Centrifugal pumps are crucial elements of innumerable industrial and household applications that require the movement of liquids with excellent efficiency and reliability. The thrust bearing is a vital part of their work, which manages axial loads and ensures continuous operation without interruption. This blog analyzes the vital importance thrust bearings hold in centrifugal pumps concerning their functions, design particulars, and operational life span. Readers will appreciate how proper understanding, design, selection, and maintenance of thrust-bearing technology improves the efficiency and reliability of centrifugal pumping systems. All of these components work in concert to help streamline centrifugal pump systems.

What is a Thrust Bearing in a Centrifugal Pump?

Understanding the Role of Thrust Bearing

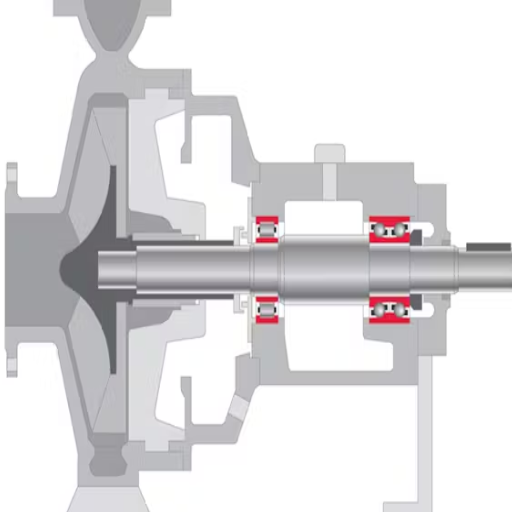

The effective working of a centrifugal pump is greatly influenced by its thrust bearings since they help balance the axial thrust created during its operation. The movement of the fluid through the pump’s impeller builds pressure, which creates a differential in the pump. Without thrust bearings, the generated force would result in considerable imbalance and excessive wear to the pump system, possibly leading to system failure.

From a technical perspective, thrust bearings mitigate the axial forces and stabilize the pump shaft. Consider the following crucial parameters:

Load Capacity: Bearings must be touristic and capable of sustaining an axial load without failure, typically given in Newtons (N) or pounds (lbs).

Material Composition: Common materials such as ceramic and steel can also be used due to their measures and strength concerning wear.

Lubrication Requirement: Oil and grease do mitigate friction and thus prolong the life of the component.

Operating Speed: Bearings must maintain the pump’s operational speed (in RPMs) without overheating or failing.

Alignment Tolerance: Accurate alignment of the shaft and bearing should be maintained to limit premature wear and uneven loading.

It is thus apparent that these thrust bearings provide the first line of defense against system failure by ensuring centrifugal pumps function under the optimum conditions of pressure and load.

How Axial Forces Affect Pump Performance

For ‘P’ beneath these balancing elements, axial forces are usually experienced or felt. Such forces act and significantly affect the hydraulic thrust bearing by putting it under thrust loads where the system is pumped under pressure. In my opinion, these forces directly affect the operating conditions and stability of the system. They are usually caused by a dynamic imbalance of hydraulic pressures, changes of supply or removal of power, alteration of the operating condition of the impeller, or shifting of the rotor’s center circle. For the amelioration of these dynamics, the following specific parameters should be measured: Load bearing capacity of the base, thermal prime performance measure, alteration rate of the supporting member translocation point energy to the repetitive axial and rotational thrust movement deflation, an initial rectangle of the loaded element of bearing and configuration of the splitter.

Some segregation schedule diagrams that estimate the imbalance correcting forces should be delimited to lessen these disturbances. Terminations for eliminating groove imbalances should include terminating to block creation and ending the created spline to the feet.

Why Thrust Bearings are Crucial for Axial Thrust Management

Thrust bearings are critical components for supporting axial thrust because they absorb the forces that develop parallel to the axis of a rotating shaft. Without thrust bearings, excessive axial loads could jeopardize critical parts such as seals, impellers, and, more importantly, the motor itself. I believe thrust bearings are instrumental in providing reliability and durability to the entire system.

Some of the most critical parameters that affect the design and operation of the system are:

Axial Load Rating: This defines the bearing’s maximum axial load capacity without damage. Properly selecting the load rating facilitates the bearing’s meeting the expectations of the particular system.

Lubrication and Friction Coefficients: Proper lubrication reduces friction and wear, maintaining the bearing’s functionality under constant axial pressure.

Material Strength and Durability: Bearings made from high-grade materials like chrome steel or ceramic are better suited to withstand high sustained axial loads for prolonged periods.

Operating Temperature helps avoid bearing performance deterioration due to excessive thermal forces. An adequate temperature range for bearing operation also enhances bearing life under specified axial loads.

If these thrust-bearing parameters are design and maintenance issues, the entire system’s performance will be enhanced regarding service life and reliability.

Types of Bearings Used in Centrifugal Pumps

Different Bearing Types and Their Applications

The classification of bearings used in centrifugal pumps has specific applications depending on the operating conditions and system requirements. Here is a summary of bearing types and centrifugal pumps’ relevant technical parameters:

Radial Bearings

Generally, these bearings carry the radial loads of the pump shaft and aid in its rotation on horizontal pumps. They are usually ball bearings or cylindrical roller bearings.

Key Parameters: Load-carrying capacity, rotation speed, and alignment degree.

Justification: For these types of bearings, the dominant radial forces can be reduced by employing considerably low frictional forces.

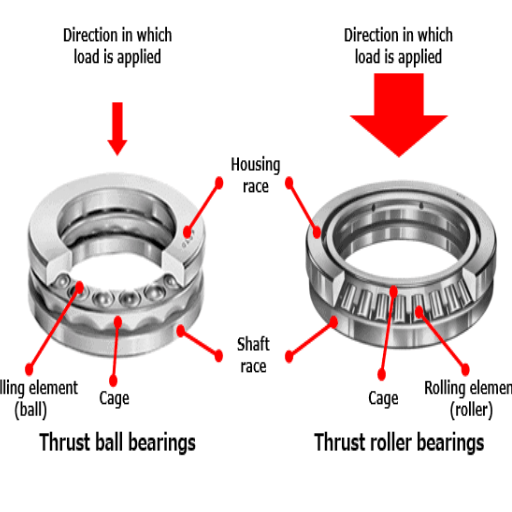

Thrust Bearings

These bearings support axial loads and are very important in vertical pump-type constructions or systems with high axial thrust. Common types are angular contact bearings or thrust roller bearings.

Key Parameters: Measures of axial load, requirements for lubrication, and range of temperature for operation.

Justification: Bearings constructed that can support enormous axial forces can provide stability and reduce shaft axis wear.

Journal Bearings

Film lubrication is used to lower the friction between the shaft and the bearing surface, fundamentally formulating journal bearings. They are appropriate for applications with high-speed or heavy loads.

Essential Aspects: Surface finish, viscosity of the lubricant, and lubrication film thickness.

Explanation: They are crucial in high-performance pump systems because they function smoothly under heavy loads.

Once these parameters are achieved, the appropriate bearing type per application is selected, ensuring the centrifugal pump works effectively, increasing longevity and reducing operational wear.

The Role of Ball Bearings and Roller Bearings

Each centrifugal pump employs roller and ball bearings, tailored for specific actions based on their design and technical parameters. In my opinion, applications with high rates of rotary speed and low radial loads do well with ball bearings, which use friction-reducing spheres. On the contrary, roller bearings are suitable for applications with high radial loads thanks to their lower-weight rolling cylindrical parts, which disperse loads over more bearing regions.

Key Technical Information for Ball Bearings Use:

Lubrication film thickness: Optimal parameters for avoiding material wear at high speeds.

Viscosity of the lubricant: Reducing overheating on increasing rotations per minute is essential.

Surface finish: A finer surface increases the precision and reduces the friction.

Key Technical Information for Roller Bearings Use:

Load-bearing capacity: Capable of sustaining significant radial and axial loads.

Contact surface area: The enlarged contact zone extends the service life of the bearing for heavy loads.

Lubrication film thickness: Important for essential speed and smooth function at high pressures.

Providing these types of bearings with the required technical parameters ensures the best running conditions for the pump while minimizing maintenance and prolonging the part’s life. None of these bear whatever type of fabrication ought to be applied without knowing the system’s specific load conditions, speed, and configuration.

How Angular Contact Ball Bearings Work

Angular contact ball bearings support combined loads, radial and axial, because of their unique internal design. The raceways and ball’s positions are at an angle relative to the bearing axis, termed the contact angle. This feature enables the bearing to sustain radial support while simultaneously withstanding an exerted axial load in one direction. To achieve quality performance and prolong durability, I always evaluate the following technical parameters:

Contact angle: 15°, 25°, 40°. The larger the contact angle, the better the bearing can withstand axial loads. However, its rotary speed range may also decrease. I select the angle depending on the load direction and speed requirements.

Preload type and level. Preloading benefits high precision systems by reducing vibration and increasing rigidity. For this reason, I make precise adjustments to the preload to accommodate system dynamics.

Material and cage design. Reliability is guaranteed in extreme conditions such as high speed or corrosive environments with high-quality materials like ceramic or steel combined with robust cage structures.

I always check against the application’s specific load conditions to prevent premature failure and the axial and radial load limits and bearing parameters.

Accurately addressing these parameters improves the bearing’s performance, reducing the wear rate. As a result, the service life of these bearings in demanding applications is extended.

How to Select the Right Thrust Bearing for Your Pump

Factors Influencing Bearing Type Selection

To select the optimum bearing type for any given pump application, I consider a few central factors that guarantee quality performance and dependability.

Load Direction and Magnitude: I need to check if the application is more of an axial, radial, or a combination of both. For example, thrust bearings are appropriate for high axial loads, while journal or roller bearings have the advantage of low radial loads.

Operating Speed: As already mentioned, the speed at which the bearing must perform is critical. In applications where loads are lifted at high speeds, low-friction bearings, particularly ball bearings, are usually used to reduce the heat generated during operation.

Temperature Range: Pumps meant to operate under very hot or icy conditions need a bearing that can withstand high or low degrees of thermal expansion or contraction, respectively. Thus, bearings with ceramic parts or high-temperature lubricants are appropriate for such cases.

Lubrication Requirements: Moving parts need lubrication to avoid wear. In this case, oil grease or some other solid lubricant is typically required. The type of lubricant is selected based on satisfactory factors, such as environmental working conditions and ease of maintenance.

Material and Durability Needs: I make sure that the supporting features are made specially for the bearings, which may be used in the pump environment to counter corrosives or abrasives. Ceramic bearings and stainless steel have the best durability and corrosion resistance.

Space and Design Constraints: I opted for bearings within the design size constraints set for the pump assembly. In some cases, compact configurations might call for a specific bearing design for effective space utilization.

In systematically analyzing these parameters, as well as their impact on the pump’s operational requirements, I can confidently state that the selection of the most appropriate bearing type for the application is correct.

Considering Axial and Radial Loads

Regarding axial and radial forces, I examine the particular loads acting on the pump bearings to ensure the pump works well. Axial loads are forces parallel to the shaft, which may result from hydraulic pressure or thrust produced in the pump. Radial loads are perpendicular to the shaft and are typically caused by the weight of the impeller or some other operational force.

To address the technical parameters effectively:

Load Capacities: During operation, I check that the anticipated axial and radial loads are within the bearing’s dynamic and static load capacities, either or both of which can be exceeded.

Speed Ratings: The balance of these loads against the pump’s rotation should prevent overheating or excessive wear in the bearings.

Material Strength: I use materials that resist fatigue for prolonged combinations of loads over time.

Lubrication Requirements: Sufficient lubricant helps reduce the friction and temperature caused by the bearings rotating in combination with an axial and radial load thrusting together at the surfaces of the bearings.

Alignment Tolerances: I make sure the coupling and housing are aligned to avoid undue factors that could impair bearing life and are permissible under combined loads.

By balancing these parameters, I can ascertain that the bearings operate satisfactorily under the defined axial and radial load conditions.

Impact of Hydraulic and Mechanical Forces

The performance and service life of bearing systems are highly affected by hydraulic and mechanical forces. I understand these components of bearing systems in depth, which enables me to perform forces systematic analysis toward analyzing the operational reliability of the bearing systems.

Hydraulic Forces: Varying fluid pressure causes these forces, which, in turn, can cause uneven load allocation over the bearing. To counter it, I ensure adequate lubrication to lessen the wear-by-induced fluid stresses. For instance, employing a particular viscosity within fluids can guarantee unavoidable stress is effective on the lubricant without surface breakdown. In this case, an ISO VG 46 lubricant should ensure adequate performance.

Mechanical Forces: Mechanical forces such as vibrations and impact loads are highly prone to applying fatigue damage. I answer this issue by incorporating high fatigue strength materials like steel alloys, around 60 HRC in hardness, and damping aids where necessary. Moreover, I calculate load ratings (C and Co) to aid in bearing support for both dynamic and static loads.

Addressing these forces allows me to handle real-world operating conditions, change the design to suit my objectives, and increase the bearing’s service life while continuously performing stable tasks.

Standard Bearing Failures in Centrifugal Pumps

Identifying Signs of Bearing Failures

In an effort to discern signs relating to bearing failures in centrifugal pumps, I tend to focus on the following indicators as well as carefully check accompanying technical parameters to justify my conclusions:

Excessive Noise – Any unusual activities such as grinding or squealing indicate some form of contamination and a lack of lubrication. Doing a thorough inspection can help determine wear levels. By employing vibration analysis tools and measuring vibration levels alongside the noise frequency, I can ensure that the values surpass the thresholds set for operational standards.

Excessive Heat—Overheating can possibly indicate signs of improper lubrication or even an incorrect alignment coupled with an excessive load. To confirm the suspicion of abnormal thermal behavior, I measure operating temperatures within the manufacturer’s recommended range, such as a maximum temperature of around 100 degrees Celsius for all bearings.

Vibration Abnormalities – Imbalance, misalignment, and extensive wear cause excess or irregular vibrations. I can locate the source of faults by employing equipment used for vibration monitoring while scanning parameters like high-frequency vibrations, particularly those above 10 kHz.

Lubrication Issues – Degraded or insufficient lubrication results in excessive friction. To confirm the issues, I assess the lubrication quality alongside viscosity values and contamination levels.

Indicators of Wear or Damage – Failure can be indicated by cracks, discoloration, or brinelling occurring on the bearing surface. I conducted a detailed inspection and compared the achieved load ratings (C and Co) to the loads applied to ensure none were exceeded.

These observations analyzed alone may not provide an accurate conclusion. Still, when aided with technical data, I can accurately give the reason for bearing failures and determine the necessary steps to advance their prevention.

Preventing Contamination and Friction Issues

To mitigate issues of contamination and friction, I implement a series of best practices and techniques that are, in my opinion, reasonably necessary.

Effective Sealing Mechanisms – When mounting the bearings, I install protective devices such as labyrinth seals or contact seals, which act as the first line of defense against moisture and dust. This step is particularly critical in zones with high exposure at risk.

Clean and Controlled Assembly – The assembly area is also free from contamination, and I wear clean gloves during work to ensure I don’t carry any undesirable particles. Keeping such a set environment helps with mitigating interference during the installation process.

Regular Lubrication – Friction and wear are a common enemy. Thus, lubrication is requisite. I use the correct viscosity lubricants (cSt) depending on the operating temperature, speed, and load requirements. For example:

- Low-Speed Applications – Maintaining a film strength necessitates using higher viscosity lubricants.

- High-Speed Applications – Using lower viscosity lubricants ensures smooth and low resistance motion.

Routine Maintenance and Monitoring – I regularly check contamination and lubrication quality along with these steps. Through spectrographic analysis or particle counting, I am able to perform these checks and identify potential problems early.

Load and Speed Ratings – I verify that operating conditions is within design limits by examining the applied loads against dynamic and static load ratings (C and Co). Abiding by these limits optimizes performance while reducing the risk of undue stress and overheating.

By constantly applying these measures and technical instructions, the risks of contamination and friction can be managed, increasing the bearings’ durability and dependability.

Maintaining Bearing Life through Proper Lubrication

Effective lubrication of bearings begins with calculating the appropriate type and quantity that aligns with the current operating conditions to achieve the desired longevity. As a start, I opt for lubricants that utilize both primary and secondary viscosity classes that function appropriately at the recommended operating temperatures for the bearing and the load and speed parameters required. For example, the lubricant index and ISO VG grades can be matched to their application, specifically for ISO VG grades and multi-grade lubricants for extreme temperature conditions.

Under- and over-lubrication, which can result in bearing failure, can be avoided by continuously checking the relubrication time intervals. These intervals are determined using speed factor intervals (n × dm) alongside temperature and application load. Regular lubrication intervals must be monitored to avoid discoloration and contamination of the bearings, which could lead to potential issues.

Effective prevention of metal-to-metal contact requires maintaining a thin lubricating film on the rolling elements and the raceways (minimum film thickness, λ ≥ 1.0). This allows the bearings’ partitions to operate smoothly, allowing them to achieve maximum service life. Performing operational checks and maintenance leads to the expected results in bearing service life.

Innovative Bearing Applications for Enhanced Pump Performance

Exploring Magnetic Bearings and Their Benefits

Electric drives have unique benefits compared to other bearing types, especially in areas with high accuracy and low maintenance. These benefits include reducing the contact between parts by employing electromagnetic forces, which increases efficiency and service life by minimizing friction. The rotors inside of the pump experience zero physical contact, which improves efficiency.

Electric drives perform well in high-temperature and high-speed conditions. For example, they can sustain a rotational velocity of over 50,000 RPM without using any lubrication systems. Furthermore, this component can function in high temperatures, exceeding 250 degrees Fahrenheit or 121 degrees Celsius. Their versatility in those conditions makes them valuable in industrial settings. Furthermore, systems that passively allow me to change the stiffness and damping of the drives can reach maximum efficiency for different conditions.

In cases where vibration mitigation is of extreme concern, electric drives have the highest priority. The continuous monitoring of the rotor position allows for features that actively reduce vibrations caused by mistakes like imbalance and misalignment, which lowers noise, thus increasing the reliability of the whole system.

With these defined parameters of speed, temperature, and vibration control, as well as the introduction of magnetic bearings at appropriate locations, I can improve the performance of the pump and simultaneously lower the upkeep costs and downtime. This novel solution guarantees the maintenance of the system over time.

Utilizing Cylindrical Roller Bearings in High-Pressure Applications

The primary consideration that underpins the application of these bearings in high-pressure systems is the ability to withstand heavy radial loads. These bearings are optimal for cases when axial loads tend to be low because they are constructed to have high radial capacity and low frictional drag. They can also work under conditions with high rotational speed and fixed load as they guarantee consistent output and outlast the competition performance-wise.

The benchmarks that I take into account for cylindrical roller bearings include:

Load Capacity: The construction of most cylindrical roller bearings permits them to be subjected to substantial radial loads, making them ideal in high-pressure systems.

Temperature Tolerance: These roller bearings are constructed to resist high temperatures, a standard for high-pressure operations.

Speed Limitations: Their design permits using bearings for operations at high speeds and thus supports systems with short operational cycle times.

Lubrication Requirements: Lubrication is paramount to mitigate friction and wear, significantly prolonging service life on the bearings.

Attending to these parameters assures me that the rollers will maintain reliability and efficiency in extreme applications while reducing the need for maintenance and operational midnight oil.

Advantages of Spherical Roller Bearings in Multistage Pumps

The Submission Suggests para 1.6: Considering the Benefits of Spherical Roller Bearings In Multistage Pumps Spherical Roller Bearings tend to have distinct features that enable them to withstand various operational conditions. Therefore, I have selected the following relevant technical parameters as well as justifications:

Load Handling: With a combination of radial and axial load strengths, these spherical roller bearings are ideal for use in multistage pumps that often use combined pumping stages. Since the spherical roller bearings have a symmetrical shape, it allows for even stress being applied to the pump components and minimizes the chances of tapering the pump parts.

Misalignment Tolerance: Shaft misalignment with these bearings is easily adjustable, which means that even when slight angular inaccuracies are present, these bearings still have smooth functionality. This feature enhances the effectiveness of the system in coping with alignment problems.

Vibration Resistance: The construction of the spherical roller bearings is sturdy enough to ensure that under broad pressures, vibrations do not compromise the performance of the bearing. That facilitates steady function under high pressure and dynamic impact.

Temperature Performance: Since these bearings are designed to be used in harsher applications, excellent temperature tolerances ensure minimal risk of thermal degradation.

Extended Service Life: Poor lubrication in harsh applications will most likely cause the bearings to lose their service life. With the proper lubrication and strong materials, spherical roller bearings are very durable, which aids in practical operation and reduces downtime.

By implementing these methodologies, I have strategically made these multistage pumps to achieve high inflow rates, longer service life, and low need for maintenance, which, in the end, achieves optimal performance on the entire system.

Frequently Asked Questions (FAQs)

Q: What are pump bearings, and how do they function in centrifugal pumps?

A: Pump bearings are devices that hold and support the rotating shaft of a centrifugal pump. They aid in maintaining the desired position, diminish friction, and sustain both axial and radial loads during operation, resulting in smooth rotation of the centrifugal pump for more extended durability.

Q: What types of bearings are used in centrifugal pumps?

A: The bearing types used in centrifugal pumps are rolling element bearings such as ball and roller bearings and plain bearings. Each type is unique and has its functions depending on the application range and the load parameters of the pump.

Q: How do thrust bearings support axial loads in a centrifugal pump?

A: Thrust bearings indeed support the load axially, which is put by the rotor and impeller of the centrifugal pump impeller. They ensure that the thrust under load does not permit the pump shaft to move excessively, so the position is correctly held.

Q: What is the role of the thrust collar in pump applications?

A: The thrust collar is a component that connects with the thrust bearing and assists in axial load application so that it is applied uniformly over the surface of the bearing. It helps to enhance the collar life and bearings due to reduced wear and tear.

Q: Can you explain the difference between radial and thrust bearings?

A: While radial bearings bear loads perpendicular to the axis of the shaft, thrust bearings take loads parallel to the shaft. Both are necessary in centrifugal pumps because of the different forces experienced by the pump shaft during the various stages of its operation.

Q: Why are rolling element bearings preferred in high-thrust applications?

A: In high-thrust applications, rolling element bearings such as ball and roller bearings are preferred because they can support considerable thrust loads with relatively high movements of low friction. This is best for performance and longevity within difficult operating conditions.

Q: How does the speed of the bearing affect pump performance?

A: The speed of the bearing is critical as it will determine how well the bearing is lubricated and how much heat is produced in the bearing casing. Exceeding the required speed can cause high friction and skimming, which may overheat the bearing, so the best operating conditions for the pump cannot be achieved without carefully selecting the type of bearing and lubricant.

Q: What maintenance practices can enhance the durability of thrust bearings in pumps?

A: The routine maintenance practices, such as checking the lubricant levels, looking for any signs of wear, and confirming the alignment of the components, help enhance the thrust bearing’s durability. Also, proving that the seals are in place will help reduce the chances of contamination and failure.

Q: What challenges do pump applications face concerning residual axial thrust?

A: In a pump’s designs, residual axial thrust may cause damaging effects on the bearings and other parts of the pump system by overloading them with excessive robust movements, which may cause damaging effects. Proper selection of the bearings and the alignment of the system’s components should be designed considering residual axial thrust conditions.