Bearings for water pumps are essential for the correct functioning and durability of different equipment, especially in the automotive and industrial fields. As with other machine parts, water pump bearings experience aging; thus, there is a possibility of failure if these components are not properly maintained or understood. Troubleshooting these problems can consume a lot of time and cost; however, understanding the root causes of these failures and ways to prevent them can drastically reduce the amount of money and time spent on repairs. The following pieces of advice focus on water pump bearing problems encountered most frequently by technicians and their causes and offer solutions to assist users in machine maintenance. From a professional technician to a simple fan of machines, everyone will benefit from this sophisticated knowledge around you.

What Makes a Good Water Pump Bearing?

Key Features of Ball Bearings in Pumps

From my experience, the key features of ball bearings in pumps are the accuracy, strength, and capability to take axial and radial loads. A reputable bearing will facilitate the movement of the pump, diminish its friction, and extend its operational lifespan. These are justified with the following parameters:

Load Capacity: Capable of withstanding both radial and axial forces simultaneously. The average load rating may vary from 1,000 N to 10,000 N based on application and size.

Material Quality: Developed from ceramic and high-grade steel for wear enablement and temperature resistance.

Rotation Speed: In high-performing applications, its active speed ranges from 15,000 revolutions per minute to upwards.

Lubrication Efficiency: Its design retains lubrication, minimizing the impact of wear and heat over time.

Corrosion Resistance: Prevents chrome and stainless steel finishes and coatings, which are used to deter degradation in the presence of water and chemicals.

The attributes mentioned above are crucial for the pumps to be efficient, minimize servicing requirements, and maximize the equipment’s lifespan.

The Role of Rolling Elements in Performance

Let us clarify the importance of rolling elements such as the bearings and rollers in pumping systems. When discussing the functionality and efficiency of pumping systems, rolling elements significantly impact both, directly impacting smooth operation through effective friction reduction. Operational reliability and life cycle directly correlate with the component’s quality.

Technical parameters play a vital role here. For example, the material of rolling elements, such as high-grade steel or ceramics, directly impacts their durability and resistance to wear. Surface finish and precision grades, ISO or ABEC, assist in allowing minimum friction and high-speed rotation, which is critical in load balancing and energy loss reduction. Moreover, benchmarks for minimal acceptable force without deformation are outlined in the load ratings, like how dynamic load capacity is expressed in kilonewtons.

By manipulating these technical parameters, operational costs and downtime can be minimized while pump performance is enhanced. Rolling elements are critical for seamless machine functionality and responsive system performance.

Importance of Lubrication for Longevity

Proper lubrication is essential for optimal function and the service life of rolling elements. Lubricants facilitate the appropriate functioning of pumps. Moreover, adequate lubrication reduces friction between surfaces, decreases wear and tear, and prevents surface overheating. However, inadequate lubrication increases the chances of surface fatigue, scoring damage, and even catastrophic failure.

When examining the technical aspects of lubrication, there are specific parameters to consider.

Viscosity—A lubricant with the correct viscosity should be selected to maintain the proper lubrication film during loading at different working temperatures. A lubricant with too high a viscosity leads to unneeded energy loss, while a lubricant with too low a viscosity fails to maintain the protective layer.

Operating Temperature Range—Lubricating oils must maintain their characteristics within the temperature limits set by the pump. High temperatures may encourage oxidation or degradation, while low temperatures decrease flow efficiency and increase hindrance.

Load-Carrying Capacity—Grease should support rolling elements, particularly during peak pressures, for the best peak pressure conditions. Oil that improves properties for extreme pressure may be required for high-load situations.

Replenishment Intervals—Following the manufacturers’ guidelines for lubricant refill and replacement ensures optimal performance is maintained over time with minimal degradation.

By paying attention to these parameters, I can guarantee that the pumps work adequately, prolong their service life, and eliminate costly breakdowns caused by lubrication failure.

How Do Water Pump Bearings Work in Automobiles?

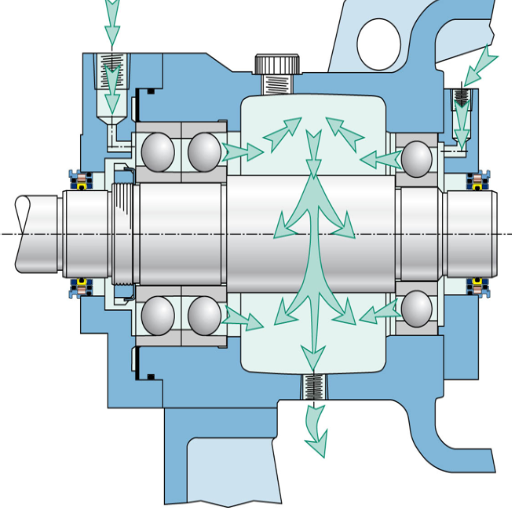

Understanding the Pump Shaft Mechanism

The pump shaft mechanism is a crucial link between the motor and the water pump and transforms mechanical energy to circulate coolant in the system. As per my understanding, it revolves around several key technical parameters:

Material Composition—The pump shaft is usually made of alloy steel with high tensile strength, which allows it to withstand rotational force without deformation or wear.

Torque Transmission—The shaft must absorb and transmit the engine’s torque without loss through precision machining and balancing.

Bearing Support: Bearings along the shaft reduce friction and facilitate effective rotation. They must be of good quality and well-lubricated to reduce operational noise and ensure a longer lifespan.

Alignment and Fit – Components of the water pump are to some extent rotatable to allow effective fit; and align the pump shaft in such a way to connect to the engine components without causing excessive stress to the parts.

Corrosion Resistance—Since the shaft operates close to the coolant, which will corrode over time, coatings or treatments are applied to protect it.

By looking into these aspects, I ensure the pump shaft mechanism is focused, reliable, and efficient for the cooling system of any automobile.

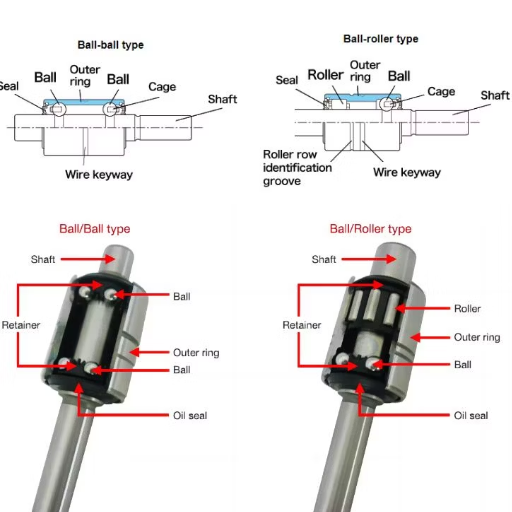

Functionality of Single Row and Double Row Bearings

As a result of their design and application needs, single-row and double-row bearings serve different purposes, and their needs differ. To me, selecting one from the other rests upon the ability to bear load, axial orientation, and duration.

Single Row Bearings – Regarding their dimensions, these bearings form and sufficiently endure radial loads and bear one-sided axial forces. Their uncomplicated design leads to low friction and easement in putting them together. Typically, they suit locations with limited working space.

Double Row Bearings – With their broad capability in load bearing, double row bearings are radial and axial loads regardless of direction. They also have a higher construction stiffness, making them apply in high mechanical working places. Unfortunately, double-row bearings require larger areas for mounting compared to the previous example.

Only with the knowledge of the requirements needed by an application can the exact type of bearing and its placement be done without adversely affecting the system’s longevity and performance. These parameters ensure the purposes they were intended for are achieved.

Impact of High Temperature on Bearing Performance

Meeting the required temperatures for bearings can be challenging, especially in maintaining the system’s reliability. I consider three main issues that come into the picture: material degradation, lubricant failure, and loss of dimensional accuracy. For example, standard-bearing steel begins to lose its ability to retain hardness, and as a result, the structure wears out more rapidly. Proper material selection is vital since high-temperature bearings are made of specialized steel alloys or ceramics, which maintain their structure at 752 °F (400 °C).

The use of lubrication can be a challenge as well. Conventional grades of lubricants do not seem to hold up to high temperatures, so high-temperature lubricants like synthetic oils with antioxidant additives can be used at temperatures as low as -40°F and as high as 482°F. Additionally, clearances within the bearings might require modification concerning thermal expansion and alignment alteration, as well as the load-carrying capacity of the system.

Considering the issues, bearing materials, lubricant grade, and positive tolerances for thermal expansion, I have devised a solution for such extreme conditions. These conditions make load-bearing withstanding at elevated temperatures a challenging task for me.

Why Do Water Pump Bearings Fail?

Common Causes of Bearing Failure

In my experience, the breaking of the water pump bearings arises from a blend of operation factors, environmental factors, and maintenance issues. Given below are the main reasons of the failure, together with the associated technical details:

Overloading

When burdened with a load above their designed capacity, these bearings fail sooner than expected. Factors such as improper shaft alignment or external forces can generate more physical stress on the device than it can withstand. These concerns revolve around load ratings such as dynamic and static and the permissible axial or radial loads specified in the guidelines.

Insufficient Lubrication

Bearings must be adequately lubricated to prevent friction and wear. Using the incorrect lubricant type in the wrong quantity can generate extreme heat, rendering the material useless. Some key parameters are the operating temperatures, such as -40F and 250F, and the lubricant viscosity. The values above are critical when considering bearing insulation. Moreover, relubrication intervals help determine the optimal lubricant quantity.

Contamination

Clearwater, dust, or particulates penetrating the bearing can restrict efficient functioning by damaging the rolling parts or the races. Quality of the seal can either alleviate or worsen this issue, as shaft seals or housing designs need to conform to water and dust resistance standards.

Thermal Expansion

If temperatures change significantly, materials expand, which can cause problems with bearing clearances and alignment. Therefore, it is essential that the bearing has the proper thermal tolerances for the material and the expected operating temperature range (-40°F to 482°F / -40°C to 250°C).

Improper Installation or Handling

Premature wear, misalignment, and even structural damage can occur due to incorrect installation or careless handling. The assembly process must be controlled by mounting tolerances, shaft/housing fit, and the torque exerted to ensure the correct attachment.

I try to systematically address these parameters and their associated factors to reduce the chances of failure and increase the reliability of operational water pump bearings.

How Corrosion Affects Bearings

Corrosion presents a significant hazard because it can lead to surface deterioration that reduces a bearing’s overall integrity and durability. In my experience, corrosion generally occurs due to protracted exposure to moisture, chemicals, or contaminants, resulting in rusting and pitting. To minimize the effects of such corrosion, I ensure that bearings are manufactured from stainless steel or coated with protective finishes such as zinc or phosphate.

The key technical parameters that I monitor are the following:

Material Composition: Selection of specially designed corrosion-resistant high-grade alloys.

Sealing Quality: Verify the effectiveness of the moisture barrier and seal design to prevent contaminants.

Lubrication Properties: Use lubricants with anti-corrosive properties and periodic maintenance to ensure compliance with the standards.

Working Environment: Controlling the environment, such as humidity and level of exposure to damaging chemicals.

By carefully managing these parameters, I hope to mitigate the challenge of corrosion and achieve reliable long-term performance for bearing elements.

Preventing Radial Load Damage

To prevent radial load damage, these tasks must be done meticulously and at a high level of professional accuracy:

Radial Load Assessment: I ensure the radial load will not exceed the bearing’s rated dynamic capacity. For precise measurement, the radial load can be calculated by P = Fr, where P means dynamic load and Fr stands for radial force, and the fit for the application can be checked.

Aligning Components: I use laser alignment systems to ensure that the shaft and housing are adequately aligned with every shaft position. Unaligned components can distort radial force and cause premature wear.

Balanced Application of Load: To solve uneven load distribution, I use some bearings with suitable angle contacts and materials. Deep grooves or cylindrical roller bearings are often the best fit for high radial loads.

Operational Condition Tracking: Checking and monitoring parameters like shaft speed, temperature, and vibration levels occasionally ensures these operational conditions remain suitable. Many applications accept vibration from 10 to 12 mm/s RMS.

Consistent Upkeep: Maintenance plans are established with timelines for inspections, lubrication, and comprehensive wearing or deformation checks. For instance, grease containing base oil with a viscosity of 100 mm squared/ s at 40° is suitable for high-radial push applications.

By taking such actions, I increase the bearing’s efficiency and lengthen its useful life while minimizing its exposure to damage from radial loads.

How to Choose the Right Water Pump Bearing Manufacturer?

Evaluating Bearing Manufacturer Quality

The essence of my prior work with a bearing manufacturer has trained my evaluation of other manufacturers on performance, dependability, and cost value. Hence, I outline below the key focal points which determine my decision-making.

Material Quality: The material used is chrome steel, and its Chemical composition and hardness are sufficient for an optimal bearing lifespan under stressful conditions. The manufacturer uses rigid-grade tools, such as SAE 52100 or equivalent, to ensure durability and wear resistance. The hardness needs to be about 58-65 HRC.

Load Ratings and Service Life: The ratings should be supported for high-quality bearings. While the name indicates Load Ratings of Service Life, I simply refer to them as C and C0. Rigorous testing must be done to provide these ratings, claimed to be ‘providing’.

Customization Capabilities: The satisfaction of offering non-standardized dimensions, specific grease fillings, and seals topping customized solutions makes these manufacturers worthy candidates.

The manufacturer’s warranty policies and technical support provide evidence of its confidence in the product and give further assurance regarding any necessary troubleshooting and maintenance.

In making sure that the bearing manufacturer is adequate for my scope of work, I also calculate the load ratings and vibrations to determine if they will be able to meet the expectation of quality and performance for my applications.

Considerations for Automotive Water Pump Bearings

I approach the selection of automotive water pump bearings with the precision of the application demand. This is how I address these factors in a nutshell.

Durability and Longevity: The bearing materials must meet the thermal and mechanical stress tolerances. I focus on steel grade, geometry optimization, and longevity, increasing designs the most.

Load Capacity: The bearing must be capable of supporting both the axial and radial loads simultaneously, which is a common requirement in the case of water pumps. Dynamic load ratings are important to sustain continual functioning without failure.

Corrosion Resistance: Anti-rust treatment is necessary to sustain dependability for parts exposed to coolant and varying temperatures. Such coatings will enhance performance reliability.

Seal Efficiency: Seals must be strong enough to prevent coolant and rubbish from penetrating the bearing. Double-lip seal designs and other advanced mechanisms look promising.

Precision and Vibration Characteristics: No excessive vibration and noise are accepted from the moving parts of the bear. Tolerance grades, balancing precautions, and wear minimization help reduce noise and improve operational smoothness.

Grease Quality: Grease must retain its lubricating capabilities in extreme conditions, liquid environments, and high temperatures. Such stringent requirements for grease emphasize the need to pay attention when the temperature is higher.

The technical features of a bearing are evaluated based on its specific application requirements. This guarantees the bearing’s effective and reliable performance in the automotive water pump environment.

Benefits of Working with Leading Water Pump Bearing Manufacturer

Collaboration with a leading water-pump-bearing company brings many benefits, considering the most important ones at hand. Here’s my reasoning concerning the benefits collaboration brings:

Thorough Knowledge of Primary Grade Materials: Top manufacturers never compromise on the grade of materials used as it dramatically affects the bearings’ life and functionality, enabling smooth movement even under extreme pressure.

Double Lip Seal Capabilities For Seals: While dealing with sophisticated double lip seals, these companies ensure no contamination and leakage while working in harsh conditions.

Stricter Tolerances and Novelty Low Vibration Operation: Exceptional manufacturing processes with low tolerance levels increase bearing life by efficient lubrication and power while reducing noise and vibrations.

Reduction of Temperature and Absorption of Moisture: High-grade silicone oil containing grease is an effective lubricant for water pumps, as it can resist high temperatures whilst providing critical lubrication even when submerged in liquid.

Custom Designs: These manufacturers often offer designs for specific applications, ensuring that the bearings suit specific automotive needs.

Steering clear of unreliable water pump bearing providers enables me to ensure that I am provisioned with the required products that focus on precision and efficiency for the pump systems. Those motives further strengthened my interest in these manufacturers.

What Are the Latest Innovations in Water Pump Bearings?

Advancements in Double Row Bearing Design

Developing double-row bearings has enhanced the performance and dependability of water pump systems. The most commendable progress is seen in the heightened load bearing, reduced friction, and improved alignment control. These significantly contribute to longer life spans and energy savings.

Load Capacity: Double-row bearings can now support high radial and axial loads, ensuring their durability in the demanding world of automotive applications. This prevents excessive wear and damage, which is central to ensuring persistent functionality.

Reduced Friction: Incorporating advanced materials and lubricants has drastically lowered the internal friction, leading to smoother functioning while reducing energy wastage and heat buildup.

Alignment Tolerance: Modern engineering allows for improved alignment tolerance, reducing vibration and noise during the operation. This is fundamental to improving the driver’s comfort and ensuring the system’s integrity.

Sealing Technology: Newer seals provide better protection from contaminants and moisture, ensuring the bearing stays free from corrosive damage and extends its life.

With knowledge of these advancements, I can ascertain that the bearings I work with provide exceptional performance, are infused with precise requirements, and meet stiff technical standards.

The Future of Needle Roller Bearings in Pumps

Future developments for needle roller bearings in pumps will emerge through innovations that increase efficiency, adaptability, and durability. Here are the areas where these innovations can be made as I see them:

Efficiency: As the use of low-friction materials and high-performing lubricants continues, power losses and heat generation will be reduced. This will generate higher operational efficiency with a friction coefficient of 0.002-0.005 and ensure that the pumps do not seize under harsh working environments.

Durability: Meeting the life cycle requirements of modern pump systems can be achieved through advanced heat treatment processes, high-strength steel alloys (ex. 52100 or equivalently high grades), and increased resistance to wear and fatigue.

Load Capacity: Compact designs and improved surface geometry and finishes allow for handling higher loads and better load distribution. Specific designs today surpass 200kN of dynamic load ratings, for instance.

Contamination Resistance: Improving multi-lip seals, integrated labyrinth constructions, and other sealing technologies will enable reliable operation in harsh working environments by filtering particles and moisture.

Tailored solutions, which include specialized coatings such as anti-corrosion or low-friction ceramics and non-standard dimensions, will meet specific requirements in newer pump designs, indicating the increasing application-specific demand.

Enhancements in Spherical Bearings for Efficiency

I believe that the improvements to spherical bearings can be summarized in one sentence: enhancing performance characteristics to meet modern efficiency needs. Below are the details of the primary improvement aspects, some with revisions at the degree of sophistication level.

Increasing Load Capacity

Due to advances in material science, the dynamic load ratings for the newer spherical bearings with high-strength alloys or composite materials are now up to 300 kN. These materials enable better durability for withstanding the constantly varying loads produced during pump operation.

Technologies for Reduction of Friction

Adding low-friction coatings such as molybdenum disulfide or PTFE results in friction coefficients as low as 0.05. This benefits energy efficiency because it minimizes the amount of power wasted and the wear on the parts driven up for extended operations.

Improved Lubrication Systems

Changes in the lubrication grooves and the incorporation of the automatic relubrication system’s optimal design ensure that oil film thickness is set (staying in the range of 1-3 µm) to reduce advanced wearing and improve reliability under extreme conditions.

Improved seals for contaminants and water ingress

Double lip seals and new rubber compositions that improve sealing mechanisms would help protect against fine particles and moisture ingress. Their performance has been benchmarked in environments up to IP69K, demonstrating that these bearings would work without failure in the most harsh or wet conditions without suffering premature damage.

Custom Solutions for Particular Needs

Spherical bearings can now be supplied in custom configurations such as unique housing designs for compact pump size and extending service life up to 50,000 operating hours with proper maintenance. These customizations make specific best incompatibility with the new advanced energy-efficient pump technologies.

To achieve these features, I ensure that the spherical bearings used in my applications satisfy the technical efficiency requirements and operational efficiency targets.

Frequently Asked Questions (FAQs)

Q: What types of bearings are used on auto water pumps?

A: Common types of bearings used in auto water pumps are deep groove ball bearings, angular contact ball bearings, and water pump shaft bearings. These water pump bearings are designed to accommodate various automotive applications’ loads and speeds.

Q: What effect does internal clearance have on the bearing performance of a water pump?

A: Internal clearance is one of the most critical measurements of the bearing’s internal dimensions. It affects the bearing’s ability to withstand thermal expansion and misalignment. The ideal internal clearance allows the bearing to perform efficiently and extend the service life for water pump applications.

Q: What is the service life of bearings used on auto water pumps?

A: The service life of bearings for water pumps can vary depending on the loads and speeds applied to them and the amount of lubrication provided. However, high-quality bearings such as the 6201 or 6202 series are designed for long life and normal operating conditions.

Q: What items should be considered for automotive water pump bearing lubrication?

A: When lubricating auto water pump bearings, the type of lubricant used, the temperature, and the pump’s speed should be considered. Well-lubricated bearings suffer less friction and wear, enhancing their service life.

Q: Are there specific types of bearings that can sustain high-speed applications in water pumps?

A: Yes. Deep groove ball bearings and super precision bearings are popularly recommended for high-speed applications in water pumps. These bearing types can sustain high rotational speeds while still performing well and not exhausting their lifespan.

Q: What are the advantages of using angular contact ball bearings in water pumps?

A: Angular contact ball bearings provide higher axial load capacity and are better suited for applications with chances of misalignment. For water pump applications, these types of bearings will increase the overall performance of the auto water pump because they can sustain load better.

Q: How do I choose the right water pump bearing for my application?

A: When choosing a bearing for water pumps, load capacity, speed, internal clearance, and the environment should be considered. Ensure that the bearings are made from high-grade bearing steel, as this significantly affects durability and performance.

Q: What is the difference between a single-row and double-row ball bearing in water pumps?

A: Single-row ball bearings are easy to use when handling light loads and can efficiently serve simple functions, while double-row ball bearings make it easier to bear heavy loads with proper balance. Due to their improved performance under load, double-row bearings might be suitable for auto water pumps.

Q: How does the water pump bearing aid in operating the steel cage’s functionality?

A: The steel cage in bearings separates the rolling elements, which enables rotation without friction. In addition, it allows for proper positioning of the rolling elements and prevents their contact, thus increasing the bearing’s service life.