Pool pumps are a fundamental part of keeping your pool clean and functional. The pool can become highly unpleasant during the swimming season if the pump’s efficiency and longevity are not ensured. One of the most recurring problems a pool owner faces is the degradation of the pump bearing. Bearings might be miniature, but they perform critical tasks like noise control, motor damage prevention, and overall smooth pool pump performance. From diagnosing loss of bearing functionality to having a complete guide for tools and steps necessary to perform a Waterway pool pump bearing replacement, this article will provide the knowledge for it all. This step-by-step guide is all for DIY lovers or even those trying to familiarize themselves with the equipment.

Why is Waterway Pool Pump Bearing Replacement Important?

Understanding the Role of Bearings in a Pool Pump

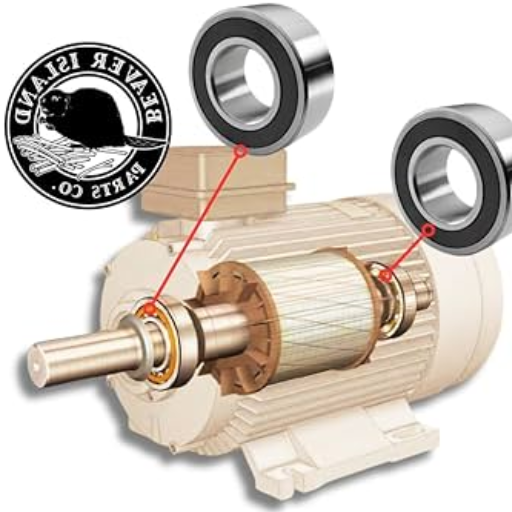

Bearings are small but crucial components of a pool pump. They help ensure the pump operates efficiently by properly reducing friction between its moving parts. These components also allow the motor’s shaft to rotate with little to no heat or wear during high speeds. Properly functioning bearings enhance the pump’s overall performance, with the added benefits of reduced energy consumption and noise, increasing its longevity.

Material—Most bearings are made from stainless steel or ceramic. Their sheer load capacity and ability to resist corrosion make these materials ideal for use.

Load Rating—When a pump operates, bearings must withstand all the axial and radial loads. The load rating for a standard pool pump supports motor RPMs of up to 3,450 revolutions per minute.

Noise Level – To lessen noise pollution in the area surrounding the swimming pool, high-quality bearings should not be added to the noise above 70 decibels in standard conditions.

Seal Design—In pool pumps, water, and contaminants are an ever-present threat that can significantly affect the operation, so sealed bearings are employed to ensure the wet environment does not access sensitive components.

Lubrication—Pre-lubricated bearings make maintenance work more manageable and support the device’s continuous operation over the years. This is extremely helpful in very humid environments.

Servicing and replacing bearings as needed guarantees optimal pump performance prevents expensive motor damage and prolongs the equipment’s useful life.

Signs Your Pool Pump Bearings Need Replacement

Unusual Noise – Several high-pitched, annoying noises may start humming or squealing, which are high signs of overheating. If your pool pump emits such weird noises, the device’s bearings might have sustained excessive damage or are worn out. The sounds as such are produced whenever the bearings lose lubrication or undergo excess wear.

Overheating—The motor’s sustained overheating can permanently damage it. The bearings are removed from good condition and can experience increased friction, which causes the motor’s temperature to rise noticeably.

Reduced Efficiency—A delay in pressure might indicate problems with bearers, which is probably why the device is forced to use more power than it is supposed to.

Vibrations or Shaking—The pump’s misaligned bearings can cause unusual shaking and excessive vibrations. Decreased engagement of the pump disturbs its smooth movements, disrupting the increased airflow.

These signs, if not, are instant warning signs for one’s motor. If one does not act quickly, the damage will only get worse. Proper maintenance and frequent monitoring can most efficiently solve these tasks.

Benefits of Timely Bearing Replacement for Your Waterway Pump

Enhanced Performance and Efficiency—When worn-out bearings are replaced, friction inside the unit is minimized, allowing it to function effortlessly. This also guarantees no strain on the motor, making the device more economical and increasing its service life. For example, spending proper time and effort on optimally aligning bearings can decrease energy consumption by as much as ten percent or fifteen percent.

Reduced Noise and Vibrations—New bearings suppress Unwanted noise and vibration levels. Properly functioning bearings alleviate rotor misalignment, ensuring a quiet mode of operation while reducing wear and tear on all other parts.

Prolonged Pump Lifespan – Well-maintained quality bearings help prevent damage to the motor and impeller, ensuring no undue breakage. Complete breakdowns due to severe friction causing excess heat are almost always bound to happen, so timely bearing replacements are crucial.

Prevention of Catastrophic Failures—Unexplained failures that result in system shutdowns and expensive repairs are often preventable with proper inspection and timely replacement of the bearings. Bearings that withstand high-temperature loads, like 120 Degrees Celsius, guarantee dependability and support during critical circumstances.

Improved Operational Safety—The risks of overheating due to mechanical instability rise drastically as the condition of the bearings worsens. This creates an unsafe environment for operation. By replacing faulty bearings on time, risks can be minimized, and better control across the pump unit becomes possible.

Preventing bearing wear enables the waterway pump to work as intended and ensures effective performance. For the most effective results, contact the manufacturer for suggestions regarding the most appropriate bearing replacement intervals and ensure suitable high-quality bearings that meet the pump’s operating parameters. Reliable and effective performance requires regular maintenance.

How to Diagnose Pool Pump Bearing Issues?

Common Symptoms of Failing Pool Pump Bearings

Abnormal Sound: The sound of grinding, screeching, or whirring noise from the pump indicates that some of its bearings are either worn or damaged. These sounds come from a combination of internal bearing friction and misalignment within the system resulting from either.

Constant Vibrations: Pump breakdown vibrations can also result from malfunctioning bearings. These vibrations can result in simultaneous wear in several parts of a pump, drastically lowering the system’s overall functionality.

Overheating: Worn-out bearings produce high amounts of heat. If reinforced by the fact that the pump housing or the motor is warm, this could be a strong sign of a problem. Any reinforcement indicating the temperature level exceeds specified ratings can also signal bearing problems.

Reduced Work Rate: Lower pressure or flow rate, indicative of a more serious problem reducing the bearing’s effectiveness, may also stem from motor degradation.

Burst bearings are known to reduce the structural integrity of the bearing housing, allowing physical wear to rust or even cause oil leaks. Any abnormal shapes or residue can signify a deeper issue.

Monitoring these parameters and symptoms allows one to notice bearing problems from a distance and avoid more serious issues with the pool pump system.

DIY Methods to Check Your Pump’s Bearing Condition

Listen for Unusual Sounds: Use an infrared thermometer to measure the range of the bearing housing temperature. During a standard cycler operation, a temperature above 82 C(SF) indicates internal excessive wear or inadequate lubrication. Check the bearing’s temperature by taking non-contact measurements.

Check for Vibrations: A worn bearing usually makes a high whining and grinding noise. Overheating, which often exceeds 82 C., is generally caused by a lack of lubrication or internal damage. Use a bearing vibration meter to measure velocity; accurate vibration levels should be less than r.m.s. 0.1 inches a second.

Inspect Axial and Radial Play: Use a metric gauge and schedule the pump system to be off. During that time, observe for any upcoming slackness. Shakes or movement over 0.002 from the outer diameter are considered critically excessive, which means they must be changed immediately.

Following the technical parameters above will help you complete these quick assessments and identify issues before they escalate. Regularly follow up with professional maintenance to ensure accuracy and resolve any lingering problems.

When to Seek Professional Diagnosis

Professional diagnosis should be considered whenever an issue goes beyond routine maintenance or uncovering abnormalities. The topics mentioned below can benefit from a professional evaluation:

Noise: Unusual and persistent grinding, squeaking, or knocking noises that cannot be solved through lubrication or cleaning means visiting a professional. These sounds could suggest internal damage or misalignment.

Excessive vibration: On machinery with a defined threshold for vibrations, levels surpassing acceptable standards, e.g., RMS velocity greater than 10 mm/s or acceleration exceeding 15 g, indicate an imbalance, misalignment, or bearing wear needing correction. Confirm these levels with a vibration analyzer to check whether these levels have been crossed.

Temperature: Bearings that are constantly above the standard recommended temperature of, say, 200°F/93 °C for most standard bearings suggest load, ineffective lubrication, and melting structural elements, so consistent temperature monitoring is advised.

Visible damage: Spall marks, fractures, or corrosion are a sign of advanced deterioration, in which case a visit to a professional becomes mandatory.

Accelerated lubricant deterioration: He must replace the lubricant at set intervals throughout his use. If he does not, it could result in internal wear and damage from the environmental condition, for which professional support is deemed necessary.

Exceeding Load or Speed Parameters: Check if the operating speed or load exceeds the bearing’s tolerable limits. Specialists must ascertain conditions like dynamic load ratings (C) or maximum speed limits for use.

Following up on such technical parameters and abnormal conditions allows one to react quickly to potential failures and avoid expensive inactivity.

What’s Involved in Waterway Pool Pump Bearing Replacement?

Step-by-Step Guide to Replacing Pool Pump Bearings

This is how I replace pool pump bearings: It can be challenging to follow the correct procedures. Here are some steps I follow:

Remove Water and Power Connections: Disconnecting any form of water supply before the process starts is of the utmost priority. This is done to eliminate any risks that may cause accidents during repairs. It is also essential to turn off electric supplies, as pumps are electrically operated.

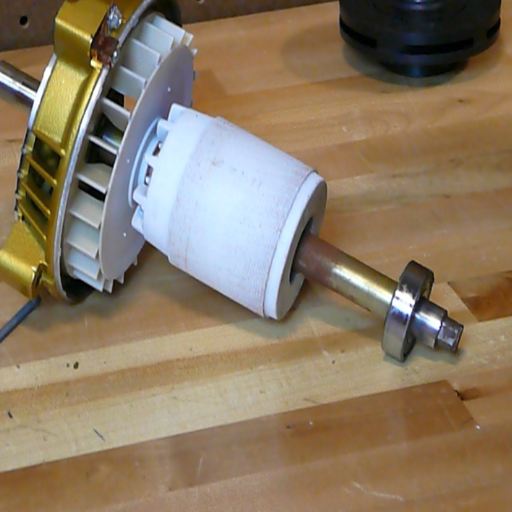

Removing the Pump Cover: After ensuring this, I would remove the pump cover, which gives access to the motor and bearing apportion. The bolts must be unscrewed, and the impeller should be detached from the motor shaft to allow full access.

Bearing Inspection and Replacement: At this point, I have access to the bearings and can check for wear or damage. Using a puller, I can efficiently remove damaged bearings without damaging the motor shaft or other components. I also check if other variables, such as C dynamic load ratings, have contributed to wear and tear.

Choose the Right Bearings: To ensure that the bearings replaced give the desired results, it is crucial to ensure that they perfectly match the specifications, such as size, speed ratings, dynamic load capacity, and so on. For example, if a pump is known to exceed dynamic ratings or speed limits constantly, I replace it with supercharged bearings.

After assembling the pump with all its parts, I replace the bearings and reconnect all the components. During the test, I monitor the running conditions, ensuring no unusual sounds or movements indicate a problem with the pump’s operation.

Combining these actions enables me to eliminate system malfunctions in a pump, increasing its operable lifespan.

Tools and Materials Needed for Bearing Replacement

Bearing Puller/Extractor: I employ this tool to extract the old bearings above everything else without harming anything else.

Bearing Press or Hydraulic Press: This tool/part is essential for replacing bearings. New ones must be fitted precisely to operate smoothly.

Lubricants and Grease: I use appropriate grease as specified in the pump parameters to avoid overheating and advancing the wear and tear of proactive lubrication.

Torque Wrenches: They help me ensure the assembly bolts are tightened with the specified torque, which affects the assembly’s structural alignment and vibration levels.

Cleaning Supplies (Solvents and Rags): I ensure that all the mounting surfaces are dirt-free, as dirt can cause misalignment that could affect rotatory accuracy.

Measuring Tools (Calipers and Micrometers) ensure that the new bearings will fit the pump’s dimensions for optimal performance.

Replacement Bearings: My selection always targets bearings with dynamic load ratings and speed limits that correspond to the operational limits of the particular pump.

These materials and tools are essential for achieving the requirements of bearing replacement and for the pump’s efficient and effective performance.

Tips for Proper Seal and Impeller Maintenance During Replacement

When servicing the pump, I check seals for signs of wear and tear, cracks, or deformation. If any of these abnormalities surface, I replace the seals with special ones corresponding to the pump’s specifications to ensure proper pressure within the pump and avoid leakage. Improper seals indisputably alter technical parameters, such as system pressure stability and fluid containment, which are critical for operational effectiveness.

As much as I conduct flow tests, I also ensure that the impeller undergoes maintenance checks to fix any erosion, corrosion, or imbalance. Imbalanced or damaged impellers lower the pump’s efficiency, provoke excessive vibrations, and lead to tremendous wear on the seals and bearings. I also checked to see that the impeller’s clearance was within the limits set by the manufacturer because the wrong setting may restrict the flow rate and the hydraulic performance. This guarantees that the technical parameters, such as its flow rate, head, and efficiency, are all set to optimal levels for the pump.

Taking all these steps aids in preventing performance problems and prolonging the life of the various pump components.

Can Bearing Replacement Extend Your Pool Pump’s Lifespan?

Long-term Benefits of Regular Bearing Maintenance

Routine bearing maintenance ensures the pumps’ appropriate functioning and efficiency within pool systems. Since bearings are integral components of any apparatus needing movement, improper maintenance can result in deterioration, overheating, or, even worse, pump failure. The good news is that changing worn or damaged bearings will eliminate operational noise while enhancing user experience and safeguarding seals and shafts from deterioration.

When speaking from a more technical spectrum, if bearings are correctly maintained, orthogonal misalignment and power losses due to eccentricity would not dominate, thus ensuring optimal pump performance. These parameters which may require maintenance are:

Vibration Levels: Excessive vibrations can cause individual parts within a pump to lose stability. The root cause is misaligned or mismatched bearings, which can be easily checked.

Operating Temperature: Metal parts lose their proper functioning range and shrink when exposed to extreme heat. Due to bearing friction and unrestrained movement, thermally induced expansion exceeds the restraining force, resulting in overheating, destruction of lubricants, and bearing failure.

Energy Efficiency: Lack of maintenance increases coupling and shaft friction, leading to higher motor power requirements. Proper maintenance ensures that the system operates at peak efficiency.

Shaft Alignment: In well-maintained bearings, the coupling and shaft are ensured to not wear since proper alignment will be obtained.

By ensuring regular maintenance and timely replacements, these parameters are enhanced along with pump reliability, reduced downtime, and increased operational life, making it a beneficial investment for any pool system.

Cost Comparison: Bearing Replacement vs. Full Pump Replacement

Replacing certain parts of the pump is also cost-effective. Supporting replacement is preferred if the rest of the pump components are in good working condition. The bearing replacement helps solve several important operational characteristics, such as temperature control, energy saving, and shaft alignment. To elaborate, new components bring the following benefits:

Operating Temperature: Replacing broken bearings ensures that the motor does not overheat, thus preventing damage to the lubricant through friction.

Energy Efficiency: Increased lubrication and less friction means the motor consumes less energy and operates more efficiently.

Shaft Alignment: As the bearing maintains its alignment, wear and tear on parts such as the coupling and the shaft are lowered.

Bearings are easily replaced, making it a quick, viable option. If there is too much wear and tear on the pump components, a complete replacement may have to be done. This would be a more expensive solution and more time-consuming. Cost-effective repairs are often better, mainly if the bearings have limited damage, allowing easy replacement.

Are There Different Types of Bearings for Waterway Pool Pumps?

Understanding Bearing Types for Various Waterway Pump Models

Every Waterway pump model has unique bearing types available. These types are usually adjustable to fit the pump’s needs and operational conditions. The most common types are roller bearings and ball bearings. Ball bearings are the most common type of bearing. They can manage radial and axial loads, increasing efficiency and lengthening life spans. On the other hand, roller bearings are designed to withstand greater radial loads, making them durable.

As with most applications, ball bearings can accommodate moderate workloads; roller bearings are usually better for pumps that experience high radial stress.

The amount of friction produced by ball bearings with inline shields is minimal, which assists with energy consumption and the general operation of the system. Roller bearings do have more friction due to the increased capacity of weight they can take on.

Different types of bearings have contrasting levels of durability. Ball bearings restricted to lighter tasks are not as durable as roller bearings and are more suited to endure impact for prolonged periods.

Bearings selected with precision and care produce less noise and vibration, improving the pump’s general efficacy.

Selecting a suitable bearing directly affects the pump’s performance, dependability, and even cost of operation. Understanding the requirements for your Waterway model will help you achieve the desired outcome while appropriately dealing with wear and tear.

Choosing the Right Bearings for Your Specific Pump

In selecting the applicable bearings for a specific type of arrangement, I pay attention to its operational needs and technical specifications. I prefer ball bearings for pumps operating under moderate loads because these parts have the least friction and energy loss, enabling smooth functioning. However, for severe radial load applications, roller bearings are installed because of their high load capacity and excellent durability.

Noise and vibration are essential to me, so I make sure those things do not compromise the alignment and efficiency of the pump or the bearings and are placed in an optimal way for my needs. Moreover, I choose roller bearings for demanding applications with extended running hours because they tend to outlast these conditions. I have to make sure I consider these factors so I can achieve the balance between performance, cost, and reliability at the same time. Of importance to me are the bearing’s load capacity, the force of friction, the degree of resistance to a particular environment, and the noise and vibration levels produced. With an approach based on these things, I engineer the pump for optimal service life and efficiency.

Frequently Asked Questions (FAQs)

Q: What are the benefits of replacing the bearings in a Waterway pool pump?

A: Replacing bearings in a Waterway pool pump helps extend its lifespan, improve its efficiency, reduce noise, and minimize the chances of more expensive repairs. It is usually not as expensive as replacing the motor or the entire pump, especially with high-quality products like the Waterway Executive.

Q: How do I know if my pool pump bearings need replacement?

A: Unusual noises stemming from the pool pump bearings, like screeches, grinds, vibrations, leaks around the shaft seal, and an overall reduction in the pump’s performance are significant indicators of deterioration. It is wise to deal with these issues instead of letting them fester to minimize the risks of inflicting more harm to the motor or other components of the pump.

Q: Can I replace the bearings, or need a professional?

A: Replacing the bearings is possible by oneself, provided one is skilled in using equipment and working with tools. However, the majority of pool owners opt for a professional. The task requires disassembling the pump, which is not very simple. If you are in doubt, it is better to seek assistance from a professional to ensure that you do not damage other pump parts or lose coverage under any existing warranties.

Q: How frequently should pool pump bearings be replaced?

A: Energies, Activities, and other Maintenance Procedures are crucial while servicing pumps. The activities carried out by the specific person will determine the life of the pool pump. Bearing replacement depends on several factors that pertain to the user’s lifestyle; in detail, regular activities on the pump should ideally extend the life of the pump bag by 3 to 5 years; under heavy use, the lifespan of using a veritable speed pump that continuously rungs at low speeds is plausible. Rather than replacing the pump bag, better ways to extend its lifespan are possible through timely addressing many issues that may be overlooked.

Q: Will replacing the bearings resolve my leak problem regarding my pool pump?

A: A solution to one seal problem arises when replacing the bearings, specifically those close to the shaft seal. However, this would not apply where the leakage stems from other aspects of the system. Replacing the o rings will not do with bearing replacement on its own. To solve the specific problem, one must first understand the demography of the seal that is leaking in the first place.

Q: What are the symptoms of a defective capacitor within the pool pump motor?

A: Although there is no immediate link to revolving part changeout, a defective capacitor can potentially create problems that may be attributed to the revolving parts. Symptoms of a capacitor issue include a motor humming but not engaging a slowly rotating pump, or a very hot running motor. When doubting a capacitor, it is better to look at it professionally to clarify the issues.

Q: Do replacing the revolving parts and the entire motor cost the same?

A: Nobody knows this, but replacement bearings are less expensive than complete motor replacements, primarily for high-end pumps. Most bearing revamps are cheaper than a new motor and return the pump to serviceable condition. If the motor has other significant problems or is old, then replacing it is the ideal solution in the long run.

Q: What are the merits of switching to a variable-speed pump, mainly when servicing bearings?

A: You won’t be changing the type of bear pump while servicing bearing replacements, but with significant changes, it would be prudent to consider switching to a variable pump. With the new design of pumps, energy consumption will differ positively. They will also run more efficiently by reducing speed and subsequently increasing the life of the bearings. In the long run, economic value will further increase.