Bearing selection is a critical factor in the design of almost any centrifugal pump system. Centrifugal pumps are indispensable for water treatment, chemical applications, and power generation. These types of pumps are almost always designed with a supporting bearing empowered with a bearing housing and other ancillary features. Since the bearing selected affects the entire life cycle of the pump, it is essential to choose the right one. This guide is intended to equip the reader with the insight to make reasoned decisions to ensure the optimal performance of centrifugal pump systems. Engineers, maintenance personnel, and even enthusiasts trying to understand pump mechanics will benefit from this guide. The choice of bearing is not limited to the type and form of the shaft; the operating conditions, materials, and load all have to be examined.

Why is bearing selection crucial in pump applications?

What are the consequences of improper bearing failure in centrifugal pumps?

The lack of proper thrust in centrifugal pumps’ bearings can affect operational performance and reliability. In my experience, the first and foremost effect is reduced efficiency, as low-performing bearing units increase friction and energy use and worsen pump operation. Such inefficiency can increase operational costs and even cause pump parts to overheat. In addition, bearing faults can result in excess vibration and noise, which, if not controlled, can damage other sensitive installations, like the shaft and impeller.

Some of the most critical technical issues to control are the following:

Load Capacity: Bearings that cope poorly with the specified axial and radial loads can fail catastrophically and shockingly.

Lubrication Needs: Poor lubrication can lead to overheating, wear, and premature failure. It is also worth mentioning that any insufficient lubrication can also be damaging.

Operating Temperatures: The recommended level of bearing temperatures must not be exceeded as it can lead to material degradation and reduced lifespan.

Alignment Accuracy: If the pump shaft and bearing housing are not aligned, the bearing and housing will become misaligned.

Provided the parameters, installation, lubrication, and alignment are controlled correctly, the risk of the pump suffering unexpected failures induced by a fault-finding mission is low, and the pump’s service life is considerably prolonged.

How do pump bearing types influence performance?

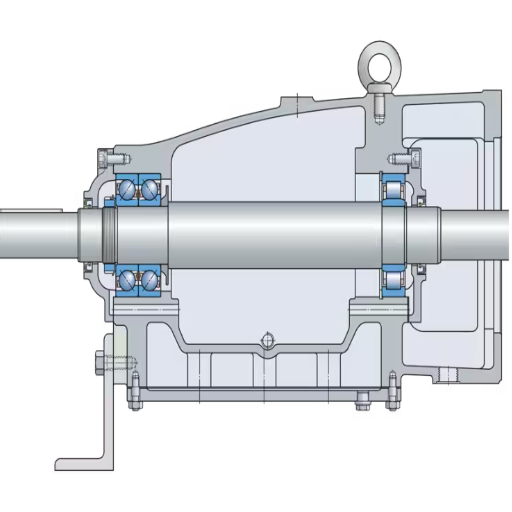

What role does bearing housing play in pump efficiency?

The bearing housing is essential for the efficiency of the shaft pump. The shaft is facilitated rotationally by bearing in the proper position and alignment. Personally, I believe that the design of the bearing housing has a lot to do with the vibration and heat levels within the pump system and its overall stability. When it comes to choosing or assessing bearing housings, I look at the following technical indicators for high performance:

Material Composition: Heavy-duty materials such as steel or cast iron have excellent mechanical properties and can withstand operational stresses.

Alignment Tolerance: Proper alignment of the bearing housing needs to be ensured to prevent uneven bearing wear which leads to energy loss and increased maintenance activities.

Heat Dissipation Features: Core components of pump housing that with integrated cooling parts or sufficient surface area around facilitate increased surface heat dissipation to the environment and increased bearing life.

Sealing Mechanisms: Seals need to be of high quality and purposed to prevent dust, moisture, and chemicals from getting into the bearings to maintain their efficiency.

By concentrating on these parameters, I can be sure the bearing housing is helping in smooth and energy efficient pump operation, which makes the device more reliable for use in a widerange of applications.

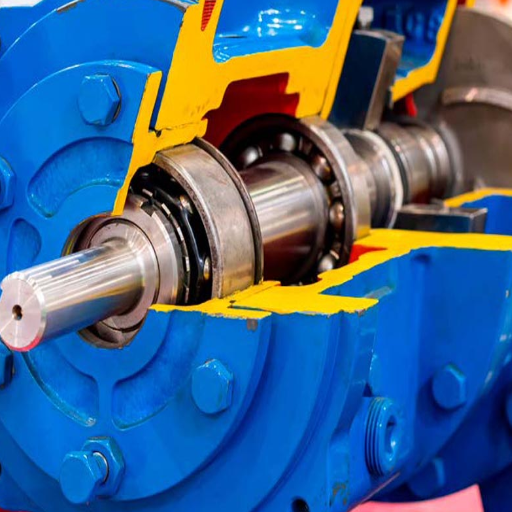

What bearing types are most effective in centrifugal pumps?

How do angular contact bearings function in pumps?

Angular contact bearings assist in both radial and axial loading without any hassle. That is why they are preferred in centrifugal pumps where multi-directional loading is prevalent. I use angular contact bearings when the impellers have considerable axial thrust to ensure the pump works efficiently under these conditions. These bearings are much more efficient because they can increase loads faster.

Technical Parameters:

Contact Angle: The contact angle directly affects an axial bearing’s ability to carry thrust; a higher contact angle results in better thrust-controlling contact between the shaft and the bearing.

Precision Grade: The higher the ABEC scale, the tighter the bearing tolerances (e.g., ABEC-5 or higher). Because of the tighter tolerances, the bearings’ vibrations are reduced when used at high speeds.

Cage Material: The best polyamide or brass cage materials ensure that the bearings operate effectively and efficiently under the conditions of a varied range of loads.

Lubrication: The correct lubrication application reduces friction and heat produced while the bearing moves continuously, increasing its lifespan.

These parameters are the reasons that make it possible for angular contact bearings to enable engineers and other specialists to support the existing pump set, improve its performance and decrease downtimes and bearing failures under high demanding conditions.

When should deep groove ball bearings be used?

Deep groove ball bearings are essential for reliable performance whenever there is a need for multi-functional and versatile deployment, especially with radial and moderate axial loads in either direction. Their simple design makes these bearings more appealing, which enhances high speed and reduces friction and maintenance needs.

Important parameters are:

Load types: Highly versatile as they are primarily meant for handling radial loads but can also manage moderate axial loads in both directions.

Speed: Their low frictional torque enables them to operate at high speeds.

Tolerance: The use of standard tolerance class guarantees precision and reliability in numerous applications.

Sealing options: They can also be provided in open, shielded, or sealed form, depending on the operating environment and level of contamination.

These features and characteristics make Deep-Groove Ball Bearings exceptionally competitive in electric motors, fans, conveyors, and other devices requiring reliable and smooth operation.

What are the benefits of double-row bearings in pump applications?

Double-row bearings are essential in pump use because they help improve its stability and load capacity. Their capacity for radial and axial loads gives them the edge in high-performance and other demanding environments. They also help reduce heat and friction in a system, enhancing operational efficiency and prolonging service life.

Technical Parameters:

Load Capacity: Double-row bearings generally have a greater load capacity than single-row designs, which can support dynamic and static loads.

Alignment Tolerance: Their design compensates for slight misalignments, diminishing excessive wear on the bearing and its components.

Speed Limitation: The operational speeds relative to pump requirements can be met depending on the bearing type. The manufacturers provide normal ranges that define limits.

Considering these attributes and the need for applications where a high degree of reliability and efficiency is required, a higher level of performance is required.

How does lubrication impact pump bearing longevity?

What is the best lubricant for bearing systems?

The choice of lubricant depends on specific conditions such as load, speed, temperature, and environmental conditions. On a personal note, I advocate for oil or grease as the go-to lubricant since it tends to excel in most use cases. Synthetic lubricants maintain consistent viscosity for friction reduction over large ranges of temperatures, which yields proper film strength. For example:

Load Handling: An EP-modified lubricant should be used for severe high-load conditions.

Speed: High-viscous oils tend to increase friction in high speed tasks, therefore low-viscous oils should be used.

Temperature: Polyurea or lithium complex greases should be used for high-temperature environments as they maintain excellent thermal stability.

Environmental Factors: Lubricants integrated with rust and oxidation inhibitors should be used in wet or corrosive settings.

These factors cannot be overstated; coherence and attention to detail are vital. Follow the manufacturer’s guidelines to enhance the efficiency and longevity of the bearing system.

How often should lubrication be performed in centrifugal pumps?

The lubrication intervals of centrifugal pumps are periodic. They are controlled by factors such as the pump’s conditions while operating, the load on the pump, the speed range, temperature, and other environmental factors. In my experience, and for pumps working in self-dictated parameters of a typical environment, moderate speed, and temperature, lubrication is needed once every 2000 to 4000 operational hours (approximately every three to six months). However, as previously mentioned, significant variability exists.

As an example, a pump that works at high speed and high temperature might need more routine lubrication intervals (monthly or even bi-weekly). Other important technical parameters are:

Operating Speed: More lubrication is required as the speed increases to cater for wear.

Temperature: At temperatures above 65 degrees centigrade, the frequency of lubrication becomes important or else the grease will be degraded excessively.

Load Conditions: Increased stress on the bearings due to heavy loads will lead to an increase in wear and, hence, reduce the life of the bearings.

Environment: Dusty, wet, or corrosive working conditions of the environment can lead to faster corrosion and thereby lower the quality and life. Hence, the lubrication needs to be paid more attention.

When dealing with centrifugal pumps, I suggest always following the manufacturer’s recommendations and maintenance instructions, which are specific to the pump’s design and working conditions.

What are the signs of inadequate lubrication?

In my experience, a few indicators point towards insufficient lubrication for a centrifugal pump:

Increased Noise: Bearings with inappropriate lubrication tend to generate noise like squealing, grinding, or rattling, which indicates increased friction or abnormal operations.

High Temperature: Overheating is a symptom among bearings that work without sufficient lubrication, and checking the temperature of the bearings is essential (critical range is usually 70°F to 160°F or 21°C to 71°C). Anything above that range can indicate overheating issues and lubrication failure.

Level of Vibration: Higher vibration levels are a direct consequence of insufficient lubrication. This can threaten everyday operations by increasing the machine’s wear and tear. Regular measurements through a dependable vibration meter can help monitor vibration levels; increases in grease or oil indicate a faulty mechanism.

Noticeable Grease/Oil Leakage: Excessive leakage at seals and bolted joints indicates faulty lubrication and contamination.

Less Productivity: An increase in lubrication can lower the overall productivity as the centrifugal pump tends to consume more energy.

Always crosscheck lubrication intervals, temperature, and vibration (IPS or mm/s) as outlined by the pump’s manufacturer to minimize facing any severe issues. Following these guidelines can maximize the life of the device and maintain optimal productivity.

How can bearing failure be prevented in pumps and compressors?

What are the common causes of pump bearing failure?

Pump bearing wear-related failures often occur from common causes directly linked to operational and maintenance practices. In my case, the most common reason is lack of proper lubrication. Improper lubrication can be granted as either excess or deficient lubrication. As an illustration, excessive lubrication may actuate the stress on seals, while insufficiency aggravates friction, leading to overheating. Furthermore, Inadequate oil or grease amounts put over by the manufacturers’ guidance leads to more significant issues.

Misalignment or imbalanced components can also put forth other challenges. Misaligned bores or imbalanced rotors show heavy loads concerning bearings and other component elements, increasing the wear from profound muscular impacts. It is resolved by aligning the components with precision using appropriate tools.

Anything else not intended to blend within the lubrication or bearing parts, like dirt, water, and certain metal parts, leads to contamination, which also causes failure. The particles infiltrating the bearing system can destroy lubricants and several bearing surfaces. Seals must be maintained appropriately, and lubricants must be filtered regularly to avoid removing them and reduce the chances of defeat.

Lastly, bearings are prone to fatigue due to minute vibrations and overloading acting together. When the vibration exceeds the mark of 0.1-0.3 inches per second (IPS) under operating conditions, dynamic balancing or some supportive vibration should be undertaken. Adhering to these guidelines regularly ensures an increase in the life span rates of the system.

How does corrosion affect bearing performance?

Wear and tear of components continues to dream of different forms of harm, one of the most damaging being Corrosion. The impacts of corrosion do not spare the components, bearings in this case, as they are bound to deteriorate in performance over time. In my professional opinion, any substance or the fusion of different materials, such as water or acid, and dirt, breaks down the protective coating or the lubricant on the metal covers of the bearings. Corrosion leads to drastic rim conditions, called the Radius of the primary rim, which are crucial to ruining the component’s primary ability to carry the load.

Deterioration of the primary rim forms a rough texture that composites the valuable motion of the rolling chambers. In layman’s terms, we can simply say that corrosion is known to cut the bearings’ lifespan drastically. Bearing fatigue life could face a critical reduction of more than 75% due to dire conditions. Withholding screws of lubricants along will with correct viscosity levels is a vital step in fighting the dire conditions. While bearings face these issues during lower temperatures or more aggressive chemical states, utilizing bearings with anti-corrosion material greatly reduces the risk of corrosion. Furthermore, it is a best practice to monitor the humidity levels, as they should never cross 60%, as well as the pH levels, as these two factors are very efficient in preventing corrosion.

What maintenance practices help in preventing bearing issues?

Various bearing-related issues must be considered to ensure the smooth operation of the machines and tools. Proper lubrication is also provided by using an optimal amount of lubricants that suit the working environment, including high temperatures, heavy weights, or corrosive surroundings. The inspection of contamination in lubricants is also done periodically to ensure no worrying wear is caused by waste. Also, efficient installation is done without hurries, so precise instruments can be used. This also means that the torque values must be strictly abided by to eliminate any further stresses or misalignment causing issues.

Apart from that, I ensure that environmental factors are keenly observed and noted, too. For example, humidity levels are maintained under 60 percent to lessen the chances of corrosion, and seals are used to further handy shields in more open-bearing scenarios. Stainless steel will be used instead of mild steel with no corrosion-resistant coating for bearings If the surrounding vicinity is near highly aggressive chemicals. Corrosion-resistant materials can also be coated on the bearings. The last things done are vibration analysis, temperature checks, and other regular condition monitoring techniques. All red flags regarding misalignment, waste, and other wear-related issues are taken to ensure the bearing’s useful life is increased while the chances of its failure are reduced.

What advantages do different bearing types offer in centrifugal pump settings?

Why choose roller bearings for specific pump applications?

The selection of roller bearings is crucial to specific pump applications because they can manage high radial loads. Cylindrical roller bearings are my favorite for pumps with little axial loading but significant radial loading because they offer a balanced load support design. Tapered roller bearings are my favorites for combined radial and axial loading conditions because their raceways allow both axial and radial loading.

For high-speed applications, I use roller bearings with low coefficients of friction and high tolerances, such as those offered in the ABEC 5 rating and above, so there is no energy loss. Moreover, the material of the rollers and races is also essential; I use through-hardened steel or case-hardened steel because they are tough in harsh environments. These factors make roller bearings suitable for a pump operating under specific load and speed conditions.

How do thrust bearings handle axial loads?

In my previous work, I have dealt with thrust bearings uniquely constructed to support axial loads. These bearings are designed to convert the axial forces applied to the bearing shaft into rolling motion. The rolling elements of the bearing are usually arranged in either a circular or angular formation to facilitate load acceptance. I tend to use thrust ball bearings for applications with moderate axial loads and speeds that are not too high because they have a simple construction and do not require much maintenance.

I switch to using spherical or tapered thrust bearings for much higher demand in axial loads. Spherical thrust bearings operate better under misaligned conditions because of their self-aligning feature. Tapered thrust bearings, conversely, enable better performance in shafts with combined axial and radial loads due to the angled contact surfaces. Some of the key technical parameters I must pay attention to when working with thrust bearings are:

Load Capacity: Make sure that the bearing is rated to carry the maximum expected axial force, which is given in kN. Operating Speed: Make sure the bearing performs reliably at the speed range of the application (RPM). Material and Hardness: Hardened steel or ceramics are preferred to provide better wear resistance and longevity under constant axial pressure.

Lubrication Needs: For high-stress endeavors, thrust bearings can be relied on, provided that proper lubrication (oil or grease) is applied to ease the friction and control heat dispersing.

Thrust bearings give reliability and durability in applications with axial loads when precision is adhered to.