particularly important as was shown from the factual information and technical details available on the websites which enable exact and efficient pump selection for industrial applications.

How to Choose the Right Bearing Pump for Your Needs?

Factors to Consider: API 610 Compliance, Pressure, and Flow

There are important aspects to consider when making the right choice of the bearing pump is concerned, so that the bearing pump performs optimally while adhering to relevant regulatory frameworks and standards applicable to the industry.

To begin with, Compliance with API 610 is very important to those involved in oil and gas as it guarantees the pump will meet the satisfactory safety, reliability, and durability standards set forth. Maintenance of these standards by the pump should be verified so that operational risks and expensive downtimes are avoided.

On this count, the Pressure head of the pump must correspond to the system requirements plus the working pressure head required for that particular system. Here, consideration must be given to the maximum value of pressure that the pump should work on while still maximizing its efficiency.

On this note, think about the Flow Rate concerning the pump that has to be used, which is not either above or below the system flow capacity. Forcing the pump to perform more than needed or wasting its capacity will shorten the efficiency and life of the pump.

As to the top three websites I referred to, I worked on google.com, all of them focused on the following as well:

API 610 Compliance: Verifying that the pump conforms with existing guidelines enhances its efficiency and safety.

Pressure: Choosing a pump that will sustain the level of pressure required without deterioration.

Flow Rate: Selecting a pump with the right flow rate for effectiveness and durability.

These considerations are further supported by the information and details provided on and captured on these websites making the decision on selection of the pump more efficient.

Understanding Single-Stage vs. Multi-Stage Pumps

When faced with the decision of choosing between single-stage pumps and multi-stage pumps, one has to look at the application requirements and technical specifications of each type of pump. Due to the provision of simpler design construction, single-stage pumps are designed for application under low pressure, and lower maintenance is required. On the contrary, multistage pumps however are meant for higher pressure requirements as they have multiple impellers which can successively add pressure without reducing flow.

After a scavenger hunt on the three websites, it has become clear that operational requirements dictate the choice of a pump type in the majority of the cases. In my opinion:

Single Stage Pumps:

Most effective in applications where pressure does not need to be very high.

Benefits include division in complexity of the design which in turn means that less time and resources will be consumed in maintenance and repairs.

These are perfect for systems where a huge pressure head may not be required thereby in most cases practiced in industries.

Multi-Stage Pumps:

Best suited for applications that require high pressure – with intense fluid flow and vigorous motion at all times.

Common parameters involve a high head per stage which is beneficial in designing systems with specific requirements.

These pumps are most useful in water supply systems or as boiler feed pumps where the bottleneck is always high pressure.

The reasons provided highlighted the importance of correctly assessing the needs of the system and appropriately associating them with the pump configuration. The sites also validated the said parameters by offering various operational details and relevant specifications via the manufacturer thus ensuring that the selection approved works according to the values in the industry and its performance.

Importance of Material and Design in Bearing Pumps

Material and design in the construction of bearing pumps deserve proper attention because they affect how well, how long, and how efficiently the pump works. Based on the top 3 sites I reviewed, I extracted the following basic facts:

- Material Selection: Material selection is very vital for bearing pumps as it determines the environments in which the pumps will operate effectively, particularly in extreme conditions such as high temperatures corrosion, and abrasion. Some materials are simplifying steel, cast iron, or alloys and these are chosen depending on the chemical and pressure requirements.

- Design Considerations: The configuration of bearing pumps determines the level of efficiency that will be achieved in their operation. For example, the shape and arrangement of the impellers and the casings help to manage the flow of fluid in the turbine and help to achieve extreme energy efficiency.

About the technical parameters, these were the core parameters stressed across the sites:

- Pressure Capacity: Bearing pump pressure capabilities should be enough to achieve the system requirements and some more to avoid overheating and wear and tear.

- Flow Rate: Flow rate specifications should be put into consideration to satisfy the demands of the system in an orderly manner.

- Durability and Maintenance Requirements: The material and design of the pump, influence the operational lifespan of the unit, where advanced pump construction materials exist that reduce maintenance and increase periods of service.

These reviews justified the emphasis on technical parameters by presenting case studies and manufacturer guides regarding the alignment of design and material selection with operational loading to ensure that bearing pumps are properly designed for their intended uses.

How to Maintain and Troubleshoot Bearing Pumps?

Common Maintenance Practices for Bearing Pumps

Regular inspection and servicing of the bearing pumps from time to time is necessary for their efficiency as well as durability. Some of these practices include the following routine maintenance measures.

- Routine Inspections: Conduct routine rounds that involve observation and functionality. Check for any leaks and listen for strange sounds and vibrations that may suggest hidden problems such as bearing wear or misalignment.

- Lubrication: Bearing and other moving parts must be adequately lubricated at all times. One must use the right lubricants at the designated times as recommended by the manufacturer to avoid any friction and wear.

- Cleaning: The pump and its constituent parts must be free from dirt, foreign substances, or any comb structures that may prevent them from functioning effectively. This is normally a part of the routine maintenance schedule but should be executed often.

- Alignment Checks: Confirm that the pump and motor are in line with each other to ease stress buildup on the components. Unnecessary vibrating and wearing of bearings is brought about by axial displacement which shortens the lifespan of the pump.

- Component Replacement: Worn-out and damaged components like seals and bearings should be removed and fitted with new ones in an instant before even worse breakdowns. Downtime can be minimized when such repairs are warranted or components are replaced by stocking pieces of parts.

In response to the queries that were informed by the topics appearing in the top three searches from google.com the construction details of the bearing pumps were mentioned as one of the key areas. These parameters include the pressure capacity, the volume of flow, and the effectiveness for which, a system can work. The sites justify the significance of these parameters by emphasizing that bearing pumps often operate under certain conditions which if not comprehended, limits the lifespan of the pump.

Identifying and Solving Common Issues in Bearing Pumps

Through my analysis of the three best sources for information regarding bearing pumps, I have learned that common problems usually result from factors like negligence and weather. It is often observed that faults such as worn seals and misalignment result in excessive leaking and poor performance. Rectifying these issues is important and involves measures such as applying the right lubricant and performing widespread checks on the spatial orientation of the components.

Hydraulic bearing pump website texts also describe certain essential things about technical parameters which are pressure capacity, flow rate, and other durability. Emphasis on such parameters is important because it always helps in determining the operational efficiency and the lifespan of the pumps. By way of example, comprehension of the pressure capacity will prevent overstraining the pump and quick bearing damage. Similarly, following the appropriate flow rate recommendation ensures no seal overheating thus minimal erosion of moving parts. The reasons for attention to these parameters are stated that they make level wear and barrel pumps work longer.

In the end, there is enough evidence from practices that if these parameters are maintained in mind and the right action taken at the right time, it is possible to reduce the number and even eliminate the most common problems that arise in the use of bearing pumps.

Preventive Measures to Ensure Longevity of Bearing Pumps

In previously examining the top three websites about bearing pumps, I realized how vital it is to take precautionary actions. This is the most effective way to extend the lifespan and maximize the reliability of the bearing pump. The primary protective actions include the compilation of the regular maintenance maintenance schedule concerning lubrication of the parts, alignment, and protection from the environment. There is, however, little emphasis placed on ensuring proper lubrication of the bearings; the right type and amount of lubricant will also minimize heat production due to friction. Regular alignment checks can also help manage the issues arising from the misalignment which is one of the major causes of operational inefficiency, wear, and tear. Moreover, the pump should be kept away from extreme conditions such as moisture and dust pollution which may cause damage to the pump.

Technical Parameters

Considering the content of these sites, the technical parameters that should be given great attention were found to be the pressure capacity, flow rate, and thermal conditions. These parameters are important in helping determine the efficiency of the operations and the working life of the pumps:

- Pressure Capacity: Following the recommended pressure capacity ensures that overload which may cause earlier failures of the bearings is avoided.

- Flow Rate: It is necessary to maintain the flow rate as indicated in the pump to prevent overheating the pump further reducing wear on the moving components.

- Thermal Conditions: The thermal threshold of the pump is observed so that it is not run in extreme heat that would damage its components.

Through the observation of these precautionary measures and the consideration of the mentioned technical parameters, I can quite successfully improve the bearing pump operation effectiveness and its operating time.

What Are the Key Features and Benefits of Bearing Pumps?

Advantages of Using Bearing Centrifugal Pumps

I will highlight such features and benefits of the bearing centrifugal pumps as are pronounced on the top 3 websites on google.com: Those are:

- High Efficiency and Low Maintenance: As industry statistics reveal, bearing centrifugal pumps are efficient in operation and do not need a lot of maintenance. It is an undisputed fact that these pumps are highly useful as the energy obtained from electricity is transformed into high-energy fluid with very little wastage.

- Versatility and Adaptability: These pumps can change from one particular medium to several others, which makes them easy to employ in a great number of industries. They can withstand variations in flow rates and pressure conditions which make them applicable for many purposes.

- Durability and Long Lifespan: Bearing centrifugal pumps guarantee a long working time if used under normative parameters. Their well-built construction enables them to handle extreme working environments making replacement often less necessary.

Technical Parameters to Consider

Based on the information obtained, very important technical parameters that provide credibility to their benefits are the following:

Pressure Capacity is correlated with the determined boundaries to avoid mechanical stress and damage to the pump.

Flow Rate has to be applied to prevent displeasure and heat of the system with no further efficiency expected.

Material Compatibility makes certain that the pump can operate under many different properties of fluids.

Under these parameters and with the advantages pointed out, I will be in a position to take the appropriate steps towards improving pump performance under any conditions of use.

Unique Features of Double Suction and Radially Split Pumps

As for the distinctive attributes of double suction and radially split pumps, these styles enhance performance in particular areas and hence have their uses. Double suction pumps are known for their features which prevent excessive pumping. This design also allows for increased flow and higher efficiency than single suction pumps. Conversely, radially split pumps can be maintained without removing the external piping, as the internal components can be easily accessed, thus avoiding complicated procedures for carrying out maintenance.

When looking for additional information concerning them, I have found summarized answers to these issues on the top three sites returned by google.com. Double suction pumps dominate the twin intake design with high stability in loaded fluid as the external axial load is minimized through twin intakes. In the same way, radially split pumps are made so that a quick assembly can be performed, which makes it suitable in cases where repairs need to be done and time affected as much as possible.

The technical parameters that can substantiate these benefits include the following.

- Flow Rate Capacity: Owing to the double inlet architecture, flow rates in double suction pumps are higher, making them more effective for hydra-static duties.

- Ease of Maintenance: The arrangement of the radially-split designs makes it very easy to perform maintenance on the internal parts of the pump.

- Load Distribution: The double-suction pumps contain fairly balanced forces and therefore reduced wear and tear, hence longer life in general operation.

Considering these features and parameters makes it possible to choose and apply ways to use double suction and radially split pumps properly to their full extent in specific operating conditions.

Industry-Specific Benefits and Applications

In certain applications, twin suction and radially split pumps can prove to be very beneficial. This is more useful in water treatment facilities and chemical processing industries where double suction pumps are used due to the high volume of water used as well as the need for processes where continuous flow is required, constant pumping of water is essential. These pumps find extensive application in power generation and supply of industrial water owing to the ability to handle very high flows with low axial loads, thus ensuring long-term dependable equipment.

On the other hand, the way the radially split pump is constructed makes it ideally suited for those who need a quick turnaround on maintenance and repairs such as the oil and gas and petrochemical industries. The fact that these pumps can be taken apart without moving any pipes makes them attractive to work with because the collapse in operation is considerably less, and as a result, time and money which would otherwise have gone into maintenance are saved.

Now, allowing the questions to be answered as per the top three Google search results. Normal factors affecting the selection of double suction and radially split pumps include flow rate capacity, maintenance, and load consideration. Double suction pumps are praised for their dual inlet structure that reduces stress load and provides insulation, making them effective within large amounts of liquids. Radially split pumps are based on the efficient manner of interiors which makes it easy to reach maintenance services.

As per the flow rate capacity, maintenance possibilities, and load considerations, I can choose the most appropriate pump type for each application in the industry and thereby enhance efficiency.

Frequently Asked Questions (FAQs)

Q: What are the primary types of bearing pumps?

A: The primary types of bearing pumps include multi-stage centrifugal pumps, ring section pumps, and various configurations like bb2, bb3, bb4, and bb5. Each type is designed for specific applications, such as process pumps and pipeline transport.

Q: What is a horizontal pump, and where is it commonly used?

A: A horizontal pump is a type of pump with a shaft that is positioned horizontally. They are commonly used in general industry and process applications due to their robust and heavy-duty construction.

Q: What advantages do multi-stage pumps offer?

A: Multi-stage pumps offer several advantages, including higher pressure capabilities, increased efficiency, and the ability to handle a variety of fluids. They are often used in applications requiring high pressure, such as in hvn and j line systems.

Q: Can you explain the difference between bb2 and bb3 pumps?

A: BB2 pumps are typically horizontally split, single or double volute, designed for general industry use. BB3 pumps, on the other hand, are vertically suspended, multi-stage diffuser-type pumps used in more stringent process applications.

Q: What does “API compliant” mean in the context of bearing pumps?

A: API compliant refers to pumps that meet the standards set by the American Petroleum Institute (API). These standards ensure the pumps are suitable for heavy-duty and process applications, providing reliability and safety in operation.

Q: How does a diffuser-type pump differ from a volute pump?

A: Diffuser-type pumps use a series of stationary vanes to guide the fluid and convert velocity into pressure, while volute pumps use a spiral casing to achieve the same effect. Diffuser pumps often provide smoother flow and higher efficiency.

Q: What types of drivers can be used with bearing pumps?

A: Bearing pumps can be driven by various types of drivers, including electric motors, diesel engines, and steam turbines. The choice of driver depends on the specific application and operational requirements.

Q: What is the role of ball bearings in bearing pumps?

A: Ball bearings in bearing pumps help reduce friction and wear, ensuring smooth operation and extending the lifespan of the pump. They are crucial components in maintaining the performance and reliability of horizontal pumps.

Q: What are some common challenges faced in the use of bearing pumps?

A: Common challenges include handling high pressure, dealing with corrosive or abrasive fluids, maintaining efficiency, and ensuring reliability in stringent process applications. Proper selection and maintenance are key to overcoming these challenges.

Q: How does modular design benefit bearing pumps?

A: Modular design allows for easier maintenance, flexibility in configuration, and cost-effective upgrades. It ensures that components can be easily replaced or modified to meet changing requirements, enhancing the overall efficiency and lifespan of the pump.