Warman slurry pumps are well-known for their efficient performance in handling abrasive and high-density slurries while operating in challenging industrial surroundings. Their reliable performance is attributed to the heart of the pumps – the bearing assembly. That is a critical component that ensures smooth operation under highly rigorous conditions. This article will delve into the meticulously formulated practices, maintenance insights, and technical strategies that are instrumental in propelling the performance and life cycle of the Warman slurry pump bearing assembly. This comprehensive guide is essential for workers on the floor and those on the managerial side, as it gives the operational insights necessary to optimize equipment efficiency, reduce equipment downtime, and enhance overall productivity.

How to Maintain Your Slurry Pump Bearing?

Understanding the Slurry Pump Bearing Assembly

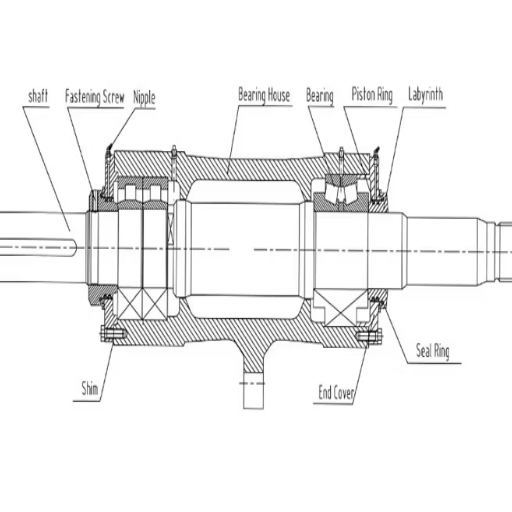

The slurry pump bearing assembly serves overly essential functions for a component. It supports the shaft and friction while running the device. From my viewpoint, understanding its configuration is very important for acceptable performance. The assembly includes significant details, such as bearings, a shaft, housing, and seals, all essential for the equipment’s alignment and avoiding removed wear. For example, the bearings are radial or axial load-carrying devices that bear friction and impact. They are usually built with precise materials such as chromite stainless Steel and endure harsher conditions.

Now, in the context of analytical aspects, here are the notable ones:

Lubrication Type: The device should accurately provide lubrication as grease or oil always does the magic, owing to recommended conditioning ISO VG 68-220.

Clearances: Follow the requirements for bearing clearances as the manufacturer instructions tell you (e.g., the classifications C3 or CN clearances).

Temperature Range: The apparatus should not exceed 200°F (93°C). Excessive heat dilutes all energies that add value and amplify lifespan.

Load Ratings: The bearings of the device cannot outstand the operational harms that add to dynamic and static load ratings and need to coincide with the operational features or conditions.

Sealing Mechanism: The device sealing againts slurry needs to employ seal that add value to the devices such as lip seals or labyrinth seals. By maintaining these elements and conducting regular checks, I am confident that I can preserve the reliability and durability of the bearing assembly,y even in the most extreme slurry transport operations.

Key Maintenance Tips for Warman Pumps

In regards to the upkeep for the efficient functioning of Warman Pumps, these are my helpful suggestions:

Lubrication Processes—I apply grease every 200 to 400 hours of Standard Operating Conditions to enhance operational efficiency. This throttle is modified in extreme conditions, and I also ensure that equipment-specific lubricants recommended by the manufacturer are used.

Monitoring of Nondestructive Testing- I constantly check and evaluate critical components of the impeller, volute, and shaft sleeve, which helps mitigate any chances of unplanned downtime. Changing these parts before they hit the wear limit ensures consistent pump performance.

Bearing Maintenance – Using, I keep the bearings below normal operating limits and at 85-100 degrees Celsius, depending on the environment. The static and dynamic load ratings are matched precisely to keep the pump’s hydraulic performance at peak efficiency.

Sealing System Inspections – Labyrinth or lip seals are checked periodically and replaced if they pose a risk of slurry infiltration, ensuring the longevity of both seals and bearings.

Adjustment of Impeller Clearances facilitates effective retention of the original design parameters and corresponds with the rising bar of Internal Efficiency Reduction. Subsequently, internal components’ life spans and wear rates are significantly reduced.

Coordinating these maintenance suggestions with their proper technical details allows me to ensure optimal pump functioning, reduced pump downtime, and increased life of the significant parts. Keeping detailed maintenance logs also helps identify trends in future servicing schedules.

Common Issues and Solutions in Bearing Assemblies

Throughout the years, I have dealt with dozens of bearing assemblies, and I have been able to devise solutions for the most common and reoccurring problems I face. Some common issues are provided below, along with their corresponding technical parameters and the most justified remedy:

Excessive Heat Generation: Misalignment and improper lubrication are the reasons for generating excess heat. In this instance, I verify that the lubricant used meets the manufacturer’s viscosity guidelines to ensure proper lubrication. Of course, there is a vital range of operational temperatures and load conditions. This type of lubrication helps dissipate heat, and friction lowers effectively.

Vibration & Noise: Unusual noises and vibrations are often flags that inform a user about imbalanced parts or bearing wear. I check the components that rotate with each other, their alignment, and the acceptance and rejection of bearing rotations. Accelerometers and other equipment can also assist with monitoring vibration levels, which helps in diagnosing patients.

Corrosion: If moisture or incompatible materials are exposed to components without care, corrosion could result. To solve this issue, I tend to apply protective coatings to bearings or use alloys that resist corrosion.

Furthermore, I monitor the humidity and temperature of the workspace. I carry out effective and competent bearing assembly processes when these problems are solved in the ways mentioned above and within certain technical limits.

What Are the Essential Replacement Parts for Your Warman Pump?

Identifying Critical Slurry Pump Parts

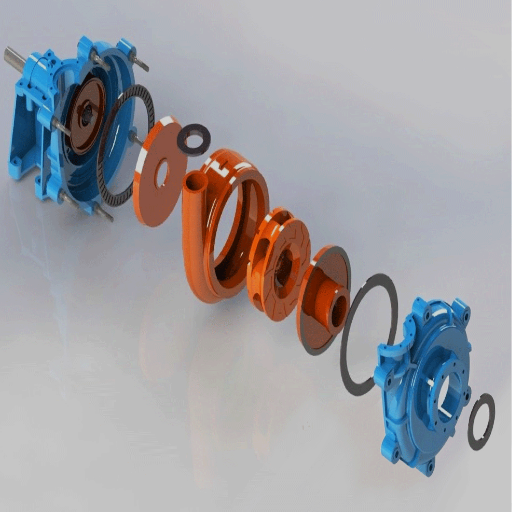

A critical evaluation of the parts most vulnerable to wear and those integral to a Warman pump’s optimal performance will help identify its key replacement parts. The impeller, throat bush, and volute liner are arguably the most critical components for this pump since they are always in contact with the abrasive slurry.

For illustrative purposes, the imparting element, responsible for the centrifugal force necessary for pumping, must be made out of a high chrome alloy in a setting full of abrasives. Additionally, the throatbush is a seal whose primary purpose is to resist wear. If the slurry is full of heavy particles, rubber and alloys will help mitigate this. Lastly, the elastomers or alloys placed on the volute liner and pump casing are used to extend the pump’s service life. These elastomers or alloys need to be relevant to the surrounding operating conditions.

When selecting these parts, corresponding technical parameters need to be factored in, such as the composition of the slurry, particle size, density, and chemistry, as well as the pump’s operating pressure and speed. Other parameters are the replacement parts’ specifications. By aligning these parameters, the pump’s efficiency is maximized under turbulent conditions while its life is prolonged.

Benefits of Using Interchangeable Parts

In my experience, using interchangeable parts in pump systems enhances flexibility and efficiency. First and foremost, this functionality aids in servicing the system faster and more efficiently because compatible components can be substituted without much delay, thereby minimizing downtime. Second, it reduces costs by allowing the reuse of standard components with various pump models.

While reviewing and picking interchangeable parts, I concentrate foremost on the broad technical parameters which I believe affects performance and durability, such as:

Particle Size: Crucial in assessing the wear resistance required by the part’s material. More robust compositions are needed for larger sizes.

Slurry Density: Measures the load and wear rate that parts can carry and handle. Denser slurries need to be remanufactured with more stress-resistant materials.

Chemical Composition of Slurry: Aids in selecting materials that are corrosion-resistant to chemicals so that components do not get chemically degraded and have a longer life.

Operational Speed: Selected components must operate within a specified RPM range with minimal wear or vibration and without exceeding the rated RPM.

Pressure Conditions: Assists in identifying parts that can withstand system pressure, ensuring efficiency and avoiding system failure.

Identifying these factors has helped me increase the system’s reliability, productivity, and the life of critical components in harsh working conditions.

How to Ensure Compatibility with Weir Products

I use a Weir Check List approach in evaluating a system requirement’s key technical parameters, ensuring that they are in sync with the performance of Weir products.

Material Selection: Weir products must be made of materials that can handle the fluid medium they will be exposed to, the temperature, and the possible corrosive environment. For instance, high-grade alloys can place aggressive chemicals in high-temperature applications. That way, they can be sustained.

Dimensional Fit: I confirm that dimensions such as flange sizes, connection types, and mounting options will fit into the assembly or system without hindrance. This step is crucial to clarify particular standards such as ASME, ISO, etc.

Operating Temperature Range: I ensure that Weir components can perform within the system’s temperature range. For example, I verify that elastomer seals can operate at -20°F and 400°F, depending on the application.

Pressure Rating: Another key issue is checking the boundaries for pressure compatibility. The European products have a low rating compared to the maximum operating pressure of my system, e.g., ANSI 150 or 300. This point would set the standards for avoiding failures.

Flow Characteristics: I may determine flow rates and evaluate Cv (flow coefficient). This verification process assures that the product will function without getting through exorbitant pressure drops or turbulence.

When analyzing the RPM and Vibration Considerations for components that rotate like pumps and compressors, stable operational conditions can be achieved at specific RPM ranges like ≤1500 RPM, as well as reducing the level of vibration and wear on the components.

For Serviceability and Maintenance, I analyze the maintenance tasks that need to be done, along with the available tools or spare parts, so that the maintenance can be performed quickly and with little downtime.

Like these parameters, I achieve a reliable match that allows me to track performance parameters for Weir products, whose technical datasheet I rely on for ensuring system and performance reliability and longevity.

How Does a Slurry Pump Bearing Assembly Work?

Role of Bearing Assembly in Connecting Pump and Motor

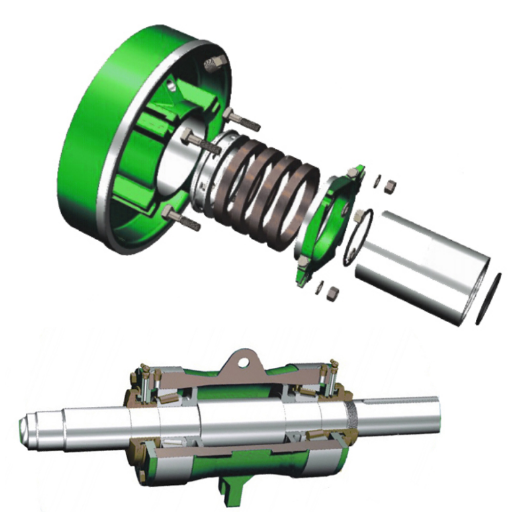

The bearing assembly is essential to properly functioning the bearing and motor since it transforms power and facilitates smooth operation. The assembly reduces friction and change in the rotating shaft while supporting the precise alignment of the motor and pump components. This alignment allows for easy energy transfer while reducing system vibration, which, if left unchecked, may cause system failure.

Load Capacity: The assembly is designed to sustain radial and axial loads during operation without significant structural change or pathetic loss of efficacy. This guarantees durability across changing slurry conditions.

Material Composition: Coupled with ease of maintenance, alloy steel materials or anti-corrosion coating are crucial to endure the abrasive and caustic environment synonymous with slurry pumping systems.

Lubrication Requirements: Lubrication helps prevent friction in the system. I consider grease and oil compatibility to get the best form of service bearing while extending the system’s life span.

Speed and Temperature Ratings: To prevent overheating, the bearing should be compatible with the pump’s operational speed and temperature thresholds throughout its life.

These parameters give me certainty that the assembly’s reliability is in line with system requirements, improving the components’ longevity.

Impact of Deflection on Bearing Life

Deflection negatively affects the bearing life by increasing stress and reducing load distribution effectiveness. I measure the deflection using the following technical parameters:

Load Distribution: Stress concentration caused by poor load distribution accelerates wear caused by deflection. I check that there is no imbalance to ensure alignment.

The shaft will permanently be misaligned. This may lead to further misalignment of the shaft, compromising bearing performance. There is a small tolerable limit, which I monitor with alignment tools.

Bearing Clearance: Deflection beyond the design limit can threaten critical clearances, leading to contact stress and thermal issues. I chose C3 bearings so there are fewer internal clearances than the system’s demands.

Material Fatigue: Overprocessing the material can lead to fatigue or severe fatigue cracking. I am monitoring the material, specifications, and operating conditions to alleviate these symptoms.

By setting these parameters, I properly control deflection and its effects on the bearing, ensuring excellent performance and reliability.

Importance of a Short Overhang Minimizes Deflection

Deflection affects both system integrity and performance. To lessen it, bending moments and structural displacements must be managed simultaneously. Increasing the level of structural support further enhances stability. This can be achieved by doing the following:

Reduce Leveraged Strains: Shortening the overhang lowers the structural leverage and minimum stress impact on the components that could cause damage.

Increased Structural Support: A stiffer, shorter overhang tends to increase the deflection-induced misalignment or component fatigue, which ranges from malfunctioning to malfunctioning.

Obtain Overhang Portion to Diameter Ratio: In conjunction with material stiffness, the overhang length measures the ratio while inverse to its diameter. It serves a purpose when overhangs do not exceed pre-calculated limits.

With these solutions, I can lessen vibration, excessive wear, and failures, eliminate risks, and maintain high precision so that the system functions under operational conditions.

Why Choose Warman AH Pumps for Your Needs?

Advantages of Using Warman Pumps in Abrasive Environments

Warman AH pumps are my go-to when dealing with harsh conditions because of their strength, efficiency, and dependability. Because they are knitwear, these pumps are built to perform in even the most strenuous conditions for the longest time possible. Their modern design, coupled with a sturdy build, assures maximum uptime and performance.

Material Selection: Warman AH pumps use high-chrome alloys integrated with elastomers, which provide unparalleled resistance against abrasion and corrosion. This simultaneously increases the lifespan and decreases maintenance effort.

Hydraulic Efficiency: Due to their intricate architecture, the casing and impeller are designed to prevent turbulence and lower efficiency. These directly decrease the overall operational expenses.

Replaceable Liners: Adding maintenance-friendly liners that do not compromise on durability offers tremendous value.

Robust Shaft and Bearings: Designed to endure high stress and shafts that are exposed to misalignment these pumps are reliable for abrasive tasks.

Operating Flexibility: These pumps can efficiently deal with a range of slurry concentrations and different granular sizes, showcasing their ability to operate in various conditions.

Focused on these parameters, Warman AH Pumps are built to deliver unmatched productivity, high system dependability, and consistent functionality no matter how tough the environment gets.

Features of Ductile-Iron Outer Pumps

In my experience, ductile-iron outer pumps have very high strength, durability, and performance in hostile environments. Remember the essential features and their technical parameters that pertain to their use:

High Tensile Strength: Ductile iron withstands stress with a tensile strength of 60,000 and 120,000 psi. This ensures the pump housing can withstand high abrasive pressure without any deformation.

Impact Resistance: These materials are designed for heavy-duty applications. They can withstand harsh operational setups, avoiding catastrophic failure.

Corrosion Resistance: Additional coatings or materials dissolved in ductile iron can be used to enhance its resistance to corrosive slurries or chemicals. Treating these metals or coatings is essential in mining and industrial applications.

Dimensional Stability: Ductile iron maintains its stability under extreme temperatures from -40 °F to over 1200 °F to function in extreme temperatures.

Cost-Effectiveness: These properties of ductile iron make it very affordable, offering a lot of performance.

With these features and parameters, I trust ductile-iron outer pumps in abrasive high-performance scenarios. They are reliable and efficient even under the harshest conditions.

Comparing Warman Mill Circuit Pumps with Other Products

Warman pumps are one of a kind in terms of durability, so I prioritize them over the rest. My first choice is Warman because their pumps boast top-of-the-range performance in abrasively challenging conditions while remaining efficient. They have high-wear resistance because of the alloys and elastomer liners, which ensure a long life. These pumps demonstrate outstanding hydraulic effectiveness, which increases efficiency while at the same time reducing energy usage.

The following are the reasons that support the choice of Warman pumps from a technical point of view:

Wear resistance: These high-chrome iron (27% to 28% chromium) pumps are designed to withstand abrasive material.

Efficiency: These pumps utilize revolutionary hydraulic designs, dramatically reducing turbulence and allowing for 5 to 15 percent of energy savings compared to the competition.

Operating range: Compared to other pumps, these can handle flow rates as high as 20,000 GPM and 300 PSI. This opens doors to a plethora of industrial options to utilize it.

Maintenance: These pumps are designed for modular maintenance and use replaceable liners, which significantly reduces downtime and increases productivity.

All these factors combined make these pumps incredibly reliable. Even under the stiffest conditions, unlike others, Warman pumps stand out as the most cost-efficient solution on the market.

What are the key product specifications for slurry pumps?

Understanding Large Diameter Shaft in Slurry Pumps

Slurry pumps with large diameter shafts are more effective and durable than standard ones. I appreciate this design innovation because it helps the pumps withstand heavy workloads.

Key Benefits and Justification:

Improved Strength: Larger diameter shafts reduce shaft deflection under high loads, extending the operational lives of the bearings, seals, and, by extension, the pump.

Reduced Vibration: The reduced vibration caused by the rotating shaft results in decreased operating noise and mechanical stresses on the pump components.

Enhanced Bearing Life: Reducing bearing deflection translates into increased bearing life since the stresses are better distributed with less deflection.

Relevant Technical Parameters:

Minimum Shaft Diameter: Generally, the minimum shaft diameter to accommodate more significant mechanical strain is over 3.5 inches (or more, depending on the pump’s size and model).

Material Composition: Usually utilizes forged carbon steel or stainless steel for fracture toughness and resistance to corrosion.

Deflection Tolerance: Must ensure deflections do not exceed 0.05 mm at the seal area to avoid excessive wear and tear of the seals, inducing premature failures.

This feature is central to the pump’s efficiency and dependability, particularly in abrasive and high-pressure slurry transportation. It guarantees that a challenging level of operation can be achieved with a very low maintenance level, thus managing operational and maintenance expenses.

Evaluating Impeller Design for Efficiency

While assessing an impeller hydraulic flow component, I must check numerous criteria to achieve the desired effectiveness in complicated cases. The most important ones are hydraulic design, material choice marketing, and the prerequisites for operational needs. The specific parameters and corresponding justifications in the technical documents are below.

Hydraulic Design

Parameter: Specific Speed (Ns): Helps ensure the impeller is a propeller for the specific application in terms of whether it is high flow or high head.

Justification: An impeller with the correct Ns enables steering with the desired amount of energy without sustaining too many energy losses for the needed ‘head’.

Impeller Material Composition

Parameter: High Chrome Iron or Duplex Stainless Steel.

Justification: These materials are functional in corrosive and abrasive environments, such as slurry or chemically aggressive conditions.

Clearance Optimization

Parameter: Wear Ring and Impeller Clearance (< 0.5 mm recommended).

Justification: Recirculating flow losses from clearance’s getting tight proximity directly improves overall pump efficiency.

Vane Geometry And Number Of Vanes

Parameter: Designed with 3 to 5 vanes for slurry applications, adjustable for flow and particle size distributions.

Justification: The optimal design with minimal cone-shaped bladed disks prevents excess turbulence and deterioration, ensuring the pump will treat solids without losing performance and with good non-deteriorating hydraulic efficiency.

By integrating these aspects into the operational environment, the efficacy of realizing the system’s goal is attained for both the pump’s durability and efficiency.

Importance of Roller Bearing in Pump Operation

Roller bearings are pivotal in reducing friction and aiding pumps in operating smoothly and efficiently. Their emphasis on the pump’s reliability, performance, and service life is excellent. The key technical parameters addressed and their justifications are given below.

Load Capacity

Parameter: Dynamic and static load ratings should be adequate to satisfy operational requirements.

Justification: Observing the radial and axial forces exerted by a pump on a bearing sleeve’s midsection, the stub’s lowermost partition has a recess designed to reduce the bearing’s weight while simultaneously providing high load capacity. The robust mechanical impacts to which the bearing is exposed will cause pain only to those bearings that have been choked up far too much.

Lubrication and Sealing

Parameter: Adequate lubrication systems and seals of sufficient quality.

Justification: Significantly reduces the chance of the bearings getting contaminated with slurry or debris while protecting the stuffing box, resulting in an improved life span of the appliances.

Alignment Accuracy

Parameter: Correct alignment during the installation and use of the machine.

Justification: Accuracy guarantees uniform load distribution onto the bearing components and decreased stress build-up in the components because of friction and quelling of the wear processes.

Temperature Threshold

Parameter: The temperature of the operation has to remain within the allowable limits of the bearing.

Justification: Special deformation-resistant, high-performance structural bearing materials enable consistent performance while blocking overheating.

Meeting and taking care of these parameters can ensure that I help optimize pump performance and diminish downtime, increasing the reliability of the entire system.

Frequently Asked Questions (FAQs)

Q: Why is top-quality Warman slurry pump bearing assembly maintenance important?

A: The longevity and efficiency of the pump aren’t achievable without maintaining a high-quality Warman slurry pump bearing assembly. This assembly incorporates a rotating shaft with a short overhang to the pump housing, meaning that even in the most abrasive environments, the centrifugal slurry pump works without any issues.

Q: To what extent does the bearing assembly facilitate the performance of Warman® AH® slurry pumps?

A: The bearing assembly in Warman® AH® slurry pumps is critical because it carries the rotor assembly and bears the loads. This enables the pumps to work and perform optimally with the highly abrasive slurries, thereby reducing downtime for maintenance.

Q: What materials comprise the construction of a Warman® AH® slurry pump bearing assembly?

A: Some materials used in constructing Warman® AH® slurry pump bearing assemblies include ductile iron for the outer casing. These components provide the bearing assembly with wear resistance and durability and ensure that these can withstand harsh conditions.

Q: In what intervals should the bearing assembly in the centrifugal slurry pump be inspected?

A: Bearing Assembly in centrifugal slurry pumps should be checked regularly to preserve optimal operational performance. These inspections should be a part of scheduled maintenance, including inspections for damages, lubrication, and other alignments.

Q: Where does bearing housing fit within the complete pump working system?

A: Bearings housing, also known as rotor assembly, is essential in the complete pump working system as it contains the bearing assembly. It provides adequate positioning and support to the rotating parts, thus facilitating the effective functioning of horizontal slurry pumps.

Q: Is it still possible for the motor, as a complete pump, to be affected by a faulty bearing assembly?

A: Yes, as with any other part of the system, a faulty bearing assembly will gravely impact the motor as a complete pump. Increased vibration and noise, along with failure of the drive power unit, are just but some issues resulting in poor performance and damage to the pump.

Q: What steps are involved in the quality control of Warman® pumps’ bearing assemblies?

A: Quality control for Warman® pumps involves several steps for their bearing assembly, including material inspection, dimensional checks, and performance tests. These activities ensure that each bearing assembly is tested for reliability and durability.

Q: What distinguishes the bearing assembly maintenance of Warman® mill circuit pumps and other pump products?

A: Warman® mill circuit pumps are made robust and built to last. This means their bearing assemblies are inspected and maintained more regularly because they deal with highly abrasive materials, unlike other pump products.

Q: What is the significance of the shaft with a short overhang in Warman® AH® pumps?

A: Short overhang shafts on Warman AH pumps reduce deflection and vibration during pump operation. The better the pump’s design, the greater its efficiency, durability, and power, especially as slurry pumping becomes more complex.