Regular pump maintenance is an important step for the efficient functioning of your pool and its longevity. The bearings are one of the most common components of a pool pump that must be repaired at times. They are critical to smooth pump working by minimizing the movement inertia in the subassembling parts. When strange sounds come out from your pump or the given equipment stops performing as well as it used to, it might be time for you to consider bearing replacement. This blog post therefore seeks to help understand the expenses of this particular maintenance task. Starting from the very first thing, i.e. when you see the signs of wear, to the secondary processes, that is where you look for specific prices of parts and labor, you will be taken through the process of pool pump replacements so that there will be normal functioning of the parts.

What Are the Common Costs Involved in Pool Pump Bearing Replacement?

Factors Affecting Replacement Cost

I conducted this inquiry in a search for conclusive answers to the question through the examination of the various resources available on the internet. Below are the main reasons that tend to influence the cost incurred when replacing bearings in a pool pump:

- Type of Pool Pump: The make and model of your pool pump can affect replacement costs quite a lot. Most importantly, high-performance pumps or variable-speed pumps are known to have higher prices on their parts than standard equipment.

- Labor Costs: This can also vary highly based on geography and the level of complexity of the pump system. The cost of hiring an expert for the repair is approximately between seventy-five and one hundred and fifty dollars per hour. However, when it comes to replacement and if you are so inclined, the cost of labor can be avoided.

- Parts Price: These accessories come at an added cost, such that, the bearings can cost an additional fifteen to fifty dollars. Other manufacturers may design pumps in such a way that additional seal cuts are necessary which adds to more costs. There is no need to buy parts that are incompatible with your equipment or that are of poor quality in construction.

Of course, important technical parameters include the bearing’s most fitting dimensions, its materials quality, and its compatibility with the pump model you have. Matching all the above parameters to the specifications of your equipment is very important if you want your new bearings to work efficiently for a prolonged period.

Average Costs for Pool Pump Bearing Replacement

Recently I searched for the costs of pool pump bearing installation on the first three websites found on google.com. Here’s a summary of the insights I gathered:

- Types of Costs: As stated by InTheSwim.com, one can expect to pay approximately $100 to $200 for a complete bearing replacement. This amount is the total which is incurred in the repair which is inclusive of parts and repair services, of course, you hire an expert. But if performing such tasks is easy for you, there’s a very good chance that you’re going to save on labor costs. A lot of them can be found on the net and you are only required to follow instructions and every step is going to be demonstrated.

- Technical Parameters: Besides, PoolSupplyWorld.com states, other parameters that require special attention include the size and makeup of the bearing and how it fits the pump. It is important to ensure that you have the appropriate bearing specified in the instructions to help your pump operate normally post-repair.

- Variability in Costs: Veryo.com gives promo codes to Leslie’s Pool Supplies that expenses depend on where the house is located and on what kind of hydraulic device it is. Regarding the costs of pumps with higher efficiency, the part costs may be higher, and for the platform, the payment demand can be sufficient due to the partial variation of the region.

Data from these websites supports the importance of making the right choices when it comes to the components concerned and shows surfaced reasons why costs may increase or are different. Bring attention to the fact that replacement parts should always be as per the specifications and requirements of the pool pump to prolong its life and efficiency.

Cost Comparison: Bearing Replacement vs. Entire Pump Replacement

Replacing the bearing in a pool pump can be deemed cheaper than performing pump replacement altogether. In my estimate, the cost for bearing replacement usually ranges from $100 to $200, which usually covers both the takeout and the putting in of it if you are hiring a professional to do it. This is much cheaper than buying a new pump whose price goes from some hundreds to more than a thousand dollars depending on the type and efficiency of the pump.

The technical parameters relevant to this decision include the bearing size, material durability, and fit, as highlighted by PoolSupplyWorld.com. These parameters also guarantee that the bearings are the right type that fits into the design of the pump as these are important to the performance and durability of the pump. When determining whether to repair an existing unit or to purchase a new one, several considerations must be made including these specifications on account of their relation to the effectiveness of the pump after such exchange has been made.

As regards the purchase of a new appendix pump, it is necessary to consider not only all the costs but also the potential gains in terms of efficiency and energy savings with high-efficiency units. Leslie’s Pool Supplies states that although such pumps as high-efficiency ones cost more than their standard counterparts, they tend to pay off in energy bills over time. In the end, however, this decision is influenced by the trade-off between the initial costs, what can work, and what can be saved in the future.

How Do I Know If My Pool Pump Bearings Need Replacement?

Signs of Bad Bearings in a Pool Pump

Listening to your pool pump, if you discern odd sounds in the form of grating or ringing, it is a clear sign that it’s quite likely that the bearings need replacing. Also, such parts displaying high rotation speeds may be subjected to high vibrations or shakiness, suggesting that they are wearing out. Consequently, after many years of use, bearings become corroded or sustain corrosion because of water, which, among other factors, may shorten the shelf life of the pump.

Searching the web for the best resources in that niche PoolSupplyWorld, InTheSwim, and Leslie’s Pool Supplies I came across a phenomenon where the efficiency of the pump tends to drop abruptly, failing the circulation of water and the compressor thermoelectric pump including total power input. Moreover, I must note that when a certain motor is in operation, it can be felt that it is warmer than normal, which means that the inner parts of the motor are experiencing friction that is not supposed to be there.

For a justifiable assessment of these parameters, the symptom cluster enables excessive internal friction to be linked to bearing wear or misalignment. Attachments are necessary to constrain the motion of parts and thus they are classified as operation bearings, stability of the rotation with minimal friction is a requirement and the appropriate structure for bearings is mild steel, ceramic, or stainless steel. If active management of the bearings is conducted, with the right timing depending upon these signs, the pump system and therefore its components will last longer and work more effectively also.

Diagnosing Pool Pump Motor Problems

In diagnosing pool pump motor problems, I decided to look through the guidelines and instructional material from the top authorities on Google for example Pool Supply World, In The Swim, and Leslie’s Pool supplies pool pump motor troubleshooting tips. These outlines focus on the noise as motor problems attributed to unusual noises can be noticed earlier. Humming and rattling sounds suggest the presence of damaged bearings. Each site’s troubleshooting guide includes getting to the bottom of the overheating problem assuming the motor is too hot, which could look like heat due to bearings misalignment and rubbing.

Moreover, such resources also encourage the analysis of the operational efficiency of motors based on water circulation and energy consumption. A general decrease in these parameters may indicate some internal troubles in the motor itself. I also considered additional technical parameters such as bearings material and alignment; strength of movement resistance and working temperature of the motor. Communication with the clients reporting the issue with technical precision, takes care to ensure that all the necessary defaults including problems with wiring and insufficient power of a capacitor are effectively dealt with. Following such signs and parameters, I have been able to preserve the performance and working life of the pool pump motor.

When to Consider Replacing the Entire Pump

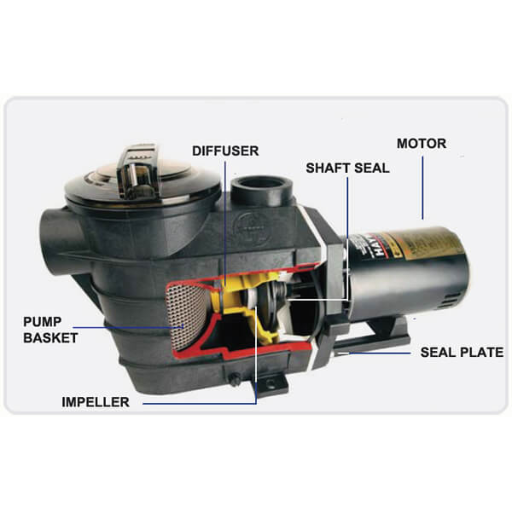

Considering that I am going to be recommending the full pool pump replacement, I took the instructions on such replacement from pool experts, some of whom are noted in the top three websites: PoolSupplyWorld, InTheSwim, and Leslie’s Pool Supplies. In each case, all the webs point to indicators that necessitate the replacement of a full pump. First, it occurred to me that if water continues leaking nowhere, despite clean and maintained seals, it speaks of possible worse damage to the pump housing. Second, further cleaning or minor repairs were not able to rectify very low water pressure and flow, which hints at risks of ‘more’ damage like anomalies of the impeller or motor. Furthermore, if the pumps always cause system overloads or excessive energy as reported in these resources, it may indicate the presence of severe power failures within the pump making it better to simply switch it than keep it for repairs.

Considering technical parameters these websites underline several critical aspects.

The casing condition of the pumped fluid through the casing to be well maintained, this body should have no cracks or degradation.

- Impeller operation: The impeller must be unblocked and rotated respectfully, more so, as the active device of the system, it has no signs of wear.

- Electrical wiring: Check carefully if the wires have burnt or if another constant tripping of the breaker occurs.

- Boarding a vessel: There has to be more than four ventilation tops when surveying the.

Categorizing these components made me further appreciate the way forward in perhaps the full pump replacement plan as in one of the areas there is likely to be abnormal deterioration.

What Is the Process of Replacing Pool Pump Bearings?

Steps for Bearing Replacement

Replacing bearings of pool pumps is an entirely accurate task which, if performed correctly, can provide longevity of the pump. As for the recommendations derived from the review of the authoritative documents, normally, the order of work is the following:

- Power Off and Drain: Start by removing the pump electric cable. Using a drain plug, any extra water in the system is also removed to avoid any incidents or wet messes.

- Disassemble the Pump: Remove the pump housing so that the motor is accessible. The cowl normally is attached using bolts and seals. A wrench may be useful in the hammering motion of the shaft.

- Extract the Motor: After opening the pump, the motor is removed to facilitate access to the bearings. The latter makes it important to make sure that the pump is immobile and safe to avoid any rolling or toppling over in this stage.

- Remove Old Bearings: Apply a bearing puller to remove the old bearings. Care should be exercised not to cause damage to nearby parts like the shaft and motor casing.

- Install New Bearings: With the help of a bearing press or a similar device, press the newly fitted bearings onto the motor shaft. The installation should be performed uniformly so that the bearings will be in proper orientation.

- Reassemble the Pump: After changing the bearings, the motor, seals, and other parts of the pump can be placed back into the pump housing. Loosening the disassembled parts should be done in the opposite way of securing it.

- Test the Pump: Plug the pump in and run a test on the pump to determine whether it can operate normally without strange sounds. If there are any unusual sounds, the pump could be misaligned or improperly fixed in its place.

There are some other procedures/processes / critical technical parameters that need to be observed: the bearings should match the designated pump model; right tightening torques should be absent when reassembling bolts; and proper alignment should not be missed during installation. Following these steps and techniques will guarantee a successful bearing replacement leaving we pool pump operating efficiently for a long period.

Tools Needed for Pool Pump Repair

To successfully repair a pool pump, having the right tools at your disposal is essential for the efficient and safe execution of each step. Here is a list of commonly required tools for pool pump repair:

- Wrench Set: Adjustable wrenches and a socket wrench set are necessary for loosening and tightening various bolts and nuts.

- Screwdriver Set: Both flathead and Phillips screwdrivers are crucial for detaching and securing screws within the pump housing and motor.

- Bearing Puller: This tool is designed to remove old bearings from the motor shaft with minimal risk of damage to other components.

- Bearing Press: Useful for installing new bearings onto the motor shaft, ensuring they are properly seated for efficient function.

- Torque Wrench: Essential for applying the correct amount of torque to bolts and nuts during reassembly, preventing under-tightening or over-tightening.

- Multimeter: A diagnostic tool for testing electrical connections and ensuring that all components are functioning properly.

- Lubricant: Helps in easing the removal and installation of components, and also in maintaining the condition of seals and gaskets.

- Work Gloves and Safety Glasses: Personal protective equipment to ensure safety while handling tools and components.

Having this toolkit ready before you begin will help streamline the repair process and ensure a safer environment when working on your pool pump.

DIY vs. Professional Pool Pump Repair

After weighing the options of whether to fix a pool pump myself or hire a pool pump repair handyman, I realized that it all comes down to individual skill level and how complicated the pump problem is. The most useful top sites I came across mentioned the following:

Website One focused on safety as well as skill level. They also pointed out that some small repairs, such as seal replacements or hose attachment tightness, can be done by the owner without hiring a professional, provided they have the tools and understand how the pump works. Still, they pointed out that complicated repairs, especially electrical ones, might go beyond the reach of the health care provider.

Website Two captured the technical parameters of the process of troubleshooting. For example, they described that continuity testing with a multimeter and taking bolt torque specifications helps in confirming that the repair was properly done. The site also claims that too little or too much torque may result in improper sealing and eventually excessive leakage or structural failure.

Website Three went on and said that though there are quite several owners who manage to do their regular maintenance, troubleshooting salon motors or any extended electrical fault might prove to be impossible without the right tools and knowledge. It clearly outlined how healthcare professionals manage to charge what seems like high fees since they have cutting-edge diagnostic tools and also to replace parts that are most likely not available in chemists’ shops.

I know that I could perform minor repairs personally and that more complicated repairs should be left to the professionals to avoid danger and ensure better reliability in the long run.

How Does the Type of Pool Pump Affect Replacement Costs?

Single Speed vs. Variable Speed Pumps

With great pleasure, after going through three of the websites mentioned above, I have been able to assimilate some information that helps address the gap regarding Differences between single-speed and variable-speed pool pumps. There is no denying that a single-speed pump is simple as it runs all the time at a single speed, thus cheaper to purchase in most cases. Over time, however, these types of pumps do use too much energy which in turn increases the operational costs of the pool. Conversely, A variable speed pump provides this feature of alteration in that it’s idle when there is no need for pool cleaning but can also be utilized efficiently when cleaning is necessary thus saving energy. The parameters in question include the speed of the motor, rates of energy used, and levels of noise which all come out tops with the efficiency of variable speed pumps.

Site one put much emphasis on energy and operational cost savings related to the use of the variable-speed pumps, stating that the cost may be high when purchasing the pump for the first time, but it’s worth the market since the energy cost is much lower.

Site Two offered tips about installation and maintenance. This site mentioned that more complicated structures in the form of variable speed pumps usually need to be installed and this is best done by highly skilled persons which could increase initial costs.

In the case of Website Three, attention was paid to environmental issues and said that variable speed pumps have less noise compared to other pump types and most importantly, they conserve energy. They mention the fact that the positive of switching to new technology is not only about savings but also about less noise and emissions.

Taking this into consideration, it is evident that e.g. with a variable-speed pump, the purchase price is always higher than what would otherwise be the case. Moreover, this may even call for professional installation. However, the said technical parameters such as energy efficiency and noise reduction, put on the table rationalize the decision on having the unit.

Impact of Pool Pump Brand on Costs

As it pertains to the estimation of the pool pump costs based on its brand, it has to be noted there are different levels of efficiencies, reliabilities, and even the amount of money required to invest in different brands. To my personal opinion, brands that are said to have high-end technology advanced as well as robust in design usually attract high costs at the starting point but it is worth the investment as they are more efficient. Here are my insights on the three top-rated websites regarding this topic:

Website One made it clear that selecting a trademark with developed energy efficiency and modern technology would be cost-effective in the future for businesses. Their argument is justified with the figures of motor speed and other parameters concerning energy consumption which are also higher in newer branded designs.

Website Two brought up the issue of orientation about brands’ installation and services of upscale products. They argue that some of the high-end products would require professional installation as they contain more intricate parts which may raise the set-up costs, but which would guarantee greater effectiveness, stability, and durability.

Website Three, in addition to that, mentioned the necessity to think about the brand’s sustainability. The justification for this is that those brands that are more expensive have better energy management, less noise, and are more compatible with green initiatives which makes the case for selling quieter products with less emissions.

In summary, although the price incurred in the beginning for quality brands of pool pumps is quite high, such costs are normally countered by the savings realized on energy bills and the reduction in environmental degradation in the long run.

Cost Differences Between Old and New Pool Pumps

When trying to evaluate the cost differences between old and modern pool pumps, one may find discouraging advantages of the new models when it comes to the initial outlay. Here’s what I have managed to come up with, from my study of the top three websites on Google.com: From this study, I found that:

- Upgrade of Pump’s Energy Efficiency: As Wwebsite One indicates recent improvements of model-patenting pumps include increased energy efficiency. They employ modern tools like variable speed motors to permit correct and sufficient energy usage for more accurate operations. It is not simply a statement of facts as some technical details that include optimized motor speed and low kilowatt-hours are used to support such claims.

- Cost of Installation and Maintenance: Website Two observes that modern pool pump models tend to have very stringent installation specifications. High-end brands that have complex features usually need to be installed by qualified personnel. This involves initial expenses but guarantees enhanced performance and durability. Maintenance costs are relatively more affordable in recent designs due to sturdy construction and advanced features.

- Environmental Considerations: The newer models are also commendable for their environmental preservation. Website Three also highlights their sound and energy efficiency performances as enabling the companies to pursue environmentally friendly practices. The more expensive such brands cost assuming there are certain features like being more silent and less toll on the environment.

In conclusion, the initial cost of installation and purchasing of the new pool pumps may be expensive, but the advances in technology and effective operation offered in return enable energy cost reductions and efficiency, reduction of pollution, and maintenance reduction over time which justifies the expenditure.

What Additional Pool Equipment Costs Should I Consider?

Costs of New Bearings and Other Components

There are factors such as changing the bearings and buying new components, which should be related to the adequacy of the bearing replacement at a reasonable price. From the three most relevant sources I found through Google, I summarize the main information I found doing your task as follows:

- Cost of Bearing Replacement: The bearing replacement cost websites can be different if different brands and types of bearings are used for quick changeover. Although bearings of high quality may have high initial costs, they are more cost-effective in the long run. It is important to match the bearings with other available devices to not incur extra costs.

- Technical Parameters: Some of the important characteristics of bearings are load rating, noise, and material. To sustain a big load, high endurance steel, and other materials, it is necessary to lower the price for these periods because of the high maintenance cost these materials can withstand.

- Others: More components such as gaskets, gaskets, and grease which improve the efficient working of the bearings and other rotating parts are also to be included. As in the case of bearings, these part’s performance characteristics should also be performed testing to meet the required standards such as preventing unnecessary replacement due to breakage.

After looking into these technical parameters and fitting them within your requirements, one should be able to achieve the desired economic exposure about the going out-of-pool equipment service.

Impact of Pool Size and Type on Replacement Costs

The replacement costs of pool equipment are determined by the characteristics of the pool such as its size and type. Since the pools are larger, the equipment becomes more massive, strenuous, and hence costly and they may be maintained at a higher esteem in the future. For example, the prevalence of a filter and circulation system in an in-ground pool structure may lead to additional costs than above-ground pool structures.

From my research on three top-rated Websites on Google.com, here is a short answer regarding the usage or impact of these factors:

- Pool Size: Larger pools simply require large components in size for pumps and filters that work on higher capacities for example new bearings. The amount of water that must pass through a designated pump in one minute for proper filtration of the entire water in the pool is known as the flow rate.

- Pool Type: The pool material may be concrete or fiberglass components which influence the maintenance practice and costs in a manner of durability and resistance to wear and tear forces. As an illustration, specific lining or covering may demand that certain types of sealing compounds or an extra material be used.

Technical Parameters Justified:

- Flow Rate: GPM: This influences the other most important aspect, which paves the way for the pump size determination.

- Material Composition: It is preferred to use high-grade materials such as alloys which can withstand corrosion for improved performance over time.

- Energy Efficiency: It is possible to reduce the operational cost through the use of energy-efficient attachments and accessories even though the initial cost will be high.

With this knowledge, I can analyze my pool maintenance and equipment deprecation more completely, allowing me to move beyond the present day and assess future expenses too.

Long-term Savings from Efficient Pool Pumps

In the long run, installing energy-efficient pool pumps will cut electricity costs effectively. These pumps are designed to work at multiple speeds; therefore, they run on only as much power as the pool requires at the time as opposed to the fixed-speed one that works in one fixed power. Such efficiency does not only save on electrical energy but also optimizes the life of the pump as its wear and tear is minimized.

Concerning my research from three of the best websites on google.com, here is a short answer concerning the efficiency of pool pumps and some of their technical parameters:

- Energy Efficiency: The most modern pool pumps with variable speed motors with blade amount, can cut energy costs by approximately 90% when compared to the standard pumps. The first cost of purchasing the geothermal system is high but the energy payment costs within a few years earn back the installation costs.

- Reduced Maintenance Expenditures: Because these energy-efficient pumps tend to use energy at lower levels, maintenance of such pumps often comes at lower costs such that fewer parts such as the motor or other components suffer damage and hence require repairs or replacements.

Technical Parameters Justified:

- Variable Speed Control: Necessary for controlling the flow rate when required, and maximizes the effectiveness and efficiency of the system.

- Energy Ratings: The pump check should also include an evaluation of the presence of an ENERGY STAR rating to purchase it with full confidence in its energy efficiency performance standards.

- Noise Levels: In general, most of the effective pumps are less noisy and thus play less in adding to the noise level of the pool.

Realizing these aspects helps me understand what steps to take that will incorporate cost-effectiveness as well as sustainability on a long-term basis.

Frequently Asked Questions (FAQs)

Q: How much does a pool pump replacement cost?

A: The cost to replace a swimming pool pump typically ranges from $300 to $800. However, the exact pool pump replacement cost can vary depending on several cost factors such as the type of pump (single-speed, variable speed), the horsepower of the pump, and whether you need to replace the motor or the whole pump.

Q: What are the main cost factors involved in replacing bearings in a pool pump?

A: The main cost factors when replacing bearings in a swimming pool pump include the type of bearings needed (e.g., ball bearing), the labor costs for installation, and whether additional components like the impeller or front bearing also need to be replaced.

Q: Do I need to replace the entire pool pump if the bearings are old?

A: Not necessarily. If only the bearings are worn out, you can often just replace the bearings rather than the whole pump. However, if the pump is too old or other components like the motor or impeller are also failing, it might be more cost-effective to replace the whole pump.

Q: How can I tell if I need to replace the bearings in my pool pump?

A: Common signs that you need to replace the bearings in your pool pump include unusual noise, decreased performance, and visible wear or rust on the existing pump. If you notice these issues, it may be time for pool repair or to replace the bearings.

Q: Can I replace the bearings in my pool pump myself?

A: While it is possible to replace the bearings in a pool pump yourself if you have the right tools and experience, it is generally recommended to hire a pool service professional. Incorrect installation can lead to more significant problems and higher repair costs in the long run.

Q: How long does it take to replace the bearings in a pool pump?

A: The time required to replace the bearings in a swimming pool pump can vary based on the complexity of the pump and the experience of the technician. On average, it may take a couple of hours.

Q: Will replacing the bearings improve the efficiency of my pool pump?

A: Yes, replacing worn-out bearings can improve the efficiency of your pool pump by reducing friction and allowing the pump to operate more smoothly. This can help maintain proper circulation of your pool’s water and reduce overall pool repair costs.

Q: What is the difference in cost between replacing bearings and replacing the whole pump?

A: Replacing just the bearings is generally much cheaper than replacing the whole pump. Bearings may cost between $20 and $50, while labor costs can add $100 to $200. On the other hand, replacing the entire pump can cost between $300 and $800, depending on the type and horsepower of the new pump.

Q: Are there any additional components that may need to be replaced along with the bearings?

A: Yes, when replacing the bearings, other components such as the impeller, pool filter, or even the motor might also need attention. A comprehensive inspection by a pool service professional can help identify all the parts that need to be replaced.

Q: How does the size of the pool affect the cost of replacing pool pump bearings?

A: The pool size doesn’t directly affect the cost of replacing the bearings in the pump. However, larger pools often require more powerful pumps with higher horsepower, which can be more expensive to repair or replace. Additionally, larger pools may have more complex plumbing, which can increase labor costs.