It is of utmost importance to ensure that the temperature of the bearing of a pump is optimal since this dramatically affects the efficiency, reliability, and longevity of a pumping system. If bearings operate outside the acceptable temperature range, equipment malfunctions, expensive downtimes, and costly maintenance procedures could occur. This article serves as a guide for the most critical aspects regarding the phenomena of the bearing temperature of a pump, possible problems, and maintenance procedures. Whether you are supervising industrial pumping systems or managing smaller applications, effective controlling of the pump-bearing temperature is an essential part that every person should know to ensure seamless operations.

How to Measure Bearing Temperature Accurately?

What tools are used to measure bearing temperature?

Any attempt to measure the temperature of a bearing accurately requires specific tools; otherwise, it would be rendered useless. This is where gd TC’s RTDs and Infrared thermometers make their entrance. Regarding rotation at the critical speed, the thermocouples were good enough. TCs are suitable for constant temperature measurement over long periods because of ТC’s high system accuracy and stability over time. IR thermometers can perform much better at remote locations than TC’s and RTD’s. Areas that are too dangerous or hard to reach require noncontact temperature measurement.

What should not be forgotten is the most important technical parameters and influences that temperature measurements might have. These parameters are two indices: bearing load capacity and degree of lubrication’s viscosity. For example, high temperature will increase the DC breakdown strength of epoxy resin, that is, it reduces lubricant effectiveness thereby increasing friction and tear. Temperature shifts will also expand materials while misaligning the equipment, altogether diminishing performance and reliability. Equipment should be maintained by utilizing the correct types of tools to help the worker attain these parameters to protect the optimal operational state.

How does the ambient temperature affect measurements?

Ambient conditions like temperature affect the measurements by influencing the accuracy, precision, and reliability of sensitive instruments and equipment. Some materials, like metals or plastics, will expand or contract due to temperature variations, which results in changed dimensions that impact the calibration and measurement outcome. Altered resistance can happen to some electronic components, causing drifted signals or inaccurate readings.

Thermal Expansion Coefficient: This measures the expansion or contraction of different materials with temperature fluctuation and changes in physical dimensions.

Temperature Coefficient of Resistance: This determines the variance in electrical resistance with different temperature ranges, which affects a sensor’s performance and output.

Measurement Stability: Noise in data acquisition systems or baseline measurements can be impacted by varying temperatures.

Sensor Operating Range: Almost all sensors have designated temperature ranges, and going above the preset can result in inaccuracy and failure.

To eliminate such effects, it is critical to maintain a temperature-controlled environment and incorporate temperature compensation in the measuring systems to attain accurate and reliable data.

What is the importance of monitoring bearing temperature?

Tracking the temperature of the equipment in question is vital to ensure the reliability of the machinery, maximize productivity, and avoid expensive periods of downtime. The equipment’s components operate under very high friction and load, which puts them at risk of overheating due to inadequate lubrication, misalignment, excessive loads, or even contamination. Overheating and prolonged exposure to excess temperatures can negatively impact the material by degrading it, decreasing the lifespan of the bearings, or even resulting in a complete failure.

Normal Operating Temperature Range: Bearings are usually designed to function between 70 to 160 degrees Fahrenheit over long periods. A dip or rise from the norm range should be investigated further.

Temperature Rise Rate: Sharper-than-normal spikes in temperature can indicate a threat to the equipment and prompt immediate manual rectification of the issue at hand, such as lubrication issues.

Alarm and Shutdown Limits: The aim of setting this alarm level is to act before initiating critical damage above 194 degrees Fahrenheit. In comparison, additional power can be withheld at 230 degrees to avoid going over the danger zone.

Combine the previously mentioned points with regular temperature checks, and you will have maintenance that is the epitome of predictive.

What is the Industry Standard for Bearing Temperature?

What are the typical bearing temperature standards?

The typical standards of bearing temperatures depend on the type of bearing, its application, and the conditions under which it operates. Most rolling element bearings work well within the temperature range of 120°F to 160°F (49°C to 71°C) under normal conditions. For grease-lubricated bearings, the upper-temperature limit to avoid lubricant breakdown is usually around 200°F (93°C). While oil-lubricated systems may allow for somewhat higher temperatures, this depends on the stability and specifications of the oil being used.

As for other specific cases, industries typically adhere to the following ranges:

Standard Operating Range: 120°F to 160°F (49°C to 71°C)

Alarm Threshold: Around 194°F (90°C)

Critical Shutdown: Approximately 230°F (110°C)

Careful monitoring and compliance with these temperature ranges will ensure that the bearings and the system as a whole remain durable and reliable. Surpassing these thresholds will likely result in excessive wear, lubricant breakdown, or possibly damage to the equipment. The precise figures for alarm and shutdown will tend to differ based on what the manufacturer suggests and how the system was designed, which, in any case, calls for more outstanding care in maintenance.

How does bearing temperature standard vary across industries?

From my understanding, the power generation and heavy manufacturing industries commonly have stricter regulations on bearing temperature and may expect failures if these thresholds are exceeded. Unlike other industries, heavy manufacturing frequently suffers from equipment malfunction if the 200 degrees Fahrenheit or 93 degrees Celsius threshold is breached. Additionally, the lubricant integrity becomes compromised, leading to unexpected consequences. However, food processing can afford to be much more lenient with the bearing temperature while still ensuring it is being monitored closely.

With bearing temperature tolerances, the attendant technical specifications that are likely to be influenced include:

Lubricant Performance: The lubricant is much more effective when the temperatures are reduced, while the chances of bearing friction and replacement become heightened.

Material Fatigue: A reasonable set temperature surrounding the bearing will increase the lifespan of the materials used.

Thermal Expansion: Overheating the bearing set temperature may lead to additional wear on the system components or misalignment.

Maintenance Intervals: Depending on which industry one works in, rest periods may be altered to counter the overdressing of the bearings due to the heightened temperatures at the working set.

Such reasoning for deviation from universal standards is guided by operations and prioritizes efficiency and the operational life of the equipment.

Why is the maximum operating temperature critical?

The maximum operating temperature is critical because it influences the performance, safety, and lifespan of machinery. Going beyond the outlined limits can lead to grave consequences like the weakening of materials, the lubrication failing to work adequately, and the breakdown of components. For example:

Material Degradation: Some steel alloys generally lose their tensile strength once they are heated above 300°F or 150°C.

Lubricant Breakdown: Many industrial lubricants do not retain their viscosity and other protective features once they are heated above 250°F or 121°C, which creates increased friction and wear.

Thermal Expansion Limits: Components may expand beyond the specified tolerances, which can threaten the mechanical integrity of the part by causing misalignment or increased internal pressure.

Electronic Component Reliability: Semiconductors are prone to permanent damage or unstable functionality if operating outside the outlined 85°C and 125°C safe range.

By adhering to the specified temperature ranges for various materials and system components, industries can save considerable expenses in repairs and unplanned downtime while ensuring optimal performance and extending the equipment’s lifetime.

How to Cool Down Overheated Bearings?

What causes the bearing to overheat?

Bearing overheating is something that can stem from many reasons, all of which are related to operational and circumstantial problems. Some of them are as follows:

Excessive Load: Bearing loads that are beyond their assigned limit can cause excessive friction and heat. Excessing the dynamic load rating C can cause temperature bursts.

Insufficient or Improper Lubrication: Friction tends to increase, causing overheating due to a lack of sufficient lubricant or poor-quality lubricants. A good example would be Viscosity, which does not meet operational speed and temperature standards, such as ISO VG 46-68 for moderately high speeds.

High Rotational Speeds: Increased friction in bearings operating at speeds surpassing n_limit speeds results in greater temperature, thus overheating. Always cross-check the specifications from the bearing manufacturer.

Contamination: Dirt, water, and other elements can enter the bearing and disrupt normal operations by creating friction, which leads to an increase in temperature.

Misalignment or Installation Errors: Poorly mounted shafts tend to have uneven load distribution, which is troublesome because it increases internal friction and overheating.

External Heat Sources: The bearing might be heated due to external factors, such as surrounding components heating up, such as motors and gearboxes.

Addressing these problems swiftly is paramount to avoid excessive wear and ensure optimum performance. Always comply with set technical guidelines, such as suitable load ratings and operational conditions.

What are effective methods to cool the bearing?

Strategic Lubrication: Bearings’ displacement and bearing speed must be considered since they significantly impact the required lubricant viscosity. High-quality lubricants with the appropriate viscosity can minimize elevated temperatures and friction along the contact surface. Increased friction would also require the use of synthetic or specialized lubricants. Furthermore, appropriate intervals for lubrication should be maintained along with the specified operations.

Dissipation Of Required Heating: Galvanic systems can be used for dipping since they increase the surface area required for heat dissipation by cooling systems within the plates. Moreover, using advanced heat pipes also actively helps improve thermal management. Active cooling methods such as forced air cooling systems significantly increase the required range.

Improving Bearing Design: Consider polishing the edges off of the bearing with ceramic or specialized hybrid bearings, as they can endure considerably high temperatures of 1000 degrees Fahrenheit, which is 537 degrees Celsius. The lower the frictional coefficient, the more the heat will be reduced.

Control of Environmental Conditions: The surrounding temperature and air pressure must remain within -22 degrees Fahrenheit to 302 degrees Fahrenheit. Lowering external temperature sources and reducing ventilation around the system can quickly help the bearings maintain tolerable air pressure.

Design Optimally: Eliminate undesirable radial and axial load limits, which the required bearings utilize as their main setting. Restraint overloading, which will increase friction and heat, makes it critical to provide a detailed guideline ensuring adequate load distribution.

If integrated within the perimeters of the specified application, all these methods will ensure the system is equipped with all the necessary thermal stability and optimal performance while increasing the service life of the bearing system aids.

How can proper lubrication prevent overheating?

Appropriate lubrication hinders overheating by lessening the friction between the moving parts of the bearing, and with this, the heat produced. It also ensures the existing heat is removed, guaranteeing the temperature is constant. This objective is of utmost importance for the achievement, so lubricant selection and application play a significant role. Important technical characteristics to focus on are:

Viscosity: Make certain to follow the instructions provided by the bearing manufacturer regarding the lubricant’s viscosity. A low-viscosity lubricant might not have adequate film strength, while a high viscosity will most likely cause excessive energy use, generating heat.

Temperature Range: The lubricant’s capability to withstand the range of the system’s working temperatures, including starting and peak conditions, prevents the modification or obliteration of its lubricating properties.

Application Method: Depending on operating conditions such as speed and load, the best lubrication method, such as grease packing or oil circulation systems, can be chosen.

Reapplication Intervals: Adhering to fixed lubrication intervals will ensure that the lubricant is not aged and is free of “dirt” or any elements that will lessen its effectiveness or strength.

These selected parameters ensure that proper lubrication will prevent overheating and improve the bearing system’s performance and life span.

What Role Does Bearing Installation Play in Temperature Management?

How does incorrect installation affect bearing temperature?

If incorrectly fitted, Bearings may have hugely negative consequences on their function, internal operating temperature, and other factors. With bearings, improper installation practices have ideally been the most avoided factor, which can result in poor alignment, uneven loads, or too much rigidity, all of which entail overheating and amplifying friction. For example:

Mechanical slips reduce the rolling contact, producing non-uniform contact and elevated friction, increasing operating temperatures.

Stress concentrations due to unevenly distributed loads will create more specific or focal issues with elevated interfacial friction.

Too much mechanical stress will contribute to the internal friction considerably, which increases the degree of resistance and takes the temperature to the boiling point.

Due to these forces, compromised lubrication quality comes into play, which greatly shortens the overall life of the bearings and their long-term efficiency and reliability. To minimize these unwanted factors and ensure high-performance conditions, correct installation using precise instrumentation, including adherence to manufacturer directions, is needed.

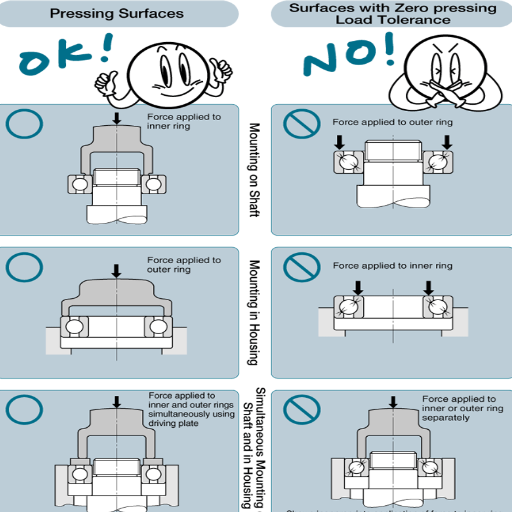

What are the best practices for bearing installation?

As with any process involving fitting a bearing, I try to emphasize elements that seek to accurately and orderly execute the task in a manner that will not compromise effectiveness. Primarily, I ensure that clean and calibrated tools are available to achieve the goal. Contamination is one issue, while incorrect alignment is another problem. Both may result from the use of the wrong tools. If a rotating element is poorly centered, the alignment will be impaired. Consequently, a rise in vibration amplitude will occur, increasing energy consumption and the rotative component wearing out at an accelerated pace.

Afterward, I followed the manufacturer’s instructions regarding the specified preloading and torque values. For example, a primary reason for higher operating temperature is too much of a set preload. Excessive preload values increase the level of friction and temperature in the process equipment, whereas low values render the system unstable, leading these settings to premature failure. Adhering to proper values tends to assist with optimal load mechanical performance.

Finally, I utilize approaches that pay special attention to the accuracy of the mounting process. For instance, hydraulic and thermal mounting techniques, when used properly, do not compromise the bearing’s raceways and rolling elements. This also helps to reduce the bearing surface’s uncontrolled erosion, abnormal load distribution, and overheating.

Lastly, I use the suggested lubricant type and quantity to precisely lubricate the bearings. If these bearings are not lubricated correctly, excessive friction could cause overheating and deterioration of functioning capacity. Proper maintenance allows the bearings to meet the set criteria of temperature, friction, and load while also elongating their lifespan.

How to Select the Right Lubrication for Optimal Bearing Performance?

What types of lubricants are recommended for bearings?

When I am looking to lubricate bearings, the two main categories I consider are greases and oils, which depend on the operating conditions under which the lubricant will operate. For most general-use applications, I pick grease because it is simple to apply, stays in position, and reduces maintenance steps. Grease further assists in the effective sealing of contaminants, thus improving the cleanliness of the bearing and its life span.

However, I tend to lean towards using oils for high-speed or high-temperature applications as they facilitate heat dissipation and lower friction in these strenuous conditions. Having the correct viscosity selection is very important. For example, low-viscosity oils are very favorable in high-speed scenarios, while low pours with higher viscosities work better under heavier loads. These directly influence technical parameters such as the operating temperature, lubrication film stability, friction, and resistance to wear so that the performance is efficient and balanced for the application.

How frequently should bearings be lubricated?

The frequency at which the bearing lubrication is done is determined by multiple factors. These factors include working conditions like temperature, the environment in which the machinery is operated, the speed of the machine, the load, and the workplace’s temperature. I usually suggest checking and relubricating the bearings after every 500 to 1000 operating hours for most common general-purpose applications. However, more extreme environments, like places with severe hot weather or high-speed operations, are often subjected to lubrication way more than once a week or even daily.

Not lubricating it often or enough, or even trying to cut back on maintenance tasks for re-lubrication, is bound to affect the technical parameters of the task directly. For example, inadequate lubrication will undoubtedly lead to increased temperature during the operation, increased friction, and wear, which will ultimately worsen the lifespan of the bearing. On the contrary, operating with excessive lubrication will, in turn, also end up causing more harm by inflicting increased temperature and decreased efficiency due to the overwhelming churning losses. In all these cases, the performance, efficiency, and the machine’s service life are ultimately bound to suffer. This is where my scheduling comes in; by adapting it to fit the operating constraints and considering the working conditions, I ensure that the bearings perform optimally.

What is the impact of lubricant on bearing temperature?

The right amount and type of lubricant improves bearing performance and temperature. In my experience, the right lubricant, when used in proper measure, lowers friction, which leads to reduced heat production in the machine. However, insufficient or wrong lubrication increases the working temperature, enhancing the wear and tear rates and risks accruing thermal breakdowns on the lubricant. On the other hand, under-lubrication can lead to a poor melting point for the lubricant, which can cause additional heating because of churning losses.

The following technical considerations with regards to the temperature of the lubricant and the bearing are:

Friction levels: Try to ensure that proper lubrication is maintained to decrease friction. Inadequate lubrication adds friction, while too much lubrication makes everything too resistant, hence increasing friction.

Operating temperature: Proper lubrication increases the temperature at which machines can work, while overlubrication is likely to reduce efficiency and increase heat levels.

Wear rate: Proper lubrication prolongs the life of the bearing and improves reliability, while improper lubrication reduces its life span.

Efficiency: Over-lubricant reduces the operational effectiveness of the machine because of the energy wasted through the churning.

By picking the appropriate lubricant type, quantity, and condition of my operation, I am able to achieve the necessary temperature control and overall performance while preserving the technical parameters.

Frequently Asked Questions (FAQs)

Q: What are the key factors affecting pump-bearing temperature?

A: Proper lubrication, ambient temperature, and shaft alignment significantly affect pump bearing temperature. An engineer should regularly ensure checks of these factors to maintain a stable temperature. Exceeding the maximum allotted temperature will cause significant problems.

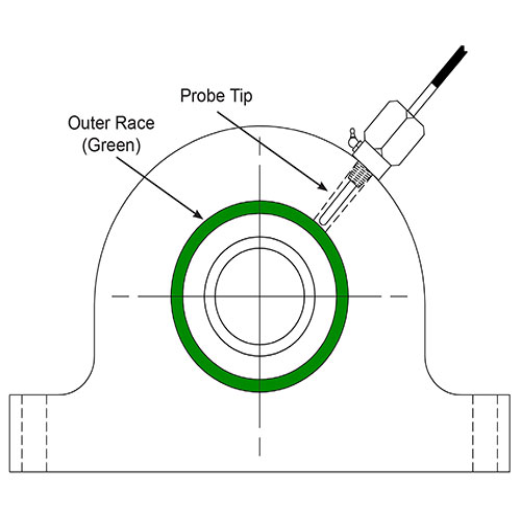

Q: How can I monitor the bearing temperature in a centrifugal pump?

A: Temperature sensors attached to the bearing housing on centrifugal pumps easily monitor temperature. These sensors allow continuous monitoring and will set off an alarm through a control system when the maximum temperature limit is reached. Sump temperature for lubrication will also need to be continuously checked.

Q: What is the recommended maximum temperature for pump bearings?

A: Most applications consider 80C to be the maximum suitable bearing temperature. Certain pumps and their designs can operate differently, so thorough testing is important. Furthermore, the ambient temperature should be regulated to around 40C or above.

Q: In what ways does ambient temperature impact the temperature of the pump bearing?

A: Ambient temperature is quite significant regarding its effect on pump-bearing temperatures. For instance, if the ambient temperature is approximately 40°C (104°F), then the maximum rise of the bearing temperature shall not exceed 40°C (72°F). This also means the maximum bearing temperature must not exceed 80°C (176°F). In the same way, if the ambient temperature is 35°C (95°F), the temperature rise can only be up to 45°C (81°F) to remain within safe limits.

Q: Which Maintenance Practices Should be Done to Achieve Balanced Bearing Temperature?

A: To achieve a balanced bearing temperature, maintenance practices should involve the following: 1. Applying the appropriate type and volume of grease. 2. Inspection of the bearing housing for any signs of wear or damage should be done routinely. 3. Shaft alignment should be checked and adjusted. 4. Clearance between moving parts should not be excessive. 5. External cleaning away from the area is essential to avoid bearing contamination. 6. Temperature readings should be taken at intervals and recorded to note changes over time so that corrective activity can be done before a real issue occurs.

Q: How Often Should Pump Bearings Be Inspected?

A: The frequency of pump bearing inspections varies depending on the conditions of operation and the importance of the particular pump. Usually, bump maintenance involves temperature and vibration readings every month and detailed checks every quarter or every other year. By 2024, it is expected that most pumps will already be fitted with new monitoring systems allowing continuous monitoring of the bearings’ condition.

Q: What factors show a pump bearing experiencing overheating problems?

A: Factors showing a pump remover bearing is overheating might include: 1. Overly excessive noise or vibration from the bearing housing. 2. Charring or discoloration of the outer bearing housing. 3. Leakage of grease in excessive amounts. 4. Increased motor power consumption and overheating of the motor. 5. Any temperature reading that is taken either approaches or surpasses the set maximum. If you notice one or more of these indicators, you must take action to prevent bearing failure.

Q: Why does the temperature stability of the bearing require appropriate shaft alignment?

A: Temperature stability of the bearing requires appropriate shaft alignment as it is vital to its functioning. Any misalignment can result in undue stress on the bearings, leading to increased friction and generating heat. Regular checks on alignments ensure that the motor and pump shafts are correctly aligned, which helps minimize undue stress on the bearings and, in turn, helps maintain the temperature within needed ranges.