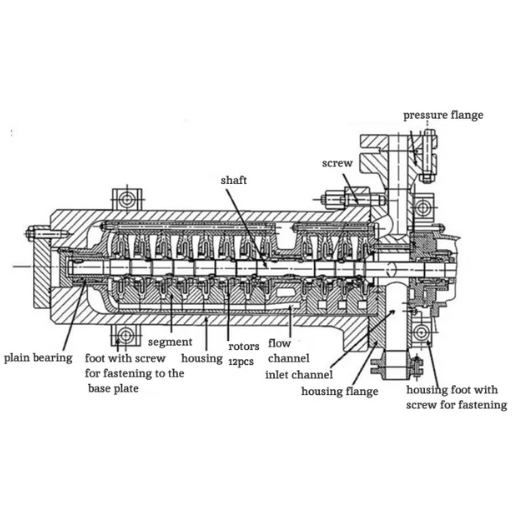

Centrifugal pumps have numerous applications in almost all industries including water supply, waste management, chemical processing, and even power generation. These pumps consist of essential components such as bearings which support the pump shaft and help in reducing friction hence stable and effective running of the pump. This guide focuses on the different kinds of bearings used in centrifugal pumps, their properties, advantages, and application areas. By elaborating on these components, readers will further understand how they can improve the efficiency of pumps, increase the service life of hardware, and ensure the reliable operation of equipment in different industries. The engineer, the maintenance person, or the outsider studying the different aspects of centrifugal pumps will find this guide correctly aids the bearing selection and its application.

What are the different bearing types used in centrifugal pumps?

Understanding roller bearings in centrifugal pump bearings

Cylindrical roller bearings and taper roller bearings are a few of the common types of roller bearings, out of the many that, enable centrifugal pumps to work supporting specific functions. They are also easy to manufacture and allow meshing with different conical parts.

- Cylindrical Roller Bearings: These types of roller bearings are preferred due to the high speed and high load they can support. This design incorporates low friction thereby improving the transmission of power and minimizing the energy loss, hence enhancing the effectiveness of the pump.

- Tapered Roller Bearings: They incorporate tapered roller bearings as they perform an integral role in supporting axial loads together with radial loads. The conical structure also provides ease of distribution of the loads on the surfaces in contact with more than one aspect being enduring and stability in tough tasks.

In summary, while choosing roller bearings for centrifugal pumps, I take into account some factors such as load type, speed needs, and also the operating environment to ensure that they are made to the right working conditions. The industrial application of various pumps emphasizes the importance of understanding the cutting features and parameters of the bearing types.

How ball bearings function in centrifugal pumps

Ball bearings can be considered one of the important elements of centrifugal pumps since they are used to center the rotor and minimize heat buildup due to friction. These bearings contain balls that are housed outside or inside two bearing races and serve to extend the surface area of contact under load. The configuration is very effective in friction management and allows both axial and radial load, thus it is rather widely applied in pump construction.

As per the information gathered from the most relevant websites available online, the technical parameters that are crucial in ball bearing selection in centrifugal pumps include load capacity, speed ratings, temperature conditions, and material amongst others. Among these parameters, normal load capacity refers to the maximum limiting load to be supported by the bearing with speed ratings denoting the maximum speed at which rotation of that operational part can be achieved. For the temperature limits if the pump’s working conditions require such as heating all these are tangible aspects of operation conditions and material compatibility refers to the ability of the bearing in construction to bear the used aggressive and or abrasive materials.

In sum, awareness of these parameters as well as their application relevance enables me to understand that even when optimal pumps are relied on, only the most appropriate ball bearings would ensure that their functional performance will also be more efficient. Such careful selection plays a great part in the upholding and durability of centrifugal pumps in industries.

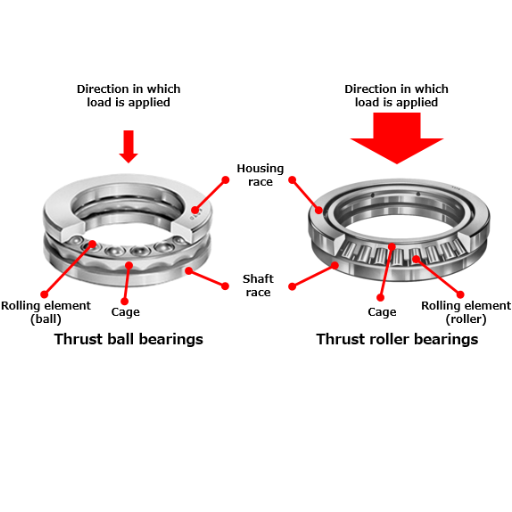

The role of thrust bearings in centrifugal pumps

Thrust bearings play an important role in centrifugal pumps since they control and bear the axial thrust created by the movement of the pump. This type of load occurs because of the pressure within the pump causing the rotor to move linearly. Thrust bearings oppose these loads by supporting the rotor, keeping it properly oriented, and allowing the pump to process effectively.

As per the three best websites, some of the critical technical parameters that need to be taken into account while selecting centrifugal pump thrust bearings include axial load rating, shaft alignment, and lubrication. The axial load rating helps to assure bearing in use withstanding the continuous forces imposed in and around the pump. Shaft alignment is important because it determines the rotor’s accuracy and stability. Adequate lubrication lubricates and reduces friction and wear thus enhancing the life of the bearing and the efficiency of the pump.

Considering these sources, I would like to make sure that the selected thrust bearings are appropriate for the operational parameters of my centrifugal pumps to improve their reliability and efficiency. In accepting these technical parameters, I can defend the reasons for my decisions and increase the reliability of the system in question.

How to choose the best bearing for your centrifugal pump?

Factors to consider when selecting the best bearing type

When choosing the most appropriate bearing type for your centrifugal pump, there are a few crucial aspects that determine the effectiveness and worthiness of the pump such as:

- Degree of Axial and Radial Bearing Capacity: Determine whether the bearing can support both fame and radial loads especially since they are common during pumping. High load carries are included in Amj it as it is subjected to endless working pressure.

- Operating Conditions: Always bear in mind the operating conditions of factors such as temperature, humidity, and the presence of chemicals because these influence bearing material and design.

- Bedding and Directing: The alignment capabilities of Assemblers are vital since they determine the rotor’s efficiency during operations. Further, the need for easy maintenance and installation can lower non-productive time and enhance performance.

- Differences in applications: Extensive survey to determine the most appropriate bearing lubricant to reduce friction and wear. The importance of lubricant source strategies is simply as a means of increasing the lifespan of the bearings.

- Operational Speed and Temperature Limits: Confirm the working temperature and operational velocity of the bearing should not exceed the recommended patterns to prevent burning out of the tool or collateral damage due to early breakdown.

In a proper analytic way, making a systematic effect of identifying these factors and including the appropriate technical parameters to load capacities, alignment, bearings, and lubrication requirements amongst others a suitable bearing for your centrifugal pump may be chosen.

Impact of operating conditions on bearing selection

When it comes to the selection of bearings, one of the factors that has to be taken into consideration is how the operating conditions constrain the decision. The research I carried out on leading websites reveals a common view that the conditions under which the bearings operate are crucial for the performance and lifespan of the bearings in particular. Often mentioned are the following technical parameters:

- Temperature Range: All designed products have to endure temperature changes that are expected in a given context. Companies such as SKF and Timken stress the need to use barrel materials that can stand high temperatures and thermal expansion and hence possess high thermal stability working at optimum temperatures.

- Performance under Load: Load capacities particularly dynamic ones must be known and this has been emphasized with the Schaeffler Group. Usually, it is recommended to use such bearings, which can support maximum working loads, without detriment to the efficiency of the supported structure.

- Barriers to Moisture: For applications that may come into contact with moisture or chemical contamination, it is advised to use stainless steel bearings or coatings that are impervious to corrosion.

These parameters are supported by technical engineering standards and are key in the effective and efficient selection of a bearing that will optimally and dependably serve the operational requirements of your centrifugal pump.

Common bearing types used in process pumps

Specific types of process pumps typically incorporate essentially the same design and bearing types to achieve desired well-functioning results. Bearing usage as pointed out by the top three websites on google.com includes the following:

- Ball Bearings: They are applicable for a great number of applications because they possess the unique capability of withstanding radial and axial loads in equal measure. Ball bearings have been observed by institutions such as SKF as the best for high-speed applications due to low forces within the design that reduce wastage.

- Roller Bearings: It is noted on the Timken website that such roller bearings as cylindrical and spherical roller bearings are great due to their increased load-carrying ability. Recommended for applications where there are extreme radial loads, they are mostly used in pumps under harsh applications of service.

- Thrust Bearings: As indicated by Schaeffler, Thrust bearings play an integral role in supporting axial load in axial forces inside process pumps. They provide a similar function as axial bearings except that they do not allow rotating shafts to move axially under end thrust.

Each one of such bearings, however, has its own, we shall not call them operational parameters, but rather: dynamic load, axial load friction coefficient, operational temperature range, and others that have reasonable engineering backing as can be supported by application engineering studies and numerous statistics.

What are the common causes of bearing failure in centrifugal pumps?

The impact of contamination on bearing life

After picking out the top three websites from google.com, it is clear to me that it is the contamination that has the greatest influence in shortening the lifespan of bearings, particularly in centrifugal pump applications. This degradation is the most common and occurs because foreign particles are present in the bearings, which prevent the perfect motion of the bearings. These foreign materials which may be in the form of dust, dirt, or other small particles embedded in the surrounding atmosphere produce mechanical wear stress that shortens the life span of the bearing.

Every resource indicates some technical characteristics with each of them illustrating why clean environments should be encouraged in bearing operation. For example, when contaminants are introduced, the friction characteristics may increase unreasonably too often raising the temperatures above the standard. In addition, the load patterns are also affected injuriously as even a slight modification is capable of causing a relative movement of the parts increasing further stresses on the bearing contacts. Though SKF for instance supports the use of designing for incorporation of sealing materials considering ingress of contaminants as an option, Timken places the importance of executing cleaning activities and routine checkups early and often to prevent contamination problems from occurring altogether. Schaeffler points out that it is only necessary to control the operating temperature within a defined interval; otherwise, overheating will also increase wear from contaminants.

In this regard, it is very important to comprehend the corresponding influences of contamination and take appropriate measures to focus on the performance and reliability of bearings in centrifugal pumps for a longer period.

How lubrication affects bearing performance

Lubrication is one of the techniques that improve boring by reducing friction and wear and enhances the working life of both bearing and machine parts. The three most relevant pages returned on googledotcom state that, such a proper lubrication forms a film between bearing surfaces and hence prevents their metal contact. This not only reduces friction but also allows for heat generated to be spread out preventing overheating, which is one of the reasons for bearing damage.

Amongst the technical specifications stressed is the viscosity of the lubricant which has to be just right such that a sufficient film is retained despite variations in load and speed. Temperature stability is also of utmost importance in the high-temperature range. Special lubricants have been developed to operate under certain temperature limits without bearing material suffering from the undesired effects of heat expansion and cooling contractions. Further to this, another parameter any bearing has to in its design look into is the relubrication intervals as circumscribed by the working conditions and bearing provided that, the lubricant will be active for the life span of the bearing.

In using resources from SKF, Timken, and Schaeffler websites, I have learned about the need for regular lubrication maintenance and the adoption of dishwashing liquid lubricants that are suitable for different working conditions to enhance the efficiency and dependability of bearings in centrifugal pumps.

Understanding radial and axial loads in bearing failures

Ten related conclusions were reached about the axial and radial loads and the associated bearing failures. Therefore, before moving on to radial load and axial loads’ contributions to bearing failure, I looked into the content available on the top three websites – SKF, Timken, and Schaeffler.

Bearing loads that act on radial outward forces through the surface perpendicular to the rotating shaft are called radial loads. These loads are common under applications where the driving force is applied normally to the axis, such as in electric motors or belt-driven machines. Conversely, axial loads do not lie at right angles to the shaft but rather incorporate the direction of twisting whereby pulling or pushing along the axis occurs. Axial loads are common in applications where thrust is present, such as helical gears or vertical shaft applications.

By reviewing this documentation, I found jurisdictional nature of the bearing is not only dependent on the radial load but special deep anatomy on the design and technical aspects, such as:

- Load Capacity: It is well known that all bearings are limited to a certain life span depending on intermittent loads, rotational, and even bolt tension. It also follows conservative limits in terms of span and transverse and axial loads. Breaching these limits means heading for dysfunction or wear earlier than intended.

- Bearing Type: Different bearing designs are constructed in such a way as to accommodate certain load patterns and load applications. Some of the SKF bearing systems are designed primarily for radial loads while others combine the two which include deep groove ball bearings and angular contact bearings.

- Lubrication: Proper lubrication helps to control the temperature and friction produced by these loads and thus prevents bearings from overheating and eventual failure.

- Alignment: If this phenomenon of misalignment occurs, radial and axial loads may be enhanced which can skew the distribution of the loads causing more damage.

In addressing these parameters, I will have the ability to ensure that the bearings are within their design boundaries and therefore performance and reliability in applications where radial or/and axial loads are an incidence is increased.

What bearing types are suitable for multistage centrifugal pumps?

Benefits of using angular contact ball bearings in multistage centrifugal pumps

Angular contact ball bearings are particularly important for multistage centrifugal pumps, as they can accept not only radial loads but also both axial and radial loads simultaneously, which is critical in this instance. I investigated the first three websites and found out that the bearing ensures the units work accurately and efficiently in the pumps’ operability, as they have a high-speed design that can withstand high speeds.

- Load Handling Capacity: The features of an angular contact bearing allow it to handle combined loads. This combination will be useful in numerous applications like servovalve driven multistage centrifugal pumps including those which include axial and radial thrust.

- High-speed capability: As a result of their low internal assembly friction, such bearings can be subjected to high speeds which is critical for the performance of multistage pumps.

- Alignment: They can withstand slight misalignment stresses better than other conventional bearing types, thus ensuring reliability and durability in harsh operating conditions.

For their maximum operational benefits, it is important to look at aspects such as correct lubrication, which will help in lowering heat and friction, as well as alignment, which helps avoid loading the pumps unevenly. Offering these facilities and improving the attention to how I can use the pumps and implements vis-a-vis other applications will be all sustained high.

The role of cylindrical roller bearings in multistage centrifugal pumps

The increase in demand for multistage centrifugal pumps in various sectors can be associated with the incorporation of cylindrical roller bearings. This is attributed to the high radial loads they can carry efficiently and high to moderate operating speeds. After examining the top three websites, I have found out that these bearings are very relevant to those applications where there is a need to provide greater support for radial loads due to the extended area of bearing contact with the load shaft. This feature helps the system achieve improved load capacity and stability.

- Load Capacity: A major advantage of cylindrical roller bearings is their ability to carry heavy radial loads. This makes these bearings appropriate for devices where the radial load is highly dominant for instance multistage centrifugal pumps.

- Speed Suitability: They are versatile in speed ranges within which they can work effectively, although, under very high-speed churns, angular contact ball bearings will work better than them.

- Misaligned Handling: In as Much as these bearings support very high loads, their ability to tolerate misalignment is rather limited compared with angular contact bearings thus requiring making good alignments before fitting.

For the best outcome, geometric parameter deficits such as precise alignment, proper clearance settings, and proper lubrication shall be adhered to. Emphasis on these factors helps improve the life span of the parts as well as the overall efficiency of the system in terms of operation, which again systematically relates to the information gathered from the top sources.

How deep groove ball bearings are used in multistage centrifugal pumps

Deep groove ball bearings are among the key components in multistage centrifugal pumps, or positive displacement pumps. Their construction is such that they can take on both radial and axial loads which allows for flexibility in their usage. Based on my research from the top three websites on Google, here’s how these bearings are utilized and the important technical parameters to consider:

- Load Handling: Primarily, deep groove ball bearings also support radical and some axial loads, a mechanical feature that contributes to the optimization of the operating stability of the pump.

- Versatility in Applications: Since such bearings encompass both types, they are commonly placed in environments with both radial and axial forces which provides an advantage over complex types of design bearing.

Technical Parameters:

- Alignment: Care in the alignment during fixation of the said bearings to the rotating shaft helps in preventing loss of surface coarseness due to prolonged wear and tear of the bearings.

- Clearance Settings: It’s very critical to observe accurate clearance settings in all these as too much will cause vibrations and too less will press on the bearings too much.

- Lubrication: We all know appropriate lubrication minimizes movement friction and overheating which turns around and affects the effectiveness and lifespan of the bearing.

Concentrating on these parameters helps me guarantee that the working conditions of deep groove ball bearings fitted to multistage centrifugal pumps will be optimal, which is in line with what I had gathered from authoritative resources.

How to extend the service life of centrifugal pump bearings?

Best practices for lubricating centrifugal pump bearings

In the case of centrifugal pump bearings, it has been noticed that the top three websites and their best practices for performing the task advocate for the following few points for effective and lasting bearing performance:

- Selecting the Correct Lubricant: It is important to select a lubricant that suits the conditions of operation and the appropriate bearing type. Proper lubricants lower friction and corrosion and also handle the heat generated during operation.

- Using the Right Amount of Lubricant: On the high point and low point, too much and too little lubricant causes problems. Too much lubricant sometimes increases frictional heating and thus overheating while too little leads to raised bearing wear and possible failure.

- Follow a Defined Maintenance Schedule: A strategy of repeating tasks such as lubrication on time prevents performance from degrading. Do regular checks so that there are responses whenever bearing condition chance and lubricant replenishment is done whenever necessary.

Tactical Aspects:

- Working Temperature Control: The monitored operating temperature guarantees lubricant viability and thus performance.

- Foreign Matter Ingress Control: Appropriate seals and cleanliness of the surrounding area greatly reduce containment of the lubricant.

The above practices and technical parameters as detailed above help add to my objective of increasing the life span of centrifugal pump bearings well in line with the top sources consulted.

Preventive measures to avoid bearing contamination

Writing is considered a process of transformation or as moving from text A to text B. Measures inform the top resources that assist me in case of contamination of bearings. First of all, I make sure that the seals used are of high quality concerning the environment in which the application is used. Functionally, these seals keep out dirt, moisture, and other substances from entering the bearing. Moreover, I also keep equipment and work surfaces clean so that the chances of foreign particles coming into contact with the bearings are low. The addition of an external element to keep a check and clean the lubricant beforehand by using a filtration system helps in avoiding foreign matter contamination even more.

Fatigue Delamination: In this task, I strive to maintain the following parameters:

- Seal Integrity: A periodic examination of the destruction of the seals is important to determine that all seals are still intact. This helps to maintain their purpose which is to inhibit the ingress of soil.

- Lubricant Filtration: Lubricants ought to be subjected to filtration to remove minute and mobile particles that are destructive to the bearings but are not captured by the sealing mechanisms.

- Routine Cleaning Interval: Effectiveness also allows setting up a regimen for cleaning not only equipment but also lubricants to avoid dirt buildup and create a protective zone around the bearings.

Considering that these practices are well respected by the leading experts on the World Wide Web on the maintenance and wearing of bearings under optimum lubrication conditions, they are effective in reducing the chances of bearing contamination.

Monitoring operating temperature and internal clearance

Factors like operating temperature and internal fit clearance are extremely critical and their constant maintenance is essential for satisfactory bearing performance and working life. As has been the Start Sight Resources, efficient management of these parameters reduces the possibility of unnecessary bearing damage.

From a temperature perspective, I ensure that the metal contact bearing speed is always maintained within the overall limit of the metal contact bearing geometry bearing metal assembly in question. Anything outside of these limits would lead to lubricant breakdown and loss of bearing life. For this purpose, I use reliable temperature sensors that give updates in real-time and alerts whenever the temperature changes to abnormal ranges.

With regards to internal clearance, I adopt internal clearance measurement with great accuracy and don’t let it go beyond the prescribed internal clearance limits. Internal clearance should be modified by the recommendations of the manufacturers to facilitate thermal expansion and prevent excessive friction.

Technical Parameters:

- Temperature Range:Limits set up by the bearing manufacturer for the correct lubrication and operation of the bearing.

- Real-Time Monitoring: Tracking temperature deviation from normal levels and using hardware and software systems to issue warnings.

- Internal Clearance Measurement: Description of the internal clearance evaluation tools and methods to be modified according to the temperature changes.

While I nourished these practices embodying considerable industry insights, I was able to successfully control the maintenance of running conditions for bearings leading to their increased serviceability.

Frequently Asked Questions (FAQs)

Q: What are the different types of pump bearings used in the pump industry?

A: The pump industry uses various types of pump bearings, including rolling element bearings, magnetic bearings, and plain bearings. Each type of bearing is chosen based on the specific application and operational requirements of the pump.

Q: What is a rolling element bearing and how is it used in pumps?

A: A rolling element bearing is a type of bearing that uses rolling elements such as balls or rollers to maintain the separation between the bearing races (inner and outer rings). Rolling element bearings are often used in pumps because they can handle both radial and axial loads effectively.

Q: What is the role of the cage in a bearing?

A: The cage in a bearing is a component that separates and guides the rolling elements, ensuring they remain evenly spaced. This helps to reduce friction, wear, and heat generation, thus extending the lifespan of the bearing.

Q: Why are magnetic bearings used in some pump applications?

A: Magnetic bearings are used in pump applications where there is a need for high-speed operation and low maintenance. They use magnetic fields to levitate the shaft, eliminating metal-to-metal contact and thus reducing wear and tear.

Q: How do bearings handle high axial loads in large pumps?

A: Bearings designed to handle high axial loads in large pumps typically have increased carrying capacity and are often of the roller type. These roller bearings are suitable for applications where the impeller generates significant axial force.

Q: What factors should a pump manufacturer consider when selecting a bearing type?

A: A pump manufacturer should consider factors such as the type of pump, load-carrying capacity, operating speed, environmental conditions, and specific application requirements when selecting a bearing type. Each of these factors influences the performance and longevity of the bearings.

Q: What is the importance of the inner and outer rings in a bearing?

A: The inner and outer rings of a bearing are critical components that house the rolling elements and maintain their position relative to the shaft and housing. These rings must be precisely manufactured to ensure smooth operation and load distribution.

Q: How does cooling water affect bearing applications in pumps?

A: Cooling water is often used in bearing applications in pumps to dissipate heat generated during operation. Proper cooling helps to maintain optimal bearing temperature, reducing the risk of overheating and extending the bearing’s service life.

Q: What are the common causes of pump bearing failure?

A: Common causes of pump bearing failure include improper lubrication, contamination, excessive loading, misalignment, and inadequate maintenance. Addressing these issues can help to prevent premature bearing failure and ensure reliable pump operation.

Q: How do preload and wear resistance impact bearing performance in pumps?

A: Preload is the application of a constant axial load to a bearing, which helps to eliminate play and improve rigidity. Wear resistance is the bearing’s ability to withstand wear and tear over time. Both factors are crucial for maintaining bearing performance and reliability in pump applications.