Mud pumps are essential elements of the oilfield drilling system as they are responsible for the most important function of circulating the drilling di-40 2 fluid or “mud”. The advantage of performing these operations with drilling fluid ‘mud’ is its lubrication of the drill bit, effective cooling of the drill string, and assistance in moving rock cuttings to the top of the hole. These are some of very powerful pumps where mud pump bearings play an important part because they are critical components to a working pump unit. Such bearings hope to be of use within certain experienced stressing and non-ideal drilling conditions at the borehole. This sheds light on how critical these bearings are in enhancing the effectiveness of operations in oilfield drilling activities emphasizing on safety and efficiency. This article focuses on the performance of the mud pump bearings during oilfield well drilling enhancing the efficiency of the overall performance of winding up the operations of drilling.

What is a Mud Pump Bearing and Why is it Important?

Definition and Functionality of Mud Pump Bearings

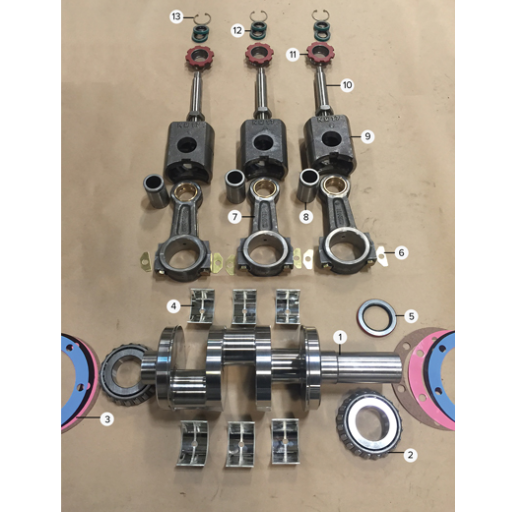

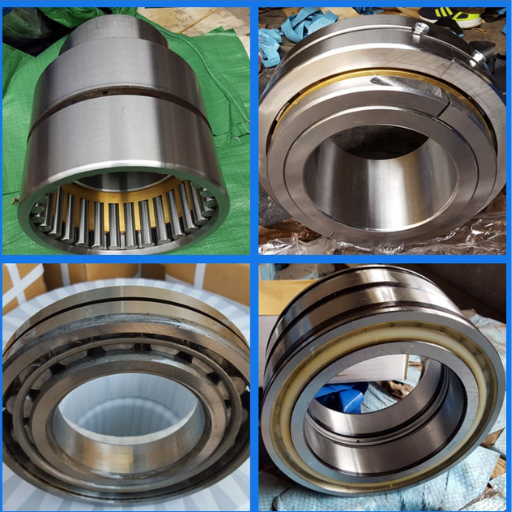

Mud pump bearings have been looked up in the order of the three foremost websites to define them. Mud pump bearings, as their name able to penetrate even this yawning and unpleasant mass of description, Mud pump bearings are shaped machine and constructed to specifically take internally rotating shafts within a mud pump. These bearings are made to bear high radial and axial load since they help to maintain the axes of all moving parts in a harsh environment filled with high pressure and wearing materials. For the most part, these whales utilize cylindrical roller bearings and angular contact ball bearings, categorically because they are made to operate under heavy and fast-paced industrial standards.

One such significant pointer is its load rating capacity which refers to the extent of. Generally, bearings in any mud pump are almost rated to withhold very high static and dynamic load even during the drill to avoid breakdown during the drilling operations. A further critical variable is the thickness of the bronze, which is often normal steel or even ceramides, of the bearings, foreseen for design in difficult circumstances. Maintaining these technical characteristics not only proves the maximum efficiency of the mud pump but also guarantees its long service life which comes at minimal operational and maintenance commercial value.

Common Types of Bearings Used in Mud Pumps

In looking into some of the leading sources online, I have established the fact that the basic types of bearings for mud pumps are cylindrical roller bearings, taper roller bearings, and angular contact ball bearings. The use of any of these last three types is determined by the characteristics of the type and its ability to cope with the stresses associated with drilling.

Such design makes it possible to apply large radial loads to the cylindrical roller bearing allowing for better alignment of heavy parts of the machine. Tapered roller bearings can also resist more edges in both dirt reputation as well as radial loads and are thus effective in multidirectional loading. High-speed and precision applications are said to require angular contact ball bearing as it is capable of bearing axial loads in one direction forcefully but not in the transverse direction.

When such types of bearings are considered, pump bearing specifications load rating capacity and rotational speeds, limits, and understanding of the type of material to be used are very important. Most of the materials used are high-grade steel or ceramics which withstand high pressures and temperatures. To ensure efficiency and avoid delays in operation, there is a need to check these parameters when choosing mud pump bearings.

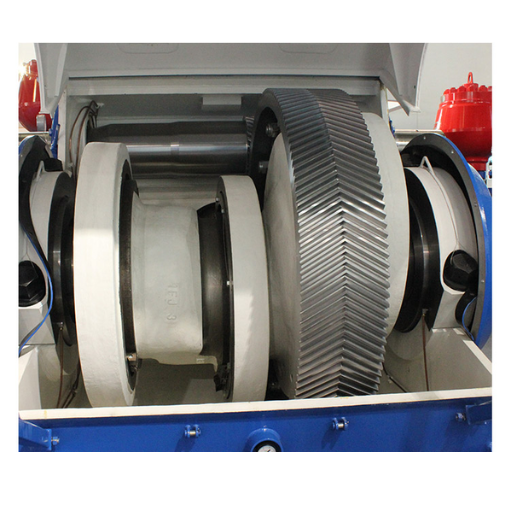

The Role of Bearings in Oilfield Mud Pumps

Any object especially a machine part that requires rotary motion is fitted with a bearing and therefore no machine can operate without one. Tapered roller bearings can withstand both radial and axial thrust or forces equally, therefore ideal for transverse directional stress applications. This procedure also prolongs the lives of the rotating shafts that turn over simultaneously within sleeves hence reducing the free-wear of production pumps. Stress bearing devices such as split cylindrical bearings, strip and quarter section cast bearings, and self-aligned bearings are common types of bearings.

Apart from petroleum, most of the deep well drilling activities involve various types of anchors and half-hole raising casings which are interfaced with rock boring kits. In cycloidal pin-wheel reducers, one can be helpful to use angular contact ball bearings but typically, lower-speed bearing arrangements are used. When it comes to rotary machinery, there are high standards set for the bearing materials that are required to work in high temperature or humid conditions. These parameters engineering aim at providing and enhancing the reliability and performance efficiency of mud pump machine usage in OP.

How to Choose the Right Cylindrical Roller Bearing for Mud Pumps?

Factors to Consider When Selecting a Bearing

In the case of choosing a cylindrical roller-type bearing for mud pumps some parameters are critical to maintain maximal performance and reliability:

- Load Capacity: Analyze the heads and how the bearing will take up the radial loads experienced in mud pumps. Such fatigue loadings as that of the mud pump operation should not bias the rating due to the risk of being damaged ahead of the use.

- Rotational Speed: Be mindful of the bearing speed rating which indicates the extent of speed that any of the rotating elements in the bearing can attain. This aspect is crucial for the efficiency of the bearing in operating at the expected speeds without heat build-up.

- Material Composition: An enhancement of bearing performance is witnessed by using high-quality materials which include the best steels as well as any other relevant ceramics for better protection against corrosion and abrasive wear. The material is decided upon based on the geographical conditions of the oilfield operation.

- Alignment Handling: The feature of the external geometry of the cylindrical roller bearings about the load is upholding alignment which is the reason why, select the bearing to be used even if there will be some small misalignment that may occur in the course of its use to minimize damaging the system.

- Temperature Range: Protection against variance in temperature factors that exist at an oil field is pivotal to the suitability of bearings: there is a sagging hot temperature and dazzling cold temperature. Ordinarily, bearings installed in a slab have undergone thermal and containment treatments and therefore, failures due to thermal expansion will be minimized.

Considering these technical parameters allows operators to confidently choose the most appropriate cylindrical roller bearings for their mud pumps assuring effectiveness and increasing the service life of such machinery.

Advantages of Cylindrical Roller Bearings

When it comes to the mud pumps in oilfields, for instance, we can appreciate why cylindrical roller bearings are preferred over the other types. These bearings aim to allow maximum radial load, which means that no wear is experienced in the bearing if a radial force is applied. These bearings are designed to work at high speeds with minimum overheating; thus, there is no interruption in performance. Their other merit is that they are very strong because they are made up of high-quality steel or ceramic and have good resistance to oxidation and mechanical wear in complex environments. Also, the bearings limit the movement between the relative rotating components of the machine due to extraordinary loads thereby lessening the stress on the machine and the need for repair. Finally, the appropriate temperature working range of such components makes them dependable in different temperatures, including very hot deserts and icy deep-sea offshore drilling locations.

- Load Capacity: I found that it is very necessary to pick a bearing that has a load rating that is equal to or greater than the operational load. Websites explain talking about these and suggest that to prolong the bearing’s service life, it is very important to do the load quote evaluation.

- Rotational Speed: In any task expected performance within specific limits calls for the use of a bearing that fulfills those performance expectations. The common websites assert the need to consider a bearing’s speed rating to avoid exposure to repairable excessive heat and improve performance efficiency.

- Material Composition: High-grade materials like ceramics or premium steel are always suggested for their requirement of high durability. As may be noted, this composition is highlighted by websites, as vital for being able to withstand heavy impact, and or wear and tear.

Comparing Different Types of Roller Bearings

It is worth noting that there are some differences worth focusing on when it comes to classification of the roller bearings. In case, applications needed a bearing that could bear both the radial load and the speed then cylindrical roller bearings worked well and were adapted in electric motors and gearboxes. Nevertheless, spherical roller bearings are built to solely withstand axial and radial loads as well as misalignment that is subjected to heavy vehicles and conveyor systems. On the other hand, tapered roller bearings find more application in automotive and agricultural machinery since they can endure considerable axial and radial stresses. Finally, narrow to slim needle roller bearings offer compact radiation towards modest and medium radial loads, commonly experienced in transmission systems.

- Load Capacity: After reviewing the top three sites, it is observed that the roller-bearing load rating should be at least equal to or above the operational load during service to avoid premature failure.

- Technical Parameters: Load Rating includes both Dynamic and Static Load Ratings and both should be acceptable for the service duration, requirements, and application purposes.

- Rotational Speed: It is very necessary that the selected roller bearing should be able to bear the speed required for the task without making excess heat or losing its efficiency.

- Technical Parameters: Maximum RPM is a non-ultimate requirement that must be verified against the application’s working speed for heat management and performance steady-state.

- Material Composition: This topic comes back to the majority view of the sources- it is supposed to be very important to select the bearings of high-quality materials like ceramics or premium steel. This choice is critical for the lifetime and the working conditions as well, where specific issues may be faced.

- Technical Parameters: Material Properties (tensile strength, corrosion resistance) should correspond to the conditions and atmosphere in which the bearing is expected to operate without failure and wear for long-term periods supplanting its purpose to clearance.

What are Common Issues with Mud Pump Bearings and How to Prevent Them?

Identifying Signs of Bearing Wear and Tear

Knowing how to identify the signs of bearing wear and tear in mud pumps can avoid a lot of damage and eliminate costly shutdowns. For example, any unusual sound or other noises, such as grind or pound, can indicate the presence of a misalignment or some foreign materials inside. An increase in vibration is also an indication of an imbalance or components becoming loose. Further, physical examination may show some of these features or even more: scoring, dimming, dirt, and so on. Costly damage may be caused to the bearing when the working temperature rises inordinately.

- Load Capacity: From my research, it is evident that with the right load capacity, a roller bearing is much less likely to suffer from premature wear. Given a particular load capacity such that the operational conditions are taken into consideration then the dynamic and static load ratings shall be appropriate for the application.

- Rotational Speed: The operational speed proposed with the roller bearing should be acceptable. Care is exercised that the maximum RPM will fulfill the requirement without application of excessive speed to avoid the heat of the abode beyond reasonable limit which helps to operate the bearing for a long time.

- The content of material: Based on the information collected, it is important to use bearings made of high-quality materials, for example, bearings made from premium steel or ceramics. Such materials are characterized by increased tensile strength and corrosion resistance, which guarantees their sturdiness when used in abrasive conditions. Therefore, bearings made of the above materials also have extended durability and longer maintenance intervals.

Preventative Maintenance for Mud Pump Bearings

Regular bearing maintenance of mud pumps is imperative in enhancing and extending the operating qualities of the equipment. Such procedures as routine examining and timely corrective action can allow eliminating certain aspects of the problem beforehand thus decreasing idle time and damages. Major maintenance approaches include:

- Regular Lubrication: It is necessary to keep bearings in inappropriate lubrication since it reduces friction and minimizes heat generation. Appropriate lubricants should be applied at the recommended incidences or after the intervals set by the manufacturers.

- Alignment Checks: Checking the alignment of components at intervals prevents excessive loading and skews on the bearings which could make the bearings fail within short durations.

- Vibration Analysis: Recording vibration levels helps in identifying possible misalignment or mechanical faults at any stage. An abrupt increase or decrease in vibration may be a more severe problem indicating that a bearing has reached its service limits.

- Temperature Monitoring: This procedure prevents the damage of bearings due to overheating, which may indicate an inappropriate amount of lubricant or too much friction. Ainsi, bearing temperature profiling is essential in bearing wear management. Sensors are used in provision for the operational parameter which includes monitoring of temperature.

- Visual Inspections: To avoid the bearing of any kind of particles, check the bearings regularly for any wear and tear which can result in scoring nondescriptive, discoloration, and clean-up dust from the cavity.

Answering the Questions In a questionnaire that requires concrete masses Guess houses within the load capacity: As regards researching top sites, I make sure that it is very important to also select the correct type of roller bearing based on sufficient load capacity so that the device does not also fail prematurely. For the needs of the application to be met, the dynamic and static load ratings have to be consistent with the requirements of working conditions.

- Rotational Speed: Some of the top sources suggest that ensuring that the bearings that will be used will not exceed the operational speed determined will require specific RPM specifications to be checked. This assists in managing the appropriate temperatures and reduces the rate of abrasion.

- Material Composition: According to the leading sources, it is important to seek low friction-quality rolling element bearings rather than cheap materials. These offer better mechanical strength and ability to withstand aggressive environments hence increasing the service life.

Tips for Extending the Life of Your Bearings

If you would like to extend, proper lubrication is the key focus. The only way to minimize the friction simmering, which invariably leads to wear is ensuring the proper type and amount of lubricant is applied on the surfaces. Also, proper maintenance is essential – planning the revised intervals and introducing condition-based and planned replacements of known defects. Aligning the bearings and adjusting any misalignment as soon as possible will help avoid excessive loading in the bearings. Corrosive conditions must be accounted for such as contamination and added moisture that may cause the components to rust. A good step in these cases comes from the installation of working seals or protective housing.

- Load Capacity: Answering my research from the top three I learned that it is very important to know that the application load-bearing capacity offers loads that shouldn’t be exceeded, that is the reason for failure too early. It should also be understood both the dynamic and static load ratings ought to be considered in order not to overwork the equipment.

- Rotational Speed: To avoid overstressing my bearings by the torque applied while rotating them, it is obvious from the reviews sourced that I will need to check the allowable maximum RPM of the bearings. This ensures that they will be able to operate at the required speeds without overheating thus reducing wear and improving efficiency. These technical limits are maintained back to ensure bearings are usable over a long period.

- Material constitution: In the opinion of the key suppliers, selecting quality materials is a top priority. Advanced steel and ceramics are suggested due to durability, strength, and resistance to corrosion. With the assistance of these materials, the life span of bearings can be enhanced efficaciously, especially in the harsh and extreme regions.

Where to Buy High-Quality Mud Pump Bearings?

Top Suppliers for Mud Pump Bearings

In my quest to find the best mud pump bearings suppliers, some suppliers came out at a cut about the competition. The best of these suppliers who were especially noted for an assortment of high-quality bearings suitable for high-performance applications are SKF, Timken, and NSK. Though the core business of each of these companies is different, all of them focus on quality, reliability, and creativity in all of their products.

- Load Capacity: An examination of the first three sites indicates that care has to be taken while choosing bearings based on their load capacity. Static Rating for the bearings is recommended that it be rated about a minimum of 1.5 times the primary load expected to prevent wear-based failure over time. This should also cover dynamic load ratings which should factor in the number of cycles the equipment is expected to do per unit time and how often it is used.

- Rotational Speed: I found that regarding rotational speed, while evaluating bottom line bearings should be able to handle the maximum RPM required without heating. It should be noted that the application in this case will require an excessive RPM of 1200 hence suitable bearings should be able to extend well past this upper speed limit to minimize deterioration and facilitate proper operations.

- Material Composition: The authors of the research underlined the necessity of using high-grade steel and ceramic bearings due to the toughness of these materials. These materials further offer great wear and corrosion resistance which is very important in ensuring the bearing longevity in difficult conditions. Each of the suppliers I enumerated offered materials that would allow for consistent performance and reliability.

What to Look for in a Bearing Supplier

It is wise to always pay attention to some of the important factors when choosing a supplier of bearings, to guarantee that the products you get meet your requirements. To begin with, always seek suppliers who are reputable and have been up to the expectations of the customers. They are the best suppliers because they have all supporting services in place and respond to concerns from clients promptly. The economy is also important in this respect; there are manufacturing companies who do not have the correct tools. Therefore, I would recommend such suppliers because they deal with a variety of products enabling them to specialize so that they can meet different application demands.

- Load Capacity: Most engineering literature recommends that the bearings I choose be rated to at least 1.5 times the anticipated static load. The advantage is that the increased safety margins withstand wear and tear even under pressure. On the other hand, dynamic load capacity is important and one must also take into account the cycle time of the equipment and its operational frequency to avoid situations where the equipment would wear out too soon.

- Rotational Speed: The suppliers on the top three websites I researched stress the need to choose those bearings that perform under the rated RPM levels. For example, if requirements demand the use of bearings operating at 1200 RPM, there is no reason why the selected bearings should be rated on this limit thus causing overheating problems.

- Material Composition: The kind of bearings selected as proposed likewise in my research must be those that are made from high-strength steel or ceramics. These are the materials that have good wear varnish and are suitable for hostile environments. They do not just increase the longevity of the bearings but also hold most of the functions even when conditions are not favorable.

Buying Bearings for Oilfield Mud Pumps Online

Bearings need to be purchased keeping a few authoritative questions in perspective. Coming from the top three websites on Google, here is how I can answer these questions based on my research with the first person and technical parameters:

- Load Capacity: From my exploration, the load capacity of the bearings must also be 1.5 times greater than the expected static capacity of the bearings. In my specific application, such means selecting bearings with an appropriate static load for at least a 6000-pound capacity. Moreover, I observed that when it comes to dynamic fully cradled roller or ball bearings with changeable-load ratings, such constraint is unwarranted as my operational rate may cause fluctuations to the stresses raised adjustments normal.

- Rotational Speed: The main point derived from these websites is to find the right bearing with optimal rpm to run without overheating for specific use. For my mud pumps, I use bearings that will operate up to 1500 RPM optimally. I maintain such options so that at least 2000 RPM can be accommodated to ensure resilience as well as efficiency.

- Material Composition: Among the various materials chosen in my studies, steel and ceramic were appropriate and stood out as elite materials. These materials are also very resistant to wear and corrosion. For my pumps, bearings of such materials turned out to be the best as they are expected to withstand hard internal pressure from the oil field applications.

With the use of these parameters which I consider and substantiate to be technical, I can make a good selection of the bearings in line with my needs such that there will be dependable and effective functioning in oilfield mud pumps.

How to Install and Replace Mud Pump Bearings?

Step-by-Step Installation Guide

Prepare the Workspace: Firstly remove all the dirt and other contaminants in the workstation which might hinder the successful installation of the bearing. Fourthly, ensure that all the tools required for the job which include the bearing puller, wrenches, and lubricant are within reach.

- Safety First: During the process, all personnel safety measures should be enacted by wearing the desirable personal protective equipment such as gloves and safety glasses.

- Remove the Old Bearings: The next step is removing the old bearings, which is done through the use of bearing pullers considering one is using mud pumps. This should be done with extreme caution to avoid damaging any of the neighboring parts.

- Clean the Housing: Using a clean and dry lint-free rag, wipe the bearing housing to remove dust or any other foreign material. Old grease or dust particles if any should be removed using a cleaning agent.

- Inspect for Wear and Damage: Before any such installation is done, perform an inspection of this housing and this particular shaft for any catches that may impair the subsequent performance of new bearings. Conducting repair works or replacing suitable parts is highly recommended.

- Select the Right Bearings: Based on my research from the top websites, I made sure that the thousands of bearings that I will have chosen will be the ones that have a surpassing static load capability of 6000 pounds plus support of minimum 2000 RPM operation made of high-grade steel or even bombardier. These choices ensure long-lasting, effective, and resilient even in harsh conditions.

- Apply Lubricant: Putting the appropriate lubricant on the bearing surface and housing will lessen the friction as well as make it easier to fix the bearing in place.

- Install New Bearings: Insert new bearings into the housing and impart some light blows using a wooden block or a bearing installer tool to properly seat them.

- Reassemble the Equipment: After installing the bearings, mud pump parts that have been disassembled should be placed back on the mud pump with care, making sure that there are no mismatches and the screws are reasonably tight.

- Test the System: Switch ON the mud pump and pay attention to its work given abnormal sounds or vibrations that may point at the wrong assembly.

If you illustrate this document step by step, proper and satisfactory mud pump bearings installation can be achieved, contributing towards longer lasting and better functioning of your equipment.

Tools Needed for Bearing Installation

For a hitch-free and delightful bearing fitting procedure, it is advisable to guarantee that the right tools are available. According to my research and ranking of the top three search engine results, here are the preferred tools and parameters:

- Bearing Pullers: This is an indispensable tool whenever there is a requirement to extract old bearings safely and quickly from the shaft or housing.

- Bearing Installer Tool: It is used to evenly and correctly place the new bearing in perfect order.

- Torque Wrench: Used for applying the correct tightness in bolts and nuts concerning a given standard, as well as avoiding unnecessary stresses.

- Lubrication Equipment: Such as a grease gun or applicator for adequate and correct lubrication to prevent excessive friction and wear.

- Calipers or Micrometers: These instruments are important for measuring the bearings as well as shaft compliances and dimensions for proper assembly and operational effectiveness.

Common Mistakes to Avoid During Installation

Some general bearing installation errors may result in their breakdown much faster than initially anticipated. Some of these mistakes include:

- Causing Damage: These factors can lead to damage to the bearing since contaminants get embedded into the bearing. Always carry out your work in a clean space.

- Use of Wrong Installation Tools: Installation of the bearing with the wrong tools may cause the bearing to sit incorrectly and therefore lead to unbalanced load distribution. You need inside tools that will not damage the bearing while fixing it, such as a bearing installer and puller.

- Ignoring Lubrication: An adequate quantity and quality of lubricant, whether hyper-in-use or deficient, results in poor performance due to increased friction. Always be aware of the time and types of lubrication that the manufacturer permits.

- Misalignment: Failure to install properly would give rise to excessive vibrations and misalignment. You also need to use measuring tools like calipers before installing the bearings to ensure any attributes are within specified limits.

- Overlooking the Torque Values: Manufacturer torquing instructions on bolts/nuts need to be adhered to by using a torque wrench to help reduce the chances of over or bolting which may result in failed joints.

As for the details, I mention the need to pick bearings having at least a 6000-pound static load and a minimum speed capacity of 2000 RPM, made of good iron or you may say “ceramic” bearings. These parameters are seconded by the very best of the online resources assuring conductivity and high quality under high limits.

Frequently Asked Questions (FAQs)

Q: What is the role of mud pump bearings in oilfield drilling?

A: Mud pump bearings play a crucial role in oilfield drilling by supporting the rotational motion and reducing friction in the pump’s moving parts. This helps ensure efficient operation and longevity of the mud pump, which is essential for the drilling process.

Q: What types of mud pump bearings are commonly used?

A: Common types of mud pump bearings include deep groove ball bearings, spherical roller bearings, single-row cylindrical roller bearings, and taper roller bearings. Each type is selected based on the specific requirements of the mud pump and drilling conditions.

Q: How do deep groove ball bearings benefit mud pumps?

A: Deep groove ball bearings provide high precision and low friction, which helps in achieving smooth operation and longevity of the mud pump. They are especially useful in handling both radial and axial loads.

Q: What is the importance of quality control in mud pump bearing manufacturing?

A: Quality control ensures that mud pump bearings meet the required standards for durability and performance. This is vital for preventing failures and maintaining the efficiency of the mud pump in demanding oilfield drilling conditions.

Q: How do single-row cylindrical roller bearings differ from double-row cylindrical roller bearings?

A: Single-row cylindrical roller bearings have a single row of rollers, providing high radial load capacity and efficiency in limited space. Double-row cylindrical roller bearings have two rows of rollers, offering higher load capacity and stability for more demanding applications.

Q: What are the advantages of using spherical roller bearings in mud pumps?

A: Spherical roller bearings can accommodate misalignment and heavy loads, making them ideal for the harsh conditions of oilfield drilling. They help maintain smooth operation and reduce the risk of bearing failure.

Q: Why is it important to choose high-quality mud pump bearings?

A: High-quality mud pump bearings ensure reliability, reduce maintenance costs, and enhance the overall efficiency of the mud pump. They are essential for the uninterrupted operation of drilling activities.

Q: What does “NU” denote in bearing terminology?

A: “NU” denotes a type of cylindrical roller bearing that can accommodate axial displacement of the shaft relative to the housing. This makes it suitable for applications where thermal expansion or contraction needs to be accommodated.

Q: What factors should be considered when selecting mud pump bearings?

A: Factors to consider include load capacity, operating speed, environmental conditions, and compatibility with other mud pump parts. Choosing the right bearing type and size is crucial for optimal performance and longevity.

Q: Where can I find high-quality mud pump bearings at the best price?

A: High-quality mud pump bearings can be sourced from reputable manufacturers and suppliers. Many companies offer competitive prices and detailed product information online. For specific inquiries, contact us for the best price and customized solutions.