From manufacturing and chemical processing to water treatment and power generation, high-performance pumps have become the backbone of innumerable industries all over the world. However, bearing housing is one element that is often neglected, although it is of great importance in the quest to achieve ultimate efficiency and reliability. Generally speaking, the bearing housing demonstrates an essential function in augmenting the energy efficiency of the entire pump system by mitigating mechanical abrasion, which then extends the life of the pump system. This article addresses how prudent maintenance design and materials bearing that are considered intelligently impact the performance of a pump. It makes specific conclusions on the importance of bearing housings for industrial purposes.

What Role Does Bearing Housing Play in Pump Performance?

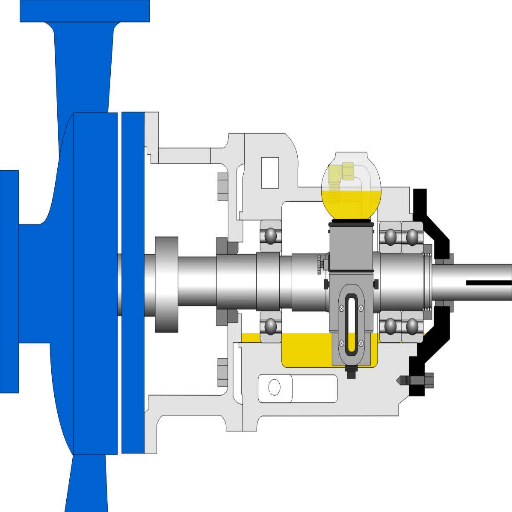

Understanding the Bearing Housing Structure

The bearing housing forms a vital part of the pieces used in a pump system as it accommodates the bearings to maintain their position and alignment relative to the rotating parts of the system. Together with the hydrodynamic journal bearings, it acts as a lubricant reservoir for the system. Several factors need to be fulfilled for the bearing housing to work optimally:

Selection of the Housing’s Material: Cast iron, steel, and top-of-the-range alloys are selected because of their strength, resistance to wear, and endurance of mechanical and thermal stress.

Design of the Structure: The housing must ensure that the shaft is positioned without allowing for elements that could lead to vibration, excessive wear, and mechanical failure. Features designed with more advanced mechanisms, such as fins, allow for better heat dissipation.

Systems of Lubrication: Components of the bearing housing are frequently designed with integrated means for grease or oil lubrication to reduce friction and heat build-up. Important parameters include oil viscosity and the operating temperature range for lubrication.

Omnidirectional Stiffness: The housing must resist both radial and axial forces from the bearings. Load capacity parameters are determined primarily by the size and type of bearings chosen based on anticipated operational conditions.

Sealing Mechanisms: Effective sealing, such as labyrinth seals or rubber lip seals, guarantees that contaminants such as dust, water, or chemicals do not enter the housing, thereby ensuring the retention of performance and operational life of the unit.

Incorporating these design aspects with meticulous technical requisites improves the functionality and effectiveness of the bearing housings in pumping systems under rigorous industrial conditions.

Impact of Bearing Housing on Pump Efficiency

Through minimizing energy consumption and enhancing the life cycle of internal components, the bearing housing is critical to the efficiency of the entire pump system. Reducing vibration and operational misalignment is crucial for achieving optimal pump performance height. Therefore, a well-crafted bearing housing is essential. For example, the housing is precision machined to tolerances typical within ±0.01 mm to ensure the shaft and bearings are properly aligned. This curing of misalignment, in turn, prevents energy from being wasted due to excessive friction or uneven loadings.

Sealing mechanisms inside the housing are just as crucial for efficiency. Effective seals, including labyrinth seals with a clearance of 0.3 to 0.5 mm, can efficiently reduce the inflow of foreign particles or fluids. This reduces part wear, maintains lubrication, and enhances drug prevention, improving the overall smoothness of the working parts.

Careful consideration needs to be given to thermal management. Special attention needs to be given in the form of the inclusion of external cooling fins, which alongside heat conductive materials can prevent the overheating of components directly and efficiently improve the thermal conductivity of steel profile around 205 W/m·K reduces the need of maintenance while simultaneously increasing component efficiency.

These technical considerations make the bearing housing one of the most essential pieces of pumps used in industrial and mechanical systems, ensuring both reliability and energy-efficient operation.

How Bearing Housing Prevents Bearing Failure

Various factors, such as high temperatures, low lubrication, or contamination, can lead to bearing failure. To mitigate such shortcomings, the bearing housing design and material properties must be optimized to address such issues.

Optimal Heat Dissipation: The efficiency of heat dissipating from the bearing’s components is paramount in its design. Therefore, the bearing housing is manufactured using materials with higher thermal conductivities, like aluminum alloys (~205 W/m·K) or cast iron (~55 W/m·K). These materials ensure maximum heat flow from the working surfaces, optimizing working temperatures while reducing thermal stress.

Practical Lubrication Systems: Bearing housings are designed to retain specific lubrication methods, whether grease—or oil-based. These ensure that moving parts do not suffer from considerable friction or excessive wear. Some housings incorporate lubrication seals and other retention systems that capture oils and greases to prevent leakage while ensuring continuous lubrication.

Seal Protection: Engineering-bearing housings with seals allow the construction to restrict dust, dirt, or moisture from entering units. Such measures sustain a clean environment within the bearing, thus prolonging its life and reducing maintenance.

Vibration Absorption: The rigid structure of the bearing housing resists mechanical loads while dispersing them evenly and collecting vibrations. This eliminates misalignment of the shafts and servomechanisms, which may produce excessive mechanical stress and reduce the bearing’s durability.

The functionality and efficiency of these features within the bearing housing allow for and significantly decrease the likelihood of bearing failures, guaranteeing dependable system performance over a vast industrial and mechanical range.

How to Choose the Right Bearing for Your Pump?

Types of Bearings Used in Pumps

To select the correct bearing for a specific pump, I assess its operational requirements, including load, speed, and other environmental factors. Below are the key classifications of bearings in pumps and their technical metrics:

Rolling Element Bearings

These are popular because they support a high load at high efficiency. They are suitable for use with pumps that have high rotational speeds. The essential criteria that I consider include the following:

Static and Dynamic Load Capacity (measured in N or kN): Guarantees that the bearing can sustain forces without undergoing deformation.

Speed Rating (rpm): A measure of the maximum recommended speed. Determines the ability of the bearing to function in high-speed operations.

Material Composition (e.g., steel, ceramic): This determines the bearing’s level of wear and tear.

Sleeve Bearings

These have wider scope of application in low-speed operations and provide excellent shock acceptance with stable performance. Some of the critical metrics are:

Operating Clearance (measured in micrometers): This figure should retain sufficient lubrication without wear and tear. Incorporating too much play is not desirable.

Friction Coefficient (dimensionless): The range of the friction coefficient is low, which is essential for practical functionality.

Lubrication Type (oil/grease): Affects the lifespan and maintenance intervals of the sleeve bearing.

Thrust Bearings

These types of bearings are designed for pumps with a high degree of axial loads to ensure no axial movement. My bearings of choice are constructed for:

Axial Load Rating(N): Essential for accommodating the thrust forces acting on the pumps.

Heat Tolerance(°C): For pumping stations that work under extreme temperatures.

Rotational Accuracy (categorical/precision grade): Ensures vertical load shedding stability.

Considering these technical parameters and the pump’s particular needs allows me to select a bearing that performs optimally and dependably in the specified conditions.

Factors Affecting Bearing Selection

While choosing the bearings, I consider a few key elements that guarantee performance and reliability. The first step is to evaluate the load capacity, which considers radial and axial loads (N). This is essential because the bearing must support the specific forces exerted by the pump’s operation while maintaining its structure. Heat tolerance (°C) is vital when the pump works under high-temperature conditions. I select lubricant and bearing material that will not fail at these extreme operational temperatures.

The next one is rotational accuracy, which is essential. Maximum load bearings with high precision grade ensure stability and smooth operations under heavy-duty and high-speed applications. An equally important component is the environment, such as moisture, dust, and other potential corrosive agents, which dictate the need for sealed anti-corrosion bearings. The last factor that I analyze is the operational lifespan of the bearing, which is used to ensure it is in line with the pump’s performance demands and scheduled maintenance intervals. These technical measures guarantee a comprehensive and logical bearing selection process for pump usage.

Importance of Lubricant in Bearing Performance

Lubrication’s role in bearing performance cannot be overlooked since it influences the system’s efficiency, durability, and reliability. To select a lubricant, I consider a few technical parameters to achieve optimal performance:

Viscosity at Operating Temperature – I check the lubricant’s viscosity to ensure that it corresponds to the operating temperature of the bearing to form a proper lubrication film and minimize friction. This guarantees smooth operation under changing thermal conditions.

Load-Carrying Capacity – The lubricant must bear the specific load characteristics of the application to minimize wear and prevent metal-to-metal contact.

Environmental Compatibility: I consider moisture, dust, and other corrosive elements and select appropriate lubricants to resist these challenges.

Contamination Control – Effective seals and re-lubrication methods must be used to retard the ingress of contamination, thus increasing bearing life.

Re-lubrication Interval – I ensure the lubricant aligns with the maintenance schedule, balancing performance and operational reliability for the prescribed lifespan.

Through comprehensive evaluation of these parameters, I ensure that the lubricant chosen meets the unique challenges presented by the bearing and its operating environment to maximize long-term performance and reduce failures.

Why is Maintenance and Repair Crucial for Bearing Housing?

Signs of Bearing Failure in Pumps

While analyzing the signs of bearing failure within pumps, the following indicators stand out to me. They are paired with specific technical parameters that correspond to aid in the diagnosis:

Unusual Noise – Abnormal sounds or increased vibration often indicate a misalignment, contamination, or insufficient lubrication. To verify this, I measure vibration levels and check if they fall within acceptable thresholds or conduct acoustic analysis.

Temperature Rise—Excessive friction or lubricant degradation always increases bearing temperature. I monitor this using temperature sensors and assess the readings against the acceptable operating range for the task.

Oil or Grease Leakage—If the oil or grease lubricant leaks, the seals are most likely worn out, which suggests contamination. I check the lubricant’s condition and viscosity to pinpoint the issues.

Reduced Performance or Efficiency—Bearing wear might hinder the pump’s efficient operation, reducing its performance. I analyze rotational speed and torque and check for excessive radial or axial loads to determine if the bearing’s capacity is being exceeded.

In evaluating these parameters as a system, failures can be identified without extensive damage, aiding in the diagnosis, repair, and maintenance schedules while avoiding further damage.

Best Practices for Bearing Housing Maintenance

To better manage bearing housings and deal with anticipated problems, I undertake the following actions:

Regular Inspection of Components

I undertake periodic checks to assess the bearing housing condition, seals, and bearings. This entails investigating whether there are any signs of fatigue, excessive wear, or deformation and ensuring that the intermixed spacing is within tolerable range. For example, I generally check alignment accuracy within ±0.05 mm to mitigate excessive loads on the bearings.

Lubrication Management

Friction and excessive heating are controlled by using proper lubrication. I practice using the recommended lubricants and further checking whether the oil’s viscosity correlates with the operating speed and temperature range. For instance, I check the oil’s viscosity and confirm it ranges between ISO VG 68 and 220 when determining load conditions and speed and adjusting as appropriate.

Monitoring Temperature and Vibration Levels

I perform configuration and measurement of bearing housing operating parameters through temperature equipment and vibration monitoring. For most conventional uses, operational temperatures should not exceed 90-100°C, and the vibration level is determined using rms velocity values and is not greater than 4.5 mm/s per ISO 10816 for general machinery.

Ensure All Seals are In Good Condition

Seals are significant barriers to contamination, and I routinely check them and other internal components. If there are signs of wear or gaps in the seal, I replace it to ensure optimal protection of internal components. Controlled environments free from dust and moisture ingress are made possible by tight sealing mechanisms.

Proper Load Management

Internal bearings are prone to excessive wear when loads are too high. I check to ensure that both axial and radial loads fall within the bearing’s specified rating. For example, C also determines the dynamic load ratings. Hence, I do not exceed these limits to maintain a reasonable service life with maximum stability.

If I follow these steps continuously and monitor any changes in technical parameters, I can guarantee the reliability and lifespan of the bearing housings. This enables the system to operate without excessive downtime while solving growing problems.

Repair Techniques for Damaged Bearing Housing

For destroyed bearing housings, my plan of action is systematic to conduct an efficient, precise repair. The first step in my approach is to examine the housing in detail and note damage such as surface wear, cracks, or deformation. In scenarios where the damage is not excessive, I utilize a combination of metal spraying techniques or resurfacing to restore the desired dimensional integrity. I would suspect more severe issues for deep cracks, which I would repair with welding or epoxy. Each method would strive to preserve the housing at its original strength and alignment.

Tolerance Levels: I To avoid operational imbalances, the repaired geometry must also comply with the bearing’s specified tolerances, e.g., (IT5, IT6).

Surface Roughness (Ra): The optimal surface finish is achieved and toleranced as usual for reducing friction and wear and is usually set to 0.4–0.8 µm Ra.

Material Integrity: During welding or resurfacing, I use verified properties to ensure that hardness and elasticity align with the original specifications.

Radial And Axial Load Ratings: The housing, afterward, should continue to support the desired dynamic load rating (C) and static load rating (C₀) without warping or any loss in performance post-repair.

Thermal Expansion Coefficients: For repairs that involve welding or heat, I ensure practical components maintain uniform thermal expansion to help avoid any future displacement alignments.

Meeting these conditions allows me to guarantee the reliable functioning and prolonged life cycle of the repaired bearing housing.

What Are the Challenges in Bearing Housing Design for Centrifugal Pumps?

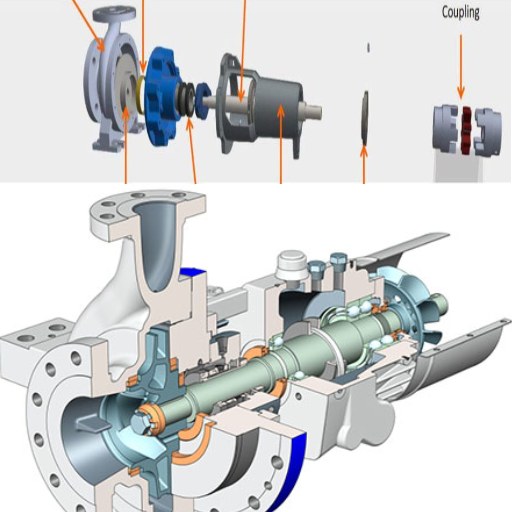

Design Considerations for Centrifugal Pump Bearing Housing

When creating a bearing housing for a centrifugal pump, the focus shifts to several criteria that must be harmonized so that the centrifugal pump will work effectively and its reliability will be assured. To properly align different components of a centrifugal pump, my first concern is dimensional precision for an efficient fit of screw shafts and bearings. Some of the tolerances required to correctly align all components within the assembly of the pump’s parts prima facie seem inconceivable. However, I achieved the tolerances needed to a level of 0.01 mm.

One of the most vital is choosing the right materials. Tough, durable, and non-corrosive materials are preferred. Cast iron and steel provide excellent deformation and corrosion resistance. Gray cast iron (ASTM A48) is primarily noted for its superb damping capabilities, while ductile iron is commonly accepted for greater tensile strength.

In addition, one must also consider the thermal aspects since any energy lost through heat is produced as a byproduct of operating the pump. I implement sufficient cooling means, such as oil lubrication with heat dissipation, to manage temperature. Depending on the pump’s operating conditions, I ensure its material compatibility with temperatures of 120°C or greater.

The housing has to endure a specific value of a dynamic load rating (C) and static load rating, so to speak, (C₀), which ensures a long service life versus different load configurations. The application’s specific requirements are calculated employing standard equations formulated by manufacturers of bearings utilized throughout the design.

I focus on easy access for bearing replacement or lubrication to accomplish proper maintenance. This diminishes downtime while improving the efficacy of a housing’s performance. To deal with these factors appropriately, I professionally guarantee compelling performances from the bearing housing, even under strenuous requirements.

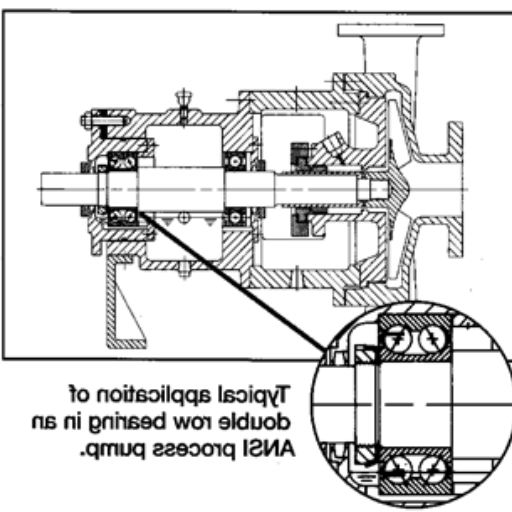

Managing Axial and Radial Loads

When managing axial and radial loads, I select bearings appropriate for the specific force conditions applicable to the application for maximum optimization. For example, in case of axial loads, I shift the expected force value considering the shaft’s longitudinal axis, then rest with a bearing selection that is adequate in terms of the required thrust load. When the application entails acute axial shifts, the bearing’s axial static load rating (C₀a) should be equal or higher to sustain the exerted forces for optimal stability and durability.

In the case of radial loads, the forces perpendicular to the shaft are evaluated, where my selection of bearings is limited to those that can withstand these stresses. This also encompasses the bearings with a dynamic load rating (C) if the work is of continuous or fluctuating radial movement. Additionally, during the load selection process, the bearings may be subjected to shock loads, where the safety factor is used to avoid catastrophe during unexpected scenarios.

In terms of the units that need added support to withstand the combined forces of axial and radial loads, I supplement them with angular contact ball bearings or tapered roller bearings, as they can resist both opposing directions of the load. I do not forget that my calculations require accuracy to be accurate, hence, I always seek supplementary bearing charts and tables provided by the manufacturer that pertain to real world operating conditions which ensures reliability and performance over an extended period.

Innovations in Bearing Housing Materials

In attempts to answer recent questions concerning innovations of bearing housing materials, one can note that his interest is toward achieving more excellent durability, lower maintenance, and better operating conditions. A very significant one is the incorporation of composites, which exhibit a good strength-to-weight ratio along with corrosion resistance. These materials, for instance, are very important in wet or chemically aggressive environments.

On examination of composites, one is primarily concerned with the following properties: tensile strength, fatigue, and thermal resistance. For example:

Some composite materials have tensile strengths that surpass classical cast steel, which can attain over 150 MPa in strength depending on the specific resin and reinforcement used.

Specific Corrosion Resistance helps achieve requisite design life for structural members in hostile environments, while control significantly reduces pitting and material degradation.

Meanwhile, values of thermal conductivity, which are lower than those of metals, are good enough to provide structural stability at operational heat loads, particularly when employing lubricants or heat-dissipating coatings.

At the same time, advanced alloys such as aluminum, bronze, or stainless steel have weight optimization at a given mechanical strength. Thus, relying on the manufacturer’s data on such materials provides an excellent justification for precise load capacity and environmental adaptability, guaranteeing performance and reliability in all applications.

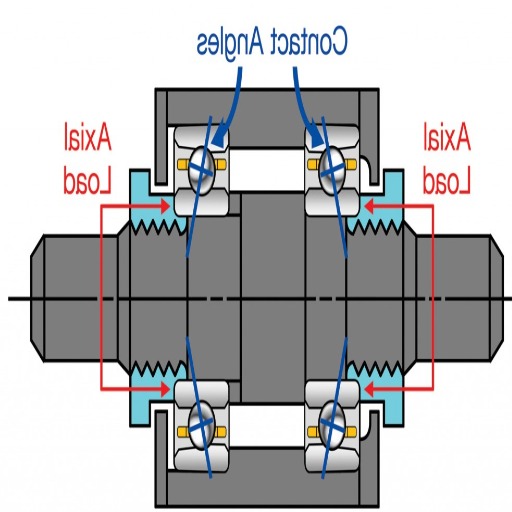

How Do Thrust Bearings Enhance Pump Reliability?

Role of Thrust Bearings in Pumps

Thrust bearings are crucial for the proper function of pumps since they take care of axial loads and motion. To me, thrust bearings primarily support several forces generated along the pump’s axial shaft. This prevents wear and tear on the moving parts of the pump. They also help ease friction while maintaining axial alignment stability, enhancing the eye pump’s reliability and life.

Regarding technical parameters, I note the following important points:

Axial load capacity: Suitable thrust bearings can take the axial load from hundreds to thousands of pounds (depending on the pump type and its operational conditions). The capacity must always be greater than the maximum axial force produced by the pump.

Temperature tolerance: Regular thrust bearings can sustain and perform well from -20 to 120 degrees Celsius. However, high-performance thrust bearings tend to function at higher ranges, which is crucial in a scenario with temperature pumps.

Material integrity: Chrome steel or ceramic is ordinary because they are rugged, durable, and resistant to abrasions, especially in high-load or high-speed applications.

Lubrication: Effective lubrication is vital to limiting wear and heat generated, improving efficiency and machine life. I also check the lubricant’s compatibility with the operating conditions (viscosity and heat flow).

Ensuring these parameters and the pump’s operational environment are correct will increase the pump’s reliability and prevent failures caused by incorrect load distribution and overstressed components.

Handling Axial Load with Thrust Bearings

In thrust bearings, the application of an axial load can be addressed in the following ways:

Understanding the Axial Load Requirements

Determining the magnitude and direction of the axial load enables me to select the most applicable thrust bearing type. For example, single-direction thrust ball bearings are appropriate for axial loads exerted in one direction, while double-direction bearings can handle axial loads exerted in both directions. If high axial forces are anticipated, tapered roller bearings or cylindrical thrust bearings are particularly suitable due to their increased contact area and greater load-bearing capacity.

Operating Speed Assessment

The operating speed significantly affects the bearing’s efficiency and life. In high-speed working conditions, ceramic and hybrid ball bearings, which have lower friction coefficients, perform best. In contrast, higher load-bearing designs will need to accommodate high speed.

Temperature and Material Resilience

I confirm that the bearing material withstands operating temperature conditions. Ceramic and high-tempered steel perform well at extreme temperatures, which is crucial for the power generation and oil and gas industries.

Lubrication Optimization

Lubrication is necessary to limit friction and collect heat, allowing the component to operate for long periods. I use lubricants with the correct viscosity index and heat transfer rate to suit the application.

With precise articulation of the above, thrust bearings will remain reliable while maintaining robust performance when handling axial loads.

Comparing Thrust Bearing Types for Optimal Pump Performance

The uniqueness of thrust bearing types must be appreciated when relating them to specific pump applications, their attributes, and their technical performance parameters. Standard thrust bearings are examined based on their parameters and illustrations set forth below:

Roller Thrust Bearings

Load Capacity: High, intended for application with higher axial load power.

Speed Limit: Moderate, inappropriate for high-speed rotation due to wear and tear.

Temperature Range: They work under normal temperature conditions, but maintaining sufficient lubrication is necessary to reduce heat.

Humidity: Heavy-duty apparatus such as pumps are typical tools that apply them, especially with constant axial force.

Ball Thrust Bearings

Load Capacity: Moderate, accommodating axial loads that are small and middle range.

Speed Limit: High, owing to their superior low friction design.

Temperature Range: Within limits, higher operating temperature is catered to with ceramic alternatives.

Humidity: Used in most small, high-speed, low-load pumps where smooth operation is dominant.

Magnetic Thrust Bearings

Load Capacity: High, depending on the design of the particular system.

Speed Limit: Very high; operation can be done without friction interference.

Temperature Range: Excellent, non-contact designs are efficient as less heat is produced during operations.

Humidity: Sharp-edged advanced systems like turbopumps or unique industrial systems that operate at high speeds demand high accuracy and low wear.

With a precise match of these parameters to the specified thrust bearing type, the pump system’s reliable and efficient long-term performance in different operating conditions can be achieved.

Frequently Asked Questions (FAQs)

Q: What is the role of bearing housing in pump performance?

A: The bearing housing supports the pump shaft while ensuring proper orientation, guaranteeing good pump operation. It also helps protect the bearings from misalignment damages that can affect the pump’s efficiency and longevity.

Q: How does shaft alignment impact bearing housing?

A: Proper shaft alignment is critical for the bearing housing since it cuts down the load on the bearings and stops them from wearing out too soon. Improper alignment will lead to high levels of vibration and heat, which will deteriorate the bearings.

Q: Why are angular contact bearings important in pump applications?

A: Because of their design, angular contact bearings are significant in centrifugal pumps as they can take radial and axial loads. They enhance the pump’s ability to maintain high pressure and increase performance.

Q: What types of bearings are commonly used in bearing housings for pumps?

A: Deep groove ball bearings, angular contact bearings, double-row bearings, and cylindrical roller bearings are common types used for pump bearing housings. As with every kind of bearing, each is chosen depending on operating conditions and loads that must be met.

Q: What is the role of seals in improving the performance of bearing housings in pumps?

A: Seals help preserve the lubricant within the housing and maintain its cleanliness. This helps retain the condition of the bearings, which can reduce the frequency of bearing failures and consequently enhance the pump’s service life.

Q: What gives poor pump performance caused by improper bearing housing design?

A: An improper bearing housing design can result in insufficient support of the pump shaft, which leads to its misalignment, excessive vibration, and noise. These factors greatly contribute to the premature wear or failure of bearings and, ultimately, the pump’s reliability and efficiency.

Q: What influence does the bearing housing bore have in bearing performance?

A: The bearing housing bore must accept the bearing outer ring with a known dimension so it will be properly fitted and aligned. If the bore is not correctly made, it may lead to poor load application, and if the rating life of the bearing is shortened, the bearing is bound to fail.

Q: What is the significance of a bearing protector in a pump system?

A: The protector ensures that the oil level is kept purposely low to prolong the functional life of the bearing and pump. In addition, it protects the bearing from external moisture and contaminants that can enter the housing.

Q: Why is the deep groove ball bearing often used in pump applications?

A: Deep groove ball bearings are used extensively because they endure axial and radial loads. Their high-performance speed capabilities make them ideal for various pump systems, including service and process pumps.

Q: How can pump manufacturers improve bearing housing design?

A: They can ensure the cross-sectional area contours of the bearing housing bore have the correct machine precision to bring the proper seals and materials to be adopted. Furthermore, performance degradation on the double-row angular contact or thrust bearing set can be avoided to improve the conditions under which the units operate.