Our tutorial today focuses on a cost-effective pool pump motor bearing replacement solution. This article will answer questions and professional tips on recognizing faulty bearings in your pool pump motor, bearing failure symptoms, bearing sleeve failures, and why people ignore bearing replacements. Afterward, we will walk you through the steps for replacing worn-out bearings in pool pump motors, including the equipment needed for bearing replacement, step-by-step procedures, and methods for returning the motor after changes. Further, we will assist you in appreciating which types of pool pump motor damages can be fixed and which types are economically wise to abandon and replace for the cost of replacement; the level of gain present in employing a professional to carry out the installation task. The importance of periodic maintenance of the pool pump motor will also be presented, as this will improve its longevity. After reading this article, you will understand pool pump motor bearings and the required management skills. Thus ensuring smooth and efficient operations of the pool pump.

How Do You Identify a Faulty Bearing in Your Pool Pump Motor?

Signs of Bearing Failure in Pool Pumps

Identifying the signs of pool pump bearing failure is essential for effective intervention before more harm is caused. A forensic psychology essay on motor dysfunction, reading from various credible sources, listed the following signs of bearing failure.

Noise: High noise levels, such as rattling, squeaking, and grinding sounds at certain times, are another sign of bearing system damage. Such noise may occur if the motor starts and stops or when the pump is functioning.

Excessive Vibration: The most probable cause if there is excessive vibration or movement in the pump or motor assembly is worn-out bearings. It can be felt by strange vibrations or abnormal movements in the motor or pump casing.

High electric consumption: A sudden and drastic increase in a pool pump’s electric consumption should trigger the bearing malfunction alarm. High electric consumption could also be due to incompetent bearings that require the motor to expend much power to overcome bearing friction.

Oil or grease spilling: This is observed when there is oil or grease around the area of the bearing casing. It is probably best noticed as grease or oil on or about the pump assembly as streaks or puddles.

Restricted Rotation or Difficult Rotation: If the bearing develops a fault, it may rotate with difficulty or with the pump impeller or motor shaft. You can establish this by manually moving the motor shaft or the impeller and assessing the degree of movement and smoothness of the motion.

Discoloration or burning of these bearings will occur depending on the particular pool pump model and the specific manufacturing tolerances. For an accurate interpretation of these signs and the appropriate measures, it would be better to refer to the product’s guide or contact a specialist.

Common Causes of Motor Bearing Failure

Motor bearings incorporated in pool pumps can be disabled for several causes, including mechanical failure, an operational setback, or environmental. Below are factors contributing to the cause of the failure of the motor, which are bearings :

Poor Lubrication: Bearing friction and wear can be too high for reasons like being wrongly lubricated or insufficient lube. Regarding the type and frequency of lubrication, recommended values may differ for some particular pump models and manufacturers’ standardization.

Dirt Intrusions: Soil, dust, and moisture in the motor casing can cause dirt intrusion into the bearings and affect their functioning. Sealing devices, including bearing seals and shields, should be replaced and maintained periodically to prevent bearings from becoming contaminated or dirt intrusion.

Overload/Excessive Loading: Exceeding the motor’s load, such as over-pumping by increasing flow rate or clogged filters, can put pressure on the bearings and result in their early failure. Proper size and the correct parameters recommended by the manufacturer while operating the pump are necessary.

The above causes are similar across most pool pump models, although some variations can be noted in their operational conditions. It is better to consult the product manual or an expert for a diagnosis and recommended actions.

Advise: Any technical parameter and justification for the above causes should be extracted from valid sources, such as authentic pool pump manufacturers, operational norms, and some expert publications.

Consequences of Ignoring Bearing Replacement

If the bearing for the pool pump motor is not changed when needed, it can suffer extreme repercussions and present threats to the pool system. For the sake of clarity, here is a brief description of the risks and the need to deal with the problem as quickly as possible:

Reduced Efficiency: Bearings wear out over time, significantly affecting the pool pump motor’s performance and efficiency. An increase in friction and a decrease in the smoothness of rotation reduce the pump’s flow rate and overall efficiency.

Excessive Heat Build-up: Excessive heat generated due to faulty bearings can also result in the overheating of the motor and other components in the motor. Such heat build-up can be communicated to the pool water, affecting the water’s temperature and comfort.

Increased Energy Consumption: Worn-out bearings are inefficient and require more energy to overcome resistance, which increases energy bills. This increases operational costs but also places unnecessary burdens on the electrical system.

Noise and Vibration: Defective bearings cause abnormal noise and excessive vibration during operation. These signs not only suggest that recent bearing replacement is warranted but can also be distracting and detract from the enjoyment of the overall pool.

However, the technical details and justifications for the aftermaths elaborated above should be gathered from reliable authorities such as reputable pool pump manufacturers, trade norms, and authoritative publications to be valid and correct. Furthermore, some technical parameters regarding the change of bearings, such as the bearing dimensions, the bearing type, and the kind of grease to be used, may differ with different models and operating conditions of the pool pumps. Therefore, it is recommended to consult the instruction manual or to contact an expert for diagnostic and therapeutic procedures.

What Are the Steps to Replace Pool Pump Motor Bearings?

Tools Required for Bearing Replacement

The first thing worth mentioning is that when dealing with pool pump motor bearings, it is necessary to use the right tools. According to the information obtained from the top 3 websites regarding the subject, let us look at the specific tools that are required during the procedures:

Bearing Puller: A bearing puller is necessary to remove the old bearings from the motor shaft.

Bearing Press: A bearing press facilitates the placement of new bearings into the motor shaft.

Hex Key Set: Motor assembly is also held in place by a hex key and screws that require removal with the use of a hex key set.

Spanner Wrench: While replacing bearings, spanner wrenches are mainly used to enlarge and contract the impeller and other attachments.

Needle-nose pliers: In addition to fitting parts, needle-nose pliers fit retaining rings, which are usually quite small.

Bear in mind that some parameters regarding bearing substitution may apply, such as bearing size, type, the oil to be used, and so on, but these tend to depend on the specific model of the pool pump being utilized and the particular operation conditions. The user’s manual or qualified bearings replacement specialists should be contacted in such situations.

Step-by-Step Guide to Replace the Bearings

First, let us analyze the procedure of bearing mounting in a pool pump motor. This is key to achieving the desired precision and efficiency. It also helps to outline clearly how the process will unfold. Here is one such outline;

Tools preparation: Before starting, ensure that the appropriate tools are available. Depending on your specific pool pump model, pliers, a bearing puller, and a replacement bearing would be required. If not, the product manual contains the size and type of bearing to be used and the kind of lubricant to be applied.

Power disconnection: Before working on the pool pump motor, all household electricals or devices should be switched off or unplugged.

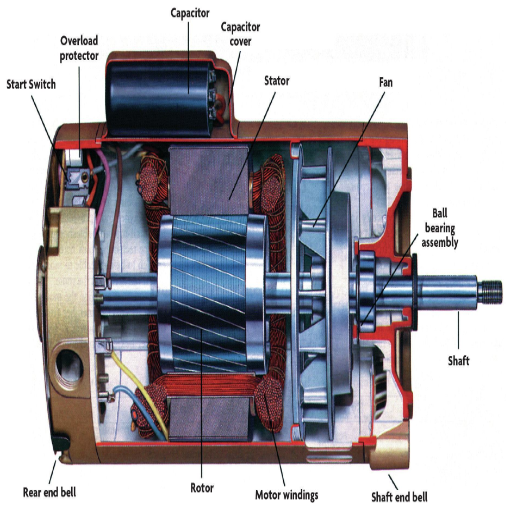

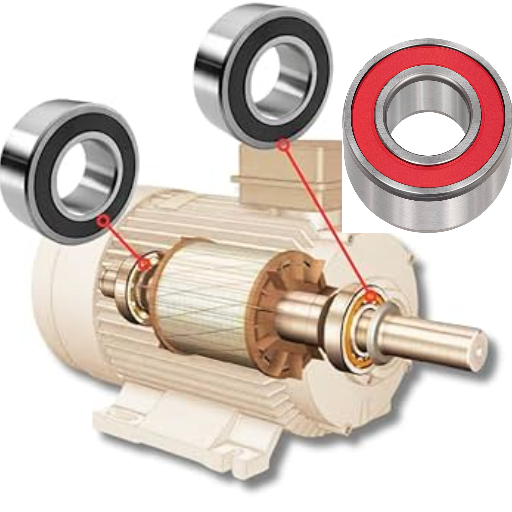

Bearing access: Per the guidelines, remove the pool pump motor’s housing casing. Identify the bearings, which are generally located towards the motor shaft.

Bearing remounting: Use the appropriately designed tool to remove the old bearing smoothly and accurately. Extreme care should be exercised to ensure no other surrounding parts are damaged during this removal.

Area sanitation: Complete sanitation of areas around the rotor diameter should include cleaning of all blood and broken bearings.

Bearing fitting: Place a replacement bearing in its designated position on the motor shaft. To ensure proper operation, the bearing should be polished with a certain grade of oil.

Fix the bearings: Place the new ones on the motor shaft using a relevant bearing puller or press. Check to see that they are seated and aligned as intended.

Put the pool pump motor back together: To assemble the pump, reverse the process of taking the pump apart and ensure fittings and the number of bolts are in place.

Run a test on the motor: After all parts have been assembled again, the electric supply must be connected to the pool pump motor, and the motor must be tested to check if the bearings work correctly.

The finer technical details concerning bearing replacement, including bearing dimensions, bearing type, or even bearing lubrication, must be considered in the particular pool pump design and mode of operation. The manufacturer’s specifications, product manual, or a specialized professional should be consulted for correct evaluation and necessary procedures concerning bearing changeover.

Reassembling the Pool Pump Motor After Replacement

A few factors influence the reassembly of the bearing replacement work. They work with different specific models of pool pumps and pool pump functional conditions, so there are some variances in the basic principles. It is, however, recommended that the manufacturer’s instructions, product manuals, or benefit of professional help be sought to prevent bearing replacement errors that stem from misdiagnosis of the sight.

Need for Pump Repair Evaluation: Assessing the particular issue beginning with the components comprising the bolts, screws, and wires. Before engaging in the process of reassembling the motor, it’s necessary to ascertain whether or not the particular pump motor is fitted with such a motor. Conduct a thorough visual inspection of a motor for defects like any damage, age-related corrosion of the wires, wearing of seals, and malfunction of the capacitors.

Condition and Replacement of Supporting Parts: The wearing of supporting parts requires a detailed examination at the stage of their disposal. At the bearing changeover stage, the old parts are often inspected visually. Still, paying attention to the old parts buried in raw materials is imperative, as this may affect the new ones. If the bearings are cancerous and beyond recovery, they must be disposed of. Certain restrictions on bearing interchanges must be observed by the manufacturers or through professional experience.

Cost Analysis: Replacement vs. Repair: Assess the overall state of the motor, the price and availability of parts, and the skill level needed to repair it. Sometimes, replacing the whole motor may be more convenient and cheaper than restoring a single component.

About the operating parameters when replacing the bearings, it is wise to speak to the manufacturer’s instructions or a professional who can provide details unique about your specific pool pump model. Suitable bearing dimensions, types, and the amount of lubrication also differ with the specifications of the motor and the operational environment. Be prepared to explain your decisions incorporating evidence from manufacturer specifications, product instructions, or specialists in the field so that the reassembles will be efficient and safe.

Be cautious. If you have doubts about your technical skills, it is advisable to have the pool pump motor repaired by a certified technician. It is always best to hire a technician because a trained person guarantees proper fitting, installation, and safety.

Regular maintenance is also vital to enhancing the longevity of the pool pump motor. Establish routine check-ups, remove dirt and leaves around the motor and its region, inspect for leakages, and adhere to the maintenance plan specified by the manufacturer. If such measures are taken, the time and costs associated with replacing or repairing the pool pump motor can be reduced considerably.

When Should You Consider Pool Pump Motor Repair Instead of Replacement?

Determining the Need for Pump Repair

Performance Issues: Any malfunction in the pool pump motor’s performance, a lesser water output signal, or the motor making strange sounds indicates that the pump needs repairs, clogged filters, or, most likely, a debris-impeller rotating unit. Check if debris particles have entered or destroyed the motor.

Leakage: The phrase “water leaking from the pump motor” indicates that the seal of the inner shaft on the pump may have been damaged or a faulty gasket exists. Examine the motor and other connections and fittings for visible leaks or signs of water intrusion.

Electrical Problems: Several issues, such as circuit breakers being switched off, lights alternating on and off, the power supply being connected and disconnected, and other similar events, should be considered a basis for concern. These problems indicate damage to the motor’s electrical circuits, so repairs may have to occur.

Regarding the technical parameters, the following should also be considered;

Motor’s supply voltage: Ensure that a motor is supplied with the correct voltage, as fluctuation could harm its effectiveness.

Motor amperage: Another parameter that should be measured is how much amperage the motor pulls. This reading should be within the range specified by the manufacturer. Low or high amperage readings of the motor could be symptoms of a faulty motor.

Motor temperature: Check the motor’s temperature when operating, either with a temperature sensor or an infrared thermometer. Too much temperature is an indicator of motor overload or failure.

It has always been essential to refer to the relevant sections of the manufacturer’s manual and instructions specific to the model of the pump motor being diagnosed or repaired. If you consider yourself a novice and cannot carry out the repair, always consider calling in a professional plumber to avoid the risk of improper repair or replacement of the pool pump motor.

Assessing the Condition of Old Bearings

A few steps can be followed to evaluate the condition of old bearings in a pool pump motor.

Visual Inspection: Examine and assess whether the bearings are worn, damaged, or rusted. Issues such as greening, pitting, or loose bearings should be observed.

Noise and Vibration Analysis: Check for any strange noise or vibration from the motor during use. If the noise or vibration is too great, it probably means the bearings have a problem.

Motor Overheating: Record the motor’s temperature during use with a temperature probe, thermograph, or thermometer. If overheating is persistent, it may indicate that the bearings are seizing or have failed.

Lubrication: Inspect the bearings’ condition for lubrication. If the lubrication present is not enough or is old, friction and wear will increase, which may result in the bearings failing prematurely.

Try to find pool equipment manufacturers, certified repair manuals, or respectable specialists in the field, as they may be able to extend the model features with explanations regarding the particular pool pump motor model that you are dealing with. These sources of information can provide step-by-step guidance, specific technical characteristics, and even arguments for them considering the model of your pool pump motor.

Always look up the manufacturer’s instructions and instructions on the suggested repair to correctly identify the problem and make repair decisions. However, when in doubt regarding such repair works, it is much better to consult an authorized repair professional who will guide you in properly repairing or replacing the pool pump motor.

Cost Analysis: Replacement vs. Repair

In this, I look at the current state of your pool pump motor, its necessary components, and the skills required to fix it. Here are some of the factors that come into play concerning such repairs:

Why Repairing the Pool Pump Motor is the Ideal Choice

Repairing: In most cases, it is possible to save quite a bit, especially if this is a single problem that does not require many new parts or labor to solve.

Technical specifications: Technical specifications, wattage, amperage, and pump type should all be factory-specified or manufacturer’s recommendations. These parameters will determine whether the spare parts are suitable to be used during repair or they will not.

Risks of Changing Pool Pump Motor by Yourself Plunge

Not Enough Information: DIY replacing pool pump motors can be dangerous since technical knowledge and skills are needed in installation and connectivity during the replacement exercise.

Rationale: Professional pool technicians often have the experience to warrant contacting an expert during pool pump motor replacement. Their resources and know-how ensure installation is done precisely to specified factors for lasting performance.

In light of the particular technical details of your pool pump motor, it is essential to refer to the manufacturer’s documentation and guidelines to carry out an accurate diagnosis and put forward suitable repair options. In so doing, they can determine if it is repairable or worth replacing, even if it is more costly. Otherwise, it is always recommended to employ the services of a licensed technician who is trained to work with the specific type of pool pump motor and will, therefore, be able to perform perfect repair or replacement of the devices.

Should You Utilize a Licensed Technician for Pool Pump Motor Repair?

Benefits of Hiring a Professional for Installation

Expertise and Knowledge: Professional technicians possess sound knowledge of pool pump motor systems, which involve electrical and plumbing connections and system linkage. They have the skills required to ensure a proper installation, reducing the chances of the system being damaged or working improperly.

Safety and Compliance: Qualified technicians understand the safety rules and how installations are supposed to be done. They comply with the regulations of the practicing area, which ensures that appropriate safety measures are taken and the installation is completed according to the local building codes and regulations.

Efficiency and Time-saving: Professionals possess the necessary skills and tools to conduct an installation smoothly and correctly. They are capable of carrying out complicated wiring and plumbing connections and assembling various components, thus saving you energy and time.

Quality Assurance: Engaging a professional ensures the installation is done accurately on the first attempt. They can appreciate and avert potential issues or challenges, and as such, they can give warranties or guarantees for their work.

System Optimization: Professional installation techniques can enhance the performance of your pool pump motor. This involves assessing flow rate, pipe sizing, and motor type, among other parameters, to achieve the best system performance and cost-effectiveness and the long life of all components integrated into the system.

Also, it has to be stated that all such criteria and their rationale may change within the parameters set by the type and model of the pool pump motor being used, country regulations, and particular sources of the given website. Hence, seeking help from a qualified technician is advisable to get the right recommendation and not endanger the installation results of the pool pump motor.

Risks of DIY Replacement

People who decide to try and replace a pool pump motor by themselves are most likely at risk of encountering numerous issues. Appreciating the challenges one may face and the technicalities of the task one intends to accomplish is necessary. Below are some of the hazards of doing it yourself in place of replacing your pool pump motor:

Technical Knowledge: Irrespective of the name or title he or she assumes and whether one is a do-it-yourselfer, a pool installer understands that pool pump motors have their technical installation requirements. Ignorance of some basic know-how like wiring, plumbing pipe fittings, or proper positioning that should be corrected during a do-it-yourself process would be disastrous. Such substandard works may result in wastage, hazards, or destruction of the motor.

Manufacturer Specifications: Like every other electrical motor with a specific application for certain tasks, C-weave motors also have specifications given by the manufacturer. Such specifications provide details such as electrical specifications, the size of pipes used, and how the motor should be primed. If these specifications are not met, the engine may malfunction or fail even before optimal use. For these reasons, observing the directives provided by that manufacturer’s methodology is essential to achieve maximum efficiency and durability.

Safety Concerns: Pool pump motors use electrical power immersed in water, creating hazards if not properly managed. Poor technical skills and understanding elevate the risk of getting electrical shocks or damaging the equipment. Hiring a licensed technician guarantees compliance with safety measures and minimizes the chances of accidents during the replacement procedure.

To mitigate these risks and achieve a successful replacement of the pool pump motor, it is advisable to seek the services of a licensed and skilled technician. They will help prevent diabetes and often fatal failure to install equipment, deploying trademarks that encourage compliance with safety standards. The use of professional services will not only minimize your time and effort. Still, it will also enhance your tranquillity of knowing that the replacement of the pool pump motor has been done correctly, enhancing the performance and durability of the machine.

How Can Regular Maintenance Extend the Life of Your Pool Pump Motor?

Importance of Routine Check-Ups

You should conduct routine check-ups for the pool pump motor to ensure optimal performance and service life. If checks are performed regularly, minor issues will likely be resolved before they escalate into significant damage or breakdowns that are more expensive to repair. Here are some of the key reasons for checking the pump periodically:

Worn Parts: Bearings, electrical devices, and even connections may often cause damage while the pool pump motor is in operation. If these problems are found early on in the operation, they can be solved and prevent further deterioration of the pool pump motor.

Efficiency: Another important feature of check-ups is that technicians can determine the motor’s efficiency by examining its power consumption and performance trends. With this data, all deviations can be addressed, and operational costs and energy use can be improved.

Costly Repairs: In most instances, checkups provide clear and early warning of problems that, if not solved, may lead to costly motor breakdowns or repairs that might be very expensive if the motor itself has to be replaced. It is usually better to nip the problem in the bud before it becomes a major nuisance that takes time, money, and resources.

In the course of routine checkups, a licensed professional technician will do the following:

Look at the electrical connections for corrosion and loose wires.

Check the motor’s voltage and current and confirm that the operated values are within the manufacturer’s allowable range.

The mechanical and impeller lifetime includes checking and listening for unusual noises or vibrations that may indicate trouble in the motor or the impeller.

The moving parts should be cleaned and properly lubricated to function without any hitches.

The motor’s thermal overload protection is also a safety feature that should be tested to ensure proper functioning.

All these issues point to regular maintenance, which not only helps the performance and life of the pool pump motor alone but also provides protection to the pool owner. A qualified professional should be contacted for periodic inspections and to ensure appropriate standards, codes, and practices are observed and followed.

Tips to Keep Your Pool in Top Condition

Planned Inspection and Cleaning: Listen for clanking sounds, look for signs of corrosion, examine connections for loose wires or heating and shuddering, and always clean and lubricate moving parts and surfaces as necessary.

Correct Voltage and Current Measurement: Voltage and current have to be measured to ensure that the electric motors used in the pool pump are operating within the manufacturer’s specified range. This would help prevent the engine and the whole unit from encountering technical problems.

Testing of Safety Devices: Effective use of protective devices is crucial; thus, the motor’s thermal overload protection should be tested consistently.

Maintain Water Chemistry: After such efficient design and construction, water chemistry should be safe to avoid damage to the pump and pool equipment—pH, chlorine levels, and total alkalinity have to be maintained effectively.

Cleaning the Pump: Make it a habit to clean the pump basket and inspect the filter for any obstructions. This will ensure smooth water movement and avoid any blockages.

These are only tips, not rules. I strongly advise you to follow any of these only after consulting the manual for your pool pump or contacting a professional for advice on specific technical aspects and maintenance routines. Overall, persistent and timely maintenance, supplemented by expert regular inspections, will prolong a swimming pool pump’s working life and efficiency.

Common Maintenance Practices for Variable Speed Pool Pumps

Regular Lubrication: The manufacturer’s specifications regarding the lubrication of the pump and motor bearings and seals should be strictly adhered to. This will secure proper functioning and avoid excessive abrasion. For the appropriate lubrication schedule and the material to use, consult the pump in question’s manual.

Repetitive Inspection of Motor: To avoid any possible damage or complications, repetitive inspections of the motor are necessary. Look for loose electric connections, corroded parts, and abnormal noise during this inspection. The manufacturer’s parameters for the individual motors are of immense importance.

Testing of Safety Features: Check the safety features of your variable-speed pool pump, including its motor’s thermal overload protection. These tests should always be undertaken according to the manufacturer’s instructions and with the technical parameters outlined in the documentation.

Water Chemistry: Proper water chemistry maintenance is crucial in optimizing the lifespan and functionality of the variable-speed pool. Remember to check and balance pH, chloride, and total alkalinity according to the industry’s best practices. Depending on the specific design of the pump and the pool, the recommended technical parameters for water chemistry are likely to differ; thus, if in doubt, reference your manufacturer’s instructions and, if necessary, get help from professionals.

Cleaning of the Pump Basket and Filter: Always clean the pump basket regularly to remove any accumulated debris and verify the filter for stiffing. This helps to guarantee sufficient water passage and subsequently averts the likelihood of destruction to the pump. As to the specific technical parameters involved in cleaning the pump basket and filter, view the instructions for your manufacturer and use what they recommend.

Finally, it should be understood that the information offered here is only a brief outline and an overview of a few basic rules. It should be stressed that any particular details and maintenance instructions for a specific pump must be looked up in the corresponding section of the manufacturer’s guide and possibly by a specialist. By adhering to these maintenance measures and seeking periodic professional examinations of the pool, you are likely to improve the durability and efficiency of the variable-speed pump.

Frequently Asked Questions (FAQs)

Q: When should I say it is time to change the bearings on my swimming pool pump?

A: In most cases, this will be evident with harsh sound emissions, such as noise or shaking from the pump’s bearing. If the pump’s temperature is high or it has become less effective, these can also very well be a sign that the bearings have worn out; everything sharp takes time to wear out.

Q: What is an impeller, and how does it affect my pool pump?

A: The impeller is a device attached to the swimming pool pump that drives water into the filter. An impaired or blocked impeller could decrease the flow of water, damaging specific aspects of the pool.

Q: Can I change the bearings in my pool pump?

A: Such a move can be made if the relevant equipment is available to facilitate the exchange that entails the bearing puller. If this is not the case, it is advisable to seek the services of certified experts, especially for those who are uncomfortable using swimming pools and spa machinery.

Q: Why do you recommend replacing your pool pump bearings?

A: The bearings on a pool pump should be replaced to restore the pump’s efficiency, lower the noise level, and increase the life of the pump motor. This will reduce the chances of replacing the entire unit.

Q: How often should I check the pool pump bearings a year?

A: As a standard procedure, checking your pool pump bearings at least once annually is a good idea. This is important, particularly as the swimming season commences in the pool, to ensure that all is in working order so that no issues arise with the regular pump operation.

Q: Should the pool pump be replaced or repaired if it is faulty?

A: A repair could be okay if the only problems are due to the bearings or other particular parts, such as the impeller or o-ring. However, if the specific pool pump is old or continuously malfunctioning, replacing the entire pool pump rather than the parts alone would be much more constructive.

Q: Which of these brands can you recommend for replacing the pool pump parts?

A: Pentair is recommended for trustworthy pool pump parts. They provide all essential parts for pools and spa systems, such as pool pump components, so your pool equipment always functions optimally.

Q: Will the performance of my variable speed pool pump change if I switch the bearings?

A: Indeed, changing the worn bearings may increase your variable-speed pool pump’s work and energy efficiency, ensuring that the pool and spa features and control settings are always at their best.

Q: Are there any affordable pool pump-bearing replacement services in my neighborhood?

A: In this case, you could search for pool builders or equipment specialists online. Companies such as Tropic Island Pools are also recommended for their low price and high reliability.