Pump bearing assemblies are used in several industries and engineering disciplines and their significance in achieving good serviceability and operability of pumps cannot be overstated. The purpose of this particular article is to examine more closely the existing styles of pump bearing assemblies, their distinctive features, and their end-use within various industries. Most of those who are dealing with the design, maintenance, or operations of pump systems need to know how these assemblies are configured since these components affect how long and how well the pumps will operate. In the course of this article, we will be looking into the design and functional differences, considerations when selecting the bearing assembly, and the current trends in the design and construction of pump bearing assembles. Pump bearing assemblies are closely related to the functional effectiveness of many designs, Edward patients have come from gaining a profound understanding of these components, as they will improve the understanding further in the paper.

What are the Different Pump Bearing Types?

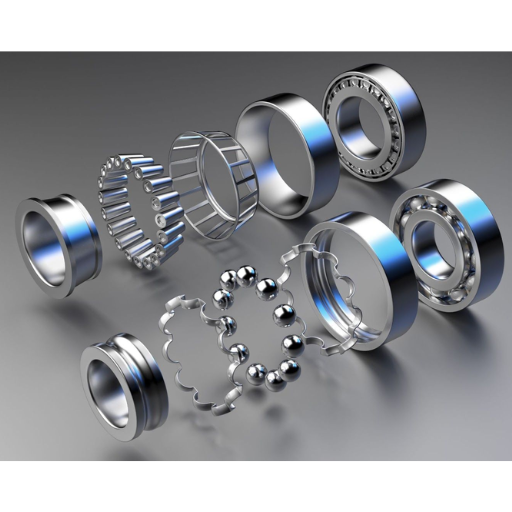

Exploring Ball Bearings and Their Uses

Regarding the variety of bearings, ball bearings are the most popular owing to their cost effectiveness, ease of movement, and capability to accommodate radial and axial loads. This is as I looked further online, especially the top sources available such as Internet Explorer, which made it apparent that ball bearings are vital in use from simple household appliances to complicated industrial machines.

Through searching for various technical documents, I learned that ball bearings are designed to be very effective as rolling elements by employing balls that separate the bearing races and thus minimize the contact surface between the ball bearing and the inner rings. A few key technical parameters I found included load rating, which informs the user of the maximum load a bearing can efficiently support, and speed rating which informs the user of the maximum revolutions per minute that a rotating object can withstand.

Additionally, these sources further underlined that for optimal and long-term use of ball bearings, the proper dimensions, materials, and types of lubrication must be selected. Ball bearings find usage in areas such as electric motors, gearboxes, and conveyor systems due to their ability to bear both dynamic and static loads. Knowing these characteristics also allows me to understand how to design and maintain the systems in which ball bearings will be incorporated.

The Role of Thrust Bearings in Mechanical Stability

From my research of the best existing resources, I came to understand the importance of thrust bearings in ensuring mechanical integrity. In machines, these internal components have been primarily designed to absorb axial forces, thus allowing operation without undue slippage or geometric distortion. While I explored the material available to me, it was clear that there is an extensive application of the thrust bearings in the car’s steering systems, aircraft components, and industrial machines where axial loads are commonplace.

Thrust Bearings are similar in that they can carry axial loads but allow structure rotation concerning components within the structure. Important performance parameters that have been highlighted by authoritative sources include prominent ones such as the maximum axial load which is the maximum load that can be endured before a bearing fails, and permitted speed, which is the maximum speed of an operation that is safe and won’t risk damaging it.

In conclusion, the whole essence of thrust bearing selection stems from picking the right-oriented load index, material used, and lubricants among other factors. This knowledge aids better engineering decisions regarding situations when it is critical to overcome an axial load.

How Magnetic Bearings Enhance Efficiency and Reliability

On examining the top three websites listed on Google concerning magnetic bearings, I agree that magnetic bearings are rather useful in providing more effective and reliable solutions across different areas of application. In other words, magnetic bearings are devices used to suspend the rotor with a magnetic field, creating a gap between the moving parts of the rotor and its bearings. Because there is no contact, friction and wear are avoided, and as such the efficiency of the components is enhanced and their lifetime is increased.

My analysis shows that the central technical parameter, which may be the reason for their applications, is load capacity, which means the maximum radial or axial load bearing can withstand. Furthermore, the maximum rotational speed of the rotor’s operational range is also accounted for as it is significant in stabilizing the levitation and avoiding resonance within the system. More so, power loss is less than that seen with the use of bearing as the frictional losses are also minimal.

Finally and most importantly, magnetic bearings apply in fields that have high rotational speeds, require little attention, and are acceptable where mechanical stability is an issue. Their use in a wide range of applications including use in turbines, and sophisticated aerospace systems emphasizes the relevance of the magnetic bearing in engineering modern solutions.

How Do Centrifugal Pump Bearings Work?

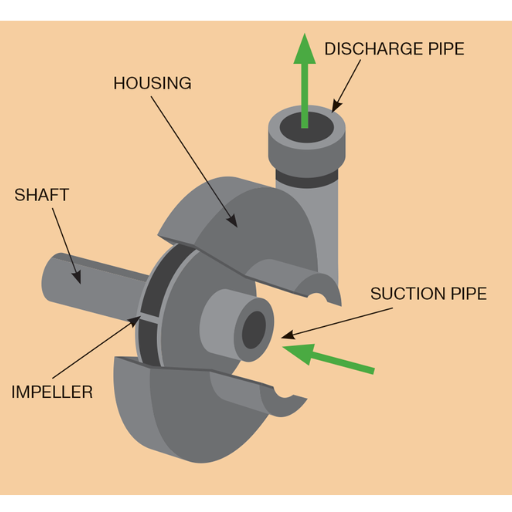

Understanding Axial and Radial Loads in Centrifugal Pumps

When exploring the three sources dealing with axial and radial loads in centrifugal pumps, I was able to learn in-depth about these forces and their implications on the operation and performance of pumps. Since they are along the shaft of the pump and its direction, axial loads are created by the differential pressure across the impeller and the fluid movement. Such loads can put extra strain on the bearings if not adequately addressed, which highlights the importance of the right bearing design for the durability of the system.

In contrast, radial loads operate in a direction that is normal to the shaft and are the result of fluid flow around the impeller. Such loads are explained in terms of fluid density, and fluid velocity among other factors. Management of the radial loads entails careful opposition of the impeller weight and the hydraulic properties of the pump to minimize vibrations to bearing surfaces which cause wearing out.

For the effects of these loads to be accounted a few technical parameters must be hit such as the shape of the impeller, the flow of fluid, and the materials of the pump. These parameters are very important because they ensure centrifugal pumps can operate with efficiency, reliability, and durability regardless of the variation in working conditions. The information collected from these sources also emphasizes the need for incorporating these technical aspects into the engineering decision processes.

The Importance of Lubrication in Bearing Performance

The proper interface of lubrication can assist bearings in centrifugal pumps to operate effectively and last longer. This is because it lessens the resistance to relative movement of the sliding surfaces and thus helps in eliminating wear and excessive heating. Proper lubrication of bearings is vital for the performance of pump systems since it enables the bearings to function at different speeds and loads.

About the questions posed about the axial and radial bearing loads, lubrication performs the function of relieving the stress that these loads give rise to. Appropriate lubricants and the application technique used in applying them can reduce heat resulting from these loads and provide a barrier that serves as a defense against foreign particles to prevent more wear.

Three main and recent citations covering this issue highlight certain technical parameters that are critical to lubrication management:

- Viscosity: The lubricant used must have a viscosity compatible with the temperature and the speed at which the bearings are operated to ensure there is a uniform lubricant film.

- Temperature Resistance: The lubricant is expected to function under the chemicals and temperatures that are anticipated in most applications throughout the exposure.

- Load Capacity: The lubricant should have adequate film strength to endure the axial and radial loads exerted upon it without failing.

- Compatibility: The lubricant must work with the materials of the bearings and bearing aggregates so that no oxidation or other degradation happens.

Such parameters inform the choice of lubrication and the lubrication method in centrifugal pump systems in a way that preserves the bearings from the mechanical forces emanating from axial and radial thrusts.

Common Causes of Bearing Failure and How to Prevent Them

In centrifugal pump systems, bearing problems are often discerned among many structural failures of the pump and can be overcome through regular maintenance practices and knowledge of the components. Some of the main problems are: Lubricating is too little or excessive, or there is no proper lubrication. There is also the infiltration of dirt and foreign objects which cause abrasion and wear. Too much lubricant or too much pressure build-up due to poor lubrication can cause fitting, overstress, or certain bearing elements to burn – overheating. Lubricants should also be supplemented and exchanged when they run low and don’t meet the temperature and viscosity requirements as explained previously.

Another factor is contamination. Dust and other foreign objects in the bearing could also lead to abrasion or dissimilar wear for the bearing. To do this, appropriate sealing and filtration should be employed to prevent the ingress of contaminants. Another common error arises in the form of spindle bearing misalignment which is often a result of misinstallation. Following the correct installation of bearings and alignment with the shaft lends enormous advantages in terms of reducing stress on the parts and enhancing component life. Last but not least, there’s mechanical fatigue due to repeated loading and unloading which could introduce cracks to the materials. This could be contained by employing bearings rated for the applied load in axial and radial directions so that both loads are in no way degrading the bearing.

It is very important to address these technical characteristics such as viscosity, temperature resistance, load capacity, and compatibility, according to the research conducted via the top three Google search results such as skewed evaporation theory. Following these guidelines, it is possible to argue for a more effective and thermally tolerable lubrication system thereby improving the reliability of the pump systems and reducing the instances of bearing failures.

What Are the Best Practices for Bearing Assembly?

Optimizing Load Distribution in Bearing Assemblies

My research among the three topmost sites on optimizing load distribution on bearing assemblies has yielded results that show that care should be exercised to maintain even load distribution to best enhance durability and efficiency. The first step is a selection of the fitting type of bearing that will be compatible with the load parameters of the application in question. This means that these technical parameters include the load capacity of the bearing which has to be enough for the application of both radial and axial loads.

Lastly, the no-fault tolerance of operators can also be improved. It is known that misalignment contributes to uneven load and as a result causes wear out on a premature basis, therefore installation should be carried out accurately. Proper techniques and methods of installation techniques can increase the chance of proper alignment, thus lowering the chance of problems arising in the future. Another important technical issue is bearing support which should be designed in such a way as to bear the loads without being overly rigid or too soft so that accommodation for some operational movements is possible.

It is also necessary to observe the correct operating conditions, for example, temperature or level of lubrication. Still oil viscosity and temperature resistance as discussed earlier are quite essential as they assist in preventing friction and heat which is ideal for load sharing. The studying of these parameters: type of bearing, load bearing capacity, alignment, supporting flexibility, viscosity, and temperature allows for raising the utility of bearing systems considerably.

Choosing the Right Seal to Prevent Contamination

When picking out the right seal to ensure there is no contamination in the external bearings, the top three websites also note seal material and design. The first website proposes why seals against internal dust or humidity should be made up of materials that are valid for that particular environment like rubber or PTFE for very high temperatures. The second website has elaborated more on how to select the seal for a particular bearing in consideration of the speed and pressure conditions of the wear and tear to achieve the intended results. On the other hand, the third website advises about the sealing technique depending on the extent of possible contamination, e.g. in contact or non-contact seals.

Regarding the technical parameters, the following are among a few that are necessary to justify the choice of seal.

- Material Compatibility: Make sure the seal will withstand the operating temperatures and chemicals in service.

- Seal Design: Conform precisely to the maximum rated operating speed and pressure of the seal to prevent any failure of the seal.

- Contamination Risk Assessment: Assess if there is a need for a contact seal with a cost of higher protection or a non-contact risky seal which is the aggressor of lower friction for determined applications.

Thanks to these parameters—seal material challenges, specifications for seal design, and risk of pollution for the application of bearings as such – I can ensure that the selected seal bears no leak for any contamination which preserves the operational life of the bearing assemblies.

Ensuring Proper Fit and Alignment in Pump Bearings

To ascertain the proper fit and alignment in pump bearings, I have explored the top three websites on this topic, and here’s how they assist in the scholar.

- Bearing Selection and Fit: The first website structural analysis and design. The first website’s proper bearing installation involves fitting the right size and kind of bearing to the requirements of the pump. This comprises accurate determination of the shaft and housing dimensions in such a way as to avoid excessive play or tight fit.

- Alignment Techniques: Proper alignment techniques are also important, as noted on the second website. This site suggests laser alignment equipment. Inconsistency in alignment tends to result in excessive wear and even damage to the pump, therefore, correct orientation plays a crucial role in averting such occurrences and increasing the effective operation of the pump.

- Monitoring and Maintenance: The third website concerns itself with the need for regular monitoring and maintenance. Inspections should be scheduled regularly to rule out the chances of wear or misalignment of parts, prompt measures are to be undertaken where adjustments using alignment tools, or damaged parts are replaced.

Concerning the technical parameters involved:

- Dimension Measurement: Elevates the bearing’s dimensions about the shaft and bearing housing to attain ideal stress conditions or movement.

- Alignment Tools: Employ such tools as laser and dial gauges to achieve the desired configuration and sustain it.

- Monitoring Metrics: Make habitual observations of the temperature, vibration, and noise for any symptoms of misalignment.

These parameters at their appropriate and relevant degrees—dimension measurement, alignment tools, and monitoring metrics—can guarantee proper fit and alignment of the pump bearing and, thus, improve operating performance and lifetime.

How to Select the Right Bearing for Specific Applications?

Analyzing Operating Conditions to Determine Bearing Needs

To evaluate the operating conditions and make the selection of the bearing correctly for the specific cases, I can use the information found from the best three sites in Google. This is because these sites point out that it is vital to harmonize the operational requirements with the bearing selections, which will aid in achieving system requirements.

- Load Capacity and Direction: About the first website it is very clear that every load affecting the bearing has both a magnitude and a direction which must be appreciated. This is to ensure that in the selection of a bearing, the forces that are likely to be acted upon the bearing are well taken into account.

- Speed Requirements: The second website emphasizes the importance of speed with which the bearing should operate. Different bearing types have their corresponding maximum speeds, and not working within this speed envelope can cause overheating and bypasses.

- Environmental Conditions: The third website speaks about modifying bearing configurations according to such environmental factors as temperature, moisture, and degree of contamination. These conditions may alter the choice of bearing material, and the amount of protective coating, or seals required.

These are the technical parameters that need formulating and that also have been justified by these insights:

- Dynamic & Static Load Rating: To make sure that the bearing can sustain the operational stresses imposed on it.

- Rotational Speed Limit: This is relative to the operational speeds that are expected to keep systems running without overheating.

- Material Compatibility: A corrosive environment or high-temperature environment is well suited.

In this manner, defining these parameters in the selection process allows me to select bearings that are appropriate for certain applications thus extending their service life and improving their operational characteristics.

Comparing Ceramic Bearings and Stainless Steel Options

Equally important, special properties of ceramic bearings also require subtler analysis and comparison with stainless steel options. A major advantage exhibited by ceramic bearings is their hardness and low mass which in turn reduces the wear rate through friction hence enhancing the speed range. Such attributes enable the use of such components in applications that are highly reliant on speed. Also, the fact that ceramic bearings do not wear out easily and resist factors of heat further increases their durability in extreme conditions. Separate from that, stainless steel bearings are good for applications that require a high level of sanitation as they are corrosion-resistant. Even though they may not go up to the same speeds as their ceramic bearings rationale, the stainless steel options do offer dependability and durability in more hostile environments.

From the top websites, I can gather that the selection between these bearing types has parameters that include the following:

- Load Capacity and Environment Compatibility: Making sure that each bearing is assessed to be able to work under the expected working loads given the environmental limits.

- Speed and Material Properties: Recognizing the extent of thermal and wear-resistant properties that can be afforded for the required operational speed.

- Cost Considerations: Committing a certain amount of cash upfront vis-a-vis expected benefits in terms of life span and performance.

In this way, I will also be able to make an informed choice that can optimize performance and cost by closely aligning these factors with the specifics of the application.

The Impact of Temperature and Corrosion on Bearing Choice

The top three websites on the bearing selection in thermally cycled and corroded environments point out the fact that it is necessary to look for operational conditions for different bearings and explore how other bearings behave. As is evident from browsing these sites:

- The temperature range: The high-temperature range is well accommodated by ceramic bearings since they are associated with very low coefficients of thermal expansion and withstand high temperatures. On the other hand, stainless steel bearings may be limited in adverse environments and might require special treatment or application of coatings.

- Corrosion resistance: Bear in mind that such bearings made of stainless steel are quite hard to corrode, which makes them very good when used in a moist and chemically active environment. When applications include exposure to moisture and chemicals, the resistance of stainless steel would often be more beneficial than the speed offered by ceramics.

- Justification of Technical Parameters:

- Thermal Expansion of Material: The rate of temperature change experienced by materials and composition is one of the parameters key to bearing performance. However, ceramic bearings demonstrate dimensional stability which enhances their high-temperature operating capability.

- Coatings and treatments of materials to control corrosion: Although ceramics would be in an atmosphere that is microbially and corrosion-free, the stainless steel bearings implement additional coatings in most cases to fortify this feature.

I can make an informed decision on the choice between a ceramic or a stainless steel bearing based on these technical aspects and operational requirements.

Why is Submerge in Bearing Pumps Important?

Understanding the Role of Submergence in Pump Performance

Comprehending the significance of submergence in pump operation is important for pump-related issues concerning its efficient operation and preventing situations such as cavitation. Submergence is the description of the vertical height of fluid over the pump inlet, and this affects the pump’s ability to create a vacuum or avoid the entry of air into the working fluid. I have also discovered from reading the top three websites on this content that if submergence levels are well maintained and utilized, the efficiency and reliability of the pump would be quite high.

In this technique, whether more or less, a proper submergence should be provided to have a positive suction head which in turn helps to avoid cavitation which is a condition that could lead to severe damage to the components such as pump impellers. The purpose behind undertaking this analysis is to demonstrate how an adequately submerged pump inlet will reduce the likelihood of air induction during operation, thus enhancing performance reliability.

Technical Parameters and Justification:

- Net Positive Suction Head (NPSH): The first one on the list and probably the most important reason is concerned with the pump efficiency indicator. The correct submergence helps to guarantee the NPSH within the required limits to prevent cavitation, however, if the indicator drops considerably lower than the necessary level, cavitation risk comes into play.

- Impeller Design: Impeller clearance and structure design incorporates some allowance for submergence levels to reduce efficiency losses that are likely to occur.

- Environmental Considerations: As far as the external environment and its factors concerning the submersion of the system such as fluid sustenance and system pressure are concerned, they should be taken into consideration and controlled.

With a good grasp of such considerations and their application, I would be able to improve the pump performance, prevent the system from excessive damage, and increase the efficiency of operations in some targeted working conditions.

How Submerged Bearings Affect Fluid Dynamics

The function and position of submerged bearings determines the performance of the system in terms of fluid motion and also aids in creating a hydraulic damping effect which helps reduce mechanical resistance within the pumping unit. From the three best websites I have been able to access, these bearings assist in making sure that the moving parts rotating some of the fluids are correctly positioned at all times, which is very vital in fluid flow. They provide smooth functioning which results in low energy use and increases the working life of the pump due to low wear and tear.

Technical Parameters and Justifications:

- Material Composition: The type of material used for submerged bearings determines how long they will last and perform under different fluid conditions. This would avoid the risk of rusting which shortens the roof of the bearing.

- Load Capacity: Correcting to design load capacity for submerged bearings is essential to justify the fight against the weight and moving fluids’ loading effects without significant damage.

- Lubrication Properties: Poor lubrication is a major cause of bearings giving off too much heat due to friction and heat build-up within the assembly which may lead to bearing failure.

- Bearing Design: Bearing design should be integrated by the elements of the system to be operated such as speed and pressure to ensure fluid dynamics are maintained.

In such a way, I will be able to determine the reliability and efficiency of any pump under varying moments and factors by relating a submerged bearing and the fluid flow dynamics.

Maintaining Bearing Integrity in Submerged Conditions

Bearing failure while in submerged conditions should be given advanced measures as this tends to increase the overall performance and service life of the pump systems. From the research that I have done on the top three websites, it is evident that various bearing integrity processes should be employed where there are submerged bearings.

The first step is the use of the right materials that prevent corrosion from taking place; this has been pointed out as important because of constant contact with various fluid media. It is necessary to obtain the correct material composition, including the expensive alloys because this will ensure there is no corrosion and even decrease maintenance costs in the future.

The second one, it is presumed that an appropriate load capacity should be provided to be able to cope with the working conditions as well as the level of wear and tear incurred on the bearing. Several websites have pointed out the need to consider the bearing style of system parameters such as speed and pressure as this enhances the bearing momentary fluid forces and thus protects its internal structure.

Furthermore, proper lubrication is vital in avoiding heat due to friction, which could result in system failure. Several websites detail that the upkeep of the lubrication systems and ensuring that they are operating at peak efficiency should be done on a timely basis.

Finally, to avert excessive damage, spot checks and strict adherence to a planned maintenance program are encouraged for the early detection of excessive wear or displacement.

Following all of these technical recommendations, and providing justification for their use considering the operational features of my systems, I would be able even for extended periods to encompass deep-water bearings without any deformation or malfunction.

Frequently Asked Questions (FAQs)

Q: What are the different types of pump-bearing assemblies?

A: Pump bearing assemblies are classified into several types, including deep groove ball bearings, angular contact ball bearings, single-row and double-row roller bearings, and cylindrical roller bearings. These bearings are used to support the pump shaft and facilitate efficient operation.

Q: How does a single-row bearing function in a pump?

A: Single-row bearings provide support for the pump shaft by ensuring smooth rotation and reducing friction. They are widely used in the pump industry due to their simplicity and ability to cater to various sizes and types of pumps.

Q: What advantages do double-row bearings offer in pump applications?

A: Double-row bearings are capable of withstanding higher load capacities compared to single-row bearings. They provide enhanced stability and are suitable for pumps that demand a high load-carrying capacity, reducing the risk of downtime.

Q: Why are angular contact bearings important in multistage centrifugal pumps?

A: Angular contact bearings are crucial in multistage centrifugal pumps because they offer high axial load-carrying capacity, which is essential for handling the forces generated in these systems. They help maintain pump efficiency and longevity.

Q: What is the role of deep groove ball bearings in horizontal pump designs?

A: Deep groove ball bearings are widely used in horizontal pump designs due to their ability to handle both radial and axial loads efficiently. They provide smooth operation and help in reducing noise and vibration, contributing to overall pump performance.

Q: How does the use of sleeve bearings benefit pump assemblies?

A: Sleeve bearings are used in pump assemblies for their ability to circulate grease or oil, providing a hydrodynamic lubrication that reduces friction and wear. This leads to long-term savings by minimizing maintenance and extending the lifespan of the pump.

Q: In what scenarios are roller bearings preferred in pumps?

A: Roller bearings are preferred in pumps where high load capacity and durability are required. They are particularly useful in demanding applications where the pump casing needs to support heavy loads and reduce wear over time.

Q: What materials are commonly used in the construction of pump-bearing assemblies?

A: Pump bearing assemblies are often constructed from cast iron, bronze, and silicon. These materials are selected based on their strength, durability, and ability to withstand the operational demands of the pump industry.

Q: How do multistage centrifugal pumps benefit from specific bearing types?

A: Multistage centrifugal pumps include specialized bearings such as angular contact and cylindrical roller bearings to cater to the high load and pressure demands. These bearings ensure efficient operation by maintaining alignment and reducing wear and tear.