Water pumps have always been vital in many areas, such as agricultural irrigation, municipal HVAC systems, and industrial processes. Bearing water pumps have consistently commanded the reliability, durability, and efficiency of the pump types available today. The attributes above allow these pumps to operate under very high pressures and during extreme temperatures, which makes them best suited to the modern management of fluids. This blog primarily focuses on the bearing water pump technology, which involves studying its basic structure, features, and the industries that utilize these pumps. Once readers grasp the operation of these pumps and the reasons behind their effectiveness, they will be able to appreciate the critical functions of these pumps across the globe.

What is a bearing water pump?

Understanding the structure of a water pump bearing

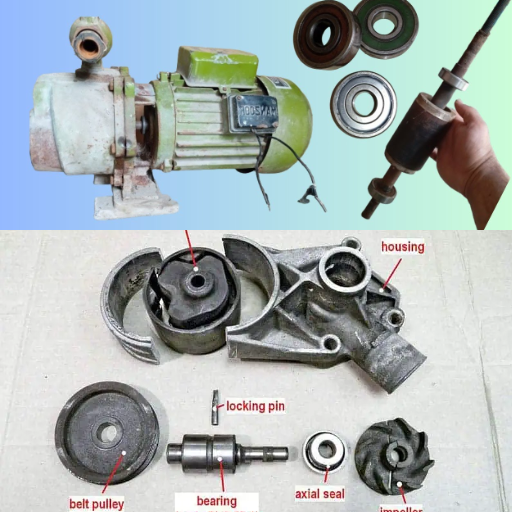

The water pump’s bearings are crucial units that support the rotating shaft while maintaining certain shear strains. These bearings integrate a shaft and bearing assembly into a singular robust system that aims for further dependability. Generally, they are composed of ball-ball or ball-roller combinations with bore holes into which precisely made steel balls or rollers are inserted into the molded shell.

Load Capacity: Nowadays, belt tension and the operation of the pump’s radials and axial loads have been accommodated using specific designs to combat the stability issues derived from motion during heavy-duty applications.

Durability: The bearings are made of high-grade chrome steel to prevent wear and tear and thus increase their bearing life.

Operating Temperature Range: Water pump bearings are constructed with -30°F and 250°F (or -34°C to 121°C) as the temperature limits, making them custom-made for such extremes.

Sealing System: Advanced sealing techniques shield the bearing from dust and moisture particles, reducing the likelihood of premature failure.

All this efficient design leads to lower friction and improved wearing of the components while increasing the effectiveness of the water pump, with the ripple effect of improved engine cooling and increased reliability.

The role of bearings in water pump performance

Bearings are critical components of the water pump system in that they can ensure smooth and efficient operation. They enable the pump shaft to rotate, effectively minimizing friction and wear. Suitable quality bearings ensure that the components are assembled correctly for effective working and durability of the bearing. Generally, water pump bearings are designed to accommodate thrust and radial loads depending on the application’s parameters, such as load, speed of rotation, and operating temperature.

Load Capacity: The bearings should withstand both the axial and radial components of the load as provisions for belt tension and fluid dynamics, which typology throws a range of between 300 – 5000, probably several thousand kg, depending on the design of the pump and its application.

Rotation Speed: Given the high-end use, the standard value is progressively pegged to bearings that can sustain an RPM greater than or equal to 6000 Hz.

Durability Parameters: Bearings can withstand the automotive mileage peg slightly above 150000 fatigue life through proper use.

Temperature Tolerance: They also are seen to work at extreme temperatures from minus 30, which I understand to be approximately -1 degrees, to a maximum of 250 Fahrenheit, with excellent performance.

Such bearings meet the technical requirements of water pumps, which can meet the demands of adequate engine system cooling even in harsh environmental conditions.

How bearing water pumps contribute to engine cooling

Bearing water pumps are vital in providing the required temperatures in the engine system as they facilitate the movement of the coolant within the cooling system. The pump’s bearing enables it to function consistently by providing enough support and strength for prolonged use. Several key technical parameters justify them as effective:

Durability: Bearings are specifically designed to last very long, sometimes more than a hundred thousand miles worth of usage, while under standard operational settings, reducing the need for repairs.

Load Capacity: They can bear both types of loads, radial and axial loads; they hold the drive system belt in tension without losing its driving capabilities.

Temperature Tolerance: They work effectively within large temperature ranges from -30 F to 250 F (-34 C to 121 C), thus allowing them to be reliable in very low and very high temperatures.

Low Friction Coefficients reduce the resistance interfering with the pump’s movement, resulting in less energy loss in the engine system.

The above features work together to ensure that the bearing water pump efficiently flows coolant, reducing the chances of the engine overheating and eventually ensuring consistent thermal control.

What are the key advantages of using a bearing water pump?

Improved durability and longer service life

Borehole pumps are designed to withstand harsh working conditions; this gives them relatively better durability and an improved lifespan compared to ordinary designs. Including high-standard bearings substantially minimizes the chances of wear, even under the most trying conditions. The major technical parameters which contribute to this are as follows:

Load Capacity: Bearings in these pumps can transfer radial and axial loads to some extent, allowing the pump to operate smoothly and consistently, irrespective of slack pressure.

Material Strength: These bearings’ Axially and radially load centers are usually manufactured from highly tempered steel materials or ceramic-type composite materials that are corrosive and breakable resistant over a long period against coolant chemicals and high temperatures.

Sealing Technology: Suitable sealing mechanisms have also been developed to effectively seal such pumps to prevent the ingress of cooling/hydraulic oil and/or abrasion particles.

Operational Lifespan: Bearing water pumps typically have a service life of more than 100,000 miles, promising reliability for long-term use.

These technical advancements ensure that the pump life is enhanced, assist in controlling engine problems, and eliminate frequent replacement and repair costs. As a result, bearing-type water pumps are traceless and ultimately cost-effective.

Enhanced coolant circulation and heat dissipation

Improvements in coolant flow and heat removal during operation are crucial to protecting the engine’s internal components from overheating. For this purpose, the water-bearing pumps have accurately designed impellers that enable proper coolant distribution in the engine’s cooling system.

Flow Rate: In standard cases, the flow ranges between 20 to 150 depending on the size and configuration of the engine and suitably cools the engine during different loads.

Thermal Efficiency: Materials such as aluminum and reinforced plastics increase the thermal conductivity of the impellers, aiding in heat-effective movement.

Pressure Capacity: Most pumps can function at a working pressure of 1-2 bar, enabling practical coolant cycling while minimizing system stress.

Temperature Regulation: During average conditions and upkeep, this system can maintain a coolant temperature between 195 to 220 degrees Fahrenheit, ensuring the engine’s efficiency and longevity.

The delicate engineering of the parameters increases the heat management capabilities and minimizes the component wear, thus improving engine performance and durability.

Reduced noise and vibration during operation

The propulsion system is effectively integrated into the aircraft’s structural system and is carried out effectively by applying vibration and noise suppression design consultants. The practical approach can specifically focus on the following:

The system has given attention to the Dynamic Balancing of Components: This appears to be very similar to the Balance of Wheels and Tyres in a Car. The Measurement of replacing a ball bearing with an identical free-moving accretion should be between 360 degrees and 540 degrees for individuals dedicated to service engineering of mechanic vessels.

Damping Materials have also been added. Bushing suspensions protect the joints between the metal frame and structural supportive materials. Furthermore, elastomeric composite materials and soft soles are used in these joints to optimize the effects of sound and vibration on the overall ship structure.

Precision Tuning of the Engine Mounts: Dispersed within these patches lie the engine mounts, which serve the purpose of semi-rubber welding through bolts in the vertical sense aligned along the side of the joints. The mounts are early stiff, cognizant of the containment that serves the needs of stairs.

The Components were designed in a more Optimized Manner: A distinctive lower objective is expected in its combat role through all types of ears, referencing the two prime motivators for creating a new Combat Reverse Ski Pylon.

How can you identify signs of water pump bearing damage?

Common symptoms of a failing water pump bearing

According to my estimation, a vibration pattern suggesting the water pump bearing of a vehicle is faulty will include the following symptoms: any form of grinding, whining, or even squealing would raise a red flag as it suggests the bearing has started faulty because of lack of wear or insufficient lubricant oil. Such sounds usually originate from internal friction within the assembly, especially the excessive ones. Moreover, a visual assessment of coolant glazed around the water pump housing would mark a bearing failure sign, as bearings can cause seal leakage problems. Also, an engine burning hot should ring bells for a user simply because it suggests the water pump is no longer viable, most likely due to the increased resistance or a disjointed alignment due to the flawed bearing.

To mitigate such abnormalities, I would solve the problem by considering focal points such as the bearing rotation speed, measured in revolutions per minute, and ensuring that they do not surpass the limits set by manufacturers. This is because heat generation and bearing loss of alignment can rapidly increase thermal wear and exceed the operational limits of the bearing in the region of 200 to 250 degrees Fahrenheit. Additionally, tracking the vibration frequency of the system and seeing that it operates at the approximate norm of 10 to 15 Hz is another effective diagnostic strategy.

Detecting leaks and unusual noises

I prefer systematic procedures whereby leaks and weird noises can be identified. It starts with leaks, easily visually located via oil stains or liquids around seals, gaskets, or connection points. So, I also examine noises by listening for grinding, hissing, and knocking, which might indicate something is wrong with the internal components. As far as diagnosis is concerned, I pay attention to a few critical technical parameters:

Pressure levels: Check pressures within the system to ensure they are within acceptable standards (such as 50-150 PSI for hydraulic systems). A pressure drop could suggest there was a leak.

Sound frequencies: With the help of acoustic monitoring, I can keep a record of noise levels. Normal machine operation noise levels tend to be constant with perhaps an increase of some form, for example, a once-off increase of 20-40 dB above the normal ambient levels. It could indicate some form of abnormal mechanical behavior.

Fluid levels are critical, as constant neglect may damage them. Fuel tanks should not be kept in remote places, as this may lead to unseen leaks. Never allow fuel reservoirs to stray from optimal capability.

Being observant and orderly helps me detect problems in advance. Hence, visual assessment and diagnostics based on parameters can enhance maintenance efficiency.

The importance of regular bearing inspections

Bearings inspections are a standard practice that helps determine whether production machines are effective and dependable over the planned life span. I consider it a best practice to regularly inspect production machinery to avoid dealing with surprises, which lead to operational losses. I pay attention to temperature, vibration levels, and lubrication during the inspections. For example:

Temperature: Apparent temperatures above 100° C (212° F ) suggest that overheating is present, and lubricant might also be at breakdown level. Infrared thermometers or thermal sensors are essential tools for accurate data collection.

Vibration levels: Vibrations greater than 0.3 in/sec (RMS) have been known to indicate some skewing or wear has occurred. Sensing fault through vibration signatures by accurately placed sensors facilitates this process.

Lubrication quality: Correct lubrication is essential to avoid the level of friction. Orders of magnitude increase of samples in a given time frame at specified locations are screened for contamination or viscosity parameters outside the manufacturer-suggested levels.

Once these factors are managed, I can notice upcoming problems, take necessary measures, and manage the machine’s efficiency.

What maintenance tips can extend the life of your bearing water pump?

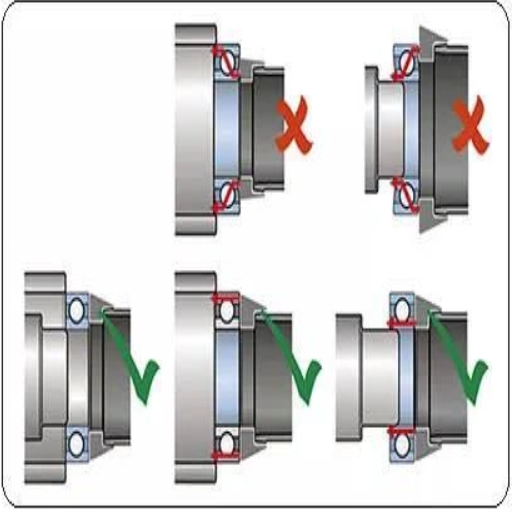

Proper installation and alignment techniques

Proper installation and alignment must occur for a bearing water pump to offer durable service. From my experience, I emphasize several important points when going through this process:

Accuracy of alignment: I must ensure that the shaft alignment is tolerant within 0.002 innocent to prevent undue stress on the bearings and seals, which can cause early termination of everyday use. Laser alignment tools are pretty helpful for this.

Base and mounting: The pump must be fixed on a sturdy, flat base to minimize vibrations. Before lifting the pump, I check the flatness of the mounting surface with a 0.001-inch feeler gauge to ensure that distortion does not occur.

Fastening torque: During assembly, the bolts must be fastened according to the manufacturers’ specified values. If they are too tight or loose, the pump will experience an uneven pressure distribution, rendering it inoperable.

Sealing surfaces: When sealing joints, I must check all sealing surfaces to ensure no particles or lumps could cause leakage.

The above prescribed step-by-step procedures, regular checks on specific recommended technical parameters, and carrying out of the setting operations ensure the easy and correct placement and alignment of the pumps, increasing the lifespan and functionality of the units.

Recommended service intervals and procedures

For the pump to provide the best possible performance throughout its life, I comply with the manufacturer’s recommendations concerning the service intervals and the tasks associated with them about the particular working specifications of the equipment and its service conditions:

Daily Health Checks Routine: I perform daily visual inspections on a pump to identify any odd vibrations, unusual sounds, or water leakages. These quick checks ensure minor problems are nipped in the bud and deeper issues do not develop.

Monthly Maintenance Practices: I examine the pump and its lubrication mechanism monthly. I check the lubrication oil levels, determine whether the oil is dirty, and replace or pour more oil as needed. Lubrication keeps parts moving smoothly and helps prevent damage due to excessive friction. I use the required grade of lubricants the manufacturers provide to ensure they work well with the pump.

Quarterly Pump Alignment Checks: I use laser alignment tools or dial indicators every three months to measure shaft alignment and ensure that the manufacturer’s accepted tolerances are not exceeded (a standard amount is about ±0.005 inches for precision pumps). A lack of alignment may damage the bearings and strain the whole system.

Annual Overhaul: I take a pump apart each year for complete inspection. Other components that were also damaged, such as worn parts, friction seals, bearings, and impeller, are also considered. For seals, I check for surface finish integrity and check dimensions with the manufacturer’s tolerances (e.g., 0.002” deformation). I also remove parts that are irrecoverably worn out and those that are approaching their working lifespan according to the manufacturer’s recommendations.

By respecting these service deadlines and complying with the exact ratios and technical requirements, I ensure that the pump does not need to stop for repairs but can safely keep functioning at all times.

The role of coolant quality in bearing protection

The quality of the coolant substance is of utmost importance when it comes to good bearing protection and the general functioning of the pump. If the coolant of the bond is either impure or of low quality, it can result in rust, ineffective lubrication, and the rapid deterioration of the bonds. For the longetivity of the device, one must keep in check specific technical properties of the coolant, such as:

pH Levels: Always maintain the pH of the coolant between 8.5 and 10.0 to avoid rusting and losing chemical equilibrium.

Contaminant Levels: Restrict contaminant levels to the tolerable limits stated by the manufacturers (solid’s < 100 ppm concentration) to reduce abrasive wear and tear of seals and bonding substances.

Coolant Temperature: As a thumb rule, temperatures should be kept between 180° and 200°, allowing appropriate heat destruction and minimizing the risk of thermal overcharge on the bonds.

Additive Concentration: The concentration of wires, cables, and tubing should be regularly changed per the supplier’s instructions to protect the metal surface.

By performing routine testing and adhering to these parameters, you can increase the life expectancy of the bearings and the entire pump, preventing unwarranted downtime.

When should you consider replacing your bearing water pump?

Signs that indicate it’s time for a replacement

Excessive Noise During Operation: A variety of sounds—grinding, squealing, or rattling—from a pump may indicate bearing wear or damage. Broken bearings cause significant vibrations, which waste energy and make the operation less efficient for the senses.

Coolant Leakage: Coolant over the pump’s housing or shaft indicates wear of the seal or bearing, which is the likely most significant cause of the problem. Look for considerable leakages that extend normal water evaporation, which occurs regularly during an operation.

Shaft Misalignment or Excess Rotation: Elevated ratios of vibration that are higher than what is accepted indicate bearing wear or inappropriate shaft positioning. Reasonable figures of rotational vibration should fall in the agreed-upon ranges of the manufacturer, e.g.,<0.1 ips RMS in the case of smaller pumps.

High Operating Temperatures or Overheating: High temperatures due to activation may be due to broken bearings. This is the cause of concern. Make sure a pump is operating in circumferences 180°F to 200°F. If the operating temperature exceeds these regions, then there could be long-term erosion of the bearings and components.

Decrease in Flow Rate or Pressure Output: A drop in either flow rate or pressure or both may often suggest internal bearing problems in the pump. To determine whether efficiency has declined noticeably over the years, examine the pump’s performance resistance curve.

Life Cycle of Plant Equipment: Such conditions necessitate regular inspection. Ensure that the oil or grease supply follows maintenance levels, as lubrication shortens the life of the equipment if lubricants are needed but not supplied.

The bearing water pump in such conditions must be comprehensively evaluated, and all the observations must be compared with the manufacturer’s technical parameters. Maintenance of equipment is done in such a manner to ensure the reliability of the system and avoid costly interruptions or extensive damages in the future.

Choosing between OEM and aftermarket options

Several factors should be examined when selecting OEM (Original Equipment Manufacturer) and aftermarket bearing water pumps to ensure smooth compatibility, smooth performance, and good reliability in the future.

Technical Specifications: OEM components are manufactured with capital precision to meet the manufacturers’ specifications, for instance, the operating temperature (180°-200°F), flow rates, and pressure limits. Customization that is tolerable is available for aftermarket parts. Thus, dear consumers and customers, invest wisely and ensure the aftermarket part matches the original’s tolerances and performance curves to avoid damage.

Quality and Durability: Each OEM option must pass stringent tests and quality constraints, which limit the operational lifespan of the part but ensure it meets the equipment manufacturer’s standard. In terms of quality, non-OEM, cheap brands can be defective as they alter parts of the system, so the result should always be based on trusted manufacturers with proof of certification.

Cost Considerations: Aftermarket options tend to be cheaper, especially compared to old parts; however, an increase in maintenance cost and an increased risk of inefficient parts need to be weighed against the long-term benefits.

Warranty and Support: In most cases, parts provided by vendors as OEMs are generally supported by a warranty and other forms of support. On the other hand, aftermarket options should also be supported equally.

Application-Specific Needs: Consider your system’s working environment and load. For example, robust design specifications of OEM parts may be required in high-pressure or high-temperature applications, while aftermarket components may be adequate in less stringent applications.

You can achieve the required performance and reliability by considering such factors and confirming them with the requirements of the technical parameters stated in your system’s manual.

Understanding warranty and service policies

While evaluating warranty terms and service contracts, it is essential to ensure they are consistent with the technical specifications required by your system. For example, looking at the following aspects may assist in making sure of that:

Duration of the coverage period: Understand the original equipment manufacturer (OEM) warranty period and all aftermarket equipment. Depending on the specific part, OEM guarantees typically last between 1 and 3 years, but aftermarket policies may be much more diverse. Ensure the period is long enough to encompass the expected product use period for operational loads and usage conditions.

Technical Parameters Supported: the warranty should support maintenance constraints like the maximum working pressure, temperature, and load.

Exclusions and Limitations: All exclusions under the warranty should be read carefully to avoid putting oneself under any questionable liabilities. For example, a few warranties do not cover damage due to improper fitting/accessing of components with parameters outside the range set out in the warranty.

Service Support: Judge the availability of technical competencies during warranty periods. Does this evidence indicate an active effort to provide servicing, such as troubleshooting, replacement, and repairs? Do OEMs or aftermarket providers require certified professionals to install the system to uphold the warranty requirements?

In conclusion, going through these points allows the user to select the service coverage and contractual obligations that best protect the system’s required performance over time while avoiding unnecessary costs.

Frequently Asked Questions (FAQs)

Q: What are the benefits of a bearing water pump?

A: Bearing water pumping components offer advantages, including greater efficiency, longer lifespans, reduced friction levels, and smoother operation. These pumps usually have enhanced flow rates, which allow them to handle higher pressures and make them ideal for use in various automotive and commercial applications.

Q: What is the main difference between water-bearing and standard water pumps?

A: A bearing water pump uses a ball or a roller bearing at the end of the shaft, which means friction and wear are minimal and, in most situations, non-existent. This makes the pumping component quieter and more pliant, making it more damage-resistant than a standard water pump, usually equipped with bushings or sleeves instead of bearings where the shaft rotates.

Q: How much life can a bearing water pump usually have?

A: Bearing water pumps have a relatively longer lifespan, ranging from twenty thousand to around one hundred thousand miles or a bit more, depending on who uses them and their maintenance history. This is further evident as most manufacturers will state a respectable warranty on the product of two years maximum or more, meaning they are confident their product will last.

Q: What warning signs or indicators indicate that my bearing water pump should be repaired or replaced?

A: The bearing water pump may exhibit some noise ranging from grinding or whining, leakage of coolant, overheating of the unit, or if the pulley of the water pump visibly wobbles. Any of these symptoms could be an indication that the water of the bearing water pump might require some mechanical inspection.

Q: Are bearing water pumps universal to all vehicles?

A: Bearing water pumps are fitted to many vehicles, but it is best to check whether they are fitted to your make and model. Several bearing water pumps are available from manufacturers for various cars, including Toyota, and bear use of water motors. Be sure that the right part is purchased for the right vehicle.

Q: Does a bearing water pump enhance the performance of a paired engine?

A: Efficient swimming of the coolants maintained within the engine assists the bearing water pump to perform at its best, in this way the engine performance gets a boost. Even the calm and efficient functioning of the water pump exerts less stress on the other components within the engine, such as the drive or timing belt, which helps increase the life of those components, too.

Q: What maintenance does a bearing water pump require?

A: Overall, the maintenance required bearing water pumps is minimal, but the unit itself must be inspected to check if no irregularities, wear, or leakage is present. Some pumps apply periodic grease on the bearings, while others are sealed units. The user must always consider what the manufacturer states regarding maintenance and inspection intervals.

Q: Is repairing or replacing a bearing water pump every time possible?

A: When a bearing water pump needs to be serviced or replaced, it is better to replace the entire apparatus rather than try to repair it. This promotes better functioning of the unit and reduces any chance of problems occurring in the future. Some minor ones might include a loose pulley or some leaks, in such cases it would be best to speak to an able mechanic and explain your specific case.