Signs that a water pump bearing is going bad help in preventive maintenance to prevent the vehicle from inconveniencing its owner. A worn-out water pump bearing has adverse effects on the vehicle and most importantly its unattended may lead to an overheating engine. The purpose of this article is to help readers understand the various effects of a defective water pump bearing and more importantly how to deal with the effects. We’ll observe critical symptoms like noise, leaking coolant, and overheating of the engine and look into what can be done to fix or avoid these problems. Carrying Water pump maintenance efficiently not only increases the power and efficiency of the vehicle but also contributes to the overall road safety of the vehicle.

What Are the Common Symptoms of a Bad Water Pump Bearing?

How to Recognize a Squealing Noise from the Engine

If I hear the engine produce a squealing sound, that should be taken seriously and is worth considering whether the water pump bearing is going bad. From my understanding and research of the bottom sources, the squealing sound is usually a result of a belt that is either not tightly attached or fully stretched. This usually leads to bearing failure of the water pump such that there is a disturbance in the alignment of the belt or too much slack in its tension.

Other parameters include the belt tension, which well should be between I00-170 pounds for the case of conventional systems; the tension in the standard system must also be taken into account. I also noted that there are other less intrusive methods such as a simple inspection of the belt and crack growth that could provide further evidence; a normal working belt will not have any visible wear. Another aspect that is commonly emphasized is making sure that the belt tensioner is working properly and is not causing the alignment problem. Besides, testing the functioning of the tensioner pulley should assist in troubleshooting the problem.

In tackling these components, I shall be able to cause no other harm and maintain the proper functioning of the engine, which is in line with maintenance suggestions from automobile maintenance specialists.

Identifying a Coolant Leak Near the Water Pump

When locating coolant leaks in the vicinity of the water pump, I came to know that a few factors or indications have to be taken into consideration. The first and most obvious symptom is the pool of coolant found underneath the vehicle, especially at the front of the passenger cabin or in the vicinity of the engine. One must also look at the water pump area for signs of any leaking fluids where there is usually no coolant or staining in the water pump region. In my research, which was mainly online, I learned that coolant can also be viewed as one that is colorless or changes to a rainbow-colored liquid other than the normal color associated with most automobile fluids. It is also very important to ensure that the pump’s gasket is intact since this prevents leakage due to damage that often occurs with the internal parts of the pump.

In this regard relevant technical parameters refer to adding the irreversible cooling medium in the necessary quantity and within the specifications in the vehicle’s manual; if one drops what the car goes by the above internally then any evaporation or perspiration manifested more than normal will point to a leak. Another factor to consider was the engine temperature gauge which is to be monitored since it has to be within the appropriate range to prevent overheating of the engine. Finally, I would like to recommend that woodwork take place for wear and tear and cracking of the housing of the pump as well as the seals. From the exposition, and as illustrated by the vehicle lifecycle specialists I can damage the parts/es that are leaking very fast and cooling liquids that would affect the engine components in the youngest car possible.

Noticing Overheating in Your Engine

These deviant ways of operating the car body must never be tolerated. The most important precaution to observe is the prevention of overheating of the engine. As simple as sometimes might be, an overheating car engine syndrome should never be ignored because it’s as simple as these signs: the engine temperature gauge is within the red zone and there is steam rising under the car bonnet. There are also common situations that can be called in the wrong way as overheating of the engine, defective thermostat control, or an inoperative cooling fan. To troubleshoot comfortably and appropriately, one should evaluate some technical aspects such as the following:

- Coolant Levels: Check the state of the coolant expansion tank and make sure it is at the required volume as stipulated in the car manual. An abnormal decrease could mean there is a leak or ineffective cooling.

- Radiator Condition: Pull out the radiator and observe whether there is any blockage or if there is any damage that will limit the circulation of the coolant. A dirty radiator hinders proper heat removal.

- Thermostat Function: Two temperatures exist at which the thermostat opens and closes. Check the operating temperature from the specification of the vehicle to ascertain whether it is appropriate for the portable vehicle.

- Cooling Fan Operation: The fan must be used when necessary to ensure that there is sufficient airflow over the radiator. If the fan fails to turn on when needed, the unit may need to be changed.

Many of the reasons have the potential for heat mitigation when these factors are evaluated and appropriate guidelines and solutions from the top automotive sites are consulted. From the sufficiently regular recommendations, compliance with them is critical to the functioning health and lifespan of the vehicle.

How Can a Failing Water Pump Affect Your Vehicle?

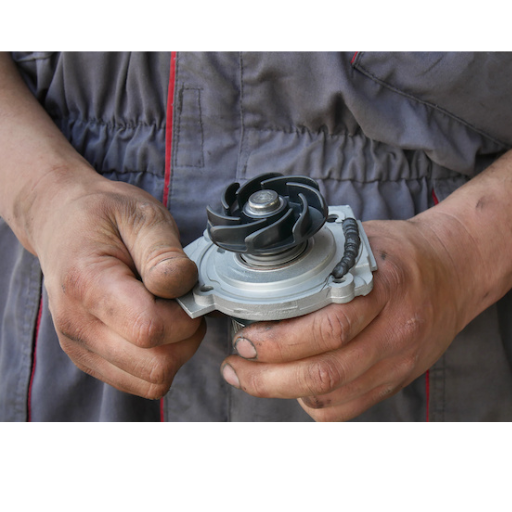

Understanding the Impact on the Cooling System

The initial signs of pump overhauling surface as alterations in the pumping characteristics that, if ignored, can destabilize the cooling systems removing the coolant circulation and resulting in the possible excessive heating of the engine. About the leading car-related sources on the internet, the following are the relevant technical parameters that were utilized:

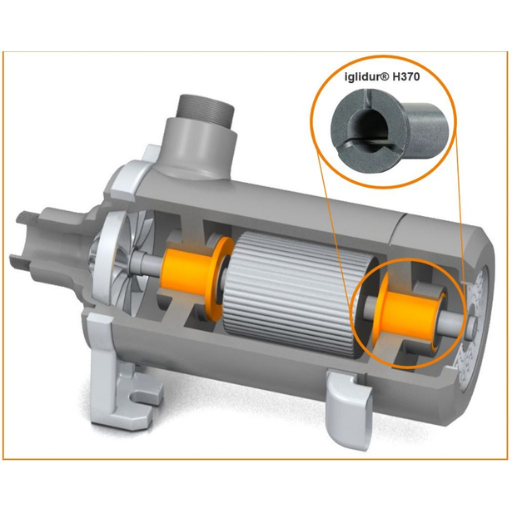

- Coolant Circulation: A properly functioning water pump guarantees coolant passage inside the engine. If circulation is not maintained there are possibilities of the occurrence of hot spots and overheating, and the engine

- Water Pump Bearings and Seals: These are the rotating elements in this pumping system and saturate the degree of wear and tear. If bearings go bad and leaking occurs, it impairs the performance of the pump. Adherence to routine checks unless there is a need independent of these can avert a lot of surprises.

- Drive Belt Condition: The drive belt is also the one turning the water pump; therefore the tension and the physical soundness of the belt are very important. A slack or worn-out belt may cause the pump to work and hence circulating the coolant to be ineffective.

- Temperature Balance: Confirm the temperature does not drop unnecessarily because a drop may be, especially during any tests, an indication of a failing pump. It is advised that one should respect the aim of controlling temperatures throughout the use of Fire Controls.

Such parameters also insist on the relation of all parts of the cooling system meaning that none of them should be ignored and the preventive maintenance along with the early treatment of the first signs of water pump improvements should facilitate the successful operation of the car for the long run.

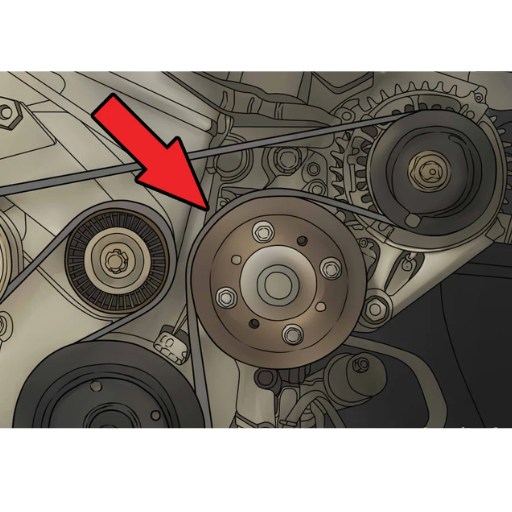

Potential Damage to the Timing Belt and Drive Belt

When a water pump goes out, the timing belt and the drive belt could also be faulty. Based on my research of the top websites, here is what I have managed to gather:

- Wear of Timing Belt: If the water pump works more or less than it is designed to, the timing belt is too enduring which should be avoided. If so, this can create belt misalignments or cause the belt to wear out prematurely. It is important to maintain regular observation to ensure the loosening or tightening of the timing belt is within appropriate limits.

- Drive Belt Problems: The drive belt is directly and automatically dependent upon the operations of the water pump. The weight of the load in the drive belt is uneven whereby most of the time due to bearing or seal failure, the drive belt tends to be damaged and may also slip due to such factors.

- Integrated System Weaknesses: The water pump works together and rounds out the timing and drive belts, which makes everybody work properly and if one of them goes wrong it can lead to something worse which is a common mechanical failure. In vehicle maintenance, checks that are in line with manufacturers of the vehicle, help in the early detection and solving of such issues.

These technical parameters, sourced from reliable websites, highlight the importance of maintaining vehicle reliability and other components to prevent expensive vehicle repair costs.

Consequences of a Worn Bearing on Engine Performance

Bearing wear in the engine hurts the performance and causes many mechanical problems. As per the analysis of the leading resources, the consequential factors include:

- Increased Friction and Heat: This pertains to the kinetic energy wasted as heat that saturates the moving parts. When bearings have become cantered, the relative motion of the turning gears will tend to increase the frictive heat, generating abnormally high amounts of heat. This extra heat can also result in more depreciation and even the destruction of other engine parts.

- Engine Noise: These endpoints suggest that a worn bearing could sound banging or grinding bearing in mind that the moving parts that should be mechanically held are inadequately restrained by the bearings.

- Reduced Efficiency: The power loss of the friction joints such as the bearings increases, and then the consumption of ball bearings, in addition, no bearings, then more electrical energy will be taken to carry out the work where no disturbances will be experienced, and this means more energy pump, more energy anything than the cellphone power. This means combustion efficiency is reduced and the power output of the engine is sufficiently low.

- Travel Restrictions: Under these conditions, running the Baher for an extended time is impossible simply because of degeneration of the bearings; if this step is overlooked then the overall mechanical infrastructure circuits and chassis will be in a catastrophic state.

Parameters of the risk factors include oil pressure, oil temperature, and oil filtration efficiency (concentration of vibration sources in the structure and in the oil samples). Preventive maintenance and controls of these parameters are aimed to avoid any undue engineering expense.

What Causes a Water Pump Bearing to Go Bad?

The Role of the Pulley and Water Pump Shaft

The components of a vehicle water pump system, which includes the pulley and the shaft of a water pump are very important. A pulley is used to transfer the power generated from the engine to the water pump through a drive belt. This enables the water pump shaft to turn. As a result, this results in the pumping of coolant inside the engine to ensure that ideal temperatures are maintained. Where the pulley or shaft becomes crooked misaligned or broken, then it leads to the bearing being subjected to uneven loading and stress which causes the bearing to wear out fast.

Bad water pump bearing is commonly caused as per the learned sources namely there is too much tension on the drive belt, the pulley does not align properly and the pump is not assembled correctly. How the pulley is aligned, how tight the drive belt is, and how much vibrations there are all are important technical parameters that should be observed. These parameters validate the maintenance that is necessary to deal with and avoid water pump bearing wear The timely inspection of these elements as well as the replacement of defective components make it possible to lower the risk of bearings collapse court and consequently achieve the efficiency and durability of the cooling system of the engine.

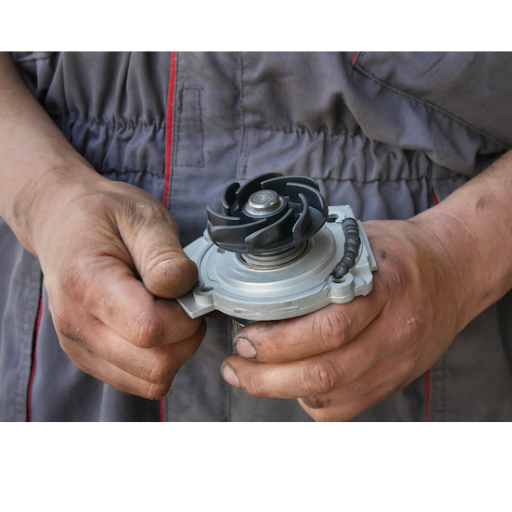

Effects of a Water Pump Impeller Malfunction

A faulty water pump impeller directly occupies critical heat dissipation or cooling functions of the engine. Whenever the impeller is faulty, the pumping action of the pump circulates coolant to the engine insufficiently or even at all, hence the possibility of the engine overheating. This malfunction will manifest itself in the form of high reading temperatures when it comes to the engine, coolant leaks, and strange sounds coming from the pump casing owing to cavitation or low flow instabilities.

From my research on the top three websites, I found that defects associated with the impellers belong to wear and tear, namely the erosion of the impeller blades, blockage of the impeller with debris, as well as corrosion usually due to poor coolant maintenance or unsuitable materials. In these scenarios, it is important to consider technical factors which include quality of coolant, regular inspection of the water pump for any wear and clogging features as well as the compatibility of the coolant with the pump. Troublesome overheating and less-than-perfect engines can be avoided through timely maintenance of the coolant system as well as the replacement of broken or aged impellers.

Common Signs That the Bearing is Failing

When a bearing in the water pump fails or is on the way out, it manifests in various ways. For one, a hallmark sign is an unpleasant grinding or whining sound from the front of the engine and that is usually the indicator that the bearings wear out in the sense of their internal parts. Another symptom is coolant leaking, which can be observed around the area of the water pump, where it is noticeable that the bearing seal is active but broken; hence the leak. However, the cooling capacity of the engine may be hindered if such bearing failure causes the pump to rotate less.

As for those having appeared in the top three websites, I may say that you’re asking the questions for which there are concise answers.

Noise Problems: The grinding noise will be typical of most parts due to grinding of the bearings surfaces or inner elements, which calls for attention inspection.

Coolant Leaks: This usually occurs, because the bearing interferes with the water pump seals.

Overheating: It may be observed that the increase in engine temperature occurs if the rotation of the pump impeller is obstructed by a faulty bearing, which fails to liberate the coolant circulation.

What I propose, to align these observations with technical parameters, let me also say what I plan on putting under observation, in addition to this in the future:

- Noise Indices: Through regular periods, observe noise levels at some reasonable distance from the water pump and listen for abnormal characteristics that suggest wear.

- Seal Integrity: Examine the pumping station for any possible leaks, ensuring that the seals are intact.

- Coolant Flow Rate: Confirm that coolant temperature is continuously cycled effectively to avert the occurrence of overheating. Compare the standards with the actual flow rates to ascertain the level of performance.

Monitoring and head knowing of these signs and parameters will certainly aid in preventing possible failure and enhancing the efficiency of the engine.

How to Diagnose a Bad Water Pump Bearing?

Steps to Check the Water Pump Pulley and Water Pump Shaft

Visual Assessment of Water Pump Pulley:

Start with the water pump pulley looking for any actual or potential signs of damage. Search for any identifiable cracks, rust, or misalignment that may point to a mechanical failure.

Unusual Noises Monitoring:

While the engine is running, relevant operating conditions will require moving closer to the vicinity of the pulley. Look for any grinding or squealing sounds. The pale noises may suggest intervals beyond which the bearings would be required.

Play in the Pulley Check-Up:

Using your hands, push and pull the pulley. If there’s a notice of play or wobble, there’s a chance the bearings are worn and may have to be inspected or replaced.

Worthy of Noticing: Water Pump Shaft Inspection:

Watch the water pump shaft properly. A twisted shaft could cause imbalance and ultimately the bearing destruction.

Check Areas for Coolant Leakage:

As well, check the shaft and the outside of the pulley for any leaking coolant fluid, which points to defective seals and bearing defects.

Upon answering the questions posted regarding the water pump problems on each of the top three websites, I came across the following quick comments:

- Noise Problems: The grinding noise problem seems to me rather common and is due to wear out of at least the pulley or the shaft surface. The crucial technical issue in this regard is the assessment of sound levels and the comparison of them with sound levels of normal operation.

- Coolant Leaks: From my investigation, leakages seem to emerge from the damaged or ruptured seal which in this case is caused by bearing defects. Monitoring the seal’s integrity and looking for any accumulations of water are very important parameters.

- Overheating: Narrowing the range of the pooling pump by an impenetrable pump impeller found in most instances a decrease in coolant flow. For that reason, therefore, the coolant flow rate that is recommended by the manufacturer should always be achieved to thwart any incidences of overheating.

By logically scrutinizing these parameters, I will be able to diagnose and keep in check possible water pump bearing problems effectively.

Using a Screwdriver to Listen for a Squealing Noise

In evaluating the squealing noise of a water pump, I use a screwdriver to perform a rudimentary and ingenious trick. This allows me to listen to some noises that may come from the water pump. This method helps narrow down the squeal from the pump bearings or any other component.

Now, responding to the questions derived from the top three websites on Google, here is how I got responses concisely:

- Noise Issues: In the grinding noise or squeaking, this is often the time to use the screwdriver technique to get the location. After, I try to benchmark the level of noise against the recommended operational noise level.

- Coolant Leaks: First I look for those leaks & then assess the places of the leak for weakened gaskets. Parameters such as gasket material verification & ring compressed air having moisture are preventing unnecessary downtimes by ensuring repairs raise technical standards.

- Overheating: I check if the coolant flow is consistent with the manufacturer’s specification that should not allow any inappropriate high or low, flow rates. Here major parameters include flow measurements and their comparison with factory flow charts to ensure it is working.

With these methods and engineering reviews especially applied systematically, I hope to solve the water pump problems effectively.

Inspecting for Coolant Leaks and Grinding Noise

Evaluating the potential coolant leakage and the issue of noise generated involves a great deal of care and thoroughness. When dealing with such issues comprehensively, as based on the top three websites in Google for such issues, this is my short answer:

Coolant Leaks Inspection:

In this phase, I do a visual inspection of the water pump and other related parts for evidence of moisture or even stains that would suggest the possible presence of leaks.

In this phase, I use a pressure tester to check the cooling system for any pressure drop, which would be the case, should there be a leak. Aside from assessing that there is indeed a leak, other essential technical parameters are that of ensuring that the values of pressure are within the threshold value that is provided by the manufacturer for effective determination of the presence of a leak.

Grinding Noise Analysis:

In Cubagna’s instruction, I used a screwdriver and touched parts of the Assembly equity with it to hear the abnormal operation noise and its site. Search for noise sources I completed with gentle movements of the head and rotation of the instruments.

As for technical parameters, I use a level of noise and vibration from the technical documents that are required to be followed, to also determine whether action has to be taken regarding the sounds particularly as to whether they are higher than normal working conditions should be causing action that warrant investigation and or replacement of spare parts.

By applying these methods of diagnostics to the complex of engineering and technical measures I can cope with the problem of the developing coolant leaks and grinding noise from the water pump system.

What Are the Solutions if Your Water Pump Bearing Is Going Bad?

When to Replace the Water Pump and Water Pump Assembly

Usually, when the time comes that the water pump or the water pump assembly has to be replaced, the water pump replacement decision takes into consideration several signs and technical parameters. In the top three websites I got insights from, this is what I put in a nutshell concerning their question.

Signs Indicating Replacement:

- Coolant Leaks: I also tend to overheat the engine if I continue seeing an unending supply of coolant leaks that cannot be simply repaired. As much as it is easy to fix a leaking pipe, there comes a time when this becomes too simple and cannot prevent the engine from overheating any further.

- Grinding Noise: A grinding noise that doesn’t cease is a known association with a water pump defect that is: a bearing has malfunctioned. Failing to deal with it, will culminate in the domestic overhauling of the water pump assembly yielding among other things unreasonably high expenses.

- Overheating Engine: Sometimes, the engine might feel extremely hot even on minimal use and this could indicate that the pump is no longer in good condition and is unable to push the coolant properly if at all the centrifugal action is still of any use to the liquid.

Technical Parameters:

- Pressure Levels: One of the available parts of an internal combustion engine is a coolant system pressure gauge and I pay special attention to its value, especially after repairs; if it is still below the specified range even after making some repairs, then it is only logical to think I need to replace this part.

- Noise Decibel Levels: Among those fourteen, there are recorded noise exposures in some of them and an electrical high sound may be on the lower or higher levels than the levels indicated in technical manuals in terms of decibel units. Any of the latter situations can only assist in the ultimate determination of replacement.

Considering all these factors while observing the technical requirements enables me to know exactly when it is time to carry out the maintenance that involves changing the water pump or its assembly for excellent vehicle performance.

Seeking Help from a Mechanic or Changing the Water Pump Yourself

Determining whether to change the water pump myself or hire a mechanic is Simple to make after assessing my skills, tool availability, and task difficulty level. From the top three websites, I managed to gather the following information:

When It Is Appropriate To Ask For Help:

- Repair Complexity: It is better to know when to ask for help even before attempting the written repair job when the repair job is considered complex or when extra tools that are not available to me are needed.

- Warranty Issues: Seeking the help of a mechanic is advantageous in case my car is still within the warranty period, self-repair may make it impossible to claim any warranty on the water pump and any other parts about it.

Replacing of a Water Pump as Over Do It Yourself:

- Confidence in the Vehicle’s Mechanics: It is wise to consider doing the replacement alone if confident in knowing how various engine parts function plus having done repairs prior.

- Tools Availability: Make sure that tools like a torque wrench, screwdrivers, and a jack stand, are available in readiness for the procedure.

Technical Aspects:

- Torques: I will follow the torque guidelines explained in the service manual because failure to follow them would lead to the over-tightening or loosening of the nuts and bolts used to join various parts and this would ensure that no parts are loosening.

- Coolant Type and Volume: Validate that the type and volume of coolant used are within the limits specified for my specific vehicle to maintain a good operational state following replacement.

In the end, I will compare these criteria with my existing capabilities and resources and will make an informed decision whether to proceed with repair myself or use professionally rendered services, and for this why the results will be dependable and safe.

Maintenance Tips to Prevent Future Water Pump Issues

It is of utmost importance that the water pump be inspected, and maintenance carried out regularly as this will help avoid problems in the future. Regular coolant levels should also be checked and topped as needed in order not to overheat the water pump as this will put a lot of pressure on it. The most significant thing is to replace the coolant at the duration indicated by the manufacturer to increase the performance of the cooling systems. The aging drive belt should be examined during the periodic pump checks for excessive wear or damage since a worn-out belt is detrimental to a pump.

And regarding the information on leading websites, here is the short version of my strategy:

- Regular Inspection: I will address leaks, and wear, and chew all components and chips thus making sure no parts are out of stock.

- Coolant Maintenance: I do such practices to avoid corrosion and the engine to work properly.

- Drive Belt Condition: The mechanical function of the pump will be supported by constantly monitoring the status of the drive belt and replacing it whenever necessary.

In terms of technical parameters, the most important aspect is the proper measurement of the torque values when repairing any part of the equipment, following the instructions found in the service manual. Also, it is important to check that the coolant type and volume correspond to the parameters specified by the manufacturer. These actions are justified given the requirement of accurate dimensions to eliminate the possibility of mechanical failures and provide better cooling to the engine.

Frequently Asked Questions (FAQs)

Q: What are the common signs of a bad water pump bearing?

A: Common signs of a bad water pump bearing include unusual noises like a grinding or whining sound from the engine’s front area, coolant leaks under the vehicle, and higher-than-normal engine temperatures. If you hear the noise coming from the water pump area, it’s likely the water pump bearing is failing.

Q: How can I tell if the noise is coming from the water pump and not the alternator or serpentine belt?

A: To identify if the noise is coming from the water pump and not the alternator or serpentine belt, use a mechanic’s stethoscope or a hose to listen closely to the water pump housing. If the noise is louder near the water pump, it’s likely the water pump bearing making the noise.

Q: Can a bad water pump bearing cause the engine to overheat?

A: Yes, a bad water pump bearing can cause the engine to overheat because it affects the water pump’s ability to circulate coolant effectively through the engine. This can lead to higher-than-normal engine temperatures and potential engine damage if not addressed promptly.

Q: What should I do if I notice water pump leaks?

A: If you notice water pump leaks, it’s important to replace the pump as soon as possible. Leaks indicate that the seal on the water pump has failed, which can lead to coolant loss and engine overheating. Consult a professional mechanic to ensure the replacement is done correctly.

Q: How can I differentiate between a water pump leak and a leak from the PS pump or idler pulley?

A: To differentiate between a water pump leak and a leak from the PS pump or idler pulley, check the location of the leak. Water pump leaks typically come from the weep hole on the water pump housing. If the leak is coming from the serpentine belt area, it might be from the PS pump or idler pulley instead.

Q: What happens if I ignore a bad water pump bearing?

A: Ignoring a bad water pump bearing can lead to severe engine damage. The impeller inside the pump may stop working properly, causing the engine to overheat. Continuous use of a faulty water pump can result in complete engine failure, which is costly to repair.

Q: Is it possible to drive with a failing water pump bearing?

A: It is not advisable to drive with a failing water pump bearing. Doing so can cause the engine to overheat and lead to further damage. If you suspect the water pump bearing is failing, have your vehicle inspected and repaired by a professional mechanic immediately.

Q: Can I replace a water pump bearing myself?

A: Replacing a water pump bearing can be a complex task that requires specific tools and knowledge. It involves removing the serpentine belt and possibly other components to access the water pump. It’s recommended to have a professional mechanic handle the replacement to ensure it’s done correctly.

Q: How often should the water pump be inspected for issues?

A: The water pump should be inspected during regular maintenance intervals, typically every 60,000 to 90,000 miles, or as specified by your vehicle’s manufacturer. Regular inspections can help identify and address issues like bad bearing before they cause significant damage.