In all organizations that use centrifugal pumps and compressors, reliability is one of the key features that govern the organizations’ effective performance. The bearings are a critical dimension of this reliability that often goes unnoticed. These are essential to the smooth and controlled rotation of the pump shaft since they assist in the bending and friction loads applied to the shaft to improve its service life. This article elaborates on the different types of pump bearings, their roles in pumps and compressors, and, more importantly, the consequences of selecting and maintaining the correct bearings for centrifugal pumps and compressors. It is vital to familiarize oneself with these parts because the more significant the understanding of them and their features, the better the performance and the maintenance of the Engineers and Maintenance professionals.

What are the bearing types used in pumps?

Exploring different bearing types in centrifugal pumps

I’ve encountered several different types of bearings while working on centrifugal pumps, having to keep in mind the various operational requirements for each of them, as I remember the most common ones to be:

Ball Bearings: For pumps where precision is key, these types of bearings are compact and ideal for high speed, and thus are highly versatile because they’re designed to be used in both radial and axial load applications. Still, it is crucial that the typical speed rating and the operational demands rating align well to ensure long-lasting durability.

Roller Bearings: In pumps that endure substantial weight and pressure, roller bearings come in handy, as they were explicitly designed to bear high radial loads, allowing for tapered designs to maintain both radial and axial loads, as well as cylindrical types that only allow determines axial movement. While making these selections, however, attention must still be paid to the radial load capacity and the permissible misalignment.

Thrust Bearings: When excessive axial loads are used, these types of bearings are essential to prevent the shaft from coming out of alignment, which is a specific job. Angular contact options are commonly found in pumps that require combined loads. Confirming the axial load capacity is also essential when dealing with these.

Sleeve Bearings: Journal or sleeve bearings can significantly assist applications where massive loads are experienced at low speeds. However, wear and tear may prove fatal over time; hence, lubricant can be utilized. Determining the maximum load and clearance levels is crucial to deciding on an efficient operation.

It is essential to use appropriate selection criteria such as load type, pump speed, environment, and best engineering practices to every kind. Proper selection and maintenance of the bearings guarantee centrifugal pump systems’ performance and long-term dependability.

Standard bearings used in compressors

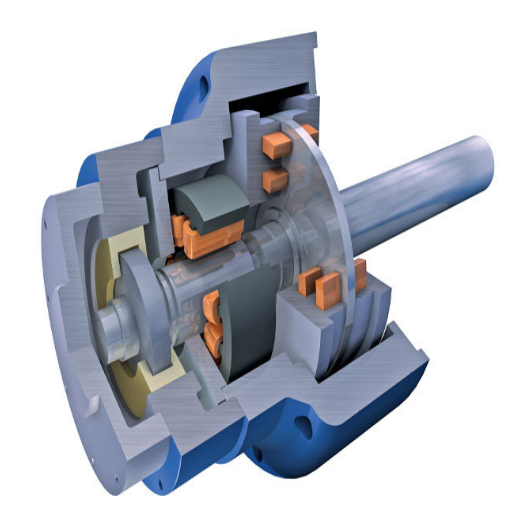

As far as compressors go, their bearings include rolling-element bearings and hydrodynamic bearings. Usually, ball and roller bearings are selected for high-speed rotation and medium to heavy loads. For compressors with a lower rotation speed history or with high load requirements, cylindrical rollers or tapered roller bearings are recommended these types of bearings due to their contact area and load distribution capabilities.

Large compressors rotating at high speeds are better fit with hydrodynamic bearings. Such bearings create a load-bearing surface by relying on a thin lubricant film, substantially reducing friction and wear. Essential parameters for hydrodynamic bearings consideration include minimum film thickness, which is meant for adequate lubrication, and maximum load capacity, which is meant to bear the stress without deformation or failure of the bearing.

Sie sollten immer darauf achten, die Flenne oder Lager nach den für die jeweilige Anwendung relevanten technischen Daten wie Drehzahl (U/min), Betriebstemperatur, Lastart (radial oder axial) auszuwählen. Zum Beispiel wenn Ihre Kompressor einen höheren Temperaturbereich hat, es ist notwendig, den Flennen so auszuwählen, der seiner Spezial komposite Materialien sowie speziellen Schmierstoffen eingearbeiteten inherente Wärmebeständigkeit erfordert. Die regelmäßige Wartung und Messung dieser Parameter kann die Lebensdauer von Lagern dramatisch erhöhen und die Effizienz des Kompressors übernehmen.

Key bearing applications in the pump industry

I will focus on the system’s operational requirements regarding key-bearing applications in the pump industry. Pumps are machines whose shaft is equipped with a bearing to minimize operation friction and load, whether radial, axial, or a combination of both. I generally assume the following parameters to ensure a failure-free system:

Speed (RPM): The RPMs that a bearing spins at should be equal to or more than the bearing; otherwise, it may overheat and lose its working efficiency. In high-speed conditions, I would instead use high-precision bearing where such conditions are met.

Operating Temperature Range: As pumps operate in different temperature zones, it is wise to install bearings made of materials that withstand temperatures, usually between -20F and 250F (otherwise, the temperature is higher). Heater-resistant materials such as ceramic hybrids or special lubricants can go a long way.

Load Type and Capacity: Deep groove ball bearings suffice in centrifugal pumps with dominant radial load. Axial or combined loads in vertical pumps best suit angular contact balls or thrust bearings. It is critical to determine the load in pounds or Newtons to be applied to the bearing to avoid excessive wear and damage.

Regularity of maintenance: One solution is to ensure that replacement is frequently performed or the bearing is well lubricated.

In pumps that work in a wet environment, using sealed or shielded bearings reduces the chances of contamination. In contrast, the pumps are subjected to higher reliability in heavy-duty industries where oil lubrication is used.

By calibrating these parameters to the pump specification, I ensure that the decision to procure the bearing, the selection of the bearings, and the application requirements are harmonized.

How do angular contact bearings enhance pump performance?

Advantages of angular contact ball bearings

Angular contact ball bearings are fabricated to bear radial and axial loads equally effectively, rendering them flexible when applied in pump systems. The more considerable axial load capacity results from the angular contact configuration, which transfers the axial load through the diagonal face of the bearing. It also reduces friction and increases the contact ratio, leading to better performance. Key features include:

High Axial Load Capacity: Allowing large axial loads to be axially directed in a single application is best suited for pumps that survive due to axial thrust forces.

High-Speed Performance: Thanks to decreased friction at the ball-raceway interface, high-speed diminutions can be effectively managed, which are necessary for the pump to work better in various situations.

Improved Rigidity: The contact angle helps increase the rigidity of the structure, which allows in out-of-surface shaft tuning and elimination of shaft vibrations.

Duplex Pair Configurations: Back-to-back (DB), face-to-face (DF), or tandem (DT) arrangements are classic ways to share load and improve performance at low or high pressure.

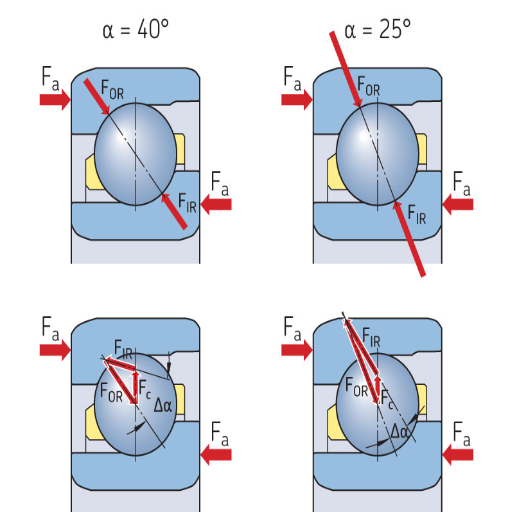

Generally, operational parameters for angular contact ball bearings may have 15°, 25°, or 40° contact angles. The larger the angle, the better the axial load capacity, available in chrome steel or ceramic materials, coupled with modern lubricants to reduce wear and tear while assisting with longevity, thus ensuring that the pump works effectively.

Managing axial loads in pumps

Regarding appropriate bearings and configurations against the delusion of axial loads in pumps, I consider the operating conditions and the load that should be handled. In the case of angular contact ball bearings, I take into account the following technical characteristics:

Contact angles: I consider 15°, 25°, or 40° to accommodate axial and radial loads requirements. Pumps that predominantly have axial loads employ 40° angle contact bearings.

Material selection: I choose chrome steel for its strength and toughness, or, in high-performance applications, I employ ceramic because it is lightweight and low-friction.

Lubrication: I apply modern lubricants to prevent wear and tear, increase efficiency, and prolong life in areas where I foresee harsh conditions.

To allow optimum bearing stuffing and suit the pump’s operational characteristics, I adopt tandem (DT), face-to-face (DF), or back-to-back (DB) arrangements. This enables efficient, reliable, and sustained pump performance while solving the challenges of the axial loads.

Role of angular contact bearings in compressors

Angular contact bearings are indispensable components in compressor units. They support axial and radial loads, ensuring the desired level of reliability and accuracy. In my experience, these bearings are highly appropriate for compressors since they are designed for high-speed applications with combined loads. By applying the right preload, I can obtain shaft positioning, which minimizes vibration and hence improves the efficiency of the compressing process.

Contact angle: Normally 15°- 25° for better axial load capacity.

Dynamic load rating: Works for the task allocated to the compressor while considering its continuous operating time to facilitate an adequate workload.

Lubrication: Do not considerably compromise any dry form or grease lubrication. Instead, select where the hydrodynamic can be applied to reduce wear and friction losses and extend the lifespan of the components.

Material composition: For a high-capacity load and strength against fatigue, steel or ceramic variants of greater tensile strength are implemented.

These parameters ensure that the angular contact bearings can withstand the further imposed or applied requirements that are detrimental to the operation of the compressor, enabling it to function optimally.

What causes bearing failure in pumps and compressors?

Identifying signs of premature bearing failure

Some key indicators help me detect premature bearing failure in pumps and compressors. The first of these indicators is hearing strange noises, for instance, grinding, squealing, or clicking. Such noises usually indicate wear or damage to the bearing surfaces. Moreover, if the pump moves above the specified operating temperature, the indication is also not good as it would imply internal wear. These high temperatures result in more aggressive wear and even the potential of altering the material’s structural properties, for example, the hardness of high-strength steel or ceramic materials.

Another indicator I use methodology is to analyze vibration because a rise in vibration attributes hectic and lateral attributes such as imbalance, axial misalignment, and other surface defects within the bearing. In monitoring these variables, I measure:

Temperature: Consistently higher than normal temperatures (>140° F / 60°C) could suggest lubrication breakdown or overload.

Lubrication Condition: Insufficient or contaminated lubrication, leading to increased friction and wear.

Vibration Levels: Early signs of bearing damage due to increased frequency or amplitude beyond system specifications.

Material Fatigue: Cracks, spalling, or any other type of deformation on the visible surface are sure indicators of a material fatigue threshold.

These technical parameters can be monitored promptly, thereby providing the basis for making an early diagnosis of the root cause of the problem and employing timely preventive measures such as repair to ensure increased pump and compressor working life.

Common causes and prevention of bearing failure

In my opinion, bearing failures can nearly always be traced to a few root causes, and these causes can be dealt with predominantly. The common causes, quantitative parameters, and technical interpretation are as follows.

Lubrication Issues: A lubricant deficiency or a lubricant contamination can single-handedly result in bearing failure. The performance indicators I watch are how much oil, viscosity, and other contaminants are available while operating. Operating oil in moderation and proper grease intervals goes a long way in preventing lubricant deficiency.

Misalignment: When shafts or housings are out of alignment, too much force is applied to the bearings. All of my machines have ERP systems. I use laser alignment tools to check shaft alignments within the ISO tolerances (angular misalignment between 0.04 mm and mm).

Excessive Loads: As the elements are designed for limited loads, bearings fail too early when subjected to loads higher than those within the design limits. A stress analysis confirms load conditions are within the bearing load limits (C or C0), and hence, I evaluate the stress levels to avoid overload.

Contamination: Substances like dirt, moisture, or debris that come into contact with the bearing interfere with its movement. I check for seals and contamination levels through vibration spectral analysis and its characteristic defect frequencies.

Improper Installation: I avoid damaging bearing surfaces due to incorrect mounting methods, such as inappropriate use of induction heaters, hydraulic nuts, etc., by adhering to the manufacturer’s prescribed installation methods.

Considering these factors and controlling the technical parameters within the permissible limits and range helps reduce the probability of bearing sealing failure and increases the pumps’ and compressors’ overall reliability and operational life.

Impact of contamination on bearing reliability

The reliability of a bearing is adversely affected by contamination, as the introduction of foreign particles can result in abrasive wear, increased friction, and even complete failure. To address this, I accentuate the necessity of a clean working environment and adopting effective sealing techniques to help stop contaminants like dirt, moisture, and dust from entering. In addition, I also stress the point of lubricating with proper solvent, which is clean and filtered and reduces the contact stress and wear.

Particle Size and Concentration: I apply the best possesses based on ISO 4406 cleanliness codes for lubricants, preventing contamination from exceeding the threshold limits.

Seal Effectiveness: I always use seals that can withstand attack, such as a labyrinth or contact seals, and are suitable for the working environment.

Lubricant Viscosity and Purity: I check solids’ lubricant viscosity and content to ensure they suit both appropriate viscosity and particle content limitations.

Using these practices would increase the life of bearings, minimize downtime, and improve the reliability of the entire system.

How does lubrication affect bearing reliability?

Importance of proper lubricant selection

The correct choice of lubricant is key to bearing life related to wear, bearing load, and heat management. In my practice, there is always a concern for matching the lubricant viscosity with the speed and load that the bearing works within. For example, a low-viscosity lubricant can be applied to a high-speed bearing rather than a heavy-duty one, which will perform better with a viscosity lubricant. Moreover, I select a lubricant whose operating temperature matches the system conditions, often involving selecting lubricants with high thermal stability where extreme conditions would be required.

I am also sensitive to lubricant additives like anti-wear agents or corrosion inhibitors, which enhance bearing performance when the operating conditions are harsh. Additionally, I watch out for contamination and control it within ISO cleanliness subcategories to avoid the chances of bearing failure due to the environment. These technical parameters are crucial as they dictate whether the lubricant provides sufficient film separation between the contact surfaces while maintaining its structure during wear.

Ensuring the service life of bearings through lubrication

In providing the service life of bearings through lubrication, I always strive to put in place a holistic technique to solve the critical technical parameters. For example, I select a lubricant appropriate to the operating speed, load, and temperature. For instance:

Viscosity: As I am concerned with the lubricant’s intended temperature region, I see the lubricant selected for application has the appropriate viscosity index. This enhances film formation and reduces wear.

Additives: I also select lubricants containing anti-wear agents, antioxidants, and corrosion inhibitors, which further increase durability and protect against oxidative breakdown and surface damage.

Contamination levels: ISO cleanliness codes are kept within acceptable limits to reduce particulate and moisture contaminants that may cause premature wear and failure.

Thermal stability: This lubricant must function under extreme heat and cold conditions without breaking down to retain desirable properties.

I also established adequate maintenance management for the lubricant application. This entails constant supervision, such as oil sampling, condition monitoring, and other measures to look for early contaminants or breakdown signs. Considering these parameters, I ensure that the proposed lubrication regime significantly increases the bearings’ working life under different conditions.

Addressing lubrication issues in high-speed pump applications

In addressing a lubrication problem in accelerated pump workings, my strategy revolves around understanding and controlling the several key technical parameters that assist reliable functioning:

Viscosity selection: A pump speed and load combination determines the lubricant’s viscosity at the pump. For high-speed pumps, it is common to lower the viscosity level to minimize internal friction and heat while still obtaining an adequate lubrication film. Such is the case, depending on endorsement and shelf requisites set by ISO viscosity grade.

Contamination control: Contamination is among the most critical problems in high-speed pumps. I also use a high-speed pumping system that conforms to ISO 4406 code limits and has status-sensing devices to reduce the chances of wearout and even failure.

Temperatures: Operating and surrounding temperatures are controlled to avoid exceeding the desired lubricant limits. I prefer synthetic formulations with better oxidation and thermal stability ratings in extreme temperatures.

Lubrication delivery: For High-speed pumps, mist, and circulating oil systems are some ways to douse components that move fast due to heat build-up quickly.

By sequentially addressing these parameters, I have significantly reduced the chances of pump failures due to lubrication.

My method revolves around active monitoring, appropriate lubricant specification, and delivery optimization– enabling high-speed pumps to operate suitably in critical conditions.

What is the role of magnetic bearings in modern pumps?

Benefits of magnetic bearings in reducing wear and tear

Magnetic bearings are critical in mitigating the impact of wear and tear mechanisms in today’s pumps by avoiding direct contact with the rotating and stationary parts. Unlike mechanical bearings, Electric motor-powered magnetic bearings operate through an electrical field that floats the shaft, eliminating mechanical contact. This means that the mechanical movement and electricity-powered components require less frequent servicing, and the electric system designed with that component can last longer.

Load Bearing Capacity: Magnetic bearings have large radial and axial separation loads, resisting contact between surfaces. Hence, relatively less wear is experienced over long periods.

Control: A bearing tune-up enables better shaft placement performance and minimizes the vibration that imbalances would otherwise cause.

Temperature Resistance: Instead of being ineffective, a suspended bearing can withstand even exceedingly challenging heat that would deteriorate an ordinary bearing.

Energy Loss: An Improved Pump bearing means friction is minimized, minimizing energy loss and enhancing the pump.

Considering these features, magnetic bearings are most suited for high-performance pumps which require endurance and reliability.

Application of magnetic bearings in high-load environments

Since they operate without touching each other, magnetic bearings do not suffer excessive wear and tear and can withstand great strain, making them appropriate for high-load settings. The best thing about them is that they can withstand radial and axial loads, which is often the case with industrial machines. For instance, the system design allows magnetic bearings to quickly transfer radial loads reaching 200 kN, and axial loads yield as much as 50 kN. These parameters are easily accounted for with their advanced electromagnetic fields and good engineering standards.

Moreover, the absence of mechanical contact dramatically reduces the heat formed, which is a significant aspect when working in high-temperature settings. In my particular case, I’ve seen magnetic bearings perform pretty well at temperatures reaching 300°C and still retain accuracy. They also do not border on inconsiderable, as their energy efficiency does stand out with the absence of frictional movement of parts elements, energy loss can easily reach 40% lowering power consumption. These through mark them suitable for turbine systems and other applications such as compressors that experience heavy-duty applications with little to no wear and tear.

Magnetic bearings compared with other types of bearings

Although the use of magnetic bearings as a substitute for traditional bearing types has been discussed, the main differences, especially in their performance and efficiency, are apparent. Thus, in my opinion, the defining advantage of magnetic bearings is that they are non-contact. This feature, in turn, eliminates the prevalent reason in traditional roller or ball bearings, which is contact and, therefore, wear and heat generation. For example, while conventional bearings tend to operate within the generational efficiency of 80%-90%, adopting magnetic bearing usage can increase energy efficiency by 40%.

Another aspect that sets them apart is sustaining significant loading operational temperatures. The ongoing works show that magnetic bearings can withstand radial loads of up to 200 kg. and axial loads of up to 50 kg. As already highlighted, traditional bearings have more limitations and are usually oil-lubricated to operate under such loads. Furthermore, magnetic bearings retain accuracy in high-temperature applications, reliably working up to 300 °C. However, traditional bearings are prone to deterioration or require eccentric materials to tolerate such environments.

Magnetic bearings also have an edge over traditional bearings regarding vibration since they are equipped with active control systems. Furthermore, their maintenance needs are less since mechanical wearing is eliminated. This results in minimal deterioration over time and lower operational costs. These aspects, reinforced by the technical specifications, explain why magnetic bearings are utilized in high-demanding devices such as compressors and turbine systems.

Frequently Asked Questions (FAQs)

Q: Why do you use deep groove ball bearings in pumps?

A: Deep groove ball bearings have several advantages in pump assemblies. They can accommodate radial and axial loads, have a low friction coefficient, and operate at very high speeds. These bearings are crucial in small-sized pumps, where vibration levels are kept relatively low and efficiency is high. They are also utilized in power and wastewater treatment operations because they are efficient and trusted.

Q: What advantages do cylindrical roller bearings have for large pumps in the oil and gas industry?

A: Large pumps in the oil and gas industry can significantly benefit from cylindrical roller bearings due to their high radial load capacity. They are capable of withstanding higher weights and pressure while maintaining stability. These bearings are manufactured to accommodate high radial loads, typical in oil and gas applications and large pumps. Their design is also expected to reduce asserted downtime and maintenance costs incurred in oil and gas operations.

Q: What are the benefits of using thrust bearings in pumps?

A: In pumps subjected to severe axial loading conditions, thrust bearings are beneficial. It is intended to absorb the axial thrust developed by the pump’s impeller to correctly position the shaft with minimum wear on other machine parts. Thrust bearings are, for instance, necessary in vertical pumps and positions where the head of the pump generates substantial axial loads. These elements are fundamental for the pump’s performance and lifetime extension.

Q: What is the role of single-row angular contact ball bearings in pumping applications?

A: Single-row angular contact ball bearings help pump applications because they can simultaneously withstand radial and axial forces. They are pretty effective in systems where the force of two types acts on the pump simultaneously. These bearings offer a decisive advantage in supporting the rotor of the pumps and allow them to run at high rotational speeds. They are commonly found in power generation and industrial pump activities that require high reliability and accuracy.

Q: What are the benefits of using tapered roller bearings in pump applications?

A: Tapered roller bearings benefit pump applications when axially and radially oriented loads are present. Their angular regulation allows for appropriate adjustment on par with radial hydraulic torque on large pumps. This bearing type can sustain axial active loads on one face and is commonly found in the US’s high-thrust radial industrial pumps. They are also angle bearings and are essential in all pump systems where load conditions are not constant, as in the oil and gas sector.

Q: What role do self-aligning ball bearings play in the pump’s working?

A: Self-aligning ball bearings play an essential role in pump performance by allowing for shaft misalignment and deflection. This is useful when working with pumps or systems in constant vibration or when they are too large to easily align accurately. Usually, such stresses would harm the hull integrity as damage accumulates. Still, in this case, the glue bonds throughout the pump help dissipate such stresses and reduce friction, increasing efficiency. These are frequently used in pumping systems of wastewater treatment plants and other systems that run in environments that might cause imprecise alignment of specific components.

Q: What are the benefits of using ceramic bearings in pump applications?

A: First and foremost, against the backdrop of the challenges mentioned earlier ceramic bearings in pump applications have many advantages on the stance of corrosion; these pumps can handle more complex applications. Cement reinforcement also does well in harsh conditions, as it wears away more slowly at higher temperatures and requires less lubrication. These qualities make them especially effective in pumps that need to be operated in a chemically active midst and in those areas where conventional setups made of metals would not be able to work due to environmental stressors. Moreover, considering the maintenance requirements are lower than those for metal units, ceramic bearings appear to endure longer.