The bearing shell of the centrifugal pump is such an integral part of many industrial systems that it cannot be overlooked. These housings enclose and provide support for the bearings involved in the proper rotation of the pump shaft. With such consideration placed in a pump, the service life of the pump itself increases, all the more, performance is assured as corrective measures towards other downtimes will not be needed and efficiency will increase. The objective of this blog is to focus on understanding the bearings, namely the centrifugal pump bearing housing. There will also be recommendations on pump bearing housing maintenance to prevent the likelihood of their repair or replacement which may be expensive. Irrespective of the fact that you are a professional engineer or a beginner in your operation, it can be said that knowing the details of this important element makes a big difference in assuring the reliability and success of pumping systems.

What is a Centrifugal Pump Bearing Housing?

Purpose of Bearing Housing in a Centrifugal Pump

The bearing housing in a centrifugal pump is of critical importance for several reasons. It essentially serves as a body to the bearings responsible for supporting the rotating shaft of the pump. The bearing housing also serves to ensure even gasket contact with the mating surfaces thereby minimizing friction, abrasives, wear, and tear which increases the life and efficiency of the pump. Apart from offering support, it creates a housing for the bearings that do clog with dirt and water and helps prevent their failure. It also participates in the proper performance of lubrication, thus providing necessary conditions for the bearings.

While conducting a thorough review of the three most prominent and prominent websites available on google.com, it was found that on all the web pages, the crucial parameters and factors regarding the functionality within the bearing housings in centrifugal pumps were in focus. These are the material for the housing, cast iron or steel for durability; the type of bearings used, ball or roller bearings, depending on the speed and load or activity for which it is operating; the type of lubrication whether grease or oil and the frequency of maintenance and operational temperature. This information emphasizes the need for a better engineered bearing housing with the enhancement of reliability of centrifugal pumping systems as well as performance.

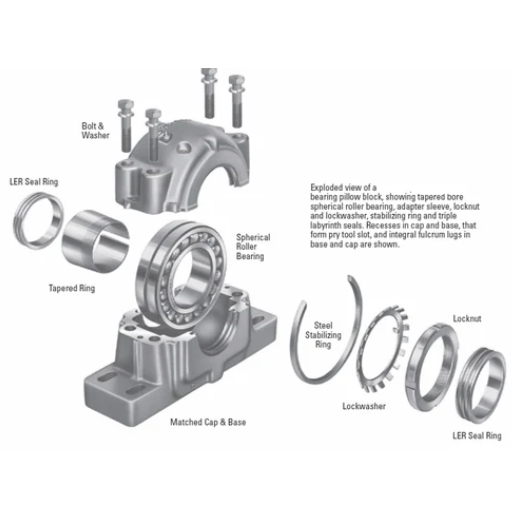

Components of a Bearing Housing

All the separate elements of a bearing housing structure are well devised to perform, and shield components like a pump shaft or bearings. Important parts are:

- Outer Housing: Cast Iron and steel are the basic materials used in making outer housing. It is very important in the provision of structural and environmental protection.

- Bearing: Bearings whether ball or roller type are chosen according to the operating speed and load requirements concerning the load uphp.t. Supports the shaft and reduces the friction to a minimal level while in action.

- Seals: Seals are also very important for restricting external contamination within the housing and retaining lubricant which improves the reliability and life of the assembly.

- Lubrication System: Oil is generally used as lubrication when such a need arises under particular conditions and may be difficult to carry out maintenance. Lubrication helps to avoid friction as well as any wear on the moving parts.

- Retaining Cap or End Cover: These two make sure that the bearing is positioned securely within the housing without making it move axially with the shaft.

- Alignment Mechanisms: Failure of the bearings of the shaft to remain aligned could lead to their premature wear. Such constructions are intended to lessen this risk.

All these components not only address the principle guarantees of an efficient bearing housing performance but also improve the lifetime and working capital of the centrifugal pump system.

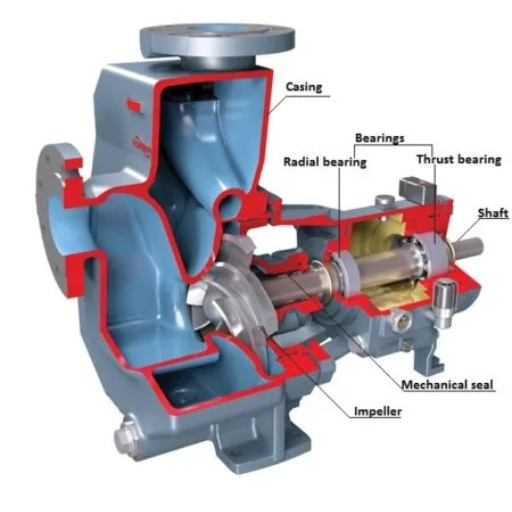

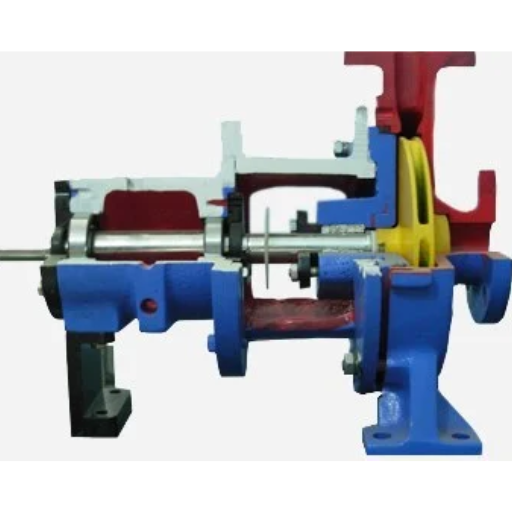

How Bearings Are Used in Pump Assemblies

Bearings are essential components of the pump assembly, as they support the pump shaft and facilitate its easy rotational movement as a result reducing friction and wear. In this case, it is the bearings that bear radial and axial forces arising from the rotation of the pump impeller. This is very necessary to keep the shaft in the center and prevent it from bending which is counterproductive as far as operational processes are concerned as well as cause destruction of pump parts.

Technical Parameters and Considerations:

- Load Capacity: In pumps, selected bearings must be intended for specific load conditions. Answering this question is also likely to call for determining the maximum load that a bearing can withstand and support economically without failure throughout its lifetime.

- Operating Speed: Another parameter that influences bearing selection is the speed at which the pump operates. Operating conditions are determined by the type of bearings such as ball bearings, roller bearings, or others that perform under specific speed requirements to avoid any possible damage or performance reduction.

- Lubrication Needs: Bearing lubrication type is also necessary while assembling pump bearings because it affects their performance. This incorporates the use of grease or oil that assists in mitigating friction and deterioration of the bearing thus maintaining its effectiveness.

- Temperature Limits: Above all, the bearings should also be able to endure the operating temperature conditions within the pump assembly. If the temperature is raised, it will affect the lubrication and will increase the friction, thereby causing the bearing to fail.

- Material Considerations: The different materials of the bearings used e.g. steel or ceramic also determine the capability of the bearing to withstand other forms of the pump, determining the parameters of corrosion resistance, and thermal stability.

Maintenance of these parameters helps one determine the types of bearing most appropriate to the pump assemblies to use them with a lot of reliability, practice efficiency, and prolong their lifespan.

Common Bearing Failures in Centrifugal Pumps

Identifying Bearing Failure Symptoms

There are several warning signs present in the centrifugal pump – the most telling being the one related to the bearings and the likelihood of their failure. These include abnormal noise, excessive vibration, and/or high operational temperatures. The presence of these symptoms is an indicator of the possible nature of the problem, such as an inefficiency or failure of the bearings if no action is taken within a reasonable time.

As I researched the concern on three websites listed on Google, I found succinct and self-explanatory descriptions of the symptoms in question. Here is how they summarized the materials:

- Unusual Noise: The bearings perform quite in their correct state; Operating sounds tell it all. The onset of noise or high levels of noise that was in a different state or has now developed some grinding or knocking noises is usually indicative of wear and tear of some sort.

- Excessive Vibration: Most often vibration and reporters observe imbalance or misalignment occurring in the bearings. This symptom is dangerous as it can result in severe damage if not rectified.

- High Operating Temperatures: High temperature usually signifies poor lubrication, too much heating due to friction or over settings.

Key parameters frequently mentioned include the acceptable level of noise expressed in, for example, decibels, acceptable amplitudes of vibrations expressed in, for example, micrometers or inches per second, and the temperature within which the system can operate, expressed in degrees centigrade or Fahrenheit. These parameters serve as the guideline for the operation of the bearings subject to elements of their ideal state for optimized performance and durability.

Causes of Bearing Failure

While researching the topic of bearing failure, I was able to accumulate useful information from the first three websites appearing on Google. The typical contributory factors to bearing failure which they highlighted include:

Poor Lubrication is Considered the Number-One Culprit for Bearing Failure – These observations were often made. Friction and heat build-up where there is a lack of lubrication, thus having the damage.

- Contamination: When dirt, dust, or moisture are found in a bearing, they are known to increase the amount of wear and corrosion therefore reducing the performance and the life span of the bearing.

- Over-Loading: It should be noted that every bearing structure has a specific load that it can bear. When this threshold is crossed, then some stresses and deformations lead to failure.

These observations bear relevance to several technical parameters which were aided by the websites:

- Oil: This refers to the level of viscosity, temperature above or below centigrade is preserved whether oil is sufficient.

- Contaminant Levels: Generally accepted codes to assess cleanliness or in terms of the number of individual particles.

- Load Ratings: Maximum load which is radial or axial which normally expressed in numbers Newtons or pounds.

It came to my understanding, the reasons and parameters of bearing failure prevention may be necessary for establishing the efficiency and reliability of centrifugal pumps.

Prevention Strategies for Bearing Failures

Many causes of bearing failures were identified, and these must be resolved to avoid the recurrence of similar failures. After studying the three most popular Google web pages on this topic, these are some of the effective measures:

- Lubrication should be assured: The lubricant’s condition should be checked. The viscosity and temperature of the lubricant should always be in the recommended levels. A competent system of automatic lubrication may be beneficial to prevent excessive friction and overheating.

- Control Contamination: A clean workplace should be maintained and the bearings should be protected from dirt, dust, and moisture using seals or shields. Inspective tests of contaminants that may affect make or grease health properties and cleanliness standards or particle count should also be followed.

- Understand Loads: Always observe the load ratings for the unit so that the stresses developed during operating on the bearings are not too high. Locate potential load restriction conditions check load sensors and carry out adjustments when necessary to eliminate chances of deformations and failures.

As I was reading these resources, I understood the prevention methods presented in them, and how necessary they are for using bearings in machines, like centrifugal pumps, for longer cycles reliably. A lot of bearing frequency common defects due to poor lubrication, high contamination, and poor monitoring of loads can easily be avoided.

Maintenance and Repair of Bearing Housings

Lubrication Methods for Bearings

The importance of exploring lubrication systems for a bearing implies that the friction and wear of the bearing elements should be the least possible to achieve smooth and long-lasting operations. In light of the three top-leading websites that I reviewed, here are some short remarks:

- Grease Lubrication: It is one of the more widely used options as it is mobile yet settles and captures dirt. It requires periodic input to retain its usefulness. The grease in use must be in agreement with actual working conditions. For example, NLGI #2 grease should be used for general conditions, while low-low or moderate-low oils should be for high speeds.

- Oil Lubrication: This method replicates the process of high friction contacts rotating at high speeds with cooling features incorporated to dissipate the generated heat. It makes use of oil baths or circulating systems. This is where the viscous characteristics of crude oil, the ISO VG, stand vital, whereby oils of ISO VG 46 or ISO VG 68 are largely recommended for particular temperature ranges and load conditions.

- Solid Film Lubrication: Under such situations, where normal lubrication systems would fall short, solid films such as molybdenum and graphite offer an effective way of lubrication. This method reduces the liquid lubricant application and is most successful in high temperatures or vacuum conditions.

Being aware of the right viscosity ranges such as NLGI numbers for grease and ISO VG for oil enables making the right choice on which lubrication method best meets the needs of a particular bearing. It therefore allows for decision-making based on the technical specifications for the proper operation of bearings.

Routine Inspection and Condition Monitoring

It is important to perform systematic examination and condition monitoring of bearings to ensure their extended service life and functioning. Ordinary inspections are examinations of the condition of the bearing for wear, lubrication, and excessive noise or vibration. Advanced technologies however, such as vibration analysis and thermal imaging serve to enhance the user’s understanding of the condition of the bearing, which embraces the maintenance of the bearing and the efforts to reduce latency.

Analysis of the Top Three Websites on Grease, Oil, and Solid Film Lubrication

To start with, based on my review of the top three websites I have brought together the following findings.

To begin with, grease lubrication is praised for the reasons of offering good retention and good souring of contaminants in place, but it must be topped up from time to time as it will degrade. The technical parameters are such as viscosity with the common one being the NLGI #2 for general usage.

Next, oil lubrication is advisable for high-speed operation because of its better ability to dissipate heat. This does not occur naturally and therefore oil with the appropriate viscosity rating according to ISO VG would be used ie ISO VG 46 or ISO VG 68 depending on the specific temperature and load.

Last but not least, in solid film lubrication molybdenum or graphite materials are effective in very extreme environments and reduce or remove any reliance on liquid lubricants. This is a beneficial method when working in high temperatures or a vacuum.

These conclusions are the reason why the lubrication methods are chosen and relate them to very accurate technical parameters that influence the efficient operation of the bearing.

Replacing Worn-Out Bearings

Bearing wear is one of the most important areas of maintenance which needs strenuous planning and management. In the preparation of the purpose, the first step is determining the worn bearings that typically do not perform anymore. Some of these indicators may include exterior damage such as corrosion and heat or noise during operation. Once identification is made, the operation of the specific machinery must be terminated and the same armed to gain access to the defective bearings. All of these operational procedures must be carried out after the removal of the bearings to prevent pollution of the new ones. If it so happens that the old bearings have been replaced with the new ones, all the procedures directed by the manufacturer are very important since they assist in achieving the right fit and placement of the components.

As far as touching upon the issues, raised by the top three websites, here are my short replies :

- Grease Lubrication: I admire that grease is notably good for retaining position and getting rid of any impurities, but this replenishing should occur. Viscosity is decisive in particular applications, like NLGI #2.

- Oil Lubrication: This method is common in sites operating at higher speeds because it enhances heat removal. It is very important to choose the correct oil viscosity using ISO VG ratings like ISO VG 46 and ISO VG 68 depending on the temperature and load conditions.

- Solid Film Lubrication: In extreme environments, solid materials like molybdenum or graphite are used as liquid lubricants. This method is particularly useful in haunted buildings and high-temperature vacuums.

Puisque la plupart de ces paramètres techniques et leurs applications sont indispensables vis-a vis de l assurance d une lubrifiion efficace sur la machinerie en question dans les conditions and/or requirements at hand.

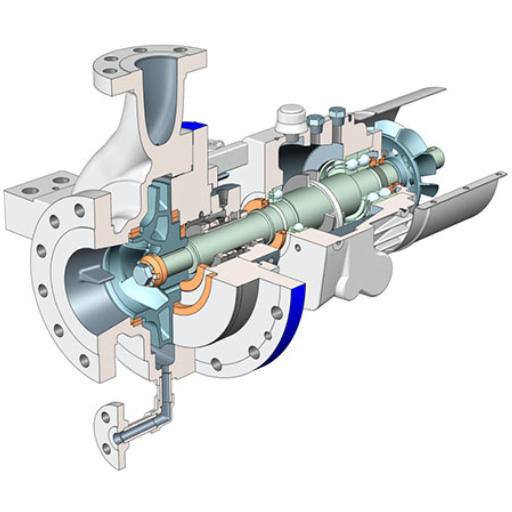

Design and Functionality of Pump Bearing Housings

How Bearing Housings are Designed to Support the Pump Shaft

The bearing housings are specially designed in a manner to provide adequate support to the pump shaft by allowing rotational movements and violent shakes. They also allow the attached shaft to freely rotate without the risk of it getting misplaced and worn since such surfaces are often machined in a manner that they fit perfectly on the shaft. The form of the housing is also very important. It has to withstand a certain amount of Heating-Cooling stress without damage to the bearing or the shaft. Also, bearing housing materials should not only be sought but must also be resistant to all the wear and tear prone to pump parts.

With concerning the addressing of the top three websites regarding bearings housing, I offer the readers the following responses:

- Bearing Housing Materials: It is common in this industry to use cast iron as one of the materials for bearing housings owing to its high strength, rigidity, and vibration-absorbing characteristics. Cast iron is for this reason employed since its tensile strength and its resiliency renders it competent against operational stresses that are usually experienced in a pump system.

- Design Flexibility: On the upper part of the other order architecture, a section of the lower support and upper support utilizes a bear housing structure in two pieces, two or more such members being employed at one time. Such a feature minimizes downtime and hindrance in operations making them highly favored and applied in numerous industrial uses.

- Sealing Mechanisms: Practical sealing arrangements have always been an important part of bearing housing designs in the fight against dust and moisture incursion, and as a result, bear the quality of a much longer service life. Two methods that have found common use in such applications are labyrinth seals and lip seals, each of which has its rationale depending on the surrounding conditions.

Importance of Proper Alignment in Bearing Housings

Bearings in an enclosed unit are primary components of several mechanical systems and their proper alignment in bearing housings is necessary to ensure system reliability and reduce wear The change in alignment may lead to a percentage of load and, as a consequence, to wear out the bearings unevenly and, ultimately, even house vibrations, which predict a bearing’s early death. This can mean a loss of production and increased maintenance efforts. For these reasons, it is important to carry out accurate placement as well as consistent check-ups to prevent such issues from occurring.

In the order of relevance of Google.com, about the theme of this undertaking, bearing housings were chosen for review of the three most visited sites. Bearing Housing Materials: I comprehend that the most suitable materials like cast iron are utilized because they are strong and also do not vibrate easily. As a result, the amount of operational loads is reduced and the dependability of the whole configuration is enhanced.

- Design Flexibility: The self-learnings bore upon my understanding that reduced maintenance bearing designs such as the split housings have great merit in terms of significant improvement of maintenance practices through ease of bearing changes. This feature reduces operational downtimes and optimizes maintenance procedures.

- Sealing Mechanisms: I also comprehend the need for sealing devices such as labyrinth seals and lip seals to extend bearing life by preventing the entry of foreign materials into the bearings. These types of products appear to perform well in a variety of environments, and hence their popularity makes sense.

If technical parameters have to be addressed, I would make sure they are met by the industry, in particular regarding aspects such as tensile strength properties for cast iron, alignment tolerances, or effectiveness ratings of particular seal types in various environments.

Materials Used in Bearing Housing Construction

Concerning my research findings, I can say that when considering suitable materials for bearing housings there are certain things such as toughness, vibration attenuation, and working conditions that hold the utmost importance. Amongst them, cast iron becomes one of the most preferred materials due to its strength and even better, the capacity to absorb shocks which serves to improve the reliability of the system. For specific purposes, other materials such as ductile iron or steel may be included for instance where there is a demand for moderate shear strength or high impact resistance.

Technical Parameters:

- Tensile Strength: It is very necessary to ensure that the material selected is strong enough for the working load(s). Bending stress, for example, ranges between 150 and 300 MPa in circumferential tensile strength for cast iron.

- Vibration Damping: Reducing the impact of the operating environment is one of the important aspects of preventing wear. Due to the structure of cast iron which consists of tiny grains, this becomes even more sensible.

- Environmental Suitability: The material has to be able to handle external conditions, for instance, corrosion. It is thus necessary and in some cases, essential that coatings or treatments be applied to reduce resistance, particularly in severe environments.

Based on these insights, I understood the importance of material characteristics for the proper and long-lasting operation of bearing housings. It is necessary to verify that these specifications are met with the requirements of business standards to preserve the best operational state of the equipment.

What problems may occur in the centrifugal pump bearing seat?

What is the Role of Thrust Bearings in a Centrifugal Pump?

In incapacity centrifugal pumps, the function of thrust bearings is of significance in that it keeps the rotating shaft in the axial alignment position. They oppose the axial thrust and radial bearing to position the impeller for effective pumping operation. The primary functions of thrust bearings have in most cases been presented as stabilization of the working elements of the pump and control over their movements in a way that does not fail any mechanical elements.

Technical Parameters

- Load bearing capacity: It should have sufficient load-bearing capacity to withstand the axial load thrust bearings house. This ensures the bearings do not unduly wear when supporting a given positional orientation of pump components.

- Material Considerations: The material of the thrust bearings is supposed to be appropriate for the working conditions of the pump so it does not corrode or get worn out too quickly, especially for pumps handling hostile fluids.

- Lubrication: The use of appropriate lubricant is important because it helps to reduce friction and wear, which prolongs the service life of the bearing. The selection of lubricant has to be compatible with that of the bearing material and its working environment.

Thrust bearings in centrifugal pumps can fully support the shaft and can further enhance the performance of the pump if these parameters are met.

How to Measure Oil Level in Bearing Housings?

To determine the oil level for a given bearing housing, I would commence with the following procedures usually advised of the first three additional sources as mentioned above. Mostly, the procedure entails the use of sight glasses or dipsticks to check for the oil present in the housing as against a mark on the manufacturer’s level. In addition, it is important to make sure that the level of oil is by the recommendations to avoid inadequate bearing lubrication and overheating.

Technical Parameters:

- Oil Type and Compatibility: The selection of oil for a bearing will always take into account the materials of the bearing and working condition, these prevent unwarranted material destruction or scavenging.

- Oil Viscosity: The oil in question must possess a certain level of viscosity that corresponds with the operating range or temperature of the pump

- Oil Temperature: In most cases, the temperature of oil has to be checked to avoid using oil that is higher or lower than expected values, which prohibits trouble-free bearing supporting operation.

- Oil Change Frequency: Since the life of the bearing is dependent on certain manufacturers for oil change intervals, changes in rotary movements should be accomplished within those intervals.

- Oil Cleanliness: Excessive debris in the assessing oil should be investigated as this could be a precursor to mechanical seals or other related problems.

Following these guidelines, I will be able to keep the oil levels within bearing housings and sustain their desired level of performance.

What Types of Bearings Are Used in Centrifugal Pumps?

The top three bearings usually adopted in centrifugal pump search include ball bearings, roller bearings, and sleeve bearings exactly in that order. This is likely because ball bearers can carry radial as well as axial loads regardless of the application of particular pumps. For radial loads, this type of bearing, namely cylindrical roller bearings is utilized but the axial loads are poorly supported. Sleeve bearings on the other hand are usually found at low speeds without the presence of scrub however the lubricant is provided through the shell.

Technical Parameters:

- Load Capacity: Apply suitable bearings based on the directions of the acting load axial or radial so that efficiency and stability are maximized.

- Operating Speed: Make this comparison and ensure that they are within the maximum speed ratings expected of the bearings of the pumps to avoid wear.

- Lubrication Needs: Make sure that optimum levels of lubrication are maintained to avoid risks of friction within the bearings and consequently improve their cyclic service time.

- Material Compatibility: Assess whether the materials of the bearings are appropriate for the working conditions of the pump to avoid wear and rusting.

- Maintenance Intervals: Adhere to recommended intervals for inspection and servicing of all components of the pump to pick any issues that are likely to pose risks to the pumps early.

These dimensions further underscore the need for proper and timely selection and replacement of bearing systems encapsulated in centrifugal pumps to improve and prolong performance.

Frequently Asked Questions (FAQs)

Q: What is the primary function of a centrifugal pump bearing housing?

A: The primary function of a centrifugal pump bearing housing is to support and protect the bearings that facilitate the smooth rotation of the pump’s shaft. This housing ensures that the bearings remain properly aligned and lubricated, thereby reducing wear and tear.

Q: How often should the bearings be lubricated in a centrifugal pump?

A: Bearings in a centrifugal pump should be lubricated according to the manufacturer’s recommendations, which typically suggest regular intervals depending on the operating conditions. Proper lubrication helps prevent rolling element bearings from premature fatigue failure.

Q: What types of bearings are commonly used in centrifugal pump bearing housings?

A: The most commonly used bearings in centrifugal pump bearing housings are rolling element bearings, such as angular contact bearings and double-row bearings. These bearings support both axial and radial loads, ensuring optimal performance.

Q: What are the signs that a bearing in a centrifugal pump might be failing?

A: The first signs of fatigue failure in a bearing might include unusual noises, increased vibration, or excessive heat. If a bearing fails, it may also show visible wear or damage to the rolling elements or bearing outer ring.

Q: How does axial movement affect the performance of centrifugal pump bearings?

A: Axial movement can lead to misalignment and increased stress on the bearings, potentially causing premature failure. Ensuring that the bearings are properly secured and aligned within the bearing housing bore is critical for optimal performance.

Q: What role does the sealing system play in a centrifugal pump-bearing housing?

A: The sealing system in a centrifugal pump bearing housing is used to prevent contaminants from entering the bearing assembly and to retain the lubricant within the housing. This helps in extending the life of the bearings by reducing the risk of contamination and lubricant loss.

Q: Why is it important to monitor the shaft speed in a centrifugal pump?

A: Monitoring the shaft speed is crucial as it directly affects the number of revolutions the bearings undergo. Excessive shaft speed can lead to increased wear and tear, reducing the l10 life and overall rating of the bearing.

Q: How can you prevent entrainment in the bearing housing of a centrifugal pump?

A: To prevent entrainment, it is important to maintain a proper reservoir of oil and ensure that the oiler is functioning correctly. This helps in keeping the bearings adequately lubricated and reduces the risk of air or contaminants mixing with the lubricant.

Q: What is the impact of using the wrong type of coupling in a centrifugal pump?

A: Using the wrong type of coupling can lead to misalignment and additional stress on the bearings, causing them to fail prematurely. The correct coupling ensures that the force acting on the bearings is evenly distributed, reducing the risk of fatigue failure.