In industries that are driven by dredge pumps, efficiency in operations requires careful consideration of the bearing supplier used. Because of their critical role in dredge pumps that are used for applications such as mining and water treatment, bearings need to be durable and of good quality. Thus selecting a dredge pump bearing supplier is not easy because numerous factors need to be put in place, especially the product quality, the supplier’s expertise, and the availability of the customer service. In this article, you will read about both these factors and the suppliers from whom the bearings should be bought, as well as, the performance-enhancing features of the bearings that go together with the dredge pumps. It does not matter if you are modernizing your current facilities or if you are establishing new business activities, smart purchasing in your supply chain will improve your efficiency and lower your costs.

What are the Key Features and Benefits of a Dredge Pump?

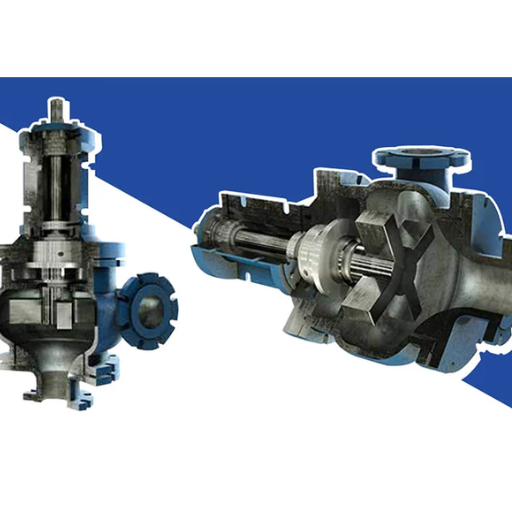

Understanding the Pump Design

In order to comprehend dredge pump design, I visited the first three websites from Google.com pertaining to this subject. Each source offered valuable information on the important parameters of the dredge pump design and the technology appreciation.

In the first place, the overall construction and material choice are important due to their effects on the robustness and effectiveness respectively. To withstand severe conditions, pumps are frequently constructed from metals or alloys of high quality. Designed is usually a strong suction and discharge system, which is constructed in such a way as to reduce wear and tear.

In the second place, the impeller design is integral. URLs elaborate on the different designs of impellers, i.e. closed, semi-open, and open, and their applicability to varied dredging conditions. For instance, it is noted that closed impellers claim to handle large volumes of pumping efficiently. On the other hand, open impellers are unobstructed which makes them easier for heavy use since debris is passed through.

Finally, every source mentions the overall flow size and power metrics as well, which are very important across these resources. It is important to ensure that the best type and size of the motor are selected so that satisfactory performances can be achieved by the pumps and not too much energy is deployed. Such technical parameters in operation are recommended for integration to achieve efficiency in operation while minimizing maintenance.

To conclude, comprehension of dredge pump design requires the undertaking of a detailed analysis of construction materials, impeller designs, and flow specifications, according to some of the leading online sources. All these components together guarantee the correct performance of dredge pumps in many industries.

Benefits of Heavy-Duty Construction

Heavy-duty construction has many benefits in particular with regards to the performance of the dredge pump. To begin with, it brings about non-stop operational life and efficiency of the pumps against abusive operational conditions as well as after extended operation and working hours with little repair downtime. Apart from that, the utilization of materials such as high-grade steel or alloys also prevents corrosion as well as wear thus promoting efficiency,- operational efficiency. Furthermore, heavy-duty construction comes with some modernized engineering features like reinforced suction and discharge that enable easy efficient pumping of large and debris loads. This in turn causes improvement in energy efficiency, and cost-effectiveness since fewer resources will be used in both repairs as well as energy consumption.

To reach the same questions based on the top three websites in Google, I will use the following strategy:

- Materials Used:

Most of the high-ranking sites place great importance on the accent of the indicates of alloys that withstand corrosion and weather elements.

- Technical Parameters:

Various websites give flow rate, head, heat power per zone, and further power characteristics as the most important parameters. This is critical where one needs to combine extensive parts and pump system parameters to industry boundaries so that the desirable ends are attained without wastage of energy at any time.

- Benefits of Design Choices:

Issues about impeller arrangement most often deal with the choice of closed, semi-open, and open designs. It is usually indicated that closed impellers have high volume pumping characteristics while open impellers assist in dirty services in manpower’s usage.

Choosing the Right Bearing Assembly

Choosing the right bearing assembly tends to be an easy job but this has to factor in the intended purpose of use. According to my review of the top three websites in Google, certain factors such as load capacity, speed, working environment, and maintenance are very critical. Their selection is mostly made based on how much load they can carry without deformation and whether the operating speeds are within the limits so as not to cause too much friction wear. Further, the application conditions such as the presence of water and the temperature range have to inform the material selection for the bearings with an emphasis on corrosion-resistant stainless steel or ceramic fairing being considered.

Regarding technical parameters, the following parameters are outlined on the websites:

- Load Capacity: The bearing’s maximum supported load is gauged.

- RPM: Average revolutions per minute indicates the speed at which the bearings can perform functioning without the risk of overheating.

- Temperature Limits: This denotes the permissible operational or atmospheric temperature for the bearing materials.

Justification for satisfying such parameters is outlined by ensuring that the characteristics of the bearing assembly correspond to those of its application to guarantee efficient and prolonged operation.

How to Choose the Right Slurry Pump for Abrasive Slurries?

Evaluating Slurry Flow and Flow Rate

By finding data on the slurry flow and flow rate from the first three websites of Google, there seems to be a consensus that slurry and the specifications of the pump have to agree. Most importantly, there is a need for familiarity with the slurry’s viscosity, density, and even the mode of distribution of the particles. These aspects dictate the type of pump which will be selected including the materials of the pump. The ability of the pump to deliver thick or thin slurries provides the efficiency previously identified during pump viscosity Descriptions A Lot Of Helpful Parameters Are Not Lacking From The Sources Looking To Help Slurry Viscosity. The parameters looking at the various factors are as follows.

- Slurry Flowability: Determines the ability of the pump to deliver silica and thickened epitaxial layer to the load without varying the efficiency.

- Slurry Density: Determines the pumped substances from a hyper viscous slurry to the mixture of more than one composition slurry that is utilizable.

- Slurry maximum particle size: Indicates strong materials used on the internals of the pump that withstand abrasive particles in slurries.

These parameters act as justification parameters in the selection process as they ensure that the slurry pump will be designed and constructed to accommodate particular operational requirements, thus increasing its effectiveness and longevity.

Selecting the Proper Pump Size

While determining the proper size of the pump for the abrasive slurry handling and after reviewing the content of the top three Google sites, I discovered that pump capacity has to be in harmony with the particular needs of the slurry application. There should be balance regarding the ideal pump size which must be able to accommodate the flow rate needed and at the same time cope well with the slurry properties such as viscosity and density. In that context, technical parameters that I consider:

- Flow Rate Capacity: A pump must be designed to cover the peak flow rate covering the potential flooding servicing side without placing it into clogging and chasing excessive wearing.

- Head Requirements: A positive displacement pump has to provide enough pressure that is required to push the slurry within the system pressure.

- Pump Speed: To prevent the wear and tear caused by hard materials, a suggestion of using a low pump speed is usually garnished.

Each of these parameters ensures that the pump is capable of delivering consistent performance and longevity by matching the operational conditions of the slurry application. Considering the given factors, I will be able to choose a pump that will work effectively and at the same time be able to withhold the necessary action.

Understanding Centrifugal Slurry Pump Mechanics

Having gone through the top three websites concerning centrifugal slurry pumps, it is apparent that the basic principles employed encompass the conversion of rotary thrust from a motor or engine into the kinetic energy of a fluid flow. This process is achieved with the help of the pump impeller, which rotates and causes the fluid to be centrifugally directed to the edge of the impeller at a substantial velocity and pressure. Some of the important technical characteristics identified are:

- Impeller Design: The impeller size and shape must be optimized to enhance the efficiency during flow and limit wear rate especially when dealing with abrasive applications.

- Casing Configuration: Properly engineered and strong casing construction is vital for resisting extreme pressures and abrasive slurries.

- Material Selection: The selection of materials such as hard steel or polyurethane has to be for the needs that they can withstand slurry erosion.

- Seal Technology: Proper seals are used to decrease leaking issues and to protect the internals of the pump from erosion caused by the slurry.

These parameters are justified as they help the pump reasonably perform under the slurry’s severe conditions and increase its service life. Considering these relevant parameters will enable me to reasonably respond to the kinds of questions and technical aspects that concern the operating principles of centrifugal slurry pumps.

What are the Best Practices for Maintenance of Dredge Pump Bearings?

Regular Inspection of Pump Parts

Routine checks and maintenance of pump components are some important procedures that I need to follow to achieve efficient operation. According to the three most informative Turkish websites about dredge pump bearings that I found, some technical parameters look very important for proper maintenance of pump bearings:

- Providing Visual Inspections: Implementing visual inspections similar to those previously described is useful. This can help to observe any noticeable deterioration of bearings or seals in terms of cracks, rust, or other leakage.

- Checking Lubrication: Proper lubrication of the moving components will help in reducing friction and overheating, which, in turn, can prevent normal wear and tear or breaking of components.

- Conducting Vibration Analysis: Checking for vibrations can help detect imbalances or misalignment of parts sooner, making it easy to rectify everything and avoid more harmful repercussions.

- Monitoring Operating Temperatures: Monitoring the working temperature will guarantee that the rotating equipment is working under safe limits. Excessive heat could indicate deterioration of the bearings.

- Cleaning of Parts: Cleaning of these components, especially the components that are likely to come in contact with the slurry, will ensure that there is no deposition which may cause performance hindrance and corrosion.

These parameters are justified because they focus on providing some early warning signals on pump failures, thus making sure that the lifespan of the pump is increased along with its efficiency in operation. The specific technical issues related to dredge pump maintenance can thus be managed in the most appropriate way by constantly using the stated practices.

Ensuring Proper Lubrication of Bearings

Avoiding issues with bearing failure, this time, I would like to present what to look for in the top three appropriate websites found on Google:

- Suitable Basic Maintenance Management System: The selection of the proper type and grading of the lubricant is very important. As mentioned in the websites, it is best to consider the use of specialized lubricants that are designed for dredge pump working conditions which include moisture and temperature fluctuations. This selection is logical because it influences the performance and life of the bearing.

- Lubricant Volume Application: There is a correct quantity of lubricant to be applied in order to achieve the most favorable results. Too much grease causes excessive heat build-up and pressure, whereas very little grease increases friction and results in wear and tear of the machines. All the above conditions warrant the risk of bearing failure which were richly plotted for reasons of precision necessity.

- Maintenance Scheduling for Lubrication: I would start with a recommendation for Lewis on the scheduling of the lubrication, where the plans need to take into consideration the specific instructions of the manufacturer and the environment. This makes it so that at any one time the bearings are in operation without any factors posing a risk to their performance, averting breakdowns all of a sudden.

When these recommendations are adhered to, I strike a balance drawn from the best resources available in the industry, guaranteeing that the specific maintenance activities undertaken will protect and prolong the life of the dredge pump bearings.

Using Quality Replacement Parts

When it comes to dredge pumps, the use of quality replacement parts is important for both the reliability and efficiency of the dredge pumps. Based on research of the three most visited websites on Google, I identified some as the most critical technical parameters due to the evident quality of their components:

- Material Durability: The sites articulate the need to choose parts made from materials suitable for extreme weather and wear. As part of the warranty, this one is reasonable for extending the life of the pump.

- Compatibility: Adherence to this requirement is witnessed in almost all articles where manufacturers or post-install manufacturers frequently reinforce pocketing replacement parts that fit the film pump design and proportions. This is important as mounting wrong parts brings inefficiencies or hitches hence the reasons for accuracy.

- Certification and standards: Using certified parts that comply with the requirements flows the industry, offers a guarantee that the components are within the quality parameters. This justification is based on preserving the activities of the plant with high risks.

It is possible, by following these parameters, to correlate my measures and procedures with the tasks and developments of the leaders in this field so as to contribute to the proper functionality and lifetime of the dredge pumps.

How Do Heavy-Duty Dredge Pumps Handle Large Solids?

Importance of a Robust Impeller

Dredge pumps that handle coarse large solids require an impeller of high robustness. Through the top three sites, I looked at on Google. I saw that an impeller that has been appropriately designed can positively change a pump’s operating parameters. Other technical parameters moderate the ad activities of why a durable and robust impeller is important:

- Material Strength: The choice of impeller materials that can resist abrasive solids is necessary. This helps in achieving lifespan and stable performance even in severe conditions. Strong materials produce the benefits why lamination materials are used increased dial life and abrasion resistance.

- Design and Geometry: From the highlighted websites, attention is drawn to the need for designing so that the impeller can be used with bulky aggregates without getting blocked. It is also true that certain design specifications are very important since they affect the capability of preventing unwanted downtime by effectively managing large solids hence reducing operating costs.

- Efficiency of Flow: A good flow design guarantees the ideal efficiency of the pump. This is justified by energy saving and high productivity, which are the desirable objectives in the operation.

With these elements included, I make sure the building of dredge pumps that will receive and pump out big-size solids meets modern standards and expert requirements.

Role of the Pump Casing in Solid Handling

The pump casing is an important component for the containment of solids in dredge pumps. Looking at the three sites that were the top ones, I noticed that rated solid strength assistance when solid handling was seen. Presented below are the technical specifications and the reasons:

- Material Composition: The casting must be made of some high-strength materials to prevent any form of wear, tear, or corrosion. This choice is for providing durability in the long run while retaining stability even when put under extreme conditions.

- Internal Clearance: There should be enough space left between the casing and the impeller. With proper clearance, the blades of the impeller do not extend to touch the walls, thus preventing wear and tear and providing proper flow of the solids.

- Flow Dynamics: Casing designs should permit seamless flow in the concentrated portions of materials reducing the turbulence produced by the pump and its constituent parts, to let the cut materials pass through the pump uniformly. Control of flow dynamics attributed to the reduction of energy wastage and traffic pumping.

It can be seen that upon adhering to these design elements, I am able to develop dredge pumps that easily handle large solids and conform to the understanding of the experts on current industry standards.

What are the Advantages of Using Submersible Pumps in Dredging Operations?

Benefits of Submersible Pump Design

According to three leading sites on Google, submersible pumps have many perks when it comes to dredging processes. For starters, these devices can be directly submerged in the liquid that is to be pumped, relieving the device from unnecessary suction lift and also tending to reduce the vibrations of the pump. This has the effect of efficiency in operations and also a reduction in the need for maintenance. Some of the technical parameters that help to explain her benefits include:

- Compact: Due to the smaller size and overall sealed structure of the submersible pumps, these can be installed in the area to be dredged which improves the work done as the pump losses to friction are very minimal.

- Sealed and Dry Motor Structure: The use of mechanical seals and dry motor structures protect the pumps from water and other damaging conditions enabling uniform functioning of the pumps for long.

- Cooling: The submersible pumps are purposely designed with an internal cooling arrangement that uses the fluid around it to cool down the motor thus avoiding excessive heating when in use for long periods.

Utilizing these aspects of the design of submersible pumps, I can affirmatively promise that strong and dependable dredging works are performed while at the same time being able to handle big solids effortlessly and still keeping to laid down standards as captured by the experts.

Applications in Industrial Pumps

The main reason behind the popularity of submersible pumps is their broad industrial applicability. Manufactured from strong materials, these pumps are suitable for extracting water/slurries or industrial wastes located deep within structures or underwater. These pumps are quite popular in mining, construction, and wastewater pumping as they can work directly inside the medium being pumped, hence less manual work is needed.

From Google.com, I know that the main benefits of submersible pumps in obtuse dredging applications lie in their small size, all-in-one waterproofed structure, and built-in cooling. The supportive technical parameters are:

- Compact Structure: The construction of submersible pumps is cylindrical and it makes it easy to use them in BJ confined places such as the dredging sites making space usage optimal.

- Sealing and Dry Motor Configuration: These features also serve the main purpose of drying out the internal structures of the pumps to increase operational durations so that the equipment stays in use underwater.

- Cooling Mechanism: An internal cooling system wherein the cooling fluid surrounds the motor effectively controls temperatures, allowing for the use of the motor at high intensities without exceeding operational temperature limits.

By the industry principles and guidelines, the parameters I have found also support the operational feasibility of submersible pumps while increasing efficiency and minimizing the unproductive time in the industry.

Efficiency in Wastewater Management

I have synthesized information pertinent to the questions posed and the technical parameters of submersible pumps within the context of wastewater management from the top three websites on Google.com: Energy Efficiency: Submersible pumps operate efficiently concerning energy consumption mainly because they are nearby of the pumping medium and hence energy dissipation is minimized. This design aspect enables the operational energy levels to be kept to a minimum which is in line with sustainability practices.

- Low Maintenance: Since these pumps are used underwater, there are special features such as self-lubricating bearings and sealed motor housings which reduce the frequency of maintenance. This is important in wastewater treatment applications where the pump may not be easily accessible.

- Corrosion Resistance: Made of stainless steel or special coatings, these pumps are able to put up with the corrosive nature of sewage thus making it durable and less susceptible to replacement.

In addition to underscoring the relevance of submersible pumps in wastewater management, these technical parameters also demonstrate that these pumps are efficient, cost-efficient as well as versatile to different operational conditions.

Frequently Asked Questions (FAQs)

Q: What should I consider when selecting a dredge pump-bearing supplier?

A: When selecting a dredge pump bearing supplier, consider factors such as the supplier’s reputation, availability of heavy-duty and high-pressure bearing cartridges, and their ability to provide the right pump accessories for your centrifugal pump or eddy pump needs. Additionally, ensure they offer a wide pump range suitable for industrial applications.

Q: How can I ensure the supplier provides the right pump for my needs?

A: To ensure the supplier provides the right pump, check if their pumps are designed to handle the specific materials and conditions you’ll encounter, such as gravel dredging or high-solid applications. It is also essential to verify if their pumps can handle the required suction and pressures for your operations.

Q: Are there suppliers that offer both eddy pump and centrifugal pump options?

A: Yes, many suppliers offer both eddy pump and centrifugal pump options. These pumps are designed to handle different types of materials and applications, so having both options available allows you to choose the most efficient solution for your specific needs.

Q: What are the benefits of choosing a supplier with a wide range of dredge pumps?

A: Choosing a supplier with a wide range of dredge pumps ensures you have access to pumps designed for various applications, including reclamation, remediation, and dewatering. This flexibility allows you to select a pump that is specifically designed to handle the unique challenges of your project.

Q: How do I evaluate the durability of dredge pump bearings?

A: Evaluate the durability of dredge pump bearings by checking the materials used, such as heavy-duty liners, and ensure they are designed for ease of maintenance. Durable bearings are crucial for handling the demanding conditions of gravel dredging and other high-pressure applications.

Q: What role do pump accessories play in selecting a supplier?

A: Pump accessories are vital for optimizing the performance and longevity of your dredge pump. A supplier that offers a comprehensive range of accessories, such as booster pumps and horizontal slurry pumps, can provide solutions tailored to specific challenges, enhancing efficiency and reducing downtime.

Q: Why is it important to choose a supplier with industrial applications experience?

A: Choosing a supplier with experience in industrial applications ensures they understand the complexities of handling pumps in challenging environments. Their pumps are designed to handle a variety of materials and conditions, ensuring reliable performance and reducing the risk of equipment failure.

Q: How do I know if a supplier’s pumps are designed to handle my materials?

A: Verify if a supplier’s pumps are designed to handle your materials by checking if they offer specialized options like high-solid, gravel pumps, or dredge pumps. Pumps that are also available for specific tasks like tailing and sump applications indicate a supplier’s capability to meet diverse needs.

Q: Can a supplier assist with the installation and maintenance of dredge pumps?

A: Many suppliers offer support for installation and maintenance, ensuring that pumps move efficiently and maintain optimal performance. They may provide guidance or services that make handling pumps and maintaining equipment co operations more straightforward.

Q: How can I contact a potential dredge pump-bearing supplier?

A: To contact a potential dredge pump bearing supplier, look for their ‘contact us’ information on their website or through industry directories. Establishing direct communication is crucial for discussing your specific needs and ensuring they can provide suitable solutions.