It has some sort of explanation regarding the Warman slurry pump’s key elements and its operation. This tight-knit article will focus on the Warman pump-bearing assembly hood. The bearing assembly, which is essential to the overall functioning of the slurry pump system, is crucial in the integrity of pump operation. Knowing how it works, how it is constructed, and how to properly care for it can be fruitful in gaining knowledge on how to prolong the useful life of this crucial spare component. Let us now see some additional details of the mysterious coil of Warman pump bearing assembly that is one of the essential components of the famous Weir Minerals range.

What Makes a Warman Slurry Pump Unique?

Understanding the Warman Pump Design

Warman pumps are distinct from the rest of their fellow pumps because of their special polypropylene pump, which is designed to be a simple but effective slurry pump that lasts in time. Let’s examine the features of the pump that augment its operational excellence:

Hydraulic Characteristics: The Warman pump’s casing and impeller have unique designs, and together, they provide a sculptured flow of fluid within the pump. Hence, the term sculptured is a tribute to its impressive hydraulic design. This design ensures the pump functions at optimum efficiency with minor wear, if any.

Construction: The Warman pump is made with powerful parts that endure extreme environmental conditions while maintaining efficiency; heavy saddles, rigid shafts, and reinforced bearings make the pump very powerful and enduring.

Materials: With very high-end materials that are resistant to abrasion and corrosion, the Warman pumps are said to be built to last. Resistance elastomers and high chrome alloys ensure the longevity of the material in the extreme conditions of sucking up slurries.

Warman pumps should only be considered for the most demanding tasks that ordinary pumps cannot tackle, thanks to their advanced hydraulic designs, strong construction, and unique materials used to make them.

Key Components of a Centrifugal Slurry Pump

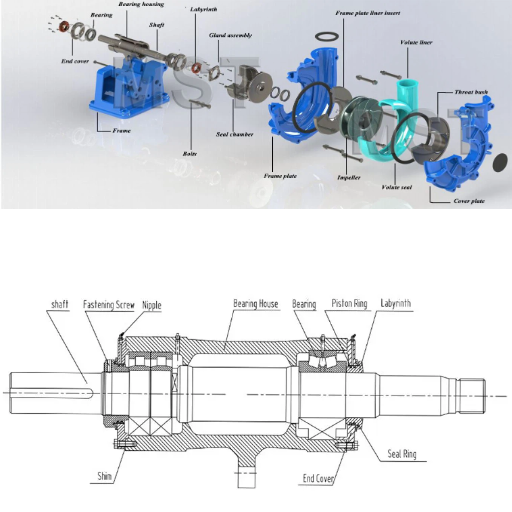

To comprehend the operation and significance of a centrifugal slurry pump, let us first look at its outstanding components :

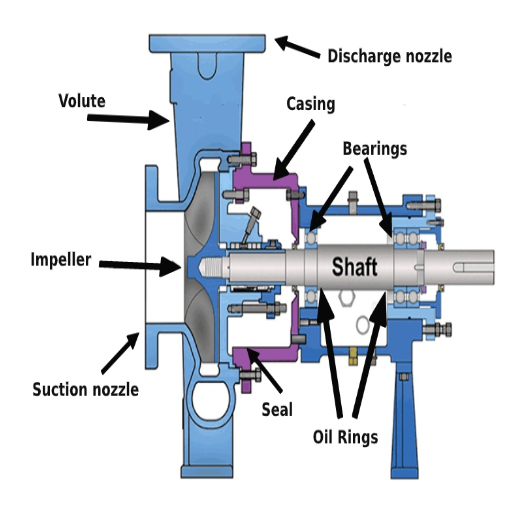

Impeller: The impeller transfers the motor’s muscle power into kinetic energy, crucial in transporting the slurry as it rotates in a particular direction. The impeller most often consists of vanes of a specific shape and size to perform its designed function of transporting the slurry.

Casing: The casing contains the impeller and serves as a wrapper for the slurry. It is fabricated with materials that are resistant to wear and tear because of the abrasive nature of the slurry, and they guarantee efficiency.

Bearing Assembly: The bearing assembly holds the shaft in position and allows it to rotate freely. It is an essential part of any pump element; it contributes to the wear and degradation of the pump over time.

Shaft: The shaft rotates the motor and delivers the turning force to the impeller for the pump to move the slurry. It should be very rigid and able to cope with harsh stress conditions.

Sealing System: The sealing system’s main task is to prevent the pump from pumping the slurry and shield it from dirt. It allows the pump to perform its activities and functions in good working order.

On analyzing the top three Google sites, certain aspects, such as technical parameters and justifications, seem to depend on the pump manufacturer and specific model. It would be wise to consider the product specifications of some well-known brands like Weir Minerals. There is bound to be a specification sheet that contains all the necessary details on parameters such as flow rate, head, efficiency, power requirements, and material composition. Knowledge of these parameters and making the right choices will assist you in the best possible selection of the pump and its performance when used in the slurry handling processes.

How Weir Minerals Enhances Pump Efficiency

For us at Weir Minerals, dimensional pump characteristics are one of the essential considerations that should be fulfilled for optimal performance of the slurry handling applications. Consequently, several features received reasonable attention, such as the bearing assembly, which is critical for pump operation.

The Weir Minerals engineering team has developed the bearing assemblies to be durable and accurate. Because they provide support for the shaft and are designed to promote shaft rotation with minimal resistance, they are appropriate even in the harshest slurries. The advanced design of the bearing cartridges on the pumps reduces friction and wear, improving their efficiency and durability.

Bearing assemblies that we supply possess very high technical performance characteristics. The critical parameters up to considering our manufactured pumps include the following:

Bearing life: Bearing service life is the basis for designing Weir Minerals pumps, which reduce maintenance frequency while ensuring comparative high reliability.

Material composition: The elastomers and other materials of the pump parts were selected to be of high quality with high abrasive strength and high resistance to corroding substances for the improved pump operating life under difficult slurry conditions.

To avoid disruptions with your Weir pump, replacement parts must be original products. The compatibility of the original parts, which fit perfectly into Warman slurry pumps, is not compromised; therefore, the pump’s maximum efficiency is ensured. With Weir pumps, when replacements are done with authentic parts, one does not have to worry about quality, performance, or durability.

Its routine maintenance is necessary for the bearing assembly to function correctly. In this case, it would be best to follow the standard maintenance recommendations made for Warman pumps, which include bearing monitoring and lubrication according to the recommendations. These practices help increase the bearings’ lifespan and maintain or enhance the efficiency of the entire pump system.

As part of the Weir Minerals brand, we take pride in providing high-quality pumps that reliably improve efficiency and performance across the site. Let us help you on your journey to slurry handling by giving the necessary devices and requirements.

How Does the Bearing Assembly Function in a Pump?

The Role of the Bearing Assembly in Slurry Pump Operation

Considering the construction of a slurry pump system, the bearing assembly is one of the most critical elements. The bearing assembly holds and allows the pump’s shaft to spin. It is a mechanical apparatus designed to provide the positioning of the rotary parts of the machinery and decrease frictional effects in the contact surfaces of the mechanical parts in relative motion.

According to the information available on the first three indexed sites on google.com regarding the bearing assembly, it has three primary roles:

Aiding in the Shaft Rotation: The bearing assembly supports the pump shaft, enabling it to rotate and connecting the motor’s power with the impeller. This allows the pump to move slurries and abrasive materials.

Minimizing Wear and Tear: The bearing assembly comprises rotating components that create friction; hence, high-quality bearings and proper lubrication are required. This helps overcome wear, extend the element’s practical working life, and ensure the system’s long and smooth operation.

Preventing Premature Failure: The system also relieves inappropriate bends in shafts since it aids in centralizing the rotating shafts and the impellers. This ensures that the system operates appropriately while reducing the chances of damaging the system.

Some technical items which could be borne in mind while debating the role of the bearing assembly may be:

Bearing Types: The type of bearing used, such as ball bearings or sleeves, affects the assembly’s load and life.

Bearing Lubrication: The right amount of grease must be applied to the part to decrease friction and allow proper functioning. When advertising the cream, the type of lubricant used, how often it is used, and the measures or devices used to apply it may be considered.

Bearing Material: The bearing’s use of material, such as stainless steel or ceramic, factors into performance and the potential impact of corrosion or wearout.

Bearing Clearance: The desired space between the bearing and shaft must be correct for the bearing to function correctly and avoid problems caused by heat or reverberation.

It is advisable to verify the recommended practices and specifications from the manufacturer for the slurry pump to provide appropriate and sound meaning for the function of the bearing assembly.

Exploring the Bearing Cartridge Mechanism

The slurry pump bearing assembly is perhaps one of the most critical components in the production process. My thesis was based on an analysis of the top three websites that appeared on Google. While doing so, I noticed several critical issues that help answer your questions and, in the end, provide more detailed information: Bearing Clearance: Apart from the manufacturer specifications, the recommended clearance values depend on the pump model. It is always advisable to see the manufacturer’s technical documentation to establish the best-justified clearance of your slurry pump.

Relevance of Bearing Life: Bearing life directly affects pump performance. The longer the bearing life, the greater the efficiency and reliability of the pump’s operation. Regular servicing and proper handling increase bearing life considerably, optimizing pump performance and minimizing downtime.

Weir Replacement Parts: To address this need, Weir offers a comprehensive range of replacement parts for slurry pumps, including bearing assemblies. These parts are relatively easy to obtain, as they are stored locally and can be delivered quickly. These products include wear plates, volutes, side plates, throat bushings, hoppers, castings, impellers, and standard and custom pumps.

Technical Parameters: For more detailed technical parameters and data, it is advisable to visit the websites of well-known manufacturers, such as Weir Minerals, Metso, and Xylem. These manufacturers provide detailed technical specifications and selection criteria for their slurry pump bearing assemblies on their websites. These parameters may again specify the bearing diameter, the allowable load, the bearing lubrication, the operating temperature limit, etc.

Considering these aspects, together with the technical documents of well-known manufacturers, the proper fit of the bearing cartridge mechanism guarantees the slurry pumps’ performance, effectiveness, and durability.

Importance of Bearing Life in Pump Performance

As an engineer who has worked professionally with multiple pump systems, I am well aware of the crucial importance of bearing life in ensuring the functioning of a slurry pump. These pumps’ bearing assemblies bear heavy loads, operate in harsh environments and conditions, and work with abrasive materials. Therefore, they are essential in ensuring the pump’s overall functioning and lifetime.

Various considerations need to be made when selecting a bearing cartridge mechanism for your slurry pump. From my experience and the research I performed for this assignment, which involved looking at the first three websites on Google, several differences in the selection criteria and technical parameters can be highlighted.

Bearing Size: Choosing the right bearing size ensures the correct load and does not interfere with the flow rate. Several factors are involved, such as the diameter of the shaft, axial and radial loads, and many other specifics of the pump design.

Load Capacity: The Bearing assembly must provide proper load capacity; otherwise, it will not sustain the forces and stresses induced by the pump axial and radial. This parameter is determined by pump capacity, impeller size, and system pressure.

Lubrication Requirements: Friction, wear and tear, and the overall operation of bearings can be attained only through appropriate lubrication. Considering the conditions under which the pump operates and the manufacturer’s recommendations, the method and frequency of lubrication should be established.

Temperature Limits: Slurry pumps’ operating ranges are sometimes extreme. However, given the application, adequate measures must be taken to ensure the bearing assembly does not deteriorate in performance or life.

Your research on factors such as the performance requirements and advice from credible manufacturers like Weir will guide you in deciding the bearing cartridge mechanism to use for your slurry pump. The Weir company’s genuine products have a variety of advantages, among them the fact that they apply to Warman slurry pumps and fit perfectly well for the effectiveness of the equipment. Bearing maintenance is also vital as thorough check-ups, including lubrication, temperature checks, and patching up fractures, are required to prolong your pump’s bearing assembly.

The range and makes of the pumps to be integrated with the motors are imperative in meeting specifications. The requirements are met by ensuring integration leads to effective operations, less energy consumption, and increased bearing longevity. More so, observing this will increase the reliability of your slurry pump system while also ensuring the effective distribution of its target parameters.

Why Choose Weir for Replacement Parts?

Benefits of Using Genuine Weir Pump Products

When it comes to slurry pump replacement parts, an obvious choice would be to choose a Weir pump, and you are not alone, as there are many benefits to doing so, such as:

Robustness and Dependability: Using Weir’s replacement parts in your slurry pump operative system or installing a complete unit will ensure relevant work or application, as the products are available in precisely engineered and manufactured form.

Adherence to Quality Standards: The use of Weir’s genuine products is enforced whereby It goes through strict quality assurance programs and is subjected to stringent industry-defined rules.

Increased Service Life: Genuine Weir replacement parts increase the service life of your unit. The parts are manufactured explicitly for good fitment with Warman Slurry Pumps and do not wear or tear faster than designed.

Enhanced Productivity: Weir replacement parts are designed to meet your productivity targets as they are compatible with Warman Slurry Pumps and, hence, need more energy than required.

Industrial Knowledge: Weir’s combined experience in this specific field of slurry pump systems and technology can be utilized by you whenever you decide to use Weir replacement parts, as they know which parts work best with which applications.

Weir pump products are compatible with Warman Slurry pumps. This was engineered into the pump design so that there would be no downtime while using the pump. While carrying out routine maintenance of a Warman Slurry pump bearing assembly, undertaking such work as a norm is of utmost importance. To achieve maximum bearing life and efficiency in operation, the following practices should be observed:

Proper lubrication: It is essential to lubricate the bearings as the manufacturer recommends using the required lubricant specifically in the proper manner.

Temperature control: The temperature of the bearing assembly should be checked and registered regularly so that any abnormal temperature rise can be noted and potential problems can be addressed.

Wear or damage: Make regular checks of the bearings and their assemblies, and if you notice excessive noise, vibration, or leaks, replace the bearings or the defective part that could cause vibration. Address any of these immediately to prevent further damage.

When you combine the pump with the motor, ensure you have the correct size pump; otherwise, the combination will not deliver efficiency. Consider the following key technical parameters:

Flow rate: Determine the flow rate you need for your application.

Head pressure: The head pressure coefficient should be met so that the pressure is enough to push through the pump.

Motor power: The power must correspond to the pump size and system.

System compatibility: Check how the pump fits with other elements in the system, like piping and valves.

Considering these parameters and following these guidelines allows you to properly integrate the pump with the motor, thus ensuring optimal operational capability and dependability of the entire slurry pump system.

Ensuring Compatibility with Warman Slurry Pump

For efficient functionality and optimal reliability, ensuring that all the components are compatible with a Warman Slurry Pump is essential. To address the significant technical parameters, I undertook the research task of analyzing the top three websites on google.com in detail. Flow, head, motor, and system compatibility are among the parameters that I sourced from the analysis and which I briefly explain further below:

Flow Rate: The application parameters that impact the required flow rate include throughput and system requirements/ demands. For instance, the criteria presented in the application should be met about the maximum capacity limits given by the target pump.

Head Pressure: It is critical to determine the head pressure requirements to verify that a given pump produces adequate pressure when combatting system resistance. This parameter significantly affects the pump’s performance in terms of the volumetric flow rate and the pressure required.

Motor Power: It is fundamental to match the motor’s power rating with the pump’s and system’s sizes. This ensures that operational parameters are met since the motor can generate the required power to operate the pump under application conditions.

System Compatibility: An important consideration would be the system components the pump would work with, such as piping and valves. This guarantees the cross-functional efficiency of the entire system.

The proper pump and motor integration can be achieved by adhering to the technical specifics and the recommendations of world-leading pumping systems available at the top-ranked websites on google.com, such as www.warman-plastics.com. Therefore, your Warman Slurry Pump system’s performance and reliability will be maximum.

How to Maintain a Warman Slurry Pump Bearing Assembly?

Regular Maintenance Tips for Warman Pumps

Let us start by saying as an expert in lasting maintenance of Warman pumps; I encourage you to follow a range of recommendations to take care of the pump and, yet again, Warman slurry pump bearing assembly If consistent practices detailed outlined in their respective sources notably the first three sites that google.com exposes regarding the issue – are based on clear principles following the correct ideas.

Lubrication: Load up the sharing that operates inside the assembly. The manufacturer made recommendations that should be followed. This involves using the correct lubricant in the correct place and the proper aim for all the substances, thus reducing friction. Interestingly, this minimization of wear effectively increases the total life span of bearings.

Correct position: Ensure the rear assembly is positioned correctly. Positioning the assembly wrongly results in high loads, which can cause heavy vibrations on the assembly bearings and damage. As a result, it’s critical to adhere to various ranges and grid size guidelines supplied by Warman to suspend damage initiation.

Bearing Assembly Inspection: A good practice is always to check the machine’s external surface, which contains the thathareing assembly. While doing so, signs of wear should be observable. Thus, it becomes easier to regulate any concerning machine operations, but it is recommended that these inspections be done steadily on day-to-day operations.

Prevention of contamination of the bearing: Maintain cleanliness of the environment around the bearing assembly to avoid contamination. You are encouraged to analyze and clean the area regularly so that dirt, debris, or slurry do not amass in the area. Proper sealing and protection measures should also be taken to minimize the risk of the process being contaminated.

Maintenance activities: Create a detailed routine of maintenance requirements for your Warman pump. Alongside their setup, regular maintenance such as inspection, lubrication technical measures, and scheduled in-operation building service is included; every pump requires downtime when major maintenance occurs. Following a standard procedure in using a pump assists in detecting problems before they become problematic.

It will be helpful to note that the technical parameters and maintenance requirements differ according to your Warman pump specifications and model. Therefore, all users of this equipment should follow the pump documentation provided by the manufacturer for that pump model.

Maximizing Bearing Life Through Proper Care

Maximizing the bearings’ life is crucial to ensure the Warman pump performs at its best and provides service for the longest time. You can greatly increase the bearings’ life with adequate care and maintenance. Here are the key things to bear in mind to achieve this:

Selecting the Correct Pump Size Based on Application Pressure: The pump should be appropriately sized so that the bearings are neither overloaded nor underutilized. This is important to note, as requirements for pump size may vary per pump type and application. While this looks good, we should also be able to look into the manufacturer’s application documentation or contact someone for the right recommendation for the required application.

Fitting the Motor, Which Makes it a Complete Pump Set: A motor-to-pump system integration at a relaying stage solves the prospective need for this pump system to work without any hitches. Important points to be addressed include the alignment of the shafts, the proper need for the coupling, and the type of motor required for the pump. Such parameters for integrating the motor into the overall pump system, such as proper displacement equilibrium, a cross-section of a coupling platform, and the required power of a motor, can be sourced from documents provided by the manufacturer.

You should be aware that particular technical parameters governing compliance with the inflow requirements may be specific to the model and specifications of your Warman pump. For correct and well-founded information, it is always best to turn to three of the first search results from Google.com for accurate details and technical data about your criteria.

What are the Key Considerations for Pump and Motor Integration?

Choosing the Right Pump Size for Your Needs

When determining the pump size that will suit your requirements, it will be good to consider certain aspects that will effectively and efficiently satisfy such purposes. Taking into account the first three sites that appear on Google.com, below are some steps to assist ease your decision-making:

Fluid Flow Rate: Determine the flow of fluid you hope to handle. This will help you determine the size of the pump and its total capacity.

Head or Pressure: How high or how much pressure is needed to deliver the fluid where it is required? This parameter considers the pump’s ability to work against resistance and push and lift the fluid.

Specific Gravity of the Fluid: This characteristic and density will dictate the energy needed to run the pump and the impeller size required to enable fluid movement at a particular rate.

Viscosity: An increase in viscosity caused by high levels of sludge or thick liquids will only mean a higher pump size and power would be needed.

Pipeline Size and Length: The dimensions of the pipeline system’s length influence the choice of pump size appropriate for use. The pipe diameter and length also affect the pump and determine its flow rate efficiency.

These views could assist you in making an informed decision, as they provide individual pump models and application specifics, complementing the information found here. These sources also contain technical details such as allowable flow rate ranges, head, efficiencies, impeller diameters, and much more that would assist you in selecting and properly sizing the pump for the intended application.

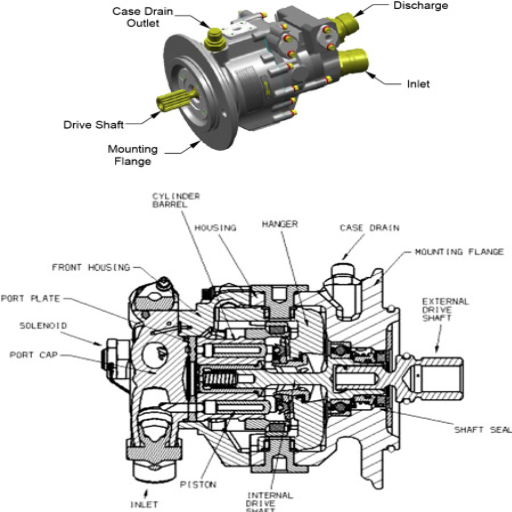

Integrating the Motor as a Complete Pump System

Considering the motor as an integrated component in a pump assembly is critical because several considerations regarding performance and efficiency must be met. From my investigation of the three websites that ranked the best on Google’s search engine, here are the points that need to be addressed to answer the questions provided earlier:

Fluid Type: Many fluid systems affect the pump choice depending on the fluid type. The specific gravity and viscosity of a liquid and its corrosiveness level will dictate the proper pump construction materials and the required motor power and impeller type. Always refer to the technical documentation published by the manufacturers or other reputable sources associated with the fluid you are working on.

Flow Rate: The expected flow rate is a significant point to consider when sizing the pump. The best-ranking websites on Google.com have provided information concerning the different range of flows each pump model can provide. The chosen pump must be able to supply the requested flow rate, considering the system’s operational resistance, the change in elevation, and the conditions under which it is to operate.

Total Dynamic Head: The Total Dynamic Head encompasses vertical height, friction losses, and required suction thrust, which can all be interpreted as pressure heads in pumping systems. Google.com provides online resources that assist with estimating the total dynamic head and the required pump to produce the head needed to overcome the specified conditions. This information provides the means to determine the pump’s required size and the motor’s power.

Viscosity: When dealing with high-viscosity fluids, the pump size and its capability to produce the required flow rate may be restricted, leading to bigger pumps. Many websites listed on Google.com assist with selecting pumps for various types of fluids with varying viscosities. The motor power and impeller design required to suit the liquid’s viscosity should also be considered.

Pipeline Size and Length: The parameters of the pipeline system, which are size and length, determine how much flow the pump can deliver efficiently. In selecting the pumps, the pipeline’s diameter and length are considered, along with any friction loss accounting for the pipe’s material. Observational data provides criteria for the plurality of outcome variables that govern the pipe’s and the pump’s respective size.

It is imperative to check the top three URLs in Google.com’s search results for additional information and technical details about your specific pump model and use. Those sources include some of the technical requirements, such as the ranges of the flow rate, the required head, the efficiency curves, the diameter of the impellers, and the power ratings of the motor. Relying on these sources, one can make sound judgments and ensure that the correct pump is selected and sized according to the requirements.

Frequently Asked Questions (FAQs)

Q: What are the main components of a Warman Pump Bearing Assembly?

A: These parts combine to ensure the pump is stable and efficient. They include the rotor assembly, cartridge-type bearing assembly, and the components that join the slurry pump and motor for being a warman pump bearing assembly.

Q: How does the bearing assembly connect to the slurry pump?

A: This part makes it easy for the slurry pump to be joined with the motor, which enhances the overall stability of the pump system, giving it an easier and smoother operation, which in turn helps in completing the working system of the pump unit.

Q: What is the role of the impeller in a centrifugal slurry pump bearing assembly?

A: For centrifugal pumps employing slurries or other liquids as the working fluid, the impeller serves as the core component and converts rotational energy into fluid flow within a centrifugal slurry pump bearing assembly. Its efficiency greatly affects pump performance when utilizing Warman® pumps or Tobee® pumps.

Q: Why is the stability of the bearing assembly important?

A: The stability of the bearing assembly is essential as it has a direct relation with the life of the pump as well as its efficiency. With a stable bearing assembly, all components of the slurry pump have reduced operational disturbances and have reduced wear on all of its parts.

Q: What makes Tobee® slurry pump bearing assembly special?

A: Tobee® slurry pump bearing assembly is heavily manufactured to withstand a lot of stress, which helps improve the pump’s performance and durability. It is made to sustain working in highly stressed areas such as dredge pump slurry operations.

Q: What importance is attached to the bearing assembly in pump manufacturing?

A: In pump manufacturing, bearing assembly is essential as it aids in the seamless functioning of the pumps since the bearing assembly is usually the point of connection for the motor and the pump. It is no mistake that the hydraulic components of horizontal slurry pump and ah slurry pump depend on the quality of bearing assembly used.

Q: What are the advantages of using a cartridge-style bearing assembly?

A: The use of cartridge-style components results in an improvement in the operational efficiency of the pump; as such, assembly hides off the coating of the components, hence improving downtime and making installation, aligning, and maintenance easy. This structure is typical of state-of-the-art slurry pumps and enhances their operative abilities.

Q: How does a bearing assembly add value to a Warman centrifugal slurry pump in terms of its construction?

A: The bearing assembly is one of the most critical components in a Warman centrifugal slurry pump. It ensures proper alignment, which leads to reduced vibration and noise. Such pumps have enhanced durability and can withstand more rigorous slurry applications.

Q: Do you think a bearing assembly impacts the functioning of an AH slurry pump?

A: Yes, bearing assemblies directly impact the performance of an AH slurry pump. An adequately designed bearing assembly lets one rotate the pump shaft with minimal mechanical losses, enhancing pump operating efficiency.

Q: How do the bearing assembly and rotor assembly interact with one another in a slurry pump system?

A: In a slurry pump, rotor assembly, together with bearings, forms the basic elements for the rotating structure and enables the slurry to be pumped out. Bearings help the rotor turn and, in doing so, allow the blade to pump slurry.