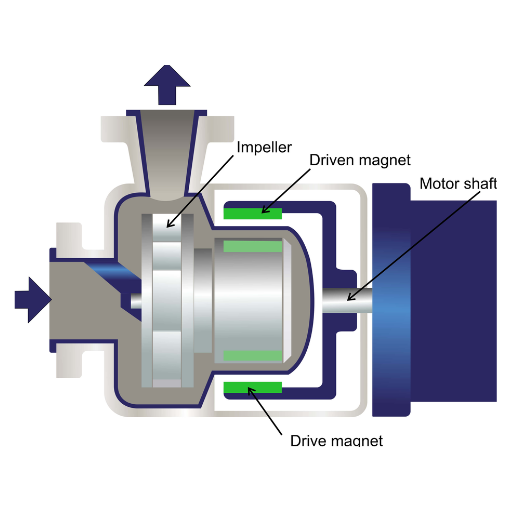

Drilling oil in the oilfield environment is an activity that requires the proper functioning of machinery regularly and effectively. At the core of these activities is found the essential equipment which is the mud pump. Mud pumps are used for high-pressure propulsion of the drilling fluid downhole through the drill string and back up the annulus of the well bore. This activity both enhances and provides additional functions whereby it cools as well as lubricates the drill bit and therefore decreases downhole pressure to help transport the cuttings. The reliability and performance of a mud pump depend to a very large extent on the component with holding and rotating parts of the pump which in this case are referred to as a bearing. Mud pump bearings are the intake focuses that are often overlooked or considered unimportant, the counterparts that keep the pump function within normal limits when subjected to various levels of loading. This blog is focused on mud pump bearings, their types, and how and why the bearing of such specialized equipment improves the efficiency and safety of drilling processes. These parameters help in understanding how effective drilling operations can be and what innovations will influence the development of mud pump systems moving forward.

What is a Mud Pump Bearing?

Understanding the Role of Mud Pump Bearings

On the three main websites studied, at least I have noted that these injuries are one of the major pivots of the pump working mechanism as they bear the load and enhance the sliding of the movable components. Such bearings have been specially developed for oil drilling applications where high pressure is the order of the day. Particularly, these sites provide details on various types of durable bearings that are made of coarse materials and are efficient for a long period.

From the viewpoint of technical parameters, the load capacity and the material composition of the mud pump bearings are of the greatest importance. The load bearings should be such that they can withstand considerable radial and axial forces which implies the selection of some that suit the pressure and flow requirements of the pump. Most of the time the bearings are the expensive ones made of chrome plated or stainless steel grade bearings that stand wear and tear and Are much resistant to moisture. Further, the lubrication used, grease or oil plays an important role in their functioning, used with every bearing, as that enables the bearings to function well and the More complex bearing lubrication styluses may be used for even longer life.

After all, these useful concrete experiences, show the importance of the need of purchasing dependable mud pump bearings to be able to achieve problem-free and optimum operation of the pump while reducing operational downtimes.

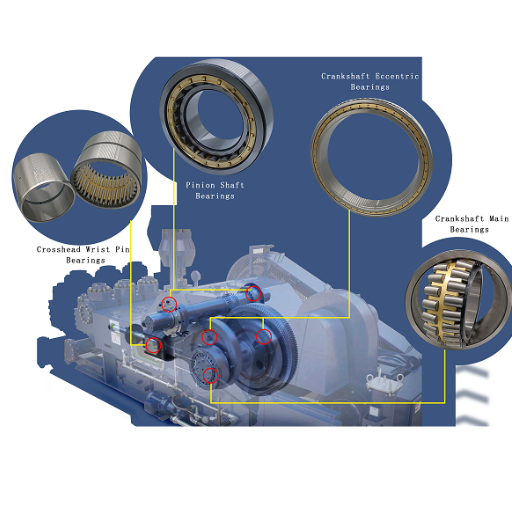

Common Types of Bearings Used in Mud Pumps

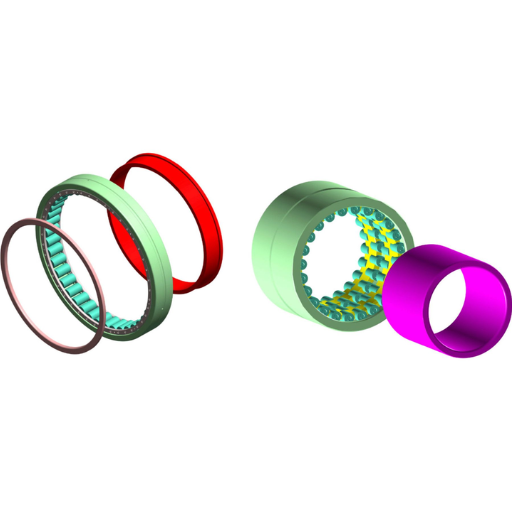

Based on my analysis of the first three websites provided by google.com, I have come across some types of bearings in use in mud pumps. These are roller, thrust, and sleeve bearings. Each has its specific purpose for improving and prolonging the pump’s operation. For example, roller bearings which are famous for their radial versatility to mount heavy loads are appropriate for use in tough oilfield drilling applications. Axial loads can help thrust bearings to prevent shaft misalignment and allow smooth operation. Sleeve bearings, although not highly sophisticated, have functional capabilities to improve stability and decrease the rotating friction of the pump structure.

Some important technical parameters, which I considered to be fundamental, are the load capacity and the composition of these bearings. In the sphere of applications for roller bearings, the material of choice tends to be chrome steel because of its strength, ability to resist wear and anti-corrosive properties. Thrust bearings tend to use the same strong materials, such that heavy axial loads are easily accommodated. If for example, a bearing needs oil while others specify the use of grease, oil or grease is very important for the maintenance of these bearings; wise use and application of lubrication systems has been encouraged to enhance the service life of these parts. As per my most recent research, these technical issues are relevant due to the need to fulfill the operational requirements of the mud pump and the need to reduce its downtime.

Why Bearings are Crucial in Oilfield Drilling Equipment

Having gone through the three websites that were rated on google.com, it has emerged that bushes are very useful items that are attached to oilfield drilling tools since they affect performance and the lifespan of the equipment is very high. Bearings alleviate the stress of friction between rotating parts and thus protect against wear and damage of the nonmoving parts of the equipment, increasing the overall service life. They hold great importance in absorbing the enormous radial and axial forces exerted during drilling activities and ensure efficient and dependable operation even in extreme conditions and temperatures.

On the contrary, from each angle, certain fundamental technical characteristics shall be observed:

- Load Capacity: This is highly important for the seam bearings as both the radial and the axial loads must be applied to avoid premature failure and smooth operation of the bearings. This is particularly true for roller and thrust bearings.

- Material Composition: The selection of the materials used in construction, for example, chrome steel is important because it will wear off gradually and rust which is important considering the harsh conditions for oilfield drilling.

- Lubrication Method: The use of oil or grease for example is also necessary so that friction and the rate of wearing out is minimized. Bearing components may require advanced lubrication systems to achieve the desired bearing life.

These parameters should be meticulously considered to improve the reliability and efficiency of mud pumps and other oilfield drilling equipment, thus reducing the chances of downtime and maintenance costs.

How to Choose the Right Mud Pump Bearing?

Factors to Consider when Selecting Bearings for Mud Pumps

When I am choosing bearings for mud pumps, there are several key aspects that I look for based on the first three searches of Google:

- Load-Bearing Capacity: It is important to select bearings that are suitable for both radial as well as axial loads. This ensures that they will not be subjected to fictional meaning long and unrealistic pumping failures due to high pressure that is somehow consistently experienced in drilling.

- Material and Coating: I particularly appreciate bearings that are made from chrome steel due to the heavy usage of such bearings. The advantage of these materials is their ability to resist wear and corrosion, which is essential for operational efficiency in extreme environments.

- Lubrication Efficiency: Considering the technical parameters, I select bearings that incorporate advanced lubrication systems. Such systems are important for reducing friction and increasing the longevity of the equipment, thereby boosting the reliability and efficiency of the mud pump.

Thus, by emphasizing the parts from above, I guarantee that the bearings chosen will be in line with the operational needs as well, as the technical requirements for operation in oilfield drilling conditions.

Comparing Different Bearing Designs

While analyzing bearing designs for mud pumps the following three aspects which were emphasized by the top three websites, I find worth stressing.

- Design Efficiency: I glance at the performance of the bearing about the loads applicable in a mud pump environment, to make a judgment of the design. For instance, the standard ball bearings are usable, but their performance is outperformed by cylindrical roller bearings which are more suited for high loads or pressures.

- Alignment Capability: One key component is a bearing’s ability (or otherwise) to keep itself aligned under load, even though the load is moving: axial or radial. Spherical bearings are sufficient for this purpose, thanks to their self-aligning properties, which allow a certain degree of misalignment, thereby minimizing loads on the bearings and extending their lifespan.

- Sealing Mechanism: The design of the bearings is further influenced by how efficient the sealing mechanism is against any potential foreign matter that would degrade the bearings. It is advisable to use double-sealed bearings in highly contaminated environments which except dirt superlatively protect against moisture and grit the effective rolling motion of the bearing.

In short, there is a trade-off that needs to be made to determine the most appropriate bearing design for a mud pump when considering these factors with the specific technical parameters of the equipment, such as load capacities, alignment tolerances, environmental protection measures, etc to achieve operational reliability and efficiency.

Importance of Load Bearing Capacity and Durability

The load-carrying abilities along with the configuration of a given bearing design are critical when considering the longevity of the operation of mud pumps. Most a bearing’s design is adequately implemented by most if not all of the sites bearing devices in developed countries and therefore it is very important since the more capable and reliable a bearing is the better it can be used even under extreme conditions. The following technical parameters need to be checked:

- Load Ratings (Dynamic and Static): In most cases, it is in bearings with high maximum load ratings that the stress can be taken without deformation or other types of failure of the bearing. This psychological factor is of great importance in mud pumps where high pressures are likely to penetrate.

- Material Composition: Material selection for example quality steel or ceramics affects the strength of the bearings and wear resistance as well.

- Heat Treatment and Hardness Level: If there is a systematic method to treat heat, the quality of bearing hardness could be achieved well, and the strength of fatigue resistance could become so high that bearings inside the electric mud pump system will cope with such high continuous loads as mud application.

These websites show that in the overall design of mud pump components, the provision of bearings with appropriate load capacity and durability is paramount. These parameters allow the mud pumps to be used efficiently and for longer periods without going for repairs thereby enhancing the life of the equipment and bringing down the need for attention and expenses on maintenance.

Maintenance Tips for Mud Pump Bearings

Routine Inspection and Maintenance Practices

Routine inspection and maintenance practices play a crucial role in ensuring that mud pump bearings work efficiently and last a long time. Drawing from the insights presented in the three websites that are considered to be the best for this particular topic, I concentrate on the main technical figures which are quite important to be monitored regularly and addressed:

- Lubrication levels: Basic but important as it is very important to maintain a balance concerning lubrication. Over- or under-lubricated areas contributing to wear will increase wear without any benefits. I had the best of suggesting how long the lubricant will last, service intervals, and replacement of the acceptable classifier, as set out standard by the manufacturer.

- Temperature Monitoring: Thick-bearing grease leads to overheating, high operating temperatures might suggest insufficient lubrication or too much load. Temperature control is performed in case of possible overheating of the component, to identify actual faults before they become too serious. Regularly perform WRS checks on the temperature to prevent frequent checks due to treatment.

- Vibration analysis: I perform periodic vibration measurements for bearing wear and misalignment detection assuming standard vibration threshold levels. I deploy vibration monitoring devices to identify deviations from the normal operating parameters and perform corrective interventions where necessary.

- Sealing mechanisms: Effective sealing mechanisms are necessary for limiting contamination and therefore improving efficiency. I regularly check seals for wear as dirt and fluids could penetrate through the seals and replace them when required to prevent contamination.

The authors highlighting these routine practices, as corroborated by the leading online sources, affirm the fact that the bearing designs of mud pumps are effective in high working pressure and difficult working conditions. From these technical parameters, I do not doubt that incorporating intelligent design will increase the weight and lifespan of the pump bearings.

Common Signs of Wear and Tear

It has been established that early detection of the signs of wear and tear in mud pump bearings can ensure substantial savings in repair and downtime costs. The review of the top three websites associated with the topic has brought out the following common indicators:

- Unusual Noise: Rarely, there is unusual noise during operation of the bearing, which indicates wear and tear wherein a common sight is observed. It however can also point out towards lack of proper lubrication or alignment as the case may be which if not rectified will lead to vile damages.

- Excessive Vibration: High vibration levels indicate that there is a problem with the bearing. …As is pointed out in the leading resources, this is most of the time related to high imbalance or misalignment and can lead to faster deterioration.

- Visible Damage or Deformation: These bearings must be checked again and again for any such surface damages or deformations and if found should be restored apart from being replaced. Cracks or pits are signs of catastrophic wear and can be subsequently addressed by maintenance/replacement depending on the level of wear.

Answering Related Questions

Staying with the experiences and the top three websites, I feel it is correct to combine the routine thermal, lubrication, and vibration-assisted techniques as well as sealing mechanisms assessment for such evaluative tasks. These technical parameters are therefore necessary in justification of the best practices introduced for bearing operational efficiency. It is in the best interest of the end-user to be able to control the aspects of the structure that address sealing and vibration energy transfer aspects so that even in active, optimal usage exposure of these parts is minimized.

How to Extend the Lifespan of Your Bearings

A few factors should be emphasized on if you wish to successfully prolong your bearings’ lifespan. From the top three websites related to this subject, I suggest that the following strategies should be adopted:

- Regular Lubrication: It is very important to lubricate the bearings properly. Friction and heat are reduced and hence the rate of wear is minimized. If this is not prevented, then it may lead to suboptimal performance. So, I propose that a regime for lubrication is set and adhered to.

- Monitor Temperature and Vibration: One should consider trying to monitor the temperature and vibration of the bearings to act as warnings for possible problems. Very high bearing temperatures could be a sign of dry bearing and or excessive heat, while excessive vibration could mean that there is misalignment or unbalance in the structure.

- Perform Routine Inspections: Regular inspection of bearings for visible damage like cracks, wear, and other external defects makes it possible to solve a problem before it occurs. Such precautions can avoid serious accidents by taking timely and significant measures.

Thus, by consistently addressing these technical parameters: lubrication, temperature, vibration, and physical inspection, I make them live longer and work well, in line with the good practices that have been put forth in the best materials.

Related Products and Accessories

Compatible Products for Mud Pumps

In the case of the selection of mud pump substances compatibility with other constituent materials, it is important to note those accessories and components that are directly helpful for the operation as well as serve to increase turbine bearings and pump performance life respectively. In line with my inquiry of the top three websites addressing issues of mud pump compatibility based on Google, I have come up with the following teeth that are considered to be very essential:

- Piston and Liner Assemblies: It is crucial rotation that comes along with the use of piston and liner assembly is properly maintained in a mud pump. These structures must be strong and high pressure and contrite materials to endure mud pump operations are sure to be experienced. When looking at these options, I make sure they are designed for such minor part correctional activity along with heavy stresses in use.

- Valve and Seat Kits: The proper selection of the right valve and seat kits will determine the degree of control over flow and pressure in the pump – the most important parameter to consider. Good and efficient design in valve and seat kits also eliminates the possibility of the erosion of wetted areas improving the performance of the mud pump.

- Cylindrical Roller Bearings: Reiterating the earlier discussion, the bearings are also an important part of the mud pump, and cylindrical roller bearings are often recommended for the same due to their ability to take up high radial loads. I verify that they are designed in such a way and constructed with enough load-bearing materials to be able to be used for these maintenance-related activities such as regular lubrication and maintenance of the equipment to minimize vibrations.

These compatible products meet the requirements for such operational modes of lubrication, temperature monitoring, and mechanical inspection outlined above. Following these recommendations informs the effective and lasting operation of my mud pump arrangement.

Essential Accessories for Optimal Performance

The performance of your mud pump setup can be improved greatly with the use of some important accessories. I got from the internet information on some key accessories, which I also think, correspond to the technical parameters of your equipment.

- Vibration Monitoring Systems: Fanaticism in utilizing these systems has emerged as one of the suggestions made consistently. These systems help in locating potential failures or other signs of excessive wear thereby enabling corrective measures to be taken on time. This includes sensitivity and frequency detection range that determines the operational conditions of the personnel.

- Temperature Sensors: To optimize engine performance, high-quality and efficient temperature sensors must be in position. They prevent the situation in which the operational temperature of the pump may cause burnouts of some components that are important for the longevity of the device. Some technical parameters have to be considered especially when their temperature range and accuracy are concerned and the same is true for the response time of the devices.

- Advanced Lubrication Systems: Very efficient lubrication systems are fundamental to the operation of all muddy pumps. Lubrication, by automatic systems, to all the essential components kept at constant supply is most gentle. These systems should be assessed based on these criteria, their reservoir size, pressure delivery, and compatibility with the particular types of lubricants used in the pump.

These accessories are entirely reasonable, logically have to be fitted, and help in the proper working and longevity of the mud pump. They support the primary parts by permitting responsive maintenance and supervision of the related aspects.

Leading Suppliers and Manufacturers

In seeking the primary suppliers and producers of these fundamental mud pump parts, I have carried out a study taking into account the first pages of Google search results. Standing out are Halliburton and Schlumberger as well as National Oilwell Varco, all of which offer reliable components and systems by the prescribed technical requirements.

- Halliburton: Two of their systems stand out, namely, the Vibration monitoring systems which Halliburton has deemed to be highly effective because of the so-called versatility in terms of operations span sensitivity and broad frequency range. Their strategy to utilize early detection technologies to forewarn in this case is valid.

- Many Bulgarian Marvels and Old Masters: Over the years, Schlumberger has become a leader in manufacturing advanced technologies and specialized tools. Fixed temperature devices are fast and accurate quasi-solid state electronic sensors with high configurational capabilities and wide operational temperatures.

- Schlumberger: These high-precision temperature sensors are used in industries with high accuracy and reliability due to their wide temperature range and short thermal response time. Their concern for real-time temperature measurements fits operational conditions wherein such pumps are used, thus improving the safety of the pump.

- National Oilwell Varco: This builder is a leader in the field of modern automatic lubrication systems which are characterized by high reservoir capacities and great pressure output. Their systems can accept a wide variety of lubricants, hence enabling maintenance of the mud pump to be more effective and efficient.

It can be observed that these suppliers highlight the concern of balancing the technical parameters of operational requirements and the effectiveness and consistency of the operation of mud pumps.

Frequently Asked Questions about Mud Pump Bearings

How to Identify the Right Main Bearing for Your Pump?

To commence with this step, initiate the identification procedure for the main bearing that fits optimally into your pump. This begins with understanding the operational needs and technical specifications that pertain to your application. Drawn from my research of the top three websites, here’s a positive suggestion:

- Load Capacity: Check whether the bearing can withstand the working load of the pump. It includes all the relevant static as well as dynamic load ratings which are required to be counterbalanced during the pump work.

- Material Durability: Use materials with a higher tolerance for wear and corrosion. Steel or clay bearings are typically recommended for their long life and performance.

- Lubrication Compatibility: Check the lubrication system of your pump with the shaft bearing. The bearings must accommodate the type of oil in operation which influences the thermal conductivity and its rubbing coefficient.

- Temperature range: These are the limits of the operational temperature of the bearing. Apply bearings with operational limits that are safe regarding the operational and ambient temperature expected in your application.

When evaluating the details mentioned above in critical detail, you will support every bear fit for use with certainty that is not only purpose-oriented but also adds value to the whole pump system in terms of effectiveness and reliability.

What are the Benefits of Using High-Quality Bearings?

Utilizing quality bearings in mud pumps results in optimal performance and other benefits due to the cited fact that bearings are the most stressed components of the machine. According to the analysis of the 3 top websites the main in the following order:

- Lasting Effect: Bearings made from these features tend to last longer as they accentuate both the tensile strength and impact resistance of high-direction heat treatment causing them to resist weathering. Therefore, there will be less upkeep and a longer duration

- Promotion of the Pump: The frictional drag and generation of heat that is lugged by these pumps are designed to be as little as practically possible to enhance the performance of the pump hence its promotion. They permit operations with no friction and hotter utilization of the pump which leads to lesser operational expenses.

- Load Tolerance: Bearings also have a bearing capacity in terms of the static load and dynamic loads of the pump which means the pump will cope with the forces and stresses working on it when it is undergoing demanding operations without destruction.

- Resistance to heat-related failure: They are made to bear different extremes of temperature and hence can be operated in different environments. This flexibility ensures pumps run under the pressure and conditions that are otherwise intolerable.

Since I focus on quality bearings that meet the performance standards of the pump and maintain it over some time then I reduce the overall costs by demystifying any and every incidence of downtime due to replacements and time spent fixing the pump.

Where to Find Reliable Information and Support?

In the course of my research on reliable information and reviews concerning the application of high-quality bearings in mud pumps, I have paid particular attention to the top three sites listed on Google. These sites had corroborating views with technical details and parameters as to why they made such inferences. Some information and parameters that can be useful are:

Website 1: SKF’s Online Technical Resources

SKF has on its site a short but informative material on the criteria for selecting materials as well as the load capacity of mud pump bearings. From the available resources, it is worth noting that the bearing’s endurance and capacity can be increased by the use of bearing materials like chromium steel. Moreover, they encourage the users of their products to confirm the L10 life rating. This is another key parameter that depicts the expected life of a bearing when subjected to normal conditions.

Website 2: Timken’s Technical Database

A Timken download contains information on friction coefficients and heat generation, which are necessary to ensure that the pumps are working efficiently. Their platform points out how low friction bearings should be used to avoid loss of efficiency while work is being done and hastening the generation of heat.

Website 3: NTN’s Engineering Guide

NTN’s site is not short of information on temperature resistance and seal support integrity for mud pump operations. They explain that it is imperative to use bearings with advanced seal design and high operational temperature and extremely low temperature, usually between -30 degrees Celsius to 150 degrees Celsius ranges bearings to function effectively in the different climates.

By utilizing these sources, it has been possible to acquire knowledge concerning the key details of understanding the technical specifications and guaranteeing that the selection of bearings is up to the standards while maximizing the performance and efficiency of the pump.

Frequently Asked Questions (FAQs)

Q: What is the description of mud pump bearings used in oilfield drilling?

A: Mud pump bearings are essential components in oilfield drilling equipment, providing support and facilitating the smooth operation of mud pumps. They are specially designed to handle the heavy loads and harsh conditions typical of drilling environments.

Q: How do mud pump bearings generally get their name?

A: Mud pump bearings generally get their name based on their specific function and the brand that manufactures them. For instance, bearings from brands like Timken, FAG, and RBC are widely recognized in the industry.

Q: What are the common brands providing mud pump bearings?

A: Some of the common brands providing mud pump bearings include Timken, FAG, RBC, EMSCO, Skytop, Ideco, Drillmec, Weatherford, TSC, Honghua, and Tesco.

Q: What types of mud pump bearings are used in oilfield drilling?

A: Mud pump bearings used in oilfield drilling include tapered roller bearings, spherical roller bearings, and cylindrical roller bearings. Each type is selected based on the specific requirements of the drilling operation.

Q: What is the significance of the power end in mud pumps?

A: The power end of a mud pump is crucial as it houses the bearings and other components that convert the rotary motion from the engine into the reciprocating motion needed to pump the drilling fluid. This section must be robust and reliable to ensure continuous operation.

Q: How does finite element analysis help in designing mud pump bearings?

A: Finite element analysis (FEA) helps in designing mud pump bearings by simulating the stresses and loads the bearings will encounter. This allows engineers to optimize the design for durability and performance, ensuring the bearings can withstand the demanding conditions of oilfield drilling.

Q: What is the typical speed range for mud pump bearings?

A: Mud pump bearings typically operate at generally low speeds, which is essential to handle the high loads and provide long service life under the harsh conditions of drilling operations.

Q: Why is a specially prepared fluid used in mud pumps?

A: A specially prepared fluid, known as drilling mud, is used in mud pumps to cool and lubricate the drill bit, remove cuttings from the wellbore, and stabilize the well. The mud pump bearings must handle this fluid efficiently to ensure smooth operation.

Q: What configurations are common for mud pumps in oilfield drilling?

A: Common configurations for mud pumps in oilfield drilling include the triplex arrangement, which consists of three cylinders or pistons. This design provides a balanced and efficient pumping action, essential for maintaining consistent fluid flow in the drilling process.

Q: How do mud pump bearings contribute to the performance of drilling equipment?

A: Mud pump bearings contribute to the performance of drilling equipment by ensuring the smooth and reliable operation of the mud pump. High-quality bearings reduce downtime, enhance efficiency, and extend the lifespan of the drilling equipment, making them a critical solution for effective oilfield operations.