Proper maintenance of pump bearings is a critical component in ensuring the efficiency, reliability, and longevity of industrial motor systems. One of the most fundamental aspects of this maintenance is the application of grease, a process that may seem straightforward but is often misunderstood or improperly executed. This guide is designed to provide a comprehensive framework for professionals looking to optimize the performance of their pump bearings through correct greasing techniques. From understanding the role of lubrication in mechanical systems to discussing best practices, signs of over-greasing, and preventative maintenance schedules, this article will cover every essential detail. Whether you are maintaining small-scale equipment or overseeing large industrial operations, the insights provided here will help you maximize motor efficiency and extend the lifespan of your machinery.

What types of grease should I use for pump bearings?

Factors to consider when choosing pump-bearing grease

There are a few factors I take into consideration while selecting grease for pump bearings so that I can make sure the equipment works to the best of its capability. First, I look into the temperature conditions. The grease has to maintain its viscosity and work within the pump’s temperature conditions, which range from -20 degrees Fahrenheit to 350 degrees Fahrenheit depending on the application. In such high-temperature conditions, I would consider using synthetic grease with higher dropping points. For instance, lithium-complex or polyurea-based grease.

Second, the factor of the rotational speed of the bearing is important and the grease’s speed factor (DN value) is the best reference. It is calculated by the bore diameter of the bearing (in mm) multiplied by the RPM. In high-speed bearings, it is important to have low-viscosity grease that is paraffin-based and has good shear strength.

Third, the load requirements are crucial. If the bearings will be under high load or shock such as sudden impact force, I select a grease that is more suitable with the desired extreme pressure (EP) additives. Usually, these greases carry an NLGI grade between 1 and 3 depending on the particular application.

Finally, I consider such as the presence of water or the possibility of contaminants entering the enclosure. In the case of wet or corrosive situations, high-performance, anti-corrosion, water-resistant grease is paramount to minimize wear and avoid tear-and-chemical degradation. By suitably tailoring these technical constraints to the operational goals, I ensure that the grease chosen starts the equipment while providing the needed effectiveness and dependability.

Recommended grease types for different pump applications

For centrifugal pumps operating under standard conditions, I typically recommend a lithium-based grease with good thermal stability and a consistency grade of NLGI 2. This type of grease provides balanced performance in terms of load-carrying capacity and resistance to water washout. For heavier loads or high-pressure applications, such as those encountered in positive displacement pumps, I opt for grease with molybdenum disulfide additives to enhance extreme pressure (EP) capabilities and improve wear protection, especially where boundary lubrication occurs.

When there are high-temperature conditions, like in the case of boiler feed pumps, I use synthetic-based greases with a polyurea or calcium sulfonate thickener. The latter is known to sustain thermal stability above 150°C without losing lubrication properties. For submersible or motor-driven pumps subjected to corrosive media, the over-environmental medium must be mitigated by using a calcium-complex or aluminum-complex type of grease with outstanding water resistance and anti-corrosion additives.

- Baseline oil viscosity: is dependent on operating speed and temperature.

- Thickener type: chosen according to compatibility and surrounding environment.

- NLGI consistency number: adjusted according to the mechanical requirements of the pump.

- Additives: anti-wear (AW), extreme pressure (EP), or anti-corrosion agents are necessary to deal with certain stresses.

By carefully matching these factors to the operating conditions, I ensure optimal lubrication performance and extended pump longevity.

Understanding grease viscosity and its importance

In the case of grease, viscosity refers to the grade of a base oil in as much as how it flows at any operating temperature about its performance under different working conditions. I usually check the operational speed and load conditions of the pump to determine the appropriate viscosity. For instance:

- Low-speed, high-load operations: Require a greater base oil viscosity to generate a lubricant film strong enough to bear the stress.

- High-speed, low-load operations: Suitable for lubricants with a smaller base oil viscosity to reduce friction.

- Temperature effects: Base oils must be able to perform effectively in a range of temperatures including both low and high extremes where, respectively, fluidity and viscosity are needed.

By adhering to these engineering technical requirements with the needs of the machine, I guarantee that the grease is suitably conditioned for prolonged use and dependable operation of the equipment.

How often should I grease pump bearings?

Factors affecting the greasing frequency

Several factors influence the greasing frequency of pump bearings, and I consider each carefully to ensure optimal equipment performance. These factors include the operating speed of the pump, the bearing type, ambient temperature, contamination levels, and the operational load on the equipment.

- Operating Speed (RPM): High-speed bearings can be expected to have more internal friction and generation of heat which would lead to a higher re-lubrication rate. On the other hand, lower speeds may lengthen the interval between applications.

- Bearing Type: Sealed or shielded bearings may result in a lower re-nip rate while open bearings usually contaminated by the environment need constant maintenance.

- Ambient Temperature: Greater re-lubrication rates can be needed for higher operating and ambient temperatures which leads to grease degradation. In case the temperature is greater than 120 degrees Celsius, I ensure that the grease applied has high thermal stability.

- Contamination Levels: Mashed environments that have dust, moisture, or chemicals intake need a high re-lubrication rate to flush out the contaminants and achieve a protective lubrication film.

- Load and Duty Cycle: Heavier loads or continuous strain or movement results in further stress on the grease film. This in the long run leads to reducing grease effectiveness. Regular intervals need to be maintained to achieve bearing reliability.

By customizing the greasing program according to these factors, I ensured that the lubrications remained constant, increased bearing life, as well as decreased possible equipment failures.

Signs that indicate your pump bearings need lubrication

- Unusual Noise: Unusual noises such as squealing, grinding, or other peculiar sounds generated by pump bearings, normally suggest that there’s not enough grease, or the grease has worsened.

- Temperature Rise: A rise in the temperature of the bearing above the acceptable operational limits is a clear indication of insufficient lubrication. Using IR sensors for frequent temperature checks can be beneficial to pinpoint this issue.

- Vibration Levels: Elevated vibration frequencies linked to the presence of bearing defects may be a symptom of reduced lubrication. Use vibration measurement instruments by ISO 10816.

- Presence of Contamination: Greases that have darkened or destroyed bits of particles or moisture are clear indications of the loss of lubricating properties, thus substituting the grease is a must.

- Reduced Performance: Insufficiently greased or old bearings lead to extreme friction which triggers an increase in energy consumption, and as a result, draws down the efficiency of the pump.

To minimize these issues, periodic lubrication schedules should be instated taking the load, speed, and environmental conditions into account, as set out in the standards for testing grease: ASTM D3527. It is mandatory to use the appropriate kind of grease – one that is of the required NLGI grade and temperature resistance to suit the application.

Creating a pump bearing maintenance schedule

To create a pump-bearing maintenance schedule, I would begin by identifying key operations such as load, operating speed, and ambient temperature conditions. These will determine the lubrication intervals and the type of grease suitable for the bearings. For instance:

- Lubrication Intervals: Bearings operating under high-speed and heavy-load conditions may need lubrication every 500- 1000 operating hours. Whereas, low speed lightly loaded bearings can go for more than 2000 hours.

- Grease Selection: use grease with a specific NLGI class required for the application like NLGI 2 for general industrial usage. Moreover, it’s important to use grease that has a wider temperature tolerance than the operating range like -20F to 300F for standard greases.

Next, I would implement a systematic logging process to document maintenance activities, failures, and component replacements. The schedule should be revisited periodically, incorporating data trends, performance anomalies, or environmental changes, ensuring it aligns with operational demands and ASTM or ISO inspection standards for pump maintenance.

What’s the correct technique for greasing pump bearings?

Common mistakes to avoid when lubricating bearings

One of the most common mistakes I have observed while lubricating pump bearings is greasing too much over the recommended limit. Over-lubrication can raise the pressure within the bearing housing beyond acceptable limits, which results in lubricant leakage or bearing seals getting damaged. Most bearings have a defined range of lubricants based on specific technical requirements and they are designed to function optimally with a specific amount of lubricant, which is usually a set quantity dependent on the size and design of the bearing and it is measured in cubic inches or grams.

Another common mistake is the use of the wrong grease. For instance, some greases are not compatible with others due to differences in base oils or thickeners. Bearings, on the other hand, need grease that has the right viscosity, and a high-temperature dropping point suitable for the operating temperature and load conditions. For pumps working on average conditions, it is best to use grease having ISO VG 68 or 100, and a dropping point over 400°F (204°C).

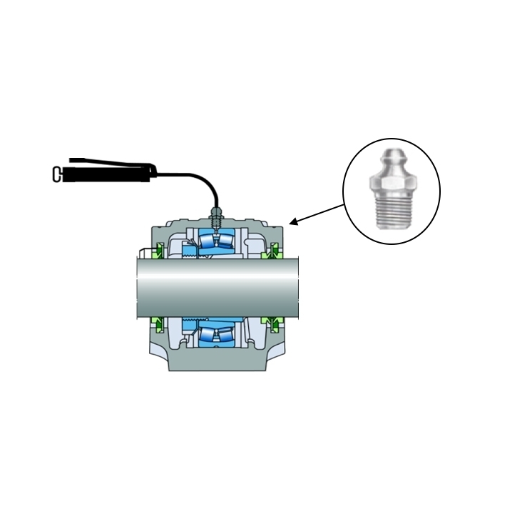

Neglecting cleaning grease fittings before use is yet another mistake. Contamination of the lubricant within bearings by dirt or dust can easily cause damage and wear. Always clean fittings and use a grease gun fitted with a filter to avoid contamination.

Finally, failing to adhere to a consistent lubrication schedule aligned with operational demands is another avoidable error. Bearings in high-speed or heavy-duty conditions might require lubrication every 500 to 1,000 hours of operation, whereas lightly loaded bearings may need less frequent intervals. Adhering to scheduled maintenance ensures optimal lubrication levels and bearing longevity.

Tools and equipment needed for proper bearing lubrication

To ensure proper bearing lubrication, several essential tools and pieces of equipment are required. First, a high-quality grease gun is necessary, preferably one equipped with a pressure gauge and a filter to prevent contamination. Hand-operated grease guns are sufficient for smaller systems, while pneumatic or battery-operated models are recommended for larger, high-demand applications due to their efficiency and ease of use.

To track the increases in temperature of the bearing while operating, infrared thermometers or thermal imaging cameras can be used to determine if there isn’t enough lubrication that is resulting in excess heat. Moreover, ultrasonic lubrication tools can determine the perfect time to put grease in while in real time measuring sound.

Metered grease dispensers and automated lubrication systems are particularly useful when accuracy is needed in lubricant application. These systems prove their value in an industrial setting because of their ability to dispense specific measures of lubrication at set times which prevents human error and ensures consistency.

It’s also important to have lubricant-specific cleaning tools, such as lint-free wipes, and storage containers designed to avoid contamination. Finally, keep a torque wrench or other applicable calibration tools available to ensure fittings are secured adequately without overloading threads or housings. Proper use of these tools ensures that your lubrication processes are technically sound and adhere to industry standards.

How much grease should I apply to the pump bearings?

Risks of over-greasing and under-greasing

Both over-greasing and under-greasing the pump bearings can have serious consequences for the equipment’s performance and lifespan. Over-greasing may cause excessive heating because of mechanical churning which shallow fry the grease. Also, an overabundance of grease can break the seals which may cause contamination or damaged seals. In under-greasing, the grease to suffice the lubrication is lacking. This increases friction and wear of the bearing components which may result in overheating.

- Bearing Size: The manual provided by the manufacturer contains the necessary information regarding the amount of grease suitable to the dimensions of the bearing.

- Greasing Frequency: Base this on operational speed and load conditions. High-speed applications typically require smaller, more frequent grease additions, whereas low-speed bearings may need less frequent re-lubrication.

- Application Method: It’s important to use calibrated grease guns to prevent any damage to seals due to the application of excessive pressure.

To ensure that lubrication is optimized with minimal risks to the pump’s reliability, I actively follow these technical requirements.

Tips for achieving optimal grease distribution

- Choose the Proper Amount of Grease: Adding too much or too little grease can lead to wear, overheating, and other malfunctions. Each bearing type and size has a designated amount, so always refer to the manufacturer’s instructions.

- Check for Compatibility: The selected grease must mix properly with the current lubricants and should also work chemically with the existing coating. Using incompatible grease can lead to problems such as separation of grease or poor performance. It is important to check the viscosity of base oil in comparison to operational temperatures.

- Adjustment of Relubrication Interval: Intervals should be set based on the operational conditions including speed, load, and temperature. In high-speed bearing systems (>3000 RPM), the interval should be changed to 1-3 months. Other low-speed systems can have intervals of 6-12 months between adjustments.

- Uniform Application: Apply grease carefully and at low speeds to avoid disturbance in the bearing structure. A pressure greater than 30 psi while using grease guns should be avoided as it can damage the seals. Grease flow can be checked by sensitive devices which eliminates the risk of applying excess pressure during critical uses.

Dust caps or seals should be used to prevent the entry of particulate matter which helps maintain a clean workplace during and after greasing. Following these tips while placing more emphasis on the provided factors allows for optimal lubrication and ensures dependable operation performance.

What are the alternatives to grease lubrication for pump bearings?

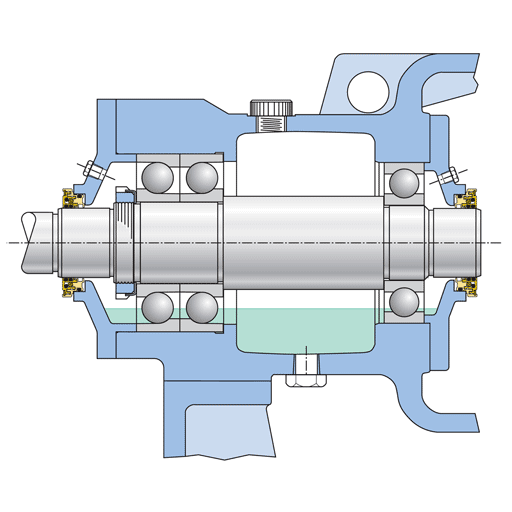

Oil lubrication systems for pump bearings

Oil lubrication systems provide an effective alternative to grease lubrication, particularly for high-speed or high-temperature applications. These systems use circulating oil or splash lubrication to deliver consistent lubrication to pump bearings, reducing friction and wear.

- Viscosity: The viscosity of the oil, typically measured in centistokes (cSt), must align with the bearing manufacturer’s recommendations. It ensures sufficient film strength to handle the operating load and speed. Common values range from 32 cSt to 220 cSt at 40°C, depending on the application.

- Temperature Range: For the oil to operate effectively it needs a proper temperature range, therefore, the oil has to perform proper modifications. Synthetic Oils with a wider temperature tolerance are better suitable for high-temperature systems.

- Flow Rate: It is important to adjust the flow of oil because of the pump and circulation so that there can be proper distribution of lubrication. The size of the bearings and the speed of the device are taken into account with the thermal values so that overheating or excess oil application is avoided.

Understanding effective factors brings many benefits to oil lubrication systems such as enhanced thermal stability, increased bearing life, and minimizing the risk of failures which come in handy in extreme operating conditions.

Oil mist lubrication: benefits and applications

Oil mist lubrication is a highly efficient method for delivering precise quantities of lubricant to machine components, especially in high-speed and high-temperature environments. Its primary benefits include reduced oil consumption, consistent lubrication, and improved component cleanliness. By atomizing oil into a fine mist, this system ensures even distribution without excessive accumulation, which minimizes residue build-up and contamination risks.

Bearings in turbines, compressors, and electric motors are some common applications as they require high levels of film strength at elevated RPMs. These systems are also ideal while working in congested areas or places where manual lubrication is hard to reach as the mist can penetrate hard-to-reach areas.

- Size of droplets: Typically, oil mist systems generate particles in the range of 1-3 microns to ensure optimal dispersion while avoiding unnecessary loss or clogging.

- Rate of delivery: The usual range is between 0.1 to 2 g/hour for each lubrication point. Proper range is determined by the requirements of the client’s oil mis system.

- The pressure of the system: Most systems work at a range of 0.5 to 3 bar, which avoids turbulence and ensures consistent oil mist flow around the machine.

- Viscosity of oil: The oil must always fit the needs of the machine so in most cases it is between 32 to 68 cSt at approximately 40 degrees Celsius.

By carefully selecting and monitoring these technical requirements, I can ensure the system achieves maximum efficiency and reliability under varying operational conditions.

Frequently Asked Questions (FAQs)

Q: What are the main types of bearings used in pumps and motors?

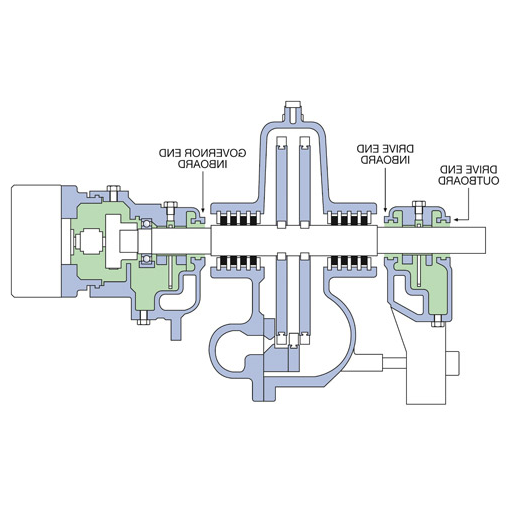

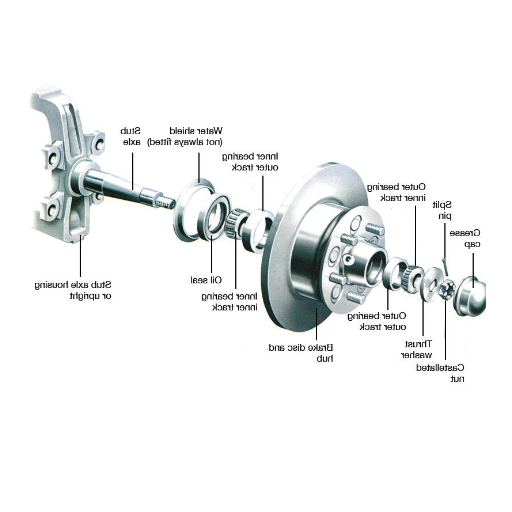

A: The main types of bearings used in pumps and motors are rolling element bearings and sleeve bearings. Rolling element bearings include ball bearings and roller bearings, which are commonly used in various HVAC applications. These bearings require proper lubrication to ensure optimal performance and longevity.

Q: How does proper lubrication affect pump bearing performance?

A: Proper lubrication is crucial for pump bearing performance. It reduces friction between the rolling elements and the bearing surface, dissipates heat from the bearing, and prevents wear. Without lubrication, bearings can overheat, leading to premature failure and reduced motor efficiency.

Q: What are the common methods of lubricating pump bearings?

A: Common methods of lubricating pump bearings include grease lubrication, oil splash lubrication, and oil mist lubrication. For grease lubrication, new grease is added periodically to purge old grease. Oil splash lubrication involves partially submerging the bearing in an oil bath. Oil mist lubrication uses an oil aerosol sprayed into the bearing housing.

Q: How often should pump bearings be greased?

A: The frequency of greasing pump bearings depends on various factors such as the bearing type, operating conditions, and manufacturer recommendations. Generally, bearings in continuous operation may need greasing every 2-6 months, while those in less demanding applications might only need annual greasing. Always consult the pump’s manual or the bearing manufacturer for specific guidelines.

Q: What type of grease should be used for pump bearings?

A: The type of grease to use depends on the specific application and bearing type. Generally, a high-quality lithium or lithium complex grease is suitable for most pump bearings. It’s crucial to use grease that’s compatible with the existing lubricant and meets the viscosity requirements specified by the bearing manufacturer.

Q: How can I tell if my pump bearings are properly lubricated?

A: Signs of properly lubricated bearings include smooth and quiet operation, normal operating temperature, and absence of vibration. You can also check the condition of the grease during maintenance. If the grease is dark, has a burnt smell, or contains metal particles, it may indicate improper lubrication or bearing wear.

Q: What are the consequences of improper bearing lubrication?

A: Improper lubrication can lead to increased friction, overheating, and premature bearing failure. This can result in reduced pump efficiency, increased energy consumption, and potentially catastrophic equipment failure. Regular maintenance and proper lubrication practices are essential for optimal performance and longevity of pump bearings.