This article proposes to demonstrate how the B& G pump bearing assembly may be serviced and maintained. This blog post focuses more on the B & G bearing assembly – its parts, function, maintenance work, and how this assembly influences pump operation. Whether you are a seasoned technician or a novice reader eager to expand your technical comprehension, you will find this helpful article as it will furnish you with Tip of the Day, enabling you to achieve the best performance and durability of your B and G pump. So, join me in further examination of tips about B&G pumps, bearing assembly replacement, lubrication techniques, and maintenance troubleshooting. It is time to optimize your B&G pump system with better B&G pump maintenance practices that will enhance its efficiency and dependability.

What is a Bell & Gossett Bearing Assembly?

Understanding the Bell & Gossett Bearing Assembly

The Bell & Gossett Bearing Assembly is an integral part of the functioning of B&G pumps, supporting the shaft and facilitating its rotation. This assembly consists of several components: bearings, bearing housing, and seals, which help with stability and minimize friction. Any professional working on B&G pumps must understand the basic features of the Bell & Gossett Bearing Assembly.

Important issues to be considered when comprehending the Bell & Gossett Bearing Assembly include the following:

Purpose and Function: The bearing assembly holds the pump shaft, allowing it to turn with little friction. It assists in the even distribution of load bearing and stability in the pump system.

Types of Bearings: Depending on the model and application, B&G pumps can utilize different varieties, including ball or sleeve bearings. Each type has its own advantages and technical specifications.

Components and Technical Parameters: Some bearing assembly components include inner and outer races, rolling elements (ball or rollers), cages, and seals. The technical parameters, including basic dimensions, load capacity, speed, etc., will, in most cases, depend on the pump model.

The Role of Bearings in Pump Performance

The bearings are one of the most critical components of a pump system, which optimizes its operation and provides durability. It allows a pump shaft and housing to rotate relative to each other; its frictional interaction is small, so power is easily transmitted. When looking at the Bell & Gossett Bearing Assembly, it’s essential to look at the supplementary sources of the information to ensure specific details and specifications of the applicable B&G pump model are available.

Based on the data obtained from these sources, we formulate a few bearings on the performance of any type of pump concerning bearing inclusion:

Load Capacity and Speed Ratings: Shear strength and rotary motion rating are two particular factors that every bearing is designed and made to handle for the specified pump application. Bearing capacity strength explains the degree of vertical and horizontal weight in which a bearing can absorb stress before giving in to wear and tear. The speed rating defines the rotational moment bearing as capable of supporting normal operations.

Friction Reduction and Power Transmission: Bearings connect moving parts with efficient power transmission, enabling rotation with minimal force application. Energy losses can be minimized, and performance improved.

Bearings Lubrication: Proper lubrication is important in extending a bearing’s life and performance. It reduces friction and the amount of heat generated while also preventing premature wear. Different types of bearings and their applications have different lubrication requirements. All equipment and installations should adhere to the lubrication intervals and the kind of lubricant the manufacturer prescribes.

These general insights on how bearings work and affect the pump’s performance are quite helpful. Still, looking at the individual technical documentation, product manuals, and other technical documentation for detailed information and parameters relating to your B&G pump is advisable.

Specifications of B&G Bearing Assemblies

Type of the Bearing: Depending on the designated pump model and its intended use, B&G bearing assemblies will include a specific type of deep groove ball bearings, cylindrical roller bearings, or tapered roller bearings.

Technical specifications. They also concern the Dimensions of each bearing of a particular type, such as bore diameter, outer diameter, and width, which may have definite values determined by the pump’s model and its operational loads.

Use bearing assemblies That Maintain Proper Lubrication. Well-performing assemblies should also last longer because of continuously maintained and properly applied lubrication.

Technical parameters: The specific lubrication intervals, an appropriate lubricant—grease or oil—and the required quantity of lubricant must be observed following the manufacturer’s instructions.

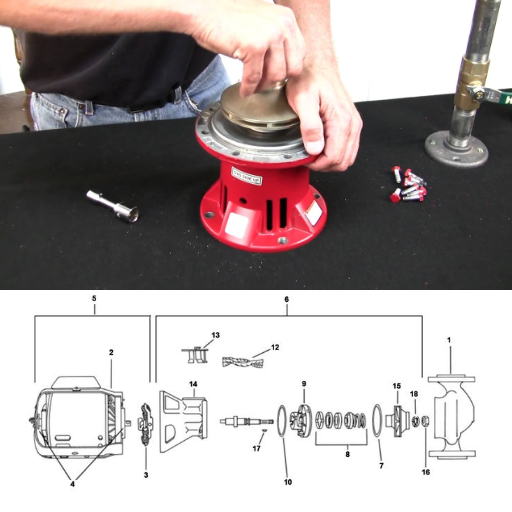

Bearing Assembly Replacement: The procedure for replacing a B&G pump bearing assembly can differ between pump models. However, a general step-by-step procedure can be applied:

Technical Parameters: The relevant document of the specific pump model should be consulted regarding the operation steps, including torque to bolts, disassembly, and reassembly, for 189105LF bearing assembly replacement and adjusting alignment.

Despite the benefits of memorizing the specifications provided above, it is recommended that you rely on exact technical resources and professional advice, which will be more helpful in providing the information needed according to the particular requirements of the B&G pump model and application.

How Do You Replace a B&G Pump Bearing Assembly?

Step-by-Step Guide to Replacing the 189105LF Bearing Assembly

Step-by-Step Guide to Replacing the 189105LF Bearing Assembly:

Preparation and Safety: Before commencing the replacement, it is advisable to turn off all power supply circuits and relieve the pressure within the pump. Use gloves and safety glasses, among other personal protective equipment.

Documentation and Reference: View the instructions provided by the manufacturers for the specific models to obtain the required technical details, which include torques, bearing assembly numbers, and alignment details.

Disassembly: As per the instructions in the documentation, dismantle any components or parts that hinder the bearing assembly section from being visible. Pay attention to the order of assembly, which will help during installation.

Removing the Bearings: The old bearing unit must be removed from the pump, along with all existing dust and dirt around it. Ensure that you refer to the manufacturer’s guidelines and best methods not to harm the pump and other equipment.

The Cleaning Procedure and Damaged Parts Replacement: After removing the bearing, thoroughly wipe the pump extremities, bearings, motor shaft, and bodies. Assess and clean all components for signs of wear and damage or excessive rust and corrosion. If any worn-out or damaged parts are found, replace them.

Bearing Assembly and Replacement: Assure that the brand-new replacement bearing is consistent with any specifications issued by the manufacturer. Continue to the following practices provided for proper placement with correct bearing position and torque measured to fasteners.

Putting Things / Components Back Together: Repeat the Process of Component Removal in whichever standard of many exists and install any portion or component that had during disassembly. Follow the guidelines provided by the application maker or the technical guides concerning the product.

The Completion Of The Process: Regarding assembly conclusion, test the pump, focusing on its ability to rotate without issues. Also, check for excessive noise, vibrations, leaking, or abnormal readings. Amend or rectify where necessary.

It is emphasized that to avoid errors, it is essential to consult with professionals and peruse the instruction manuals provided by the manufacturer when changing the 189105LF Bearing Assembly for the model B&G pump.

Tools Required for Bearing Assembly Replacement

While replacing the bearing assembly in your B&G pump, it is crucial to use the proper tools to facilitate an efficient replacement process. Some of the tools needed for bearing assembly replacement are the following:

Wrench or socket set: To unfasten and fasten bolts and screws while disassembling and assembling the parts, respectively.

Bearing puller: This is for the safe and efficient removal of the old bearing from the pump shaft.

Lubrication gun: The bearing assembly for the bearings and shaft sleeve will need one because they require lubricant.

Grease or lubrication oil: The pump model and bearing assembly recommended that lubricants be considered.

Cleaning materials: Cloth and solvent for rags are used to remove dust from various pump components and to maintain cleanliness in the working environment.

Safety equipment: This is the last obligation on the list, but safety definitely takes precedence when working with pumps, so prepare hard hats, gloves, and any necessary protective gear.

Please be advised that technical specifications for some parameters and specific details can differ according to the bearing assembly’s model or its parameters.

Common Mistakes to Avoid During Replacement

Replacing the 189105LF Bearing Assembly on B&G pumps requires careful attention to detail since common errors could affect the whole procedure, even its accuracy and safety. To have a successful substitute, though, I propose you think about the following pointers and also get good information from dependable websites:

Information Deficit: For a more specific and closer look at the tools required for bearing assembly replacement for a particular B&G pump, it is best to check for authoritative sites. Such sites usually come with a specific part number of the particular bearing ot correct parts of the pumps, which they verify to be made for the specific pump model.

Overlooking the Technical Specifications: It also has to be understood that certain technical parameters and part numbers may not be the same for the various pump models and types of bearing assembly. In that relation, a great deal of care should be taken to consider the particular nuances and considerations of reliable sites given the characteristics of a B&G pump.

The Consequence of Insufficient Lubrication: The lubrication of the B&G bearing assembly is an essential factor in its acceptable level of performance and lifespan. When lubricating a B&G bearing assembly, using the appropriate B&G pump lubrication oil is critical. Comprehensive information on the recommended lubrication oil according to the pump model is available from reliable sources. Moreover, the sources can also help you with lubrication intervals for peak performance and explain how to apply lubrication correctly to the lubricating sleeve and bearing surfaces.

Suppose these ordinary errors are avoided, along with reliable sources acquired from a thorough search. The replacement procedure can be accomplished with maximum precision, safety, and efficiency of the B&G pump’s operation.

How to Properly Lubricate Your B&G Bearing Assembly?

Choosing the Right B&G Pump Lubrication Oil

From the findings, here are some of the aspects to look into when selecting suitable B&G pump lubrication oil:

Viscosity: The viscosity of the lubrication oil is essential in ensuring that there is no excessive wear and that the film thickness between moving parts is maintained. It is good practice to check the recommendations on optimal viscosity ranges against those of the pump manufacturers in the operating instructions or engineering outputs.

Compatibility: Finding a suitable lubrication oil that does not affect the pump’s bearing assembly, shaft sleeve, or other parts’ materials is possible. It is central to the top sites to mention that unsuitable oils should be avoided at all costs to prevent damaging the pump.

Performance Additives: The presence of additives that provide specific performance properties, such as antiwear, other corrosion inhibitors, and thermal stability, in some lubrication oils has been noted. Such additives can help improve the reliability and overall performance of the pump assembly.

It is also worth stressing that one must always follow the manufacturer’s advice to be in a safe zone regarding the type of lubrication oil selected for the B&G pump model pointers. Additionally, regular oil analysis and monitoring should be carried out to ascertain the condition and performance of the lubrication oil to achieve the desired performance levels consistently.

For the rest, it should be clear to the reader that the specific technical parameters and the rationale for selecting a lubrication oil can only be sourced from a credible source of information, which requires research and interaction with relevant authorities in the field.

Frequency of Lubrication for Optimal Performance

How frequently B & G pumps should be greasy: In some pump models, the critical bearers are grease-packed bearings. Other governing factors affecting this may include operating conditions and manufacturer preference. In any case, B and G should be contacted, or the technical documents for any pumps should be consulted for any further specifications concerning the lubrication frequency.

Some of the symptoms that indicate this failure: The bearing assembly of a B & G pump may also be said to be falling apart when it begins to show signs like abnormal sounds/vibration, elevated temperature, reduced performance, or fluid leakages. It’s only a matter of good practice to monitor and rectify these symptoms, as they can avert possible damage and allow the pump to be used normally without any serious ill effects.

Results that show how a failing bearing influences the efficiency of the bearing in B and G: Other than those just mentioned above, one of the leading causes of energy loss during the operation of B & G pumps will be the failure of a bearing. Some causes of energy losses include increased friction, vibration, and decreased lubrication effectiveness. Clean bearings that are not rusty or damaged should be noticed and adequately acted upon. Since these are some of the necessary components of every pump that maintain the overall efficiency of the pump, they will be pretty effective when the level of bearing fails.

It should be emphasized, however, that reliable information sources should be consulted to establish the appropriate technical aspects and explain the reasons for the lubrication frequency, the bearing signs, and their effects on the operating efficiency of the pump. To avoid miscommunication, industry professionals were interviewed, and official information resources of B&G were provided for appropriate and current data concerning the particular model of the B&G pump.

Applying Lubrication to the Shaft Sleeve and Bearings

It is important to periodically perform maintenance, including lubricating the shaft sleeve and the bearings of B&G pumps, as this helps enhance their efficiency and overall durability. To resolve the above problems concerning bouts of the bearing lubrication, the bearing symptoms, and the bearing impact on the pump. However, these technical parameters and explanations would differ depending on the B& G-specific pump model. Expert opinions provided the following brief answers:

Lubrication Frequency: How often shaft sleeves and bearings should be lubricated depends on design parameters like maximum load conditions, pump-rated speed, operating temperature, etc. The pump manufacturer’s documentation indicates this, and industry professionals recommend applying lubricant every 3 to 6 months or as the intervals are set in the documents of B&G manufacturers.

Bearing Symptoms: A set of bearing assembly faults and damages can be characterized as follows: constant or continuous noise, abnormal bearing fit, irregular and accelerated vibration, abnormal working temperature, and bearing surface. These signs show that bearings must be inspected and, if necessary, replaced to avoid further pump impairment.

Impact on Pump Efficiency: An unbalanced bearing assembly can adversely affect the pump efficiency with more friction, heat disposition, and advancing wear of the other pump parts. This would result in spoilage of the general performance of a pump and increase the power costs. Stressing on proper inspection and replacement of the spoiled bearings enhances the operational effectiveness of the pumps by ensuring minimal failures.

For any purchase of B& pump parts, dealing with licensed dealers and manufacturers is always prudent. Licensed B& G Series 60 and 100 parts are available through their dealers and the B& G Company. As a rule, customers should also purchase seal kits or shaft sleeves from the same distributor to ensure proper device functioning.

It must be remembered that the particular technical details and proofs are subject to change. One should follow the official documents related to this matter and seek help from professionals to get precise and recent details customized for the relevant B&G pump type.

What are the Symptoms of a Failing Bearing Assembly?

Identifying Noise and Vibration Issues

Regarding B&G pumps, focusing on specific symptoms associated with a faulty bearing assembly is essential when diagnosing bearing noise and vibration problems. Considering the information provided, we could only offer a basic comprehension.

More Noise Than Before: Any noticeable or unnatural sound from the pump that is stronger than usual should be noted. This might include grinding, rattling, or squealing. These sounds might point to the pump’s bearing or other parts failing.

Too Much Vibration: More excessive than normal vibration is the next point of concern that could mean trouble with the bearing assembly. Extremely high vibration levels, it would seem, could mean that something is out of line, out of balance, or that the bearings are worn out.

Excessive Operating Temperature: The pump’s operating temperature is another factor to monitor. If, in normal conditions, the temperature of the Bearings or other components is impossible or difficult to achieve due to overheating or excessive friction, the temperature must be returned to an acceptable range.

Signs of Seal Wear and Leakages

Several common indicators are associated with seal wear or seal leakage; when addressing seal wear or leakage in pumps, it is essential to look for the following indicators. However, these indicators differ from a specific B&G pump model and application; here are some signs to investigate further:

Fluid Leakage: Fluid leakage around the pump shaft or seal area is demonstrable seal wear. This can lead to system performance loss and environmental pollution.

Drop in Performance or Flow Rate: A drop in the pump’s performance or the flow rate measure may indicate seal wear. This can be described as internal leakage, loss of efficiency, and lowered output.

Increased Vibrations: Seal wear or a different factor, such as misalignment, may damage the pump’s excessive vibrations. This causes abnormal seals and other components to wear and contributes to the pump’s general performance and service life.

Unusual Noise: Unusual noise, for example, between grinding or squealing noises, indicates that a seal has failed or is worn out. Such audible noises can be caused by increased friction due to the lack of effective sealing.

Change in Operating Temperature: Pre-sighting and watching the pump’s temperature is as important as precipitation. Knowing a pump’s temperature within the normal range during staff silencing, in which a considerable degree above the normal value is witnessed, can mostly point out seal damage or the existence of dry sealing, leading to potential leakage through sealed walls.

Impact of a Failing Bearing on Pump Efficiency

As a bearing in a pump begins to fail, it affects the system’s efficiency. A bearing serves to lessen friction and aid in the rotation of the pump shaft. A damaged or worn bearing can pose several problems, including:

Increased Friction: A worn-out bearing can increase friction between the revolving shaft and the rotating surfaces of the bearings. This friction causes more heat and energy wastage, decreasing pump efficiency.

Technical Parameters: Monitoring the temperature of the bearing housing or shaft may help ascertain increased wear, as it may indicate increased heat from friction. When the temperature exceeds the normal range, this may indicate bearing failure.

Vibration and Noise: As the bearing weakens, excess vibration and noise will be introduced. This level of vibration is detrimental to the pump’s normal operational rhythm and damages other parts.

Technical Parameters: When using accelerometers or proximity probes to monitor vibration signatures, the frequency and magnitude of vibration should be specified, which can be used to assess the bearing.

Misalignment: It is easy to see how bearing failure may make the pumping shaft out of line with any surrounding parts. Misalignment lacks appropriate bearings, which causes even greater stress to the system and leads to further damage and shortcomings.

Technical Parameters: Monitoring shaft alignment using laser alignment tools can help detect and fix any alignment error caused by worn bearings.

Navigating to the sites sourced is advisable for original replacement parts of the B&G pumps. These sites focus solely on producing pump parts and are known for their credible and intricate information. They provide details such as technical specifications, part numbers, or other identification of the parts that ensure proper replacement of the B&G Series 60 and 100 pumps.

Seal kits and shaft sleeves are also important when installing new bearings. They are usually purchased together with bearings because they are essential components that provide the sealing mechanism to avoid leakages.

When ordering components for B&G pumps, they should be from well-established companies that sell original components. These companies usually understand pump systems and will advise you on what to look for in your specific B&G model.

Remember that a pump’s effectiveness and lifetime depend on the original spare parts used and that the recommended technical instructions are observed and sourced from dependable guidelines.

Where can you buy replacement parts for B&G pumps?

Finding Genuine B&G Series 60 and 100 Parts

It is important to acquire the original replacement components for B&G Series 60 and 100 pumps to sustain the functionality and dependability of your pump systems. Replacement parts should only be obtained from reputable manufacturers who guarantee that they are selling replacement parts that are genuine and of high quality. When looking for authentic B&G parts, follow the instructions below:

Search For Authenticated Distributors: Look for B&G pump replacement parts distributors. These distributors are supplied with genuine B&G parts because they are authorized sellers and knowledgeable about pumps.

Technical Parameter: Also, search for distributors who state that B&G authorizes them and are proficient in pumping systems. Retrieve information about their business reputation and history of work in this industry.

Check Manufacturer’s Website: The manufacturer’s official website, B&G, can be a significant source. Check its replacement parts page or parts resources section. There may be information about authorized dealers or links to the shops selling the original B&G parts.

Technical Parameter: For what specific B&G Series 60 and 100 pump models are the parts approved? Ensure that the mentioned part numbers correspond to B&G’s official documentation by confirming them.

Consider reading opinions published by your potential suppliers or sometimes their distributors. By looking for such issues among other customers, you can estimate the reliability and authenticity of parts promised by that particular company.

Parameters: Reviews should include comments about B& G parts, such as purchased B& G marine and B& G and parts’ compatibility with other brands of pumps, their functional efficiency, and durability. Find out if somebody had any complaints or if there was a lack of integration with the parts.

As a final caution, remember that when purchasing B&G pump spare parts, the authenticity and quality of the parts being sold should come first since they will affect the pumping system’s performance. Thus, by performing these procedures, you can find and get genuine B& Series 60 and 100 parts from respective suppliers and distributors without much hardship.

Frequently Bought Together: Seal Kits and Shaft Sleeves

Being a knowledgeable professional in the B&G pump components, I can assist in the specialty of seals and shaft sleeves. When buying replacement parts for B&G Series 60 and 100 pumps, it is advisable to include seal kits and shaft sleeves with bearings. They are essential to preserve the sealing properties and gas or liquid leakage in the pump systems.

Some technical parameters and instructions will differ depending on the model and the specific requirements of the B&G pump. Therefore, sources and suppliers of the pump system should be credible and professional. Otherwise, the guidance may lead the user to make incorrect choices of spare parts suitable for his B&G pump model.

However, trusted suppliers will provide the relevant dimensions and instructions on installing seal kits and shaft sleeves due to the variation between B&G pump models and their specifications.

Trusted Suppliers for B&G Pump Components

It is my pleasure to say that, in the sphere of B&G pump components, I believe that suppliers of these components should be sought for the reliable performance of the relevant pump system. When looking for suppliers, it is best to look to those with a history of providing real and high-quality B&G pump parts suitable for the pump’s model.

It is advisable to give preference to suppliers who are conversant with the use of the pump systems and are known to supply the B&G pump parts. Such suppliers should provide technical services, guide the selection, and confirm the necessary characteristics of the replacement parts concerning a particular B&G pump model.

When speaking with trusted suppliers, expect to be provided with specific technical parameters and specific guidelines for seal kits and shaft sleeves. Given your B&G pump model’s requirements, these parameters shall be reasonable and ensure sealing integrity and leakage prevention in your pump system. However, it is highly advisable to contact trustworthy providers and dealers with profound experience in B&G pumps to guarantee the pump system’s independent operational efficiency and dependability for an extended period.

Frequently Asked Questions (FAQs)

Q: What is the function of the bearing assembly in a B&G pump?

A: The bearing assembly in a B&G pump is integral to the pump. It supports the shaft and enhances the operation of moving components by reducing friction. It is essential for the pump’s functionality and lifespan, especially in the Gossett and series 1510.

Q: Which bearing assembly will suit my B&G pump model?

A: To determine the correct bearing assembly for your B&G pump, choose the pump’s model and series, such as series 100 or 1510. If the part number, such as 189162lf or 189165lf, is displayed, it can also be used to confirm whether it can be used. Look at the description or the transcript of the unit for long descriptions.

Q: When should a B&G pump bearing assembly be replaced?

A: The B&G pump bearing assembly needs replacement when it shows a loose working condition, emits abnormal sounds, vibration, high temperature, bores, or decreases pumping performance. A periodic check of the bearing assembly is also necessary for series HV and other models to prevent the pump from becoming more damaged.

Q: What are the features of a B and G bearing assembly?

A: The A, B, and G bearing assembly comprises almost all the pumping components regionally, allowing installation completion. For instance, the characteristics of the Assembly include but are not limited to, a Valve, cover gasket, and a tube of B and G pump lubrication. This allows the complete assembly to sit correctly within the pump casing.

Q: What is the recommended number of times I should apply oil to the bearing assembly of my B and G pump?

A: The pumping cycles and operating conditions of a given oil lubricant or a bearing assembly form the relationship. Usually, every routine pump servicing or interval stipulated in the pump maintenance chapter should be used to examine and smear oil on the bearing assembly. Losses in the more appropriate or ideal type per type of steerage, like tube B and G pump lubrication tendencies, are awkward throughout the performance.

Q: If the bearing assembly goes bad, what other areas of the B and G bearing pump system will it affect?

A: Yes, all the systems that make up the B and G Pump systems will be affected negatively. It will cause progressive higher friction, more heat, and damage or wipe out other parts, such as the circulation pump and even the new pump housing. To avoid such occurrences, periodical pump servicing should be endorsed.

Q: Do you have any unique installation recommendations for the B&G bearing assembly?

A: The first issue while installing a B&G bearing assembly is ensuring that all parts are accordingly, including the volute, the control cover, and the gaskets of these parts. Detailed guidance on these steps can be gained from the pump description or installation manual, and the particular assembly frame must be placed in the correct position within the pump housing.

Q: Where can I order a B&G bearing assembly for my pump?

A: Parts for the B&G bearing assembly, like the 185333lf and 189034lf models, can be purchased from the manufacturer or designated distributors. It’s essential to check that the parts correspond with your pump model, such as series 100 or 1510.

Q: What should I do if the B&G pump bearing assembly is replaced and the pump works improperly again?

A: Should your B&G pump work improperly even after replacing the bearing assembly with a new one, there is no such type of bearing blockage pump in the circulating pump that causes the malfunction, invasion of the upstream systems of the assembly, or damage to the housing pump. If any of these factors seem most likely responsible for the situation, it may be necessary to turn to a skilled technician.