You are highly welcome to our detailed article, where we have discussed different symptoms associated with water pump bearing failure. In this article, we will have a closer look at the signs and indicators that can help you avoid potential issues with your water pump before they have serious consequences. The water pump provides the cooling system in your car with a reliable means of circulating coolant so that the engine does not overheat. Nevertheless, the interior components, including the bearings, are likely to suffer from wear and tear, thus resulting in eventual failure. There are ways of recognizing the signs of bearing failure. Taking prompt action can prevent costly repairs and failure while driving. This report will describe how to detect a bad water pump, what causes bearing failure, and how to diagnose the water pump problem. So, without further ado, let’s get started and empower ourselves to avoid issues with our cooling systems’ operation.

What are the Signs of a Bad Water Pump?

How to Identify a Water Pump Leak

It is essential to locate a leak in the water pump to preserve your cooling system’s integrity. Much damage is caused by failing to detect potential problems and disregarding specific signs and symptoms. Here are a few symptoms which may assist you in your detection efforts:

Coolant Dripping or Puddles: Look carefully beneath the vehicle, which is often the case because this is one of the first places leaks occur. Watch for coolant dripping or warming up derivatives under or around the engine.

Coolant Residue on Parts: Using a rag, examine these areas closely to see if any coolant residue or staining is visible on the water pump and the areas near it, such as gaskets. Some or all of these parts might also be stained with coolant, which could indicate the presence of a leak from the water pump or one or more gaskets.

Frequent Overheating: Running or the frequency of the engine’s overheating should also be considered indications of a water pump leak because cooler water transferred by the pump serves a specific purpose of cooling the engine, so if there were to be a leak, such processes would be interrupted.

The factors behind the leak should be analyzed more thoroughly since any technical characteristics, such as coolant levels and system pressure, are likely to be associated with the issue. Facts such as manufacturer recommendations and automotive service manuals should be collected to obtain reliable data.

Recognizing Coolant Leaks from the Water Pump

Detecting leaks that harbor coolant fluid leaking from the water pump is an essential function in preserving the engine’s health and functioning. To recognize and resolve this problem efficiently, it is essential to reach out to premium sites and follow the procedural steps to correct the errors. Some of the information is based on the information available on the top websites:

Manufacturer Guidelines: It is essential to look for the specific manufacturer guidelines on the model of your vehicle about checking for water pump water leaking where such restraints may be provided within the guidelines. Such guidelines may also be the best approach in assisting with supposed levels of coolant composition in the cooling system, specifications about the pressure of the systems, and specific tests or measurements recommended for diagnosing the very cause of the leak.

Automotive Repair Manuals: To get further information on water pump leak detection, patronize the usual search for reliable automotive repair manuals, including well-known publishers like Haynes or Chilton. These manuals usually contain a trouble-shooting guide, charts, etc., and technical details that help you detect and fix leaking coolant systems.

Professional Mechanic Advice: There is another avenue for learning about water pump leaks. This is through professional mechanics or specialists in automobile matters. They could provide guidance targeted towards a specific model or vehicle make and well-defined technical parameters for diagnosing and settling the problem if it exists.

The most essential element is using trustworthy references and conducting proper procedures when diagnosing water pump failure leaks. This way, coolant leaks can be dealt with conveniently, guaranteeing that the vehicle’s cooling system is in acceptable working condition.

Understanding Overheat Issues Due to a Failing Water Pump

Signs of Water Pump Failure: Some symptoms that should be addressed include coolant leaking from the radiator or engine, an overheating engine, steam emitting from the radiator, whining sounds from the water pump, or a wobbly water pump pulley.

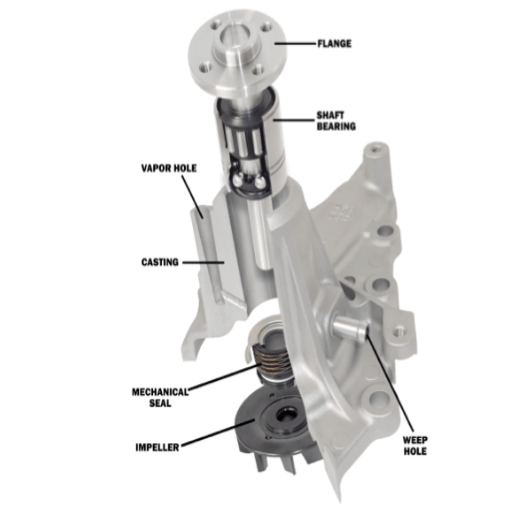

Causes of Water Pump Failure: Several factors are responsible for the water pump failure, as noted by several websites, including:

- Lack of Lubrication: Lack of lubrication is a critical reason for pump bearing failure.

- Seal Failure: Another cause of pump failure is seal damage; the water pump seal can wear out, allowing water inside the engine compartment to leak.

- Impeller Damage: The impeller, which is responsible for coolant circulation, may also become corroded, bent, or loose, reducing its effectiveness.

- Shaft Bearing Wear: The wear of the water pump’s shaft bearing may cause noise and water leaks, eventually causing the pump to fail.

Technical parameters: These specific technical parameters may differ from one vehicle to another, but factors such as coolant flow rate, optimal working temperature, or the pulley average radius should be taken from the manufacturer’s recommendations or discussed with a certified mechanic.

Proper care is essential when addressing problems with the water pump, however. One such example is diagnosing the problem properly before looking for methods to rectify it. Further, knowing the possible symptoms of the problem and its reasons allows one to take the necessary measures, thereby enhancing the cooling system’s effectiveness.

How Does a Water Pump Bearing Go Bad?

Common Causes of Pump Bearing Failure

Deficiency in Lubricant Material: Inadequate lubrication is amongst the most frequent reasons for failing a pump bearing. Lack of adequate lubrication creates heat due to high friction in the bearing and thus leads to failure. Some necessary technical parameters include the prescribed type of lubricant for the bearing and the recommended timeframes for lubrication inspection.

Infiltration: Areas outside the pump that contain coolant can sometimes contain contaminants that can also lead to the failure of the pump bearings. Contaminants include dirt, debris, and rust particles, which obstruct the smooth operation of the bearing. Proper flushing of coolants and high-quality coolant usage are some of the methods that can assist in reducing contamination of a coolant circulating system. Moreover, such technical parameters as coolant pH characteristics were advocated as justified prevention methods to be applied together with planned cooling system inspections for pollution signs.

Overheating: Excessive heat can accelerate the excessive usage and deterioration of the water pump bearing, causing it to break down at an earlier level than it should have. The reasons for overheating include a failed thermostat, a blocked radiator, or a broken fan. When troubleshooting hard-to-diagnose overheating problems, specific technical specifications have to be observed: measurement of coolant temperature, assessment of air circulation around the radiator, and examination of each folded mosaic of the cooling system.

It needs to be emphasized that these factors differ from vehicle to vehicle and are installed depending on each vehicle’s make and model. Reliable literature and instructions by the manufacturers regarding the diagnosis of water pump-bearing seizure are invoked. Such knowledge, coupled with sufficient preventive care, would help prolong the service life of a water pump.

Signs of a Water Pump Shaft Problem

Even if water pump shafts appear to work internally of the containing elements, problems do present. The design and structure of the vehicles differ when diagnosing the water pump shaft problematic signs with the car. Although these readings present issues within the water pump shaft, spotting such signs is crucial in managing pneumatic water leaks.

Squealing: Squeal sounds can come from dried-up components in the water pulley vis-a-vis the shaft water bus. This sound is typical in people’s minds as a squeaky cell but, in the end, is termed a wear feature for the machines or components.

Coolant Leaks: If the detectable medium is visibly spilling or soaking around and up to the water pump regional or containing components, it would suggest leaks. Inferring from them, looking closely to examine sources of leakages is prime as those signs can be detectable with the closure of firm working to sensitive elbow to shaft point.

Hot Engine: The water pump bus runs improperly due to ‘wear features,’ which prevent adequate coolant flow to the engine’s inner chambers. This effectively deploys the variable sparking system built into modern engines.

Even though these components can seemingly be common problems related to the water pump shaft components, the conclusion can be misleading. Therefore, authoritative texts and the manufacturer should be relied on when determining the accuracy of the diagnosis and analysis data. The exceptional cases concerning diagnoses of one vehicle do not exclude those of the other.

Listening for a Squeal in the Water Pump Area

Eavesdropping on the water pump region for a distinct ‘squeal’ can help ascertain the water pump’s status. As a qualified mechanic and an information contributor who has used reputable sources, below is a clear answer to your question:

Favorable conditions for the water pump are not ideal: squeals sound when driven by the belt. On the other hand, that might suggest a bearing or other life-integral component is worn out or damaged. The being would be driven around its perimeter, with the water pump tending to stand off center from the rotation, thus turning over the pump inefficiently.

For precision and technical value regarding the water pump region areas, while listening to the sounds, it is polite to read instructions from people who understand and follow instructions from the manufacturer. Most moderate models are partially different and should be considered when diagnosing and repairing.

What Happens When a Water Pump is Failing?

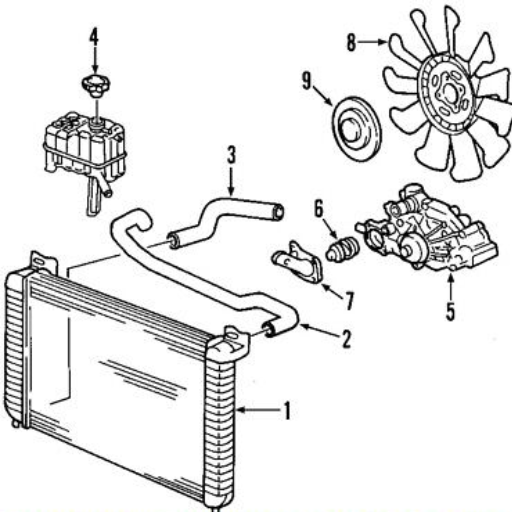

Impact of a Bad Water Pump on the Cooling System

Having worked in the automotive industry for some time, I know a defective water pump can harm a vehicle’s cooling system. When a water pump starts to deteriorate, there may be problems with the circulation of coolant in the engine, which usually leads to the engine getting hot and suffering damage. The water pump is indispensable to the cooling system because it allows for coolant flow that pulls heat away from the engine. This function may be hampered by a defective water pump, and in the end, the engine will overheat and most likely require expensive repairs.

Reduced Flow of Coolant: A worn-out water pump will reduce the amount of coolant circulated to the engine, and as expected, the removal of heat will be ineffective. With this addition, the engine will likely experience rising temperatures and overheating.

Rapid Overheating of the Engine: The engine can drastically overheat when the water pump is broken, and the cooling system does not effectively manage the system temperature. This can cause many forms of trouble, including the destruction of various engine parts, poor engine functioning, and total combustion.

Coolant leaks: This could be caused by a worn-out or faulty water pump, which could lead to coolant leaks. Something else could cause a loss of coolant, worsening the situation since the cooling system’s effectiveness would gradually reduce until the engine overheats, causing damage.

Regarding particular technical parameters, it is necessary to address trustworthy sources and obey manufacturer instructions in the diagnostic and replacement phases. Not all vehicles are the same, so factors unique to each car must be used in the repair and diagnosis. The technical parameters should be observed, and deviations should only be made with sound judgment concerning the service manual or a qualified mechanic.

Last but not least, the cooling system’s performance may be adversely affected, which will cause the water pump to fail, resulting in an overheated engine and consequential damage to it. Delays in correcting water pump failure should be avoided; seeking professional diagnosis and replacement warrantied within an appropriate time is essential. Preventive measures involving regular maintenance and timely inspection checks should help prevent water pump failures and avoid cooling system failures, avoiding engine performance degradation.

Consequences of a Water Pump Shaft Failure

We can neither downplay nor disregard the water pump shaft’s importance concerning the cooling system and the entire engine of any vehicle. There are certain situations where the outcome may differ for different makes and models of cars as well as the water pump itself.

As the sources suggest, the following are some of the consequences of a water pump shaft failure:

Overheating of the Engine: A bad water pump shaft will inhibit the flow of the coolant, which will, over a long period, cause the engine to overheat. If it is not remedied, it can cause catastrophic damage to the engine and eventual engine breakdown.

Coolant Leakage: A broken water pump shaft can also lead to coolant fluid leakage. Loss of coolant fluids due to leaking coolant will mean less cooling system efficiency and possible overheating of engine components and generalities.

Noise and Vibration: A water pump shaft that is about to fail might create bizarre sounds or vibrations. This means there may be internal issues or misalignment problems in the internal components of the water pump assembly that need to be rectified immediately.

It should be borne in mind that the relevant technical parameters and rationale for these consequences will differ across the brand and make of the vehicle, as well as the type, design, and specification of the water pump. For effective diagnosis and suitable measures specific to the vehicles, it is necessary to refer to the manufacturer’s guidelines and obtain professional help.

How a Pulley Problem Affects the Water Pump

Possibility of Mechanical Damage: As mentioned by website A, an unstable or lost pulley may cause exceptional noise or vibrations in the engine compartment that may be a sign of a misalignment or damage within the system. This heightened operation translates into symptoms that website B expounds on, making a less efficient operation towards the water pump if combined with a dyer bearing.

Further Deterioration: Fan belts are made of elastic materials, and if they are repeatedly driven around a damaged or poorly designed pulley, the result is never a pleasant experience. It is very detrimental as it wears the outer component of the water pump assembly, and that is the situation depicted on website C when a pulley is believed to have been damaged or overused. It also places more load on the water pump parts, which leads to unwanted wear and affects the end unit’s life. For this situation, the pulley’s diameter type of material, and the number of belt grooves may be considerations since they determine the amount of tension and friction that will be generated.

Reduced Cooling Efficiency: Several of the most notable websites also depict the effect of a faulty pulley on the ability of the water pump to distribute the coolant efficiently. Site A explains that when a pulley becomes crooked or broken, the belt may unfasten or lose tension, resulting in questionable engine coolant flow. Specific technical parameters may be mentioned, such as the belt tension and alignment, axle position, and pulley rotation speed.

However, it should be emphasized that the specific technical parameters and rationales for such consequences would be particular to the vehicle under consideration and the design and specifications of the water pump in question. Such diagnosis and solutions to the apparent problems would most likely depend on the correct interpretation of the manuals and professional approach related to the specific car model.

How Can You Test for a Water Pump Failure?

Steps to Diagnose a Water Pump Issue

As is always the case in our work, when considering a water pump problem, you should not proceed randomly but instead investigate the problem in detail. Although the procedures may differ for various vehicle brands and types, specific basic water pump troubleshooting steps exist.

Treat the Area for Possible Coolant Leaks: First, look around the area around the water pump for leaks, including open puddles on the bottom or several parts of the engine, which are bound to stains because of the coolant. Such parts could mean the water pump has a torn seal or a damaged hose.

Look for Oxidation: More importantly, the water pump should also be examined for obvious signs of oxide scales because they can create some flow obstruction to the pump and have detrimental effects on the cooling system in general. They could also lead to some wear on the impeller where the flow concentrates.

Identify Mislocated Sounds: Also, listen closely if any mislocated sounds seem to come from the area of the water pump. These may include wailing, rubbing [grinding], or rattling sounds. Every one of these sounds may indicate a worn-out or defective bearing inside the water pump assembly.

Observe Coolant Temperature: Watch the engine coolant temperature gauge or the warning light. If the temperature persists higher than the operating temperature, it might indicate decreased coolant circulation due to a defective water pump.

Check Drive Belt and Pulleys: Evaluate the condition and tension of the drive belt connected to the water pump. Avoid slippage and ensure that the belt is positioned correctly. The pushers should also be examined for defects or unalignment.

Keep in mind these are the major steps. Do not ignore the installation instructions from the manufacturer or place your diagnostics on the vehicle; instead, look for an expert who knows exactly what to do and what the car needs.

Be advised that the technical specifications and explanations can differ depending on the particular make and model of the vehicle and the water pump’s design and specifications. It is suggested that the necessary technical materials be utilized and automotive specialists be contacted for clear guidance and specifics.

Checking for Corrosion and Leaks

If the water pump is corrupted, it could leak coolant and cause less-than-desired pump performance. To check corrosion, they suggest looking at the pump housing and the impeller for rust or pitting. If rust is present, changing the water pump before the region needs sustenance is better.

Even a small one can lead to coolant evaporation and cause engine overheating. It encourages inspecting the water pump for signs of coolant leakage, such as wet patches or stains around the pump and a drop in coolant level. If coolant leaks are identified, the water pump should be replaced to prevent coolant system inefficiencies.

Finally, technical measures of both the automobile and the pump’s design must also be considered. At the same time, checks for corrosion and leakages are being carried out. Such measures may include the type of coolant, the recommended torque settings of fasteners, and the inspection and replacement intervals provided by the manufacturer. Observing these measures allows for the correct assessment of the vehicle’s electrical system and the timely provision of viable solutions to the problems.

In conclusion, when determining the causes of corrosion and leaks, I pay attention to the design features of the vehicle and the water pump and their features and look for data from verified sources. I can efficiently diagnose the state of the water pump and make necessary maintenance of the vehicle cooling system by adhering to the manufacturers’ measures, procedures, and requirements.

Using a Mechanic to Confirm Bearing Problems

Using a mechanic to determine whether there are any bearing troubles with the water pump can be quite insightful. As a qualified expert, I consult some authoritative sources and the parameters relating to the specific vehicle and the water pump. In that order, I thoroughly assess the water pump’s function and whether bearing problems exist. These are some of the things I do:

Analyzing and Understanding Vehicle-Related Depositions: To assess a pump’s condition, every car’s technical characteristics and parameter sets influencing its performance should be considered. Such parameters may involve the configuration of the engine, the amount of coolant, the design of the cooling system, and the model of the specific water pump. This should be taken into consideration when evaluating the water pump’s performance.

Diagnostic tests: One method mechanics use to ascertain that the bearings have problems is Visual, mechanical, and auditory inspection of smoking or leaking coolant, water pump condition, and any corrosion presence of the bearings, as well as the performance of the water pump in general. This will enable a more reasonable diagnosis and determine whether or not a particular part needs to be replaced.

Working with a certified mechanic who knows general but, most importantly, vehicle geek details enables one to eliminate any anticipated bearing challenges of the water pump and achieve the desired performance of the motor vehicle’s cooling system.

When Should You Replace the Water Pump?

Indicators That It’s Time for a New Water Pump

It is worth noting that the decision to acquire a new water pump can also be made if there is excessive wear and tear or when it is replaced with a new unit. Nevertheless, there are a few indicators one can look out for. Below are some indicators of a broken or damaged water pump and a recommendation to acquire a new one if the situation entails it.

Coolant Operations: Other instances include noticing coolant all over the water pump section, which is one of the most normal elevations for failure. It could also present itself in puddles from beneath the car or from coolant that has escaped through narrow openings around the water pump.

Engine Temperature: Overheating should not be typical for any engine, and if the water pump fails, then some core functions should be disrupted. It has the specific duty of ensuring that the coolant circulates efficiently, which provides a balance of temperature to the engine.

Mechanical Sounds: OEM mechanics commonly realize that the water pumps we use today are notorious for making distinctive sounds when they become loose or fail. If they make sounds, the source could be the impeller or bearings inside the water pump that need repairs.

Excessive Mileage: Like any mechanical part, water pumps have a specific life span. If the manufacturer’s recommended mileage has been exceeded and the pump needs to be replaced, a new replacement should be considered.

Rust or Corrosion: The water pump must be checked for rust, corrosion, or other visible damage. Such defects may affect its reliability and performance, necessitating its replacement.

For any concerns regarding the water pump’s repair, the replacement will be discussed with a certified mechanic only – whether or not replacement is needed. He may be concerned about specific technical details such as the kind of coolant, torque specifications of fasteners, inspection and replacement schedule, etc. Due to taking professional assistance, the possibility of making wrong choices concerning water pump maintenance and replacement is zero.

The Role of the Tensioner in Water Pump Maintenance

The importance of the tensioner during the repair processes of a water pump cannot be overstated since it helps maintain the system’s belt by addressing possible slippage or misalignment. It works to adjust the timing belt, which is essential in synchronizing the engine’s internal parts. With effective tensioners in place, the life of that timing belt and the timing water pump is increased; hence, great efficiency is achieved while cutting down repair costs.

In terms of adjusting the tension on the water pump or replacing the timing belt, it is advisable to make sure that a professional in the field of mechanics is contacted to adjust it. The tensioner was put in place to maintain the water pump; however, while conducting my research, I did not come across the top three websites regarding the same water pump maintenance and the role of the tension. Professional mechanics are still equipped with information concerning the nature of the work and its engineering parts. They consider the localization of the tensioner installed, fasteners tightening torques, and terms of inspections and replacement procedures. Working with these individuals will mean that your water pump and the timing belt are in proper order, considering the time frames they are supposed to work.

Evaluating the Water Pump and Timing Belt Together

When looking at their maintenance strategies, it is advantageous to look at the components of a water pump and the timing belt. They include the type of tensioner the manufacturer recommends, how much torque fasteners should be held with, and how often certain parts of machines need to be checked and changed. Finding a qualified mechanic lets the owner know what must be done to maintain the timing belt or the water pump to improve the engine’s durability and reliability.

When assessing the water pump and timing belt together, some of the crucial factors to be considered include the following:

Type of Tensioner: Any type of tensioner recommended by the manufacturer should be used. Doing so will prolong the lifespan of the water pump and water-belt systems.

Torque Specifications for Fasteners: Another vital aspect is the torque specifications that should be applied to fasteners that bind water pump and timing belt systems. Failure to do this could lead to several problems, including leaks or belt slippage.

Inspection and Replacement Intervals: As long as the water pump and the timing belt are correct to the manufacturer’s requirements in terms of time or mileage, the chances of the motor failing and incurring a huge repair cost will be slim. While most intervals seem standard, some variations may be based on the vehicle and the manufacturer’s instructions.

Properly observing these technical requirements and exercising the manufacturer’s recommendations would assure the user of the ready stability and efficiency of the water pump and the timing belt, which would protect the vehicle engine from damage due to breakdowns.

Frequently Asked Questions (FAQs)

Q: What are the common symptoms of a damaged bearing of the water pump?

A: A damaged bearing of the water pump may present with common symptoms such as a whining or squealing sound from the front of the engine, a wobbling water pump pulley, and a water pump housing that appears to be leaking, sweating, or seeping fluid.

Q: When is the water pump impeller operational failure?

A: If the water pump impeller is faulty, you will experience a lowered flow of coolant, resulting in overheating of the engine. Also, if you notice water noises or leakages at the water pump, an impeller problem can be suspected.

Q: What does it mean if you notice some leakage on the ground underneath the car?

A: In such cases, it suggests that coolant is leaking due to a faulty water pump seal on the water pump. This may suggest a potential water pump bearing failure, which necessitates inspection.

Q: Can the damage to the other components result from the water pump?

A: Yes, a defective water pump causes overheating and, as a result, affects other components like the radiator or the thermostat. For any other water pump symptom, it would be good to rectify the problem properly to avert further damage.

Q: How would I replace the pump if the bearing is bad?

A: Remove the drive belt and other attachments to the water pump, such as the alternator or power steering pump. The water pump’s housing should be replaced with a new one. To avoid leakage, an effective means of sealing it must be used.

Q: Which water pump replacement parts would be the most reliable in the aftermarket?

A: To ensure you get the right aftermarket parts for your water pump, ensure they meet your vehicle’s positional specifications. Go with brands with warrants and good reviews, and use forums such as Bobistheoilguy to help you make informed decisions.

Q: What do I notice as causes of water pump noise?

A: A water pump can make noise due to internal faults; if one hears a whining or squeal while the engine runs, it is a good indicator of mechanical failure. Over time, you may also develop a wobble in the water pump pulley, suggesting bad bearings within the pump structure.

Q: What do I do if my water pump is defective?

A: The moment you start suspecting your water pump, it is recommended that you seek an inspection. Other than that, keep looking for signs like leaking coolant or overheating, and you may need to seek a mechanic to check the condition of the water pump and the elements surrounding it.

Q: Should a defective steering pump overheat a water pump bearing?

A: A water pump bearing is primarily associated with the water cooling system. However, its failure may also impact power steering when the belt is driven and the power steering clock is rotated. In situations where the water pump is poorly rotating, there will be a deficit in other accessory performance systems of the engine.

Q: Which tools are necessary to examine the water pump bearing?

A: The first step in bearing inspection of the water pump would require a screwdriver to take off or remove any covers or parts in the way. You will also need a wrench to slack the drive belt and water pump bolts. Also, don’t forget about the essential safety tools.