Water pump bearings have become integral to various mechanical systems construction, such as automobiles, industrial equipment, and machinery. Knowing what influences the price of the water pump bearing is essential whether you are an owner of an enterprise, a technician, or a fan of the machinery. This guide focuses on the approximate cost of water pump bearings by seeking views from leading manufacturers, assessing the effect of material grade, methods of construction, and economics. If you are looking for low-end or high-end products, this article helps you better understand the prevalent factors and trends in the water pump-bearing market.

What factors influence water pump bearing prices?

How does bearing type affect the cost?

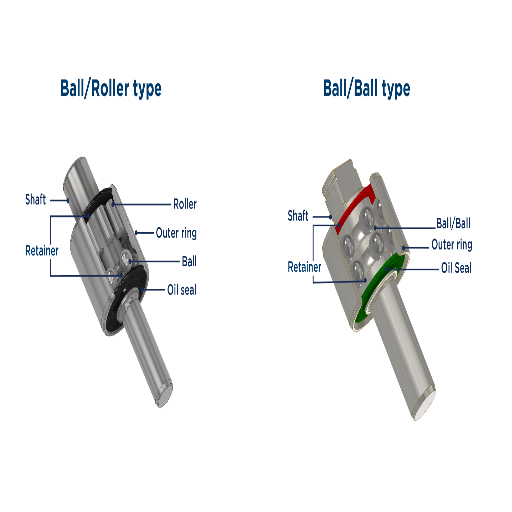

Water pump costs vary and are influenced by the types of bearings used in their construction. The most common types are ball-type or roller-type. These types differ in cost, construction, and operational characteristics.

Ball Bearings: Uses simpler designs than others and offers moderate support against radial and axial loads, however it can operate efficiently at extremely high speeds making it less expensive than other types.

Technical Parameters: Distinctly dynamic load rating, maximum allowed rotating speed and RPMs, and ISO Accuracy Rating class.

Roller Bearings: Known to be stronger, more load resilient, and more durable. This means they are relatively expensive due to their advanced features, which allow them to withstand harsh industrial requirements.

Technical Parameters: Achievable static and dynamic radial limits, length-to-diameter ratio, and operating temperature limits.

Thus, a balance should be established between the performance requirements, the operational environment, and the budget to ensure maximum efficiency regardless of the bearing type.

What role does material quality play in pricing?

The quality of materials greatly influences the pricing of bearings, as it determines the bearing’s performance, safety, and longevity. A high-grade stainless steel or ceramic bearing has better corrosion resistance, higher load-carrying capability, and improved wear resistance. Such materials are essential for these bearings used in hostile environments.

Hardness: This factor affects the cavity of the bearing. For example, if the bearing is operating under extreme pressure, the hardness value would at least slightly work in favor

Corrosion Resistance: This factor is relevant in bearing applications where the bearing is in contact with water or chemicals

Thermal Stability: Material that has been appropriately engineered can operate under broader temperature conditions without impairment.

Load Capacity: A load shear that does not yield structural failure possesses static and dynamic load, allowing the material to be under provision with a much higher grade.

Although high-quality materials may raise initial costs, they lower maintenance costs and increase the bearing’s life cycle, which means that the company will benefit from them in the long run and improve its efficiency.

How do manufacturing processes impact bearing prices?

This explanation will address the relevant technical parameters in the bearing price formulation while also elaborating on how the manufacturing process can impact the price. While precision-manufactured bearings tend to be more expensive because of their finer tolerances and better surface finishing, they are crucial for maximizing bearing life as they effectively reduce friction. For instance, grinding and polishing processes improve the roundness and smoothness of the bearings, thus making them perform better in speed or load, such as in high-speed and high-load applications.

Furthermore, manufacturing heat treatments increases hardness and fatigue resistance, ensuring better wear and tear. Some bearings are manufactured using better alloys or are equipped with other coating requirements, and meeting the demand for such bearings entails using specialized processes such as vacuum sintering or plasma. Still, the expenditures ensure that corrosion and wear are adequately maintained.

A further defining factor is the production method as that determines the size of the batch, for instance the cost of precision hand fabricated bearings is greater than cutting stock ones. Funding such high-end processes guarantees a product designed to meet stringent performance criteria, thereby validating the costs with the final product, such as heat resistance, load capacity, and duration of use.

How do you choose the right water pump bearing for your needs?

What are the key considerations for automotive applications?

To achieve high levels of performance and to increase the operating life of the vehicle, I look at several parameters to select the most suitable water pump bearing for automotive purposes:

Radial and Axial Load—A bearing should withstand a reasonable amount of radial and axial load. Due to varying pressures, most automotive water pumps should generally have bearings with a dynamic load rating of 10-20 kN.

Corrosion Materials – High-grade steel pistons or ones where these materials have anti-corrosion coatings are beneficial in preventing wear and degradation caused by coolant and other environmental effects.

Maximum Operating Temperature – Considering that water pumps are prone to high engine temperatures, the bearing should be able to endure temperature ranges of onset 120 to 150 Degree Celsius without any failure in performing its function.

Sealing System – Contaminates from dust and the escape of lubricants out of pumps, which need to be effectively sealed, protects the pump from harsh environments, and doubles its life span.

Rated Speed – To Guarantee high efficiency, the water pump bearing should be within the rated speed of the vehicles, which usually ranges between 2000 to 7000 RPM, depending on the type of the vehicle.

Longevity and Maintenance—If I choose bearings with a long life span and minimal upkeep, replacements can be few and far between. This area greatly affects return on investment.

I work with these parameters, which allow me to select a bearing that can withstand the working conditions of automotive systems without any problems.

Which bearings are best for industrial water pumps?

When choosing bearings for industrial water pumps, I pay attention to those suitable for those specific systems’ operating conditions. For example, such bearings must withstand high radial and axial loads, be ideal for damp environments, and run continuously for long periods. I consider the following key technical parameters:

Load Capacity—To efficiently deal with the imposed axial and radial forces during pump operation, the bearings must be able to sustain significant dynamic and static loads usable in pumping systems.

Material Resistance – The use of stainless steel and specially coated alloys, which have corrosion resistance, is essential so that deterioration through exposure to water or chemicals does not take place.

Sealing Mechanism – Sintered or shielded bearings protect against water, dust, and dirt, which can extend the bearing’s life in extreme conditions.

Temperature Range – Bearings operating over an extensive temperature range (usually from -30F to 250F) are needed for industrial water pumps as they face different working conditions.

Lubrication – Using pre-lubricated bearings or those that are water grease-proof dramatically reduces friction and the need for maintenance.

Durability and Longevity – Providing water pumps with durable bearings that are resistant to high rpms and heavy-duty performances increases the time between maintenance of water pumps and the length of the bearing’s overall life.

These factors guarantee that the selected bearings are efficient and reliable when exposed to the harsh circumstances of industrial water pumps.

How do you select bearings for agricultural machinery?

There are several essential and interrelated factors that, in my opinion, should be considered when selecting the bearings for agricultural equipment. I emphasize load capacity first. This is because most radial and axial loads, which farming tools and implements handle, are heavy. Extensions to the expected operational loads in terms of life estimated dynamic load ratings (C) of any bearing are a must to avoid failure of the bearings in standard service. A second consideration is resistance to soil and moisture, as quite a reasonable amount of soil, dirt, and moisture are present in farm fields. I seek pipes or shielded bearings to keep lubricated components from coming in contact and minimize bearing damage.

In addition, accurate cut bearings are necessary for cases where mechanical parts such as harvesters or tractors prevail over shafts, which are not always positioned perfectly straight. Self-aligning or spherical roller bearings can take care of this kind of situation. Also, it is worth mentioning that strength is an important criterion, specifically in high-wear environments. Thermal Manageme-bearing forests of alloys with corrosion-resistant coverings work best. Finally, I consider the required rotational speed of the bearings, taking care that the max of the bearings meets the speed necessary for the performance of the clamp to avoid heating or wearing the bearings.

These are the ways through which, after properly evaluating these technical parameters, I can be sure that the selected bearings will efficiently operate under the extreme conditions of agriculture applications while minimizing maintenance efforts and costs.

What are the price ranges for different types of water pump bearings?

How much do deep groove ball bearings typically cost?

Deep groove ball bearings may be purchased for approximately five dollars to fifty dollars each, this is dictated by their size, materials used and performance requirements. The agriculture sector can also afford such a range, considering load, speed rating, and type of seal. This is because bearings that support extremely radial and axial loads or have modern sealing systems that can resist contamination are at a higher limit in this range. Many more factors have a significant effect on the price, and the most important are as addressed below:

Load Capacity (dynamic and static): There is a relationship between load-bearing capacity and cost, and this stems from the fact that capacity bearings are usually made of complex and advanced designs and materials.

Sealing Options (open, shielded, or sealed): The cost is also affected by whether the bearings have shields or can be fully sealed, as fully sealed bearings provide better moisture and dust protection.

Speed Ratings (max): The higher speed rating of bearings can also be a reason, as it results in high heat levels. Possibly, the incorporation of expensive materials or optimizations increases the cost.

Material Quality (e.g., stainless steel vs. standard steel): These materials often inflate costs but enhance their durability in harsh environments.

In conclusion, by balancing all the factors above with the requirements of the machine in question, I can find cheaper options that do not compromise the equipment’s reliability or performance.

What’s the price range for cylindrical roller bearings?

Cylindrical roller bearings’ price highly depends on the technical aspects or features and application purpose. On average, the price ranges between 50$ and several hundred dollars for each unit, and some premium models exceed this range. The following are the key technical parameters that move the prices up:

Load Capacity: Higher load ratings must have a sophisticated design or materials, making them costly.

Speed Rating: Other bearings are for higher speeds and, therefore, require precision engineering and specialized materials, which will most likely increase the bearing cost.

Material and Coating (e.g., stainless steel, special coatings): Prices increase if additional features for corrosion resistance, wear, and heat resistance are added to the bearings, especially for harsh environments.

Sealing and Lubrication: The enhanced operation of bearings equipped with advanced sealing or lubricating systems increases the prices of the bearings.

Tolerance Class (e.g., ISO P6, P5): An increase in bearing cost arises as there are better tolerances.

To ensure that you have a reliable but cost-effective bearing, you need to purchase one that addresses and targets the requirements and needs of the application. Considering these parameters, I can guide you on how to meet the performance and cost requirements.

How do needle roller bearing prices compare?

Generally speaking, needle roller bearings are less expensive than either cylindrical or ball bearings due to the more compact structure and material usage, but their price may depend upon other technical parameters:

Load Capacity: Needle roller bearings have a relatively sized PIN and high radial elation for which their rating is increased, and increased dimensions bear a relatively increased price.

Material Quality: Bearings produced from alloys of high carbons or noncorrosive properties are offered higher than others.

Cage Design: Improvement in performance or endurance through alteration in shape and size of cage material construction, polyamide cages, or metal cages would cause price increases.

Dimensional Tolerances, e.g., ISO Class 0 and Class 2: Better dimensional tolerances result in better alignment and smooth components running but better production costs.

Customization: Pricing on custom products, such as those with extended shafts and integrated seals designed for specific uses, tends to be higher than standard models.

Considering these parameters for the application’s working conditions, I can make a proper recommendation to help the application perform excellently while remaining within budget.

How does brand reputation affect water pump-bearing prices?

Are premium brands worth the higher cost?

The cost factor and the value for money features may be viewed from the perspective that if a motorcycle, for instance, breaks after six months, then the Japanese brand will be seen as being better value because the first thing to consider when looking at premium goods is Longevity, second Reliability of Engineering, and third service that is provided making the deciding point the warranty duration. The Faster an item breaks down, the faster the cost per cycle increases, making it more costly. In the long run, the price remains, proving value for money, especially since quality control mechanisms are apparent. More towards the technical specifications, several key factors still justify the excessive expense.

Material Quality: High-quality alloy grades and heat treatment processes, such as those offered by premium brands, reduce failure risk while providing excellent added wear resistance properties.

Precision Engineering: Manufacturers such as Timken provide excellent offerings and bearings with a broader range of dimensional tolerances (ISO Class 1 or better), helping with proper alignment, improved vibration stability, and a smoother result quality

Innovative design features: The Addition of more complex structural components, such as advanced sealing systems or more complex cages, are better able to prevent foreign contamination and therefore offer enhanced lifespan of the component

Testing standards: Premium brands indeed do apply to focus on carrying out sufficient extensive testing under maximum or other modified structural load tellers for the product to be optimal after it transitions into the market

The initial cost might be a disadvantage, but the premium features, if looked at in the long run, considering the reduced required replacements, lesser maintenance, and irrelevant downtimes, do seem like they justify the loss at the beginning of the product cycle. One can see the return on investments, in this case, adding significant value based on the parameter of the criticality of the application.

What can you expect from budget-friendly options?

Lower price tags often never come with the highest quality standards, especially when considering the budget-friendly options. In such cases, more often than not, the focus is cost cutting, hence it is very very predictable that they would restrict themselves to standard materials and take a basic approach during the manufacturing process. I typically observe the following outcomes with these components:

Material Quality: Because they tend to employ lower-quality materials, wear resistance may be reduced, and the lifespan may decrease.

Precision: High noise or vibration may occur during operation due to missing close tolerances and loss of efficient alignments, as more precise cases are too expensive.

Load and Speed Capacities: Because they are more budget-friendly, they might only be suitable in applications requiring a lighter load and a moderate speed.

Testing Standards: No testing for extreme conditions could be a potential risk since these are low-range items for which the testing process is not as exhaustive.

Still, as mentioned earlier, one cannot deny that the components are functional in many scenarios, especially in noncritical applications or working for a shorter time. Still, even then, quick functions should not be favored over the main aim, to seek the best possible outcome, keeping the demands in perspective.

What are the long-term cost considerations when choosing water pump bearings?

How does bearing lifespan affect overall value?

Bearing service life is critical regarding the total bearing value, particularly considering the long-term operation cost. I believe a bearing with a longer service life will be replaced less frequently, reducing material, labor, and potential downtime costs. Among the relevant technical parameters that can be used for evaluation are:

Dynamic Load Rating (C): A bearing’s dynamic load rating indicates the maximum load an unloaded or rotating ball bearing can continuously withstand. The higher the bearing’s dynamic load rating, the greater the load it can withstand over time, thus affecting its longevity.

Operating Temperature Range: The operating environment’s temperature range significantly impacts the bearing’s life, enabling it to be designed to endure temperature variations.

Material Quality: Integrating high-quality steel or ceramic materials enhances a material’s wear-resistive property and fatigue strength.

Lubrication Requirements: Sealed or pre-lubricated bearings offer sufficient lubrication to minimize wear on the contact surfaces and bearing parts, increasing the bearing’s working life.

In scenarios where the bearing application is singular, the proper selection that provides a life span optimally suited for the work strengthens reliability while reducing maintenance costs.

What maintenance costs should you factor in?

In terms of maintenance expenditure that I take into account in the first place, aiming at efficiency and reliability includes a few essential factors:

Replacement Costs: Even worse, Distributors must deal with increased costs when bearing support dynamic load ratings (C) are low and have to be replaced more frequently. Purchasing a bearing with a higher load rating does involve some added initial cost since the justification for this expense will be the penetration rate of replacements of such a bearing.

Lubrication Expenses: Using specialized lubrication systems / pre-lubricated bearings implies a much lower requirement for frequent replacement of such systems, incurring lesser practice costs while achieving the entire purpose of wear reduction and increasing system longevity.

Operating Temperature Management: Greenfield industrial bearings operating in extreme temperatures recommend cost analysis as the operating temperature range is reduced, increasing the bearing life cycle and reducing replacement frequency. Such a temperature does not require extra bearings, minimizing the costs.

Inspection and Downtime Costs: More efficient materials, such as high-grade steels or ceramics, are abundant in these fields. This also leads to bearings that can minimize downtime by being less susceptible to wear and, hence, require less inspection.

With such right choices made at the outset, I can realize a fair amount of yearly savings in expenditures. I am guaranteed that performance in terms of efficiency and reliability stays at the same level over time.

How do replacement frequencies impact the total cost of ownership?

In one way or another, replacement frequencies shift the total cost of ownership by influencing the replacement costs and operational downtime. In my opinion, there are some bearings whose replacement frequency can significantly increase the parts’ costs and the labor used to service the machine, causing machine downtime and overall productivity loss. To reduce these effects, I concentrate on selecting bearings with technical parameters as follows:

Dynamic Load Rating (C): Bearings with more excellent dynamic load ratings are generally more likely to last cycles before needing replacement, as routine loads are applied. Thus, the frequency at which the bearings need replacing is lowered.

Fatigue Life (L10): A high L10 rating bearing life is expected to be greater and helps avoid high replacement rates resulting from dealing with premature failure of the bearings.

Material Quality: Steel-bearing materials’ replacement ratios are wear—and fatigue-resistant when subjected to more stress, guaranteeing their replacement under extreme conditions.

Seal Efficiency: The improved sealing of the bearings enhances the bearing replacement rate by extending the working period, guaranteeing no contaminants interfere.

Lubrication System: Using integrated or spilled lubrication systems allows improved operation stability and prevention of premature bearing failure, which relates to low replacement frequency.

With these considerations, in the first place, I can try to extend the operational life of the bearings and aim to execute their replacement only when it is necessary by other maintenance work programs to reduce the total cost of ownership over time.

Frequently Asked Questions (FAQs)

Q: What factors are crucial when determining water pump bearing prices?

A: Water pump bearing prices are determined by several factors, such as the steel grade, brand, load capacity, bearing types (e.g., radial or double row), and size. Selling prices can also differ depending on whether the bearing is sold directly from the factory or in wholesale volumes, as well as the intended application (e.g., automotive, truck, or industrial bearing).

Q: How does the type of water pump bearing affect pricing?

A: The cost of water pump bearings is also influenced by specific needs due to a drop in a bore design and its intended use. As a result, some applications, such as water pump bearings for automobiles, may attract a price different from those for industrial bearing applications.

Q: Does being expensive mean better quality for water pump bearings?

A: Water pump bearing prices tend to rise for the most expensive options, particularly when high-quality materials and strong manufacturing techniques are required. However, a reasonable quote is most definitely available for a hard-wearing bearing. Bulk orders, direct selling prices straight from the factory, or special discounts from suppliers in conjunction with retail prices can all rapidly reduce the cost of high-end bearings.

Q: How does the manufacturing location impact water pump-bearing prices?

A: The manufacturing location, in one way or another, influences prices. For example, bearings made in Chinese factories may have lower prices, given the low cost of production. On the other hand, bearings manufactured by well-known companies in different countries may be sold at higher prices because of the quality or the brand value.

Q: What role do bearing dimensions, for example, the outer ring size, play in terms of price?

A: Bearing dimensions also influence financial costs. For example, a bearing whose inner and outer rings are larger is more expensive. The bigger the bearing, or the more specialized it is, such as the 6203 or 885144 bearings, the more expensive it becomes due to the materials added to it and the more complex production processes.

Q: How do automotive applications affect Water Pump Bearing prices?

A: Water pump bearings for automotive applications include those on car water pumps and water pumps on trucks, and their prices may not be the same as those of bearings used in different applications. This is due to specific requirements, such as the durability or maximum speed requirement, or the type of water pump system that must be used. The price may also depend on the type of car it would be used on, be it a regular car or an engine where almost every performance is high.

Q: Do water pump bearing prices get cheaper for bulk orders?

A: For many customers, buying water pump bearings in bulk is a wise decision, as it usually works out cheaper. This is especially true when a supplier or manufacturer engages in wholesale selling or provides wholesale discounts. This is especially true when dealing with a manufacturing plant or a large wholesaler who sells on factory terms.

Q: Is it true that the bearing cost is primarily affected by the load capacity of such a bearing?

A: The price does depend on the load bearing capacity of the bearing, more load bearing capacity generally translates to higher price range. This is because more substantial materials, better forms, more precise works, and often advanced configurations like double-row designs are required. A price increase is also justifiable where a greater load-bearing capacity is needed for the application in question due to the performance enhancement enabled.

Q: Are any specific brands known for offering competitive prices on quality water pump bearings?

A: There are indeed specific brands, for instance, Bajaj Bearings Private Limited, that have already earned a reputation for supplying water pump bearings at very competitive prices, although the price may prevail over specific differences. It is prudent to check prices and quality with many suppliers, including those available on the Alibaba.com website, for the optimum price-quality – performance that meets your requirements.