Reliable pump performance is critical across different working sectors, while bearing life is the primary attribute that keeps the operation running correctly. Let us start by explaining that bearings are one of the main components of any rotating outfit; as such, they affect the operational parameters such as efficiency and even the life span of the rotating item. However, the epistle emphasizes some of the significant factors which, if I may say, are most often ignored. This discussion articulates the two most essential factors in determining bearing life and, therefore, has prepared some appropriate recommendations for improving pump reliability and serviceability. Be it a maintainer or an operational manager, knowing these components will help effectively use machinery and eliminate snag-free processes.

What are the primary factors influencing pump-bearing life?

How do operating conditions affect bearing life?

Bearing units in pumps have a specific lifetime determined by various operating conditions. The factors influencing bearing performance and endurance include load, speed, lubrication, and temperature. However, although the maximum load rating on the bearing should not be exceeded, radial or axial loads, which are direct causes of bearing fatigue, should not be excessive as they may overstrain the bearing and lead to premature bearing wear and tear on one hand or high speeds usage, on the other hand, may cause overheating and wear and tear of the bearing in question.

Extraction of the bearing from the enclosure removes the ideal bearing life, which ranges between 4 degrees centigrade and 60 degrees centigrade, with a provision that generally does not exceed 40 degrees Fahrenheit and 140 degrees Fahrenheit. If the operant temperature exceeds the lubricating temperature, bearing life will weaken, leading to the lubricant falling apart and friction rising. Adequate protection is crucial for lubrication function so that the viscosity of oil grease that fits the bearing description mainly falls within the 10 to 100 centistokes depending on the bearing application. Ideal lubrication should help prevent foreign materials from coming into contact with and damaging the surface of the bearing, making the above measures only work to extend its overall service life.

Operating conditions that lead to bearing pitting, such as dust, moisture, or exposure to contaminants, can be reduced by ensuring adequate sealing and a scheduled maintenance routine for an appropriate bearing environment.

What role does bearing type play in service life?

The selection of bearings is of great interest to the service. It is directly related to its bearing type, as load capacity, speed limits, and performance in given operating conditions influence bearing selection. For example:

Load Capacity: Rolling element bearings, such as cylindrical or spherical roller bearings, perform well when there are large radial loads, while thrust bearings tend to have larger axial loads. However, ball bearings can only be used in applications demanding lower loads as they assist in more significant speed rotation.

Speed Capability: Where higher RPMs are needed, bearing rollers provide a larger contact area than ball bearings. This causes greater friction and heat, which results in poorer performance.

Misalignment Tolerance: Spherical roller bearings are self-aligning, and shaft deflection allows dynamic or uneven loads to some extent. However, rigid types, such as cylindrical bearings, must be perfectly oriented.

Temperature Tolerance: Extreme working temperatures do not break down specific bearings, such as ceramic hybrid bearings with extended lifespans in hot environments.

Corrosion Resistance: It is preferable to use stainless steel or coated bearings in moist or chemically aggressive environments to decrease the likelihood of premature failure.

When suitably followed through during the bearing selection monotony, technical and unique application requirements ensure system reliability, improved efficiency, and increased service life.

Understanding the impact of load on bearing reliability

A system’s bearing selection determines the overall performance, reliability, and service life. The chosen bearings directly affect load capacity, speed limits, misalignment tolerance, temperature tolerance, and corrosion resistance.

Load Capacity: Each bearing type is designed to meet specific load requirements. For example, cylindrical and spherical roller bearings are best suited for applications requiring large radial loads, thrust bearings are preferred for axial loads, and ball bearings are used for applications requiring lower loads and higher speeds.

Speed Capability: If a high RPM application is necessary, ball bearings can withstand it much better than roller bearings. Due to their greater contact area, roller bearings tend to create more friction and heat at higher RPMs, decreasing their performance.

Misalignment Tolerance: Some applications require a bearing that permits shaft deflection or misalignment. Self-aligning spherical roller bearings will work for these as they allow for dynamic or uneven loads. In contrast, cylindrical bearings do not allow for that, as they are stiff and must be aligned correctly to work.

Temperature Tolerance: Operating in environments with extreme temperature changes requires bearings with fantastic thermal properties. High-temperature conditions, for example, allow the effective use of ceramic hybrid bearings, which provide a longer service life without degradation.

Corrosion Resistance: Bearings should be constructed from stainless steel or other materials with protective coatings in moisture—or chemically hostile environments. These materials help combat premature failure caused by corrosion.

For instance, bearing users can enhance a system component’s effectiveness, reliability, and life span by analyzing technical and application requirements during the bearing selection step. This methodical approach is essential for optimizing the operational capabilities of various industries and applications.

Which bearing types are commonly used in centrifugal pumps?

Deep groove ball bearings vs. roller bearings

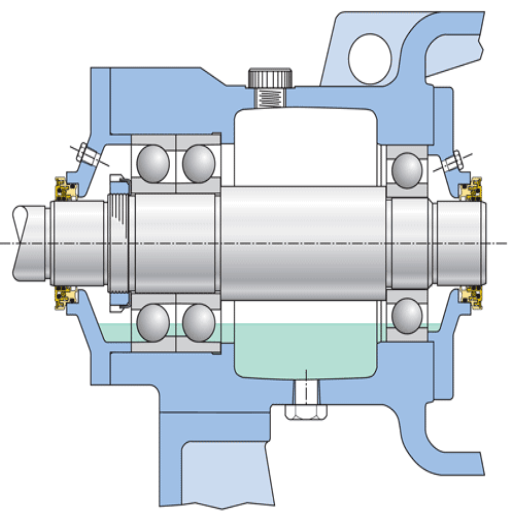

In centrifugal pumps, deep groove balls and roller bearings are designed differently and have advantages based on application and working conditions.

Deep Groove Ball Bearings have a broad application in pumps as they can withstand both radial and axial loads and have a high speed, low friction, and stable operation, enhancing the pumps’ performance. Among the key technical parameters are:

Load Type: Has moderate radial and axial loads.

Speed Rating: Possesses a higher capability than a roller bearings-rated speed.

Friction Level: It has a low value, lowering energy loss and generating heat.

Applications: This category of pumps is used on applications that require smooth, accurate operation in a range of low to medium pumps.

Roller Bearings provide better radial load support with their rolling elements having line contact with the raceways and are better structurally when used with centrifugal pumps for demanding occupational conditions. Among the key technical parameters are:

Load Type: Provides superior handling capacity for radial loads, however is limited in handling axial loads.

Durability: This endurance is derived from their ability to withstand higher load conditions, which results in longer service life when used for heavy-duty operations.

Speed Rating: Always lower than the deep groove ball bearings in rotary speed.

Applications: Another wide application is high load conditions, particularly high-impact forces or situations requiring more muscular mechanical strength.

The choice of the radially grooved ball bearing and roller bearing type depends upon the pump’s operational load, speed requirement, and service frequency. For example, in cases where the speed requirements are high, although with moderate load conditions, deep groove ball bearings deliver efficient and reliable service. On the other hand, roller bearings are best suited for applications that require heavy loads, strength, and robustness.

When to use thrust bearings in pump applications

Thrust bearings support axial (thrust) loads in a pump setup. They are essential when using high axial loads, such as multistage, high-pressure, and vertical pumps. In contrast to other types of bearings, thrust bearings can withstand these loads, ensuring stability and wear over time.

Technical Parameters of Thrust Bearings:

Axial Load Bearing—Thrust bearings are designed for heavy axial loads, starting from 10 kN and exceeding 100 kN, depending on the bearing’s size and usage.

Operating Speed—Most thrust bearings are fastened with moderate to high-speed options, with some designs featuring speeds reaching 3000 RPM or more. Speed ratings should match the pump’s requirements for effective results.

Lubrication methods—Adequate lubrication is necessary as most thrust bearings use axial loads, which create more friction. Oil or grease lubrication systems offer lubricant viscosity measures suitable for cooling and achieving the needed rotation temperature.

Elemental Composition—Hardened or stainless steel is a common material used for bearing rings and rollers/balls to avoid deformation under excessive forces and wear and tear.

Operating Temperature – The efficiency of thrust bearings is within the temperature range of -30 degrees Celsius to 120 degrees Celsius. However, advanced materials or coatings can improve the coverage for specialized applications.

Use Cases:

Vertical Pumps: Due to their design, these pumps also generate substantial axial loads, making them ideal for using thrust bearings.

Multistage Pumps: As there is an increase in the pressure across stages, the axial forces do increase, too, and strong thrust bearings have to be present as well.

High-Pressure Systems: These applications require considerable handling of axial loads with radial forces, and thrust bearings are used in them.

While analyzing the above parameters and use cases, the selection of thrust bearings can be optimized for tool reliability and service time in demanding applications and environments.

Advantages of angular contact bearings in pumps

Angular contact bearings are the bearings that are most suited for pump applications as they can withstand axial loads along with radial loads. These bearings are mainly meant for high-performance conditions where accuracy and reliability are core requirements. The following are the main benefits and their relative technical specifications:

High Axial and Radial Load Capacity: Angular contact bearings can bear isolation and excessive contact between the radial and axial forces. It allows them to excel in pumps that operate in high-pressure or multi-staged systems.

Parameter Justification: A variable angle (usually between 15 and 40) increases the bearing’s capacity to handle an axial load, which can then be adjusted according to the desired usage of the bearing.

Operational Stability at High Speeds: The angular contact bearings, with their accurate design and less friction contact, operate very smoothly at higher speeds, reducing vibration and noise levels.

Parameter Justification: Depending on the load delivered to the bearings, the load racing contour and high-quality oil supplies will work over 10,000 RPM.

Enhanced Durability and Service Life: Using better-quality chromium steel and heat treatment processes, angular contact bearings can resist wear and fatigue in harsher environments.

Justification of Parameters: Fatigue load ratings (C) and dynamic load ratings (Cr) serve to estimate the bearing life for the particular load scenarios.

Techniques Against Heat Expansion: The angular features facilitate the management of heat and expansion, maintaining the functioning capabilities.

Justification of Parameters: Properly adjusted bearings, which are lubricated adequately, can avoid overheating even during constant running.

Possible Applications in Configuration: The design of single-row and double-row angular contact bearings allows them to be used in tandem, back-to-back, or face-to-face, which contributes to the equipment’s effectiveness.

With these attributes and their technical background, angular contact bearings can help pumps operate effectively, reliably, and for a longer period in harsh conditions.

How does lubrication affect pump bearing life?

Choosing the proper lubricant for pump bearings

Selecting the correct lubricant dramatically affects the performance and durability of pump bearings. I would like to highlight three factors that I consider the most important when deciding on the type of lubricant: viscosity, operating temperature, and load-bearing capacity. Each of these factors must be considered for maximum pump efficiency.

Viscosity: The lubricant has to be tailored according to the pump’s rotational and thermal levels. In my experience, I have always chosen low-viscosity oils for graphite-lubricated ward pumps for high-speed usage. I have also always chosen oils with a higher viscosity when my pumping tasks involve slow rotation while carrying a heavy load. Most standard pumps should have a 95 to 150 mm2/S viscosity index.

Operating Temperature: I must consider the temperatures of the environment within which the pump operates and decide upon the types of lubricants that could work within that range of temperatures. Thermal degradation is one of the issues that many lubricants face, this is more evident in temperatures that exceed 100 degrees Celsius therefore synthetic lubricants would fit this role more appropriately as they are thermally stable.

Load Capacity: If I know that the pump is going to be under a heavy load or is going to be under shock loads, then I choose lubricants that have good load-carrying abilities. EP lubricants increase the lubricity between the bearings and reduce contact pressure.

Suppose I select the lubricant end product while considering the specified technical requirements. In that case, I can say that the bearing lubrication system provides adequate protection against wear, reduces temperature increase, and enables safe bearing operation for the required lifespan. Proper lubricant application enhances the bearing’s service life and reduces the costs and downtime associated with maintenance.

The impact of lubrication methods on bearing reliability

The choice of lubrication methods influences bearing reliability as they satisfy essential operational requirements. I determine the lubrication method depending on the following parameters: load, speed, operating temperature, and environmental factors. For example:

Load: I select grease with a high base oil viscosity and a thickening agent for a strong lubricating film for heavy lifting scenarios. This protects the bearings from excessive wear when operating under load conditions.

Speed: When required rotational speeds are high, I use lubricants with lower viscosities to lower friction and avoid excessive heat during operation.

Operating Temperature: Lubricants with a low to high operating temperature range and a high degree of thermal stability are used to prevent grease from thinning or solidifying at extreme physical application temperatures.

Environment: Where contaminants such as dust or moisture are present, I select sealing greases or lubricating agents that are water-resistant and oxidation-resistant to protect the bearings from these elements.

Matching these parameters to the specific lubrication method, such as the injection of grease, oil bath, or automated lubrication system, ensures proper formation of the lubricating film, reduced risk of tearing, and increased bearing lifespan. This methodological technique eliminates guesswork, logically guiding the technical choices previously tailored to suit the operational conditions.

What are the unique bearing properties required for pump systems?

Heat resistance and its importance in bearing selection

Others might factor in various elements when choosing bearings for pump systems. Still, I will focus on heat resistance as an aspect that must be considered when working with high-temperature pump systems. To ensure the system’s reliable operation, I start by selecting the type of bearing that could perform or, more specifically, work without changing any of its critical performance characteristics at high temperatures. The key technical parameters I consider include:

Material Composition: Steel alloys or ceramics are the best materials for high-temperature bearings, as they have good thermal properties and do not deform when exposed to heat.

Lubricant Compatibility: I take into consideration the lubricant’s ideal properties and check whether it great for high-temperature operating conditions, for instance, the application temperature limits are 150°C or even over, depending on the application.

Thermal Expansion Coefficients: The temperature expansion of the bearings must be controlled so that they are not too bulky or loose to misalign.

Each of the parameters stated above is my primary consideration during pump design. This is to avoid mechanical failures, overheating, and minimal underperformance of the bearings, which can affect the pump’s effectiveness under harsh conditions.

Corrosion resistance considerations for pump bearings

When choosing materials for pump bearings and their coatings, it’s critical to examine the chemistry around them and, in turn, ensure that they are suitable for corrosive environments.

Material Selection: Most of my work begins with stainless steels, such as 316 and even duplex steels, which show excellent resistance to above- and below-neutral pH environments, such as chlorides and acids. For even harsher surroundings, superalloys such as Hastelloy or ceramic withstand almost 99 percent of corrosive environments.

Protective Coatings: A simple technique such as using PTFE or ceramic coatings, which are anti-corrosive, helps to prevent damage along the bearing surfaces, ensuring the durability of the component.

Proper Sealing Systems: I also place importance on bearing sealing systems for safeguarding against external debris, as it also aids in corrosion prevention.

Environmental Factors: In my professional opinion, the pH level and the temperature also contribute significantly to the selection of materials. For example, antibacterial materials may be suitable for use in low pH environments of 4 and below or high pH of 9 and above due to the abrupt destruction of the contained chlorine content levels.

This level of focus on these technical parameters is undoubtedly a job requirement to ensure the pumps remain reliable and efficient. Any failure on the end of the system could prove detrimental to a system with a corrosive environment.

What strategies can extend pump bearing life?

Implementing proper maintenance routines

In all pump bearing designs, I tend to recommend preventative and regular maintenance from an engineering point of view to achieve reliable operations. This is how I tend to approach it:

Frequent Maintenance—Specific Maintenance Tasks: I perform periodic inspections, which include sounding for high-frequency vibrations or noise that indicate impending bearing failure. This helps me intervene promptly, reducing extensive damage that requires overhaul repairs.

Effective Lubrication Control: I replace bearings with the right materials that require the correct amount of lubrication to operate optimally. For example, I use grease that will not liquefy in extreme temperatures, eliminating wear and tear, such as bearing pulls or tears.

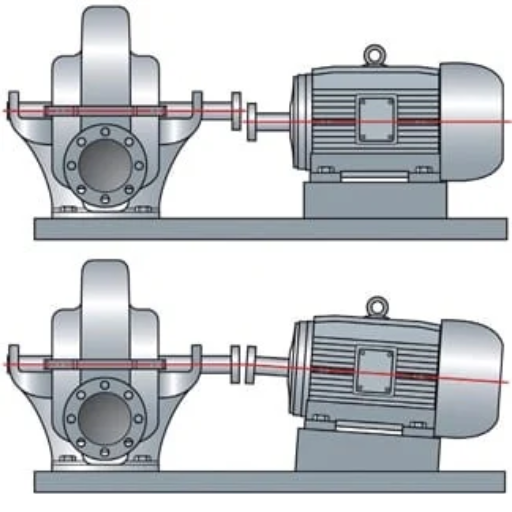

Conducting Shift Audits: The load line angle creates potential interference fit, resulting in inappropriate situational loading that can severely damage bearings. I routinely check shafts connecting to couplings, ensuring they are aligned and making any adjustments needed to avoid unnecessary stresses.

Evaluation of the level of contamination: Contamination by dust, moisture, or chemicals should always be controlled. I periodically clean the bearing house and change worn-out seals as a preventative measure. In such environments, it is crucial to minimize wear, which can promote wear or chemical damage.

Evaluation of the speed/load Ratio: I ensure that the speed or mechanical load on bearings is reasonably under their design limits, as exceeding them will lead to overheating or material fatigue.

At every stage, these measures seem more relevant to withstand the weak points’ mechanical strength and operational stability.

Proper maintenance avoids unnecessary standstill, reduces repair expenses, and ensures the pump bearing assembly’s reliability throughout its long service life.

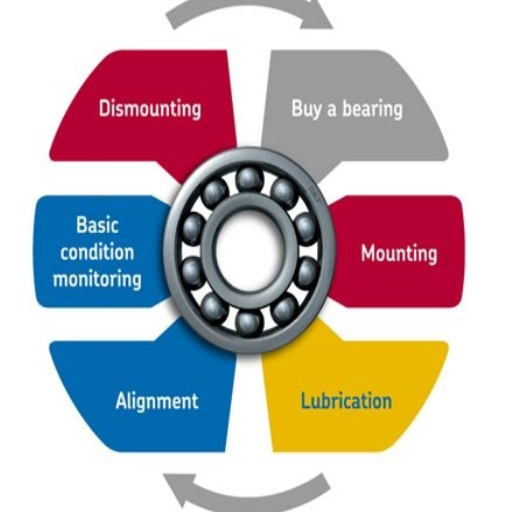

The role of condition monitoring in preventing bearing failure

If used properly, its condition monitoring can guarantee a proactive approach toward dealing with any weaknesses or threats around the bearing that might eventually become a full-fledged breakdown. There are many technical criteria I employ when monitoring, which help me pinpoint and diagnose accurately:

Vibration Analysis: Abnormal patterns or frequencies need to be measured and controlled, which is the case for vibration levels. To do so, I use accelerometers to measure vibration levels regularly. If misalignment, imbalance, or wear come into the picture, they will lead to vibration amplitudes getting higher to a point where it needs immediate application of iso 10816 standard.

Temperature Monitoring: Great heat is often due to structural issues around temp which leads to the operating deviation from or breaches the 80 degree limit this being the upper limit., hence i constantly monitor whether a problem is arising around this temp.

Lubrication Quality: When measuring or controlling, the type and the grade of viscosity are extremely critical vulgar, and if breached alongside the NAS 1638 standards, there exists a high chance of contamination or degradation taking place, which is why I take utmost care while dealing with lubricant.

Acoustic Emission Testing: If cracks, pitting, or other signs of fractures occur at a microscopic level, sound waves at high frequencies can capture them. It’s best to rectify the situation before it escalates to a greater degree, as one already knows it will eventually.

With the power of these criteria together comes the ability to strategically counter them should bearing life, equipment reliability, and the safe operating function come under threat, all the while managing to create an efficient environment through intervention.

Selecting the right bearing design for longevity

I extensively consider the application and technical parameters when deciding on the appropriate bearing design to maximize a bearing’s lifetime.

Load Capacity: I assess if the expected loads are satisfied in both the static and dynamic loads of the bearing. For instance, bearings subjected to oscillating action should have a high dynamic load rating of ‘C’ to ensure that the bearing operates under preferable conditions.

Operating Speed: The maximum rotating speed of the application must be considered. In addition, I think the limited speed offered by the manufacturers, the type of lubrication, and the bearing size to use appropriate figures.

Temperature Range: I check if the different materials used in constructing the bearing can withstand the desired temperature range for High-temperature applications. For example, heat-resistant materials or lubricants may be needed for some high-temperature situations to function appropriately.

Environmental Conditions: Sealed or shielded bearings and other corrosion-resistant materials such as ceramic or stainless steel bearings are utilized in such environments.

Alignment Tolerance: I opt for self-aligning bearings for their properties of preventing angular deviation and, therefore, would not wear out quickly.

In this way, I can choose a bearing design that ensures durable and reliable use since these parameters have been matched according to the working conditions. Further monitoring and information obtained during the working of the equipment also support these bearings.

Frequently Asked Questions (FAQs)

Q: Do different pumps impact the lifespan of bearings?

A: The type of pump affects the lifespan of bearings due to the specific loads and operating conditions to which they will be subjected. Different types of pumps may require different types of bearings, such as cylindrical roller bearings, spherical roller bearings, and angular contact ball bearings, which have other properties that affect their lifespan.

Q: Do life adjustment factors carry any significance in the calculations of bearing life?

A: The adjustment factor is very important in bearing life calculations since it incorporates all bearing performance conditions found in the assembly and in the control of the bearing during its lifetime. This factor includes also the effects of lubrication, contamination and temperature, therefore, the predicted bearing life is closer to reality than the basic rating life which does not factor these conditions.

Q: What is the effect of radial load on pump bearing life?

A: What radial load does is very important; it is one of the significant loads that act upon the bearing, and it greatly influences the life of the pump bearings. With radial loads increasing, the radial supports stress in the elements of the bearing, such as the inner ring, outer ring, and rolling elements, and this stress tends to reduce the fatigue life of the bearing.

Q: What role does the bearing manufacturer play in determining bearing life?

A: The bearing manufacturer significantly determines bearing life by setting up specific bearing ratings, life assumptions, and relevant usage policies. They perform experiments and give information concerning the basic rating life, the L10 life, and a range of other parameters that support giving a precise bearing life estimate in pump applications.

Q: How does the bearing system configuration impact the overall pump life?

A: The geometry of the bearing system configuration, whether a single bearing or two or more bearings are used, influences the overall pump life as it ensures load distribution and proper shaft alignment. In systems with several bearings, the equipment’s life is often controlled by the bearing with the least serviceable life. This makes it paramount to consider the system’s life as a whole rather than the life of several bearings.

Q: What is the significance of the basic rating life in pump-bearing applications?

A: The basic rating life is referred to as L10 life, which is very important in pump-bearing applications as it defines the number of revolutions or hours of operation that 90% of the identical group of bearings will be able to perform before developing operational fatigue. Such metrics provide the L10 basis for more advanced life cycle expectancy computations that factor in the exigent circumstances of operational conditions and life adjustment factors.

Q: Are there specific identifiable life expectancies of different bearing types used in pumps?

A: Regarding bearing lifespan, pumps use sleeves or any modification that fits their design and load-carrying ability. For example, cylindrical roller bearings can withstand a lot of force and are great at radial loads. Angular contact ball bearings can withstand wide loads, as well as radial and axial loads. A pump may be designed to use tapered roller bearings or spherical roller bearings. It is essential to understand the purpose of the bearing so that the desired applicability of the pump is attained.

Q: Why do specific conditions need to be met alongside the conditions of the pumps in particular bearings?

A: Bearing life is calculated for pumps based on primary rating life, which includes life adjustment factor, radial load, axial load, revolving speed, operating temperature, lubrication, and bearing type. Such calculations are based on the life expectancy that is determined by the American Bearing Manufacturers Association which provides a standard framework for predicting the performance of the bearing in the most reliable manner.