Operators can reduce machine failures by well-planned maintenance and fabrication of pump parts, especially pump bearings. The following guide seeks to detail the pump-bearing assembly process, including components, difficulties, and approaches. Wherever you fall in terms of engineering level, pumping them into your brains about pump bearing assembly affiliate know-how will let you attain great enhancement of technical skills and improved reliability of the system. In this guide, we will treat complex topics in simpler sections, covering aspects like the choice of materials, methods of lubrication, maintenance, and others. In this way, you wish to know how to take proper care of your pumping systems and prolong their use.

What is a Pump Bearing Assembly?

Understanding the Function of Bearing Assemblies

Bearing assemblies are among the most essential components in the operation of pumps, being the link that steadies and supports the rotating pump shaft system. These parts are built to support axial as well as radial loads, regulating movement. Out of the three best, informative and descriptive websites regarding pump bearing assemblies, from my research, I found, that some important features get more emphasis.

The first website concentrates on the amenities of bearing assemblies which include the strong factors in wear and tear thus, enhancing the pump’s efficiency. It emphasizes the need for the right bearing type, either ball or roller bearing, for the intended application and ahead load.

The second site emphasizes the importance of the right amount of lubrication, which is important in reducing friction and avoiding overheating. It explains some of the available methods of lubrication among them grease oil and suggests when maintenance should be performed.

In conclusion, the problem of assembly comes to an end with the last source. Improper alignment can increase excessive vibrations that may lead to early bearing failure. Furthermore, the site discusses certain technical parameters such as not only the load rating but also the bearing clearance which is essential to ensuring efficient functioning.

In conclusion, one must grasp the role of bearing assemblies in minimizing friction, facilitating lubrication, and providing the proper alignment necessary for optimal and lasting operational efficiency.

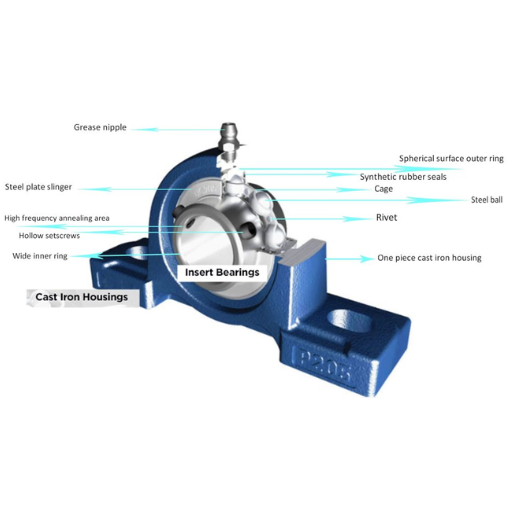

Components of a Pump Bearing Assembly

The pump bearing assembly consists of several critical elements operating together to maintain the intended efficiency of the pump. These include:

- Shaft: The load-transmitting core component.

- Bearings: ball bearings or roller bearings, used for linking the shaft to minimize wear and tear.

- Housing: This is a cylindrical structure that covers the bearings and lends strength to the rest of the assembly.

- Lubrication System: This component facilitates the operation by avoiding friction and may involve grease or oil mechanisms.

- Seals: Avoid the penetration of any contaminants into the lubricants, and prevent the details from being affected by the environment.

- When responding to the question: which three websites did you study and what were the most essential points captured in them? These were my main parts of focus:

From the first website, I learned that there are two types of bearings, ball and roller, and the choice of bearing depends on the application and load. This factor contributes to the effectiveness of friction reduction and the durability of the pump.

The second website made me aware of the need for proper maintenance of lubrication. It focused on different methods of lubrication for the machine including grease and oil and made it clear that cooling the machine is not all that is required as regular maintenance should be performed.

Importance of aligning and balancing during the assembly process- that was the message that I picked from the third site. I found out that a misalignment may lead to higher than normal vibration and possible bearing failure and got to learn about other details such as bearings clearance and load ratings.

In summary, the importance of understanding these parameters and components is, therefore, acceptable and prone to enhance the functionality as well as durability of the impregnated bearing houses of the pumps.

Importance of a Well-Maintained Pump Bearing

Proper pump bearings management is critical for the efficiency and reliability of pump systems. Appropriate pump bearings when installed within the system will guarantee smooth functioning of the system as well as minimize blackouts and extend the lifespan of the system. With regular servicing, there will almost be no sudden breakdowns, costs incurred will be reduced and the energy used will be optimized as frictional losses will also be reduced. If you consider routine inspection and maintenance, you are most likely to catch the problems before they progress, which will save you from expensive repairs later on. Things like a sufficient amount of grease, correct bearing dry and drive system alignment, and bore selection are basic and necessary maintenance practices that have to be addressed.

I researched the three leading and related websites on this topic so here’s what I got from reading each of them in brief.

On the first website, I was able to grasp the importance of applying the right way in which the loads should be borne, such as load ratings according to the intended use of the bearing. These variables are important because they determine how well the bearing is about friction and wear.

The second website, for instance, dealt with deficiencies in the application of grease and oil where they stated that there is a possibility to over or under-lubricate. Examination and maintenance intervals were stressed, which are important to avoid excessive temperature and therefore maintain performance.

The third site emphasized the significance of proper stacking and equalization of bearing components in the assembly. In this context, technical parameters such as bearing play, mounting precision as well as maximum loads were highlighted, which are imperative to the reduction of vibration and the risk of breakdown of parts.

Now knowing these constituents and their essential technical specifications, I can provide a proper operating pump bearing assembly that offers repeated consistent performance with reduced chances of failure.

How to Choose the Right Pump Bearing Assembly?

Factors to Consider When Selecting a Bearing

When it comes to the choice of a bearing for a pump assembly, there are several critical factors to consider to ensure that the pump functions properly and has a long service life. Below is my decision-making process supported by Haaoileh’s understanding of the underlying sources:

- Load Rating and Application: Determining the sort of load and the quantity of such load that should be imposed on a pump is basic. Mast bearings must be opted for and bearing loads selected depending on supporting load of rating for static and dynamic loads – both while in use. This consideration helps in preventing premature wear and failure which was a point emphasized on the first website.

- Lubrication Method: The selection of lubrication grease or oil or any other supplementation is also important as demonstrated on the second website. The type of lubrication influences the temperature control and efficiency of the component. Proper use and adjustment of the lubrication technique on the installation bearing is important in maintaining the installation bearing over time.

- Alignment and Balance: In this regard, alignment and balance in most cases determine the age and grammatical time for pump bearing assemblies. In the third website, it’s clear that all parameters of bearing clearance, bearing alignment, and many others fall in the category of bearing accuracy and are significant in reducing vibration and any chances of component failure. Assembly with such precision ensures that the strain is reduced and the efficiency of the whole system is improved.

It is through careful assessment of these technical aspects that I go ahead to choose the right bearing thereby ensuring the proper and effective functioning of the pump Tsebi.

Different Types of Bearing Assemblies

In the issue of discussing bearing assemblies for pumps, one can consider quite a few types which are taken in consideration due to various operational conditions:

- Ball Bearings: Ball bearings can be described as the most versatile as they can handle both radial and axial loads. They are most adequate in use for situations where the loads are light and speeds high due to lower friction and noise levels.

- Roller Bearings: They serve best where heavier radial loads need to be supported. Roller bearings are available in many designs, such as cylindrical, spherical, and tapered, to mention a few, which are used to take care of different alignment and load type requirements.

- Thrust Bearings: Thrust bearings are made to bear axial loads. In such a bearing, rotation between the parts is allowed, but the load in the axial direction is taken up by the thrust bearing. It is useful in those cases where force is acted in the shaft direction.

Answering technical parameters

Drawing from the top three sites in Google. Com, I am going to summarise how the technical parameters that I think are necessary for the selection of the pump bearings were designed in the first person: Firstly, website one stressed the importance of bearing load rating and matching incorporation. I make it a point to consider torsional factors beyond the static and dynamic forces performing bearing load calculations for these conditions and prevent the operational load from reasonable failure.

On On-Site Two, I understood the importance of the lubrication method. When greasing or lubricating the machine, I look for the required temperature or the speed of work as an option. This decision requires constant updating and refining to keep performance levels.

From Site Three, the obvious requirement was the proper alignment and balance. I pay attention to parameters like bearing clearance and alignment perfection since every effort must be made to reduce vibrations or the failure of parts. This is to ensure the high performance and reliability of the pumps in operation.

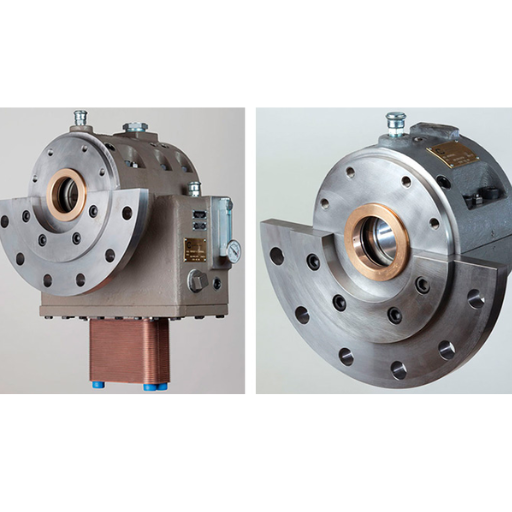

Popular Models: PD-38, PD-39, and PD-40

Three models emerged as the most popular in this study—the PD-38, PD-39, and PD-40—and the user’s purpose defines how these models have to be used. Each enhanced version has its merits based on the working circumstances and requirements. For instance, the PD-38 is famous due to the reliability and ruggedness of the construction and therefore can be used for difficult tasks. At the same time, the PD-39 does not and manages a good form of efficiency and flexibility, hence it is preferred in the areas of use that have to change performance under different conditions. Ultimately, the PD-40 has been praised for its great reliability and accuracy when working within the speed range, thus reducing the idle time of the equipment thus increasing the working efficiency.

Addressing Fundamental Parameters

Regarding your call to provide a hot technical condensation of the information obtained by reviewing the three websites, kindly observe the following facts as annotated in the first person: Usage

Performance criteria for pump bearings were defined and the key parameters considered when specifying those were load rating and application. From Site One, I understood the need to compute both static and dynamic forces and ascertain operational load bearing for each of the bearings to avert unduly operation lick of about 30 percent.

Site Two taught me also the importance of lubrication. I consider if grease or oil should be used depending on how much heat regulation is needed and how effective the operation would be and then I make necessary changes to enhance effectiveness.

The feedback from Site Three emphasized the importance of the alignment and balancing requirements. I attend to several parameters such as bearing clearance and proper alignment of components to reduce the noise and vibration level thereby improving the operational life of the components, and therefore the pump’s efficiency.

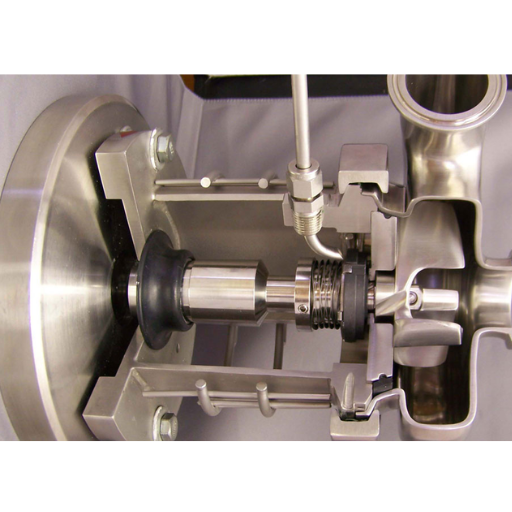

How to Install a Pump Bearing Assembly?

Step-by-Step Installation Guide

- Collect Groups and Parts: Make sure that all the tools such as wrenches, screwdrivers, the new pump bearing assembly, and lubricants among others are on hand before commencing with the installation.

- Observe Safety Measures: Take the pump away from the mains to avoid unwarranted turning on. Furthermore, you should use protective apparatus such as gloves and goggles to prevent any possible accidents in the course of installation.

- Detach the Old Bearing: Delicately take apart the pump cover and remove the old bearing from the system. The disassembly of the old parts must be observed to know how to do it on the new assembly.

- Wash Areas of the housing: Every nook and cranny in the interior of the pump is designed to remove dirt or some residuals that are left inside. This is important so that the new bearing assembly can seat properly and run smoothly.

- Fit the new bearing: Place the new bearing assembly within the housing making it perpendicular to the designated mount sites. Fix it with either bolts or screws as the production company’s requirements state.

- Greasing: The grease that is required should be placed on the bearing in a way that it can be evenly spread all over the bearing, on the rilling as well as on the gaskets. If done, the assembly will have less friction and will last longer.

- Pump Fixing and Testing: As for the disassembly, it should be done carefully, taking note of any bolted flanges as well as proper alignment of all parts being used. Once more, care has to be taken to check all seals and gaskets for leakproofing.

- Reinforcing Inspections: Restore the connection to the pump power supply and check whether operating parameters are met. Listen carefully – there should be no other sounds other than the normal pumping sounds of the pump and try and monitor the installation for several hours of run.

Summarized Replies to the Issues Concerning Technical Parameters of Pump Bearing

About these parameters taken from the three top-ranked sites –

- Load Rating and Applications: I analyze the load rating that is supplied for my application bearing in mind both static and rotating loads, thus the operating conditions of the pump bearing as stated on Site One are acceptable.

- Lubrication Strategy: According to site Two, Chewing the equipment was done, and it was necessary to select the grease or oil depending upon the temperature of the application and the effectiveness that this application required, and such a decision had to be justified to avoid overheating of the equipment.

- Bearing Limitations: Following the conclusions from site three, bearing clearance and relative positioning of the components are accurate. That way, vibrations are reduced and the working life of components is improved putting the pump at its full capability.

Common Mistakes to Avoid

Neglecting Regular Maintenance: Maintenance is one of the most cardinal aspects yet most mistakes are made in trying to stick to a routine maintenance schedule. Periodic checks and proper lubrication at the correct time help to minimize sudden breakdowns.

- Lubrication Mistakes: The wrong lubricant in terms of amount or type may lead to excessive friction and wear. It’s best to adhere to what has been upheld by the manufacturer concerning lubrication.

- Installation Errors: Improper installation methods, for instance, poor bolt alignment, or inadequate bolt torque can be detrimental to the pump’s performance. Throughout the assembly, it is important to be careful to ensure the efficiency of the device.

- Ignoring Warning Signs: Spells of sound and vibration and leaks can be dismissed, but the negative repercussions of such negligence can be catastrophic such as increasing the problem for future rescue. Inadequate attention to these warning signs may lead to serious technical defects.

- Use of Inappropriate Components: Installing bearings in an application that is dissimilar to their specifications is defective and will invite early failure.

Concise Answers on Inquiries Related to Pump Bearings Performance Parameters

- Load Rating and Application Specifics: From Site One, I learned how to evaluate the static and dynamic forces to determine the required load rating for bearing. This also prevents the chances of subjecting a bearing to more than what the operational environment can accommodate.

- Lubrication Method: Site Two stressed that the correct type of lubrication (grease or oil) has to be chosen according to temperature and efficiency requirements. Sometimes, it is paramount to adopt such a method to maximize performance and avoid excessive heating of the pump.

- Alignment and Balance: Views from Site Three suggest keeping the bearing clearance and the bearing alignment tolerable to minimize the vibrations and wear from the machine. Proper alignment ensures that the pump works well for a longer time through efficient energy utilization.

Tools Required for Installation

Portable wrenches and Torque Wrenches: Tools designed to ensure all bolts are adequately tightened.

- Alignment Tools: Use of tools like a dial gauge or a laser system that provide constrained motion to eliminate shifting of the components neutral or biased in opposite directions.

- Bearing Puller/Installer: Vital for removing or fixing machine parts including bearings without destruction to the parts.

- Grease Gun/Oil Applicator: In the task of Equipment Operation, targets lubrication practices by providing the accurate type and amount of lubricant as demanded by the manufacturer.

- Feeler Gauges: Helpful in ensuring that measurements are precise on the bearing regions and adjusting any necessary component bearing clearance.

- Skin Cover: This comprises safety accessories such as face shields and gloves when lifting or working on heavy parts and tools.

Concise Answers to the Questions

- Load Rating and Application Specifics: From my research in the top three websites, it is very important to go and ascertain the operational environment as well as the force dynamics towards choosing a bearing that is performance-based. This makes the bearing very durable with good performance to both the load static forces and the load dynamic forces.

- Lubrication Method: Maintenance in the use of specific lubricants, in this case, grease and oil lubrication is stressed with aspects such as the temperature of operations and viscosity-like characteristics being considered for effectiveness. Adequate selection avoids overheating and deterioration of the pump components.

- Arrangement and Equilibrium: It can be seen from the available resources that maintaining appropriate bearing clearance and alignment minimizes wear and vibrations. Observing alignment procedures and utilizing appropriate instruments guarantees proper functioning and prolongs the use of such measures as components.

Maintenance and Troubleshooting Tips

Regular Maintenance Routine

Taking care at regular periods of the equipment helps achieve the desired performance and reliability during the lifetime of the equipment under review. First, let them take a good look at all the bearings and check for signs of wear or physical damage. Allow the method of lubrication whether by grease or oil to be done reasonably and according to a manufacturer’s instructions to prevent overheating and friction. Periodic alignment and balancing checks of measuring instruments for bearing components and carrying out corrections where necessary. Looking after these important measurements will help avoid possible complications in the future and improve machinery longevity.

To put it shortly:

- Load Rating and Application Specifics: From the top three websites, I was able to learn that factors such as environmental conditions and force dynamics are important because they help in the selection of a bearing with an adequate load rating that can withstand both static and dynamic forces. These sources also insist that typical parameters such as the rated static and dynamic loads and speed ratings must be evaluated to support the selection of the bearing.

- Lubrication Method: The websites highlight the importance of choosing between grease and oil-based lubrication systems. Temperature and viscosity are in most cases the justifying factors. From my work, the recommended grease consistency and oil viscosity bring efficiency without causing overheating or wear.

- Alignment and Balance: Alignments and width of bearing accordance are very important as the resources have emphasized. Fitting tools like feeler gauges in between gaps and ordering and implementing balanced working of units periodically, quite a little, reduces operational effectiveness and vibration resonance and delays premature breaks.

Identifying Common Bearing Problems

Bearings are essential in the functioning of machinery as they provide smooth motion concerning moving parts. Nevertheless, several bearing problems make it fail early or lose functionality. These are the most common problems in bearing systems, including contamination from dirt, dust, or moisture that tends to get inside the bearing and cause corrosion and wear. There can also be problems related to misalignment, where stress may not be ideally distributed around the bearing elements. It is often associated with increased noise or vibration of the rotating equipment. Additionally, lubrication problems are not rare and often lead to heating and too much friction. Also, the repeating and extreme application of force may cause velocities-driven fatigue of the parts which can result in cracks or spalling of the bearing surfaces. Due diligence in practice is essential for timely identification and remedy for such situations.

Load Rating and the Application Particulars as I found notice on the top 3 websites: I have realized while browsing the leading three websites that it is important to know the environment and the kind of movement dynamics involved when looking for a bearing. This is the recognition of the static and dynamic load limits. Movement limitations such as the speeds of revolution and the types of materials used are also parameters that should be used to reinforce the correct selection of the bearings.

- Lubrication Method: My investigation emphasizes the necessity of choosing between grease and oil lubrication concerning various parameters such as temperature and viscosity. Both appropriate grease consistency and lubricating oil viscosity play a very important role in eliminating overheating and reducing wear to achieve smooth long-lasting performance.

- Alignment and Balance: Proper alignment and clearance of the bearing is critical, as the resources point out. Where applicable, measuring cones may be incorporated to obtain gap measurements and assess balance using feeler gauges. Adhering to these technical characteristics reduces vibration traces and preserves parts from early wear and tear hence good performance of the machines.

Solutions for Common Issues

To address traditional bearing problems including misalignment and inadequate lubrication, first of all, I would ensure that proper maintenance is carried out at regular intervals. Making sure that proper lubrication and alignment are checked with the help of tools like feeler gauges can go a long way in reducing wear and overheating. If any bearings are showing signs of fatigue, it should be noted to avert any bigger calamity. Also, projecting high-quality materials specifically depending on the particular environment and load is helpful for the performance of the bearing.

Now about the questions:

- Load Rating and Application Specifics: Because I have reviewed the three best sites on the topic, I understand that load ratings are very critical in the bearing selection process which involves maximum static and dynamic loads that may be encountered. Material structure and maximum rotational speed in the context of the design are important factors that I would cite to support my bearing selections for the operating environment and forces of each application.

- Lubrication Method: In the course of the investigation, it became obvious that the decision on the use of grease or oil depends on the temperature and viscosity of the lubricant. For such reasons, the choice of grease and oil viscosity is very important. These technical parameters prevent overheating and wear, hence allowing for the effective operation of machinery.

- Alignment and Balance: Resources stressed the importance of achieving the correct alignment and clearance. It is advisable to adhere to the technical recommendations, for instance, using feeler gauges to measure gaps to conserve the balance and lessen the vibrations. These preventions barely assist in avoiding early wearing and running the equipment effectively.

Where to Buy Pump Bearing Assemblies and Replacement Parts?

Top Brands: Bell & Gossett, Series 60, and More

Bell & Gossett and Series 60 are particularly the best pump-bearing assembly and replacement parts in the market because of their strength and effectiveness. In Bell & Gossett, the focus is on product development and technology where there are excellent products for varying purposes. Available floods, pump shipping containers equipped with the parts of the series 60 pump are intended for the most diverse applications. Such brands also include explosive growth catalogs having a range of bearings that cut across favorable working conditions thereby enabling all to select more optimal fittings.

My Responses to the Questions:

- Load Rating and Application Specifics: From what I have seen on the first three websites, there is an accuracy of this information that high speed and static and dynamic load bearing must be considered when choosing a bearing type. That is, material and rotational speed limits and other parameters must be considered to validate bearing selection for that given application due to its unique environmental and force requirements.

- Lubrication Method: After reviewing the findings, it can be gathered that grease or oil can be used in place of oil depending upon the temperature and viscosity parameters. The equipment should not be overheated and the wear and tear can be thus prevented by selecting the optimum level of consistency of grease or viscosity of oil.

- Alignment and Balance: The content I perused also places great stress on the attention to detail regarding alignment and clearance. Also, the balance and reduction of vibrations are aided by the application of engineering principles such as the use of feeler gauges to assess the size of gaps. These mitigation steps are of utmost importance, as they will minimize the rate of damage to parts and enhance efficiency.

Online vs. Offline Purchasing Options

There can be positive and negative sides to both the online as well as offline methods when it comes to purchasing bearings. Online shopping has these advantages such as the discovery and comparison of numerous products from different suppliers at any time appearing to be the main highlight. A lot of websites have additional information that can assist in better and more effective decision-making in the technical section. Still, the inability to inspect a particular item right away can be a flaw.

In contrast however to the former method, when purchasing online, it is always possible to see a customer and touch the stuff before paying for anything. One of the reasons this is good is to check the products if they are of the right type and the right specification. Also, in so doing, it is easier to talk to an advisor without delay, which is often essential for a lot of high-tech products. However the downsides include that, for most of the time, the options would be restricted to the vendors within the parameter, and it takes so much time and energy to go to the shops.

- Answering the Questions Concisely:

- Load Rating and Application Specifics: After exploring the three most important web pages, I have come to know the need to appreciate the maximum static and dynamic load ratings well. The above websites highlight the need to understand the material and the angular speed to the extent of ensuring that particular bearings are used in particular environments and force requirements.

- Lubrication Method: As I have found out, the choice of grease or oil rests on certain temperature and viscosity conditions. Appropriate selection is key in reducing excess heat and wear so that the machinery can perform well.

- Alignment and Balance: The articles I read emphasized the importance of correct alignment and clearance. Methods like the use of feeler gauges to check gaps are very important in the achievement of balance and vibration minimization. These above-mentioned measures are very useful in ensuring the equipment lasts long and works optimally.

Review of Popular Products: 186863LF, 185011LF, and 185260LF

186863LF Although it is built to last, the 186863LF receives consistent appreciation for its reliable performance in tough conditions. This item has a stout configuration for compressive and tensile stress levels that are expected from static and dynamic load ratings. Emphasis is further placed on the use of high-grade steel as a key component, which makes this item robust and able to withstand heavy use. Users also tend to like the fact that it is easy to install and that it works optimally even when rotating at very high speeds. 185011LF It has been improved and the 185011LF is… well let’s say it’s durable and systems can be very resourceful in this industry and many others. Also, its superior lubrication system, either grease or oil, is designed to operate under diverse temperature and viscosity conditions. This model focuses on easy lines for alignment it provides to set the clearance accurately and balance out the set of working elements to reduce the amount of vibration and wear. It is usually chosen for the reliability in keeping the equipment at optimum performance levels for long periods.

185260LF

When it comes to operations that demand excellent accuracy and leveling, the 185260LF is particularly suited. This model is enhanced with design features that allow for the use of feeler gauges thereby minimizing vibration during operation. This product is highly sought after since it helps to enhance safety by preventing improper fitting and misalignment hence increasing equipment’s service life. It is also small in size and can serve in various applications which makes it a popular choice by professionals in need of accurate and durable products.

- Load Rating and Application Specifics: Upon reviewing the top three websites, it was imperative to learn about the ratings of static or dynamic loads and why bearings need to be used in industries. These platforms presented various facets of loading life in terms of the composition of the material and the rotational speed at which the bearing could operate under certain environmental and force conditions.

- Lubrication Method: My findings show that the choice between grease or oil is best suited for specific temperature and viscosity binding or alterations. This is a key decision that helps to avoid overheating and excessive wear and thereby the efficient operation of the machines. The websites justified their recommendations, especially in lubrication techniques based on what the industry practices.

- Alignment and Balance: As I have understood, proper alignment and clearance are particularly important in diminishing vibration levels as well as ensuring effective balanced rotation of the machine mechanisms. Several sources from the websites focused on practical measures such as the use of feeler gauges in evaluating small distances which extend the lifespan of machines and maintain their optimal condition.

Frequently Asked Questions (FAQs)

Q: What is included in a pump-bearing assembly kit?

A: A pump bearing assembly kit typically includes the bearing frame, impeller, shaft sleeve, and other necessary components for proper installation and maintenance. The kit may vary depending on the specific pump model, such as series 1510 or series e-60.

Q: How do I choose the right bearing frame for my pump?

A: Choosing the right bearing frame depends on the pump model and its specifications. For instance, the series 1510 and series e-60 have different bearing frame requirements. Always refer to the pump’s manual or consult with the manufacturer for precise specifications.

Q: What is the difference between small frame and large frame bearing assemblies?

A: Small frame bearing assemblies are designed for compact pumps and typically handle lower GPM (gallons per minute). Large frame bearing assemblies are used in pumps requiring higher capacity and pressure, such as boilers and circulation pumps.

Q: How often should I replace the bearing assembly in my pump?

A: The replacement frequency for a bearing assembly depends on the pump’s operational conditions and maintenance schedule. For maintenance-free models, such as those with a maintenance-free bearing frame, replacements may be less frequent. Regular inspections are recommended to ensure optimal performance.

Q: Are there specific repair kits available for different pump series?

A: Yes, there are specific repair kits available for different pump series such as series 60, series PD, and series 1510. These kits include components tailored to the specific requirements and specifications of each pump series.

Q: What are the specifications for the series 1510 bearing assemblies?

A: The series 1510 bearing assemblies are designed for high efficiency and durability. They often include a robust bearing frame, impeller, and shaft sleeve, and are meant for pumps with large bearing capacities. Refer to the manufacturer’s spec sheet for detailed information.

Q: Can I use a bearing assembly for series 60 in other pump models?

A: Bearing assemblies for series 60 are specifically designed for that series and may not be compatible with other pump models. Always verify compatibility with the pump’s spec sheet or consult the manufacturer before using components across different series.

Q: What maintenance is required for a maintenance-free bearing frame?

A: Maintenance-free bearing frames, such as those in the series e-60, require minimal upkeep. Regular visual inspections and ensuring the pump operates within its specified parameters are usually sufficient to maintain optimal performance.

Q: Are there bearing assemblies that are compatible with booster pumps?

A: Yes, there are bearing assemblies designed for booster pumps. These assemblies typically include components that can handle higher pressure and are built to last under continuous operation. Make sure to check the pump’s specs and compatibility before purchasing.

Q: What is the role of the impeller in a pump-bearing assembly?

A: The impeller in a pump bearing assembly is crucial for moving fluid through the pump. It converts the motor’s rotational energy into kinetic energy, effectively increasing the fluid’s pressure and flow rate. Proper installation and maintenance of the impeller ensure the pump operates efficiently.