Centrifugal pumps are key parts of numerous machines and processes in industrial and commercial usage, enabling the movement of fluids under different conditions. In centrifugal pumps, the bearing assembly is the main component that helps hold and rotate the pump shaft with meshes such as friction and wear. The effectiveness of the bearing assembly increases, and as such, worsens the bearing assembly, improves pump operation, increases pump durability, reduces energy consumption, and minimizes the maintenance of pumps. This is accomplished by examining why bearing assemblies are critical in centrifugal pumps, their advantages, how they work in the system, and how they affect the system’s reliability. This can also allow you to increase the efficiency of the centrifugal pump, or it ensures that the pump will work under certain conditions without interruption. To unleash the true power of your centrifugal pump, you need to know how significant this part is.

What is a centrifugal pump bearing assembly, and why is it important?

Understanding the role of bearing assemblies in centrifugal pumps

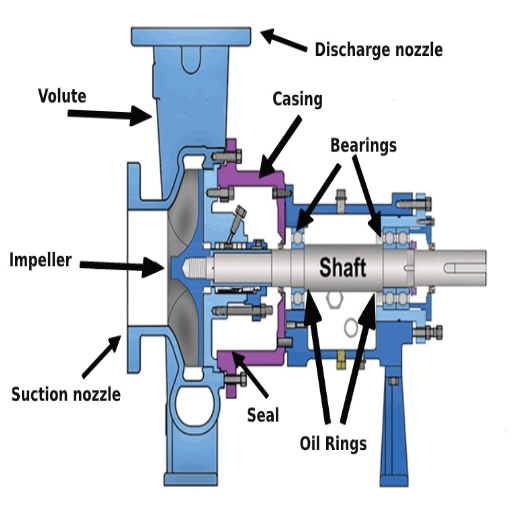

The primary purpose of the assembly for bearings in centrifugal pumps is to bear system torsion by holding the rotating shaft in place, which enables the impeller to operate freely and vice versa. The other purpose is to carry radial or axial loads and control misalignment of pump parts during operation, which is imperative to performance and the overall lifetime of the equipment.

Load Capacity: During pump operation, the bearings are subjected to radial and axial loads. The radial load may come from the action of the rotating impeller, while the axial load results from the hydraulic force produced from the interior of the pump.

Operating Speed (RPM): To avoid excessive heat and wear, the bearings must rotate at the same speed as the pump. Centrifugal pump bearings might run between 1200 and 3600 RPM.

Lubrication Type: Bearings are lubricated (with grease or oil) to reduce wear and tear. Appropriate lubrication prevents overheating and prolongs the life of the equipment.

Material Composition: Generally, composite materials consist of many lots, such as chrome steel or ceramics, which are all anti-corrosive, heat-resistant, and able to withstand harsh conditions.

Temperature Range: The range in which the bearings can work effectively depends on the temperature at which a pump operates and can vary from -20f(-29) to 250f(121), depending on the use.

When these requirements are adhered to and regular servicing is done, the bearing assemblies enhance the operational life of centrifugal pumps, optimizing their performance and averting unexpected breakdowns.

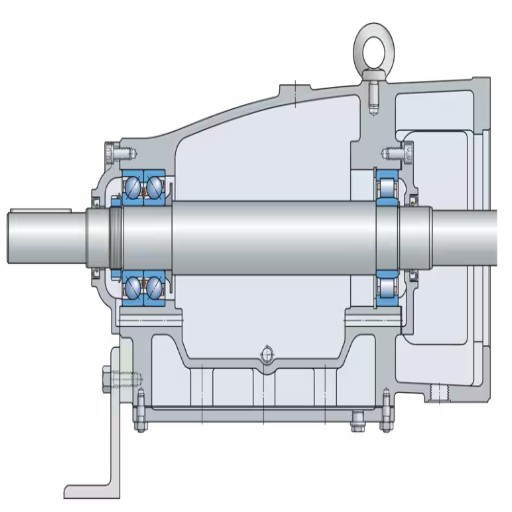

Key components of a pump bearing assembly

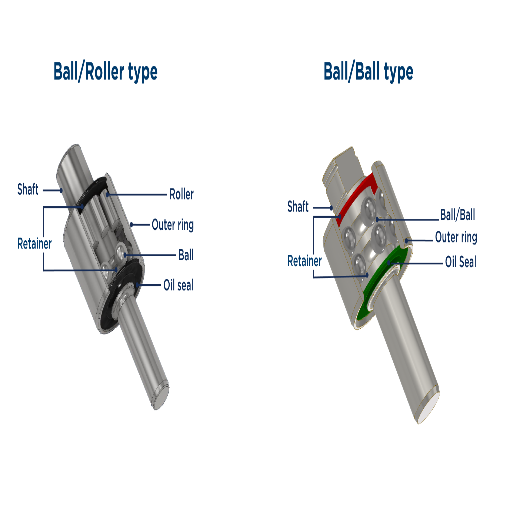

Bearings are essential components supporting the rotating elements and reducing inter-part friction. Well-known examples are ball bearings and roller bearings. Technical parameters consist of bearing load capacity, rotational speed of the bearing, and type of material used, such as stainless steel or ceramics, for better performance.

Shaft: The shaft rotates and transfers power to the impeller. It is designed to be highly strong and stiff enough not to bend during use. The most common materials used here are carbon steel or alloy steel, which is sufficiently rigid for service.

Seal: This seal maintains the fluids being pumped within the system, which should prevent external contamination of the bearing assembly. Mechanical seals or packing are generally used, taking into consideration the temperature and chemistry of the medium used in the pump.

Housing: The housing contains the bearings in a bath, preventing them from being destroyed by dirt particles coming from outside. Close tolerances in the machining operations and the toughness of the materials, such as cast iron or aluminum, are crucial for the structure.

Lubrication System: Viscous shear diminishes wear and decreases temperature. Dominant systems are oil or grease-lubricated with the defined viscosity grade and replacement time intervals.

Temperature Sensors (optional): These are key in critical application areas as they assist in monitoring the working temperatures of other systems to accommodate high temperatures, which could be damaging.

Adequate consideration of these components, combined with rational technical characteristics, enables a pump-bearing assembly to enhance its reliability, durability, and efficiency in harsh working conditions.

How bearing assemblies impact pump performance and longevity

Bearings are significant for the strength and smooth functionality of pumps. They reduce moving parts’ wear, encourage low friction, and improve mechanical working. If the bearings are correctly selected, they will affect the reliability, energy efficiency, and the entire pumping system’s lifetime. In the following paragraphs, some of the most important technical parameters and their relevance for the pump use are given:

Load Capacity: The pumps are defined by their application loads, such as radial and axial loads that the bearings must support. Also, oversizing and undersizing bearings will eventually lead to pump failure. For example, if the application has high loads, roller bearings with more dynamic load ratings than the working conditions are necessary.

Speed Ratings: RPM on the pump run must be observed on the bearings. Otherwise, this will lead to the bearings overheating and harmful alteration of the lubricant; either is surpassed. When dealing with high-rpm pumps, ensure the bearings can handle such speeds.

Material and Coatings: Bearings made from stainless steel or ceramic hybrids are corrosion-resistant and offer longevity. They can withstand harsh environments caused by abrasive or corrosive fluids.

Lubrication Systems: Oil or grease are adequate lubricants that provide quality lubrication by ensuring less friction and heat. However, the working lubricant viscosity must not exceed the operational speed and temperature requirements. For instance, if the pump’s working temperature is moderate (ISO VG 68) or if the speed is high, it will require VG 32.

Misalignment Tolerance: The shaft misalignment of the pumps in operation requires the buildings to have self-aligning features, such as self-aligning roller bearings, to avoid uneven loading and mechanical stress.

Clearance and Fit: Keep maintaining the proper internal clearance, which is widened to allow for thermal expansion during operation; otherwise, workings are also efficient for temperature variation.

Considering this deal and the correct way of installing and servicing the equipment, the bearing assemblies help to enhance the performance and durability of the pumps, which, in turn, helps minimize downtime and operating costs.

What are the main benefits of a high-quality centrifugal pump bearing assembly?

Improved pump efficiency and reduced energy consumption

An emphasis on individual components translates into increased pump efficiency consumption and minimization of energy usage. A good centrifugal pump booster would be worked on bearing assemblies. This frictional reduction is linked to smoother and more efficient load operations. Less mechanical resistance means more energy savings, and the pump accomplishes the required volumetric flow with less power input.

Bearing materials and coatings such as ceramic hybrids or PTFE guarantee low friction coefficients, which means minimal energy loss.

Higher radial and axial load capacities are guaranteed with enabling bearing assemblies when operational conditions are not constant.

Performance is reduced by misalignment and poor rotation. Increase performance & optimization rotation using isolative Tolerances machining grades on a precise or aggressive basis of ISO P5 or P4.

Oil Direct injection or grease lubrication hones great performance by minimizing wear and Burnouts; hence, power requirement further drops.

Poor heat dissipation leads to scorching and prevents bearings from thermal management; hence, constant machine operations have limitations.

This centrifugal pump system is useful for ensuring smoother processes, inexpensive operations in the long run, and viable energy consumption.

Extended pump lifespan and decreased maintenance requirements

Due to numerous enhanced design features and efficiencies within pumping systems, CENTRIFUGAL pumps can achieve superior durability and lower maintenance and operational costs. Important factors extending the life span are utilizing corrosion-resistant materials, which minimize wear in aggressive environments, and having finely engineered components that reduce mechanical stress and vibration. Regular lubrication systems also contribute to improved component longevity and enable smoother pump operation over time.

On the more technical aspects, materials like duplex steel or stainless steel can function in conditions of high pressure and corrosion, thus enabling a longer life cycle of components. Vibration caused by significant load over time can be reduced to below 2 mm/s using bearings with better load ratings and dynamic balancing, ultimately cutting down wear. Seals have also improved since mechanical ones are capable of handling 25 bar of pressure (often reducing the chances of leaks and thus maintaining the system integrity)

Effective maintenance strategies include innovative monitoring systems that track critical parameters such as bearing temperatures below 80°C, vibrations, and pump output efficiency. These real-time diagnostic aids are predictive maintenance, minimizing downtime while increasing the pump’s overall performance consistency. Incorporating all these technologies together means that pump systems will require less servicing, reducing operating costs simultaneously and assuring reliability over prolonged periods.

Enhanced reliability in various industrial applications

Pump systems’ high-end monitoring and diagnostic features allow them to be used in various industries and varying conditions. For example, in the oil and gas industry, pumps work in harsh environments, such as high pressures of 3000 psi and temperatures from -20°C to 150°C. Depending on the requirements, the pumps work at a volumetric flow rate of 10-2000 gallons per minute (GPM), reducing mechanical disturbances and resource wastage.

For instance, in chemical processing, the materials are exposed to corrosive fluids, so it is essential to have pumps made out of Hastelloy or other more advanced alloys. Pumps must undergo a lot of stress; hence, the pumps vibrate, and the vibrations need to be controlled to not damage the equipment, which is generally under 1.5 mm/s RMS. In facilities that treat water, maintaining constant efficiency throughout the working hours requires using VFDs in conjunction with the motor, ensuring pressure stays between 50-150 psi.

IoT-driven Predictive analysis ensures that such variables are worked on so that damage doesn’t occur suddenly. With these features, venturing into the unknown becomes less daunting as reliability increases and other processes become more efficient.

How do I choose the correct bearing assembly for my centrifugal pump?

Factors to consider when selecting a pump bearing assembly

In my experience with centrifugal pumps, choosing the appropriate pump bearing assembly involves several important considerations, which include:

Load Type and Amount: The type and amount of load on the pump are one of the first considerations; this will, in turn, dictate which bearing can be chosen that will be able to handle the load without causing any deleterious effect on the pump’s performance or lifespan. For example, angular contact bearings are preferred for combined axial and radial loads.

Pump RPMs: Another factor I consider is the pump’s operating speed. The bearings must operate at the pump’s RPM; otherwise, they may overheat or wear out too quickly. I consider self-aligning ball bearings with high rotating speeds.

Lubrication: If self-aligning ball bearings are used, lubrication becomes even more crucial so that the bearing can last longer and operate more efficiently while withstanding higher operational loads. I try to ascertain if oil or grease would be best as friction depends on different speed and temperature conditions.

Ambient Temperature: The loads listed above mean that the ambient temperature can significantly affect bearing performance. For most applications, I would require a bearing capable of withstanding thermal environments between 0 and 200C, but this also depends on the requirements.

Material: Bearing construction requires either stainless steel or similar coatings, such as chrome plating, to protect bearings from preventive corrosion, especially for pumps in corrosive environments.

Bearings: Any disturbance to the alignment will lead to failure. Hence, realignment is essential for pump-bearing assemblies, as it can provide an instant solution. Self-aligning cartridges are appropriate for these applications.

Ease of Service: Ease of service also affects the point at which replacement is required. It dictates how complex or straightforward the assembly design will have to be, determining the period for average downtime.

Mastering those technical parameters allows me to select a robust bearing assembly that suits the pump’s work specifications.

Compatibility with different pump models and series

While evaluating prospects of interchangeability and compatibility with varying pump types and series, I strive to ensure that the bearing assembly design and pump in which it will function are integrated. This is what I consider in hand from a technicality:

Dimensional Fit: I check the shaft diameter, housing bore, and overall assembly size so that the bearing corresponds with the pump size to avoid interference or misalignment.

Load Capacity: I also note the particular axial and radial forces the pump will face and ensure that the bearings can adequately withstand these forces while maintaining the necessary safety margins.

Operating Conditions: I also review the pump’s discharge speed, temperature, and lubrication to select bearings with suitable tolerances and material strengths that can withstand such operating conditions.

Material Compatibility: The materials used in the pump and bearing must be chemically compatible to prevent corrosion or wear during prolonged exposure to working fluids.

Standardization and Interchangeability: I also check whether the selected bearings comply with the bearing industry standard to ease the replacement and interchangeability of the bearings with other pumps within one series.

By addressing these parameters, I can confidently recommend any bearing solution that will withstand the prescribed performance of different pump models and make the system more durable and efficient.

Evaluating material options for optimal performance

When analyzing material options for better performance, I emphasize a few key aspects that would guide the selection of materials to meet the operational requirements specifically for the pump. This is how I do it:

Corrosion Resistance: Materials with high corrosion resistance are essential when the pump operates in hostile or chemically reactive environments. Due to their resistance properties, 316 SS stainless steel or duplex stainless steel would be preferred when pumping corrosive fluids.

Wear Resistance: I also use wear-resistant materials to reduce the wear of components in contact with abrasive fluids. Because they help to prevent the deterioration of the material, which is necessary for such situations, more rigid materials like tungsten carbide or ceramic composites are optimum.

Mechanical Strength: Sufficient tensile strength and endurance materials are essential to withstand high operational pressure and heavy loads. High strength-to-mass ratio carbon or alloy steel grades are better options where weight will be an issue, particularly in stress regions.

Thermal Properties: It is essential to ensure that the material can withstand temperature changes or extreme temperatures. Nickel-based alloys, due to their high melting point and good thermal conductivity, are ideal for high-temperature applications.

Cost and Availability: Although I prefer high-performance materials, I consider cost and availability to balance performance with budget constraints. For cost-effective benefits, non-critical applications are deemed to be made with low-grade materials such as cast iron.

So, by evaluating these parameters, I can choose the pump materials that will satisfy the functional requirements and guarantee the best performance, robustness, and reliability.

What are the signs that my centrifugal pump’s bearing assembly needs replacement?

Common indicators of bearing assembly wear and tear

Every centrifugal pump makes a noise, but it’s vital to assess what type of noise it is when you check the coefficient of hardness of a centrifugal pump’s bearing. Following are some of the observations worth noting:

Noise: As centrifugal pumps operate, there are cases of excessive panic noise caused by vibrations and grinding. One definite possibility is the bearing being destroyed or worn. These irregular sounds, such as pitting and misaligning, can become a nuisance.

Temperature: For mechanical pumps, temperatures over 120 to 180 degrees Fahrenheit recommend poor conditions that require lubrication fitting. Looking for heat means looking for unhealthy bearings.

Efficiency Drop: A loss of presence within the bearing assembly can trigger Federation accentuations, which can collapse material efficiency and push it to the fatigue stage.

Visually Affected: Many times, things like scoring or discoloration of the color of the bearing surfaces are looked at. Such seems can act as confirmation for the requirement of replacement.

Abnormal Shaft Movement: Failing bearings can cause increased axial or radial play in the pump shaft. If not addressed promptly, this misalignment can lead to further mechanical issues.

By systematically monitoring the condition of elements such as temperature and shaft alignment and referring to the acceptable values provided by the manufacturer every single time, dry bearing replacement can be avoided, which would otherwise disrupt the work cycle.

The importance of regular bearing assembly inspections

Periodic bearing assembly encompassing is instrumental in ensuring the equipment’s overall intact working and lifespan. I, for one, use such inspections in a more predictive manner – to avoid failures in operation. By employing routine checks, I can measure the abnormalities in such parameters as;

Temperature Tolerances: Most bearings have optimal operating temperatures between 90 °F and 150 °F (32 °C and 65 °C). Any variation outside the boundaries of the ranges set by the manufacturer should be a cause of undue concern and could indicate overheating due to excessive friction or lack of proper lubrication.

Vibration Levels: To prevent imbalance, vibration measured in terms of velocity or acceleration should lie within acceptable limits, say, less than (0.2 IPS) on the general purpose machines.

Lubrication Condition: The viscosity of the lubricants (ranging 20-100 cSt based on system requirement), and any contamination should be within the acceptable limits. Otherwise, it leads to the failure of the bearing.

Shaft Alignment: Radial and axial movement misalignment leading to tolerances greater than 0.002–0.005 inches (0.05–0.127 mm) should be avoided, as it increases stresses on the bearing assembly.

Miserable performing systems may require amending maintenance such as replacing bushings, attending angular drives, enforcing grating operations, checking the work order, air movements, etc, and trying such a treater results in reasonably redundant future systems.

When to schedule a bearing assembly replacement

The standards mentioned above are essential to set the expectations in triaging when a bearing assembly replacement is to be scheduled, and in so doing, I concentrate on specific technical parameters and performance anomalies. For instance:

Vibration Levels: I regard vibration levels above 0.05 inches per second or any increase over 10% relative to the operating point baseline internal readings as if they may also suggest or point to possible imbalances or damage to the bearing assembly.

Temperature Thresholds: Bearings that operate sexually cycled above 150 degrees Fahrenheit or at a constant increase of 10-15 degrees Fahrenheit without consistent bearing augmentation indicate inconsistent lubrication, wear, and depreciation.

Lubricant Condition: The above regarding the lubricant viscosity being below the 100 and 20 cSt level is a serious risk of having the bearings not being able to stand with the irregularity that poor lubrication brings along, which is witnessed in the contamination, discoloration, and dewability deterioration of the lubricant.

Noise Levels: This deficiency in lubrication and augments In misalignment may result in Abnormal noise coming from the bearing during functioning, accompanied by grinding and squealing.

These are the factors that can be monitored and if they exceed the recommended thresholds by the manufacturer, replacement can be made, otherwise faster corrective action not only aids in achieving minimal system retention but enhances the expedient.

How can I properly maintain my centrifugal pump’s bearing assembly?

Essential maintenance practices for bearing assemblies

Lubrication of the members: I presume I have sufficient lube within the correct viscosity range and as the supplier recommended. The goal is not to agitate the element perms of the bearings. Depending on the mechanical working conditions, they are to be changed whenever required, either due to extreme wear or contamination that a visual inspection would allow them to gauge.

Alignment in load conditions: I can constantly check how well the gears are connected regarding mated surfaces by noting how often the drum handle is tightened. The frequency usually starts to decrease as the gears wear. For this reason, I ensure that structural deformation does not begin if the elements have met the required contact percentage.

Thermal Stability: Bearings can be checked for operating at the required temperatures by being placed in a heating chamber connected to temperature-measuring sensors. Non-insulated areas must also be checked regularly throughout the testing. A specific threshold of no insulation or bearing heating can be conveniently spaced to prevent overheating or insulation deformation even if subjected to intense external pressure.

Contamination checks: A visual check must be performed frequently. For instance, checking whether I’ve sealed all the manual openings on the pumping body is crucial since I want to avoid adding contaminants from the outside, such as dust particles. Allowing contaminating particles to break the surface levels of the bearings may agitate core mechanics and thus wear out the piece significantly quicker.

Noise Checks: I utilize a stethoscope and a vibration analyzer to focus on the noises that the bearing makes while in use. Sounds such as churning or squeaking often indicate a problem, which in most cases could be an internal fault or a misalignment, leading to more examinations being conducted.

Scheduled Overhaul: As the manufacturer suggests, I try to follow the planned periodic examinations and overhauls of the bearing assembly to aesthetically exchange worn-out parts, perform alignment checks, and check the lubrication system and seals.

With the practice guidelines and selected parameters in mind, I can extend the life span of my bearing assembly and decrease the chances of sudden crashes.

Lubrication techniques for optimal bearing performance

Primarily, for the performance of the bearings, I have several effective lubrication techniques that are appropriate for the operational condition of the assembly. The first aspect concerns the type of lubrication- whether it would be grease or oil. This is guided by parameters such as load, speed, and temperature. For example, heavier grease is required for high-load and low-speed applications, whereas systems that operate at high speed require low-viscosity oil.

I ensure that the lubrication intervals are correctly defined and that the lubricant is reapplied at the specified period recommended by the manufacturer. This is important as it protects the system from over-lubrication that could lead to overheating or, worse, is protective against under-lubrication, which could increase friction and wear. The operating application is done considering factors such as the temperature range and the environmental conditions under the lubrication. As a result, the viscosity and the protective characteristics are maintained.

The following have governed the detailed tactics of lubrication on my part:

Viscosity: Contributes to the stabilization of the film by ensuring it does not become too scarce, thus ensuring surface contact is minimized.

Temperature Range: The maximum and minimum temperatures of the lubricant are related to the working conditions.

Load Capacity: Lubrication that is adequate for mechanical usage is chosen.

Contaminant Resistance: Lubricants that can resist water and other debris are considered.

With the consistent consideration of these parameters, I can ensure that their performance rating meets and passes the mean requirements. That room for operational risks is mitigated if not eliminated.

Troubleshooting common bearing assembly issues

Excessive Noise: The first step I do is searching for lubrication to avoid noise. This can often be attributed to under-lubrication or using an inappropriate viscosity lubricant. Maintaining a well-defined viscosity index for shear or deformation between two or more surfaces is essential. In addition, I also check for contaminants like dirt or moisture that could have compromised the lubricant, making deleterious particles encapsulating additives important, such as silicon-based polymeric materials.

Overheating: I realized that depending on the extent of thermal regulation, lubrication may not be effective. Therefore, the use of adequate temperature lubricants may prevent overheating. For most lubricated applications, the ideal lower limit working of the lubricant should mean that it can support the operational thermal loads of the application and all specified shielding qualities. Exceeding loads could also be an issue; that is why the critical load condition of lubricant also has to be examined to do away with such problems.

Premature Wear: Premature wear is also due to insufficient film strength or poor lubricant selection. This leads back to viscosity and load capacity because I am concentrating on a lubricant that would provide a surface layer aid against contact stress while coping with mechanical stress as well. Additionally, grit and other types of wear particles can worsen the situation, emphasizing the necessity of contamination resistance.

I hope that addressing these issues with these parameters as a guiding framework will allow the bearing assemblies to efficiently whereby there is minimal time wastage and loss sustained.

Frequently Asked Questions (FAQs)

Q: What is the description of a centrifugal pump bearing assembly

A: Bearing assembles in centrifugal pumps are essential pump elements supporting and turning the shaft. In the most typical fashion, it involves the housing, seals, and the bearings themselves. The general idea of this assembly is to assist in minimizing friction, securing the precise orientation, and smooth turning movement of the shaft, which is one of the primary requirements of the efficiency and life of the centrifugal pump.

Q: Why is a reliable bearing assembly necessary for centrifugal pumps?

A: The bearing assembly of centrifugal pumps is vital in centrifugal operation as it determines the centrifugal pump performance, and the centrifugal pump does not fail in the course of its working. It assists in maintaining proper axial and radial alignment of the shaft, helps in reducing pump vibrations, and the degree to which the other parts, such as the impeller and the mechanical seal, are rotatable concerning the casing. Improvements in energy consumption and the frequency of repairs and maintenance also minimize wear and tear of bers and mechanical seals and bearings, which otherwise impinge on the efficiency.

Q: How do I know when to repair or replace the bearing assembly?

A: Some of the reasons or the symptoms of the weakening or collapse of the bearing assembly include excessive vibrations around the pump casing noise, most often in the form of grinding, or squealing sounds, abnormal behavior of the shaft, sometimes shape change, frequent consumption of power supply, and breakdown of seals. Regular assessment and supervision of the life of a pump are conducive in early detection of the few issues mentioned above.

Q: Which components can one generally find in the centrifugal pump bearing assembly?

A: The centrifugal pump bearing assembly consists of the following components; generally, the parts include a set of bearings (usually a ball or roller type), bearing housing, a shaft sleeve, seals (mechanical seals or lip seals), and a lubrication system (oil or grease). Other assemblies can also be fitted with parts such as o-rings, gaskets, and locking devices to enhance the sealing and alignment of the centrifugal pump bearing assembly.

Q: What steps do I follow to replace the bearing assembly in a centrifugal pump?

A: To ensure that a new bearing assembly is installed correctly, some steps have to be followed. 1) Make sure all parts are cleaned properly and completely. 2) Check the shaft thoroughly for damages. 3) Heat the bearings before fitting them on the wheel-bearing assembly. 4) Fit the bearings on the shaft, making sure they fit in place appropriately. 5) Follow up by fitting the seals and other parts as well. 6) Then attach the assembly to the casing of the pump. 7) Finally, ensure the shaft is positioned appropriately. 8) Apply grease as recommended by the manufacturer. Ideally, the pump’s manual or an expert should be contacted for accurate explanations.

Q: What advantages can be derived from using an oil-lubricated bearing assembly?

A: An additional benefit of oil-lubricated bearing assemblies is increased service life and performance in high-speed applications. They allow easier visual monitoring of the bearing condition through oil samples and provide better lubrication in some situations. However, they may require more maintenance interventions than grease lubrication systems that only require fewer manual interventions.

Q: How does a trustworthy bearing assembly assist centrifugal pumps in saving energy?

A: A reliable bearing assembly assists in maintaining the pump shaft in the axial and radial orientation and movement it experiences when the pump is running. This reduces efficiency losses due to surface friction and helps eliminate problems due to shaft angular shifts, which can lead to reduced efficiency of the impeller. As a result, less effort is needed from the motor rotation to efficiently run the pump, thereby saving on energy that would significantly increase the operating cost

Q: What are the considerations when getting a new bearing for a centrifugal pump?

A: There are several things to consider when selecting a replacement bearing assembly, such as the operating conditions of the pump, the type of fluid to be pumped, the desired life of the bearing, and, course, the compatibility with other elements of the pump. Providing that the bearings are of better quality, the high-quality components from known manufacturers can be manufactured without any fear. Therefore, the performance and reliability of the bearing can be assured. Asking a pump engineer or the original equipment manufacturer for guidance may aid in achieving the most suitable option.