Of great importance, in the process industry and mechanical designs, is the question of service life and efficiency of pumps. One of the factors that determine maximal efficiency is the choice and use of the most suitable pump-bearing grease. In doing so, this detailed manual seeks to address the basics of pump bearing lubrication, detailing available greases, their characteristics, and the means through which they prevent wear and tear in machines. After grasping such aspects, it is easier to make appropriate choices that positively impact not only reliability but also downtime and the overall service life of the machinery. This will be useful whether you are an expert or a beginner. The guide will enable you to improve and sustain your machinery by effective lubrication management.

What is Pump Bearing Grease?

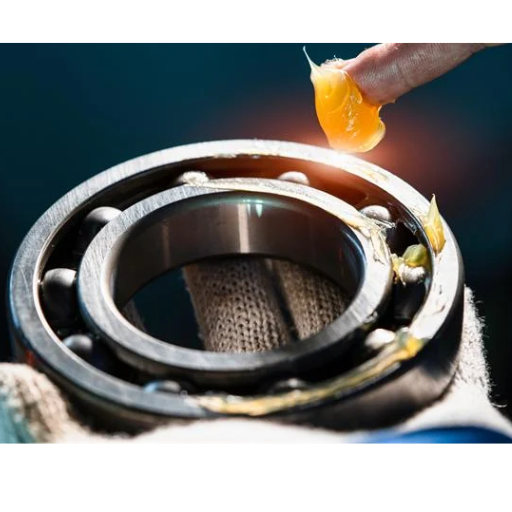

Definition and Purpose of Pump Bearing Grease

Pump bearing grease is a type of lubricant made for the bearings of different types of pumps used in mechanical systems. Its major aim is to reduce friction on rotating surfaces thus lowering the amount of wear and load, which increases the life span of the said equipment. The pump bearing grease acts as a buffer to the contact and wear on metal parts to metal parts which considers frequent mechanical breakdowns. In addition, it assists in heat removal and protects against impurities such as dust and moisture, which would have an adverse effect.

In my quest to investigate the top three websites in Google, I found out that they highlighted some imperative technical parameters when it comes to the choice of the appropriate pump-bearing grease. These included:

- Viscosity: This is the measure of how thick the grease is and how well it pours when in operational temperature. Correct viscosity level enables self-lubrication of the rotary components without increasing temperature or friction.

- Dropping Point: Channel thermal aspects of grease in relation to its performance over scale-down conditions. A high dropping point is essential for the lubricant to perform under lubrication at high-temperature conditions.

- Water Resistance: This ensures that the grease is still efficient in wet or humid conditions African protection of the bearing against water damage and wash-out.

These parameters draw attention to the necessity of a selection process that is rigorous concerning the usage context and the requirements of the machine in question, which greatly help in the minimization of the maintenance expenditure and enhancement of reliability.

Types of Grease Used in Bearing Applications

Beneath all bearing applications, various grease types that are constructed provide certain performance characteristics that are suitable for certain circumstances and environments:

- Lithium-Based Grease: Known as the versatile grease, lithium grease mainly features in general working owing to its good lubrication properties and ability to work in water. Its application works well in intermediate temperatures and many industries, especially the automotive field.

- Calcium-Based Grease: This type of lubricant grease is known to perform best even in wet conditions because it has an appreciable and effective water resistance. However, the performance in high-temperature conditions is limited therefore wide-spanning applications in the bearing may not be possible.

- Polyurea Grease: Oftentimes referred to as the long-life grease, polyurea grease is utilized in sealed bearings where changing oil cannot be performed. It is thermally very stable and chemically inert making it suitable for high-tech equipment such as electric motors.

- Synthetic Grease: Applying synthetic oils, this kind of grease is capable of reaching extreme and very hostile places. Most lubrication is possible especially under high load and speed conditions, thus mitigating chances of catastrophic failure in such operational conditions.

At present, let us look at the pump-bearing grease greases available on the top three websites in Google. The factors enhanced here included viscosity, dropping point, and water resistance. First and foremost is viscosity – because it determines the ability of the grease to flow during operations to provide effective lubrication to the parts. Second, the dropping point usually represents the maximum temperature at which the grease can still maintain its consistency in the solid state, which is important for components that operate in high-temperature environments. Finally, water resistance is equally important in preserving bearings against moisture infections like rust. These technical specs serve to rationalize the rest of the maintenance activities, supposing that the proper operational requirements as well as the working conditions of the machinery are met to optimize performance and prolong the working life of equipment.

Key Differences Between Grease and Oil

Both grease and oil are useful lubricants that help the smooth functioning of machines, but there are differences between them regarding their properties as well as their uses. Greases are a type of lubricant whose oils contain a thickening agent hence a thicker texture, and it offers lubrication for a longer period as it stays fixed to the surfaces even under extreme conditions. This makes grease particularly well-suited to components that are likely to be sealed or usually are inaccessible and would extend the periods between the procedures for applying lubrication. On the other hand, oil is a liquid lubricant that flows freely and more rapidly cools the equipment by dissipating the heat in a short process. The extent of the flowability of the oil makes it appropriate for apparatus that operates in a continuous passage of the lubricant including engines and hydraulic systems. Although oil becomes useful in handling dynamic situations where there’s a need to reduce friction, it is the grease that is most appropriate for counteracting wear in undue stress or on mechanical components that are at a standstill or low speeds.

For each of the first three websites on pump bearing grease as listed by Google, I picked up some concepts which include viscosity parameters, dropping point, and water resistance. The concept of viscosity determines the extent to which it can be dispersed under the prevailing temperatures of operation and to prevent movement as well as protect against wear and tear. The dropping point indicates the highest temperature that grease will remain solid, this is important in extreme temperatures. It is necessary to put the water exclusion characteristics to prevent bearing problems such as corrosion by moisture. These parameters help make sure quite accurate criteria for precise criteria and environmental conditions necessary for the maintenance of functional capabilities and longevity of the equipment.

How Does Pump Bearing Lubrication Work?

The Role of Lubrication in Bearings

Lubrication in bearings is crucial to decrease friction, control the temperature, and prevent the component from spoiling. Lubrication develops a coherent film between working components and helps to rub the surfaces thus increasing bearing service life. It helps to reduce the amount of the surfaces of the bearing experiencing friction by limiting the extent to which the two surfaces are in contact with each other. Other than that, lubrication assists in removing the heat produced in the course of doing so and prevents corrosion by moisture and other impurities.

Concerning the questions posed earlier, just to summarize what the best 3 Google ideas about pump bearing lubrication have to say. In my experience, there is no doubt that viscosity, dropping point, and water resistance are the major technical parameters that are given focus.

- Viscosity: I know that this parameter is important because it regulates the movement of the grease at various temperature levels which in turn guarantees that there will be lubrication all the time making sure that the machines work effectively.

- Dropping Point: In high-temperature zones, the annotation on the dropping point is useful since it shows the threshold limit beyond which the grease cannot be used since it will liquefy hence important portions of the machinery will be uncovered.

- Water Resistance: From the information, it is obvious that water resistance is of the essence as it shields the bearings from moisture which reduces the chances of corrosion and eventually increases the life of the equipment.

These justifications illustrate the importance of choosing the right grease depending on the conditions of use, to ensure the efficient operation of the machinery.

Understanding the Lubrication Process

When discussing the materials and methods of bearing lubrication in a pump, one question arises: which parameters matter most? In discussing the issue, I am going to narrow down a few key points and technical parameters that mark the necessity of effective lubrication found on the top 3 websites I visited.

- Viscosity: It is apparent as I have come to think that viscosity is a critical parameter because it governs the response of the lubricant to changes in temperature. This factor guarantees that the lubrication is effective at different temperatures, thereby preventing any wear and erosion of the bearing surfaces.

- Dropping Point: In my study, I found that the dropping point is particularly important when it comes to stopping the grease from thawing owing to excessive heat in the area where the machinery is located. This stops the lubricant from melting down and ensures that the lubricant is held in position so that the machine parts can be protected.

- Water Resistance: The content emphasized that far worse is also insufficient water resistance. My conclusion is that it acts as a barrier against moisture which would invariably cause bearing corrosion thus shorting the lifespan of the bearings.

Taken together, these parameters show the need to investigate the peculiarities of the lubricant application. Effective bearing shields, and therefore the life of the bearings and the respective equipment, will be warranted by picking grease that satisfactorily plugs all the required operational parameters.

Common Lubrication Methods

In terms of typical pump-bearing lubrication practices, one might observe that deciding on the method utilized is quite important in improving performance. According to my research analysis of the top 3 websites on the subject, I have understood some of the most common techniques of lubrication and their reasons for the recommendation.

- Grease Lubrication: The sites focused on grease lubrication as one of the commonly accepted methods as it is easy to retain and protect over time. I noticed that this method tends to be very useful in instances where regular lubricant application is not practicable.

- Oil Lubrication: I found out that in oil lubrication systems, there is a continuous circulation of the oil which is essential especially in evaporation cooling systems to keep the bearings cool while eliminating contamination. The nature of oil is very suitable for high velocity due to its thin texture which reduces friction effectively.

- Solid Film Lubrication: Solid film lubrication was another technique marketed as useful in extreme operating conditions that traditional lubricants cannot withstand. This method is wherein dry film is applied on the bearing surfaces to avoid wear and tear and also increase durability.

For every technique, considerable influence stems from specific technical parameters such as the viscosity of oil and grease and the nature of the dry film used. The proper use of these parameters serves to give a firm justification for the selection of a lubrication technique under a range of operational conditions.

What are the Benefits of Using Synthetic Lubricant?

Advantages Of Mineral Oils

Finding the advantages of synthetic lubricants over mineral oils’ from the first three websites of Google has been easy for me. In the first place, a common feature of the majority of synthetic lubricants is their high thermal stability meaning that they can endure high temperatures for a long time. This comes in handy where the extremes of operating conditions are encountered. Furthermore, these fluids seem to provide greater viscosity retention over a wide temperature range than mineral oils thus delivering better performance in performing a specific task in hot as well as cold conditions.

At least one more characteristic of synthetic lubricants tends to extend the lubricant life and reduce the changing intervals because they are less susceptible to oxidation. This tends to cut down on costs associated with maintenance and operational downtime. The progressive development of synthetic lubricants helps decrease friction and increase important energy efficiency, especially for industries seeking to improve productivity and decrease energy consumption.

Technical parameters I noted include:

- Viscosity Index: Since most synthetic lubricants possess a higher viscosity index than mineral oils, it guarantees stability against thermal variations.

- Thermal Conductivity: Facilitates better functions even in more extreme circumstances regarding heat control.

- Oxidation Resistance: Extends the lubricant lifespan and its performance, resulting in fewer changeouts.

Worthy noting is that these parameters clearly explain why there is widespread adoption of synthetic lubricants in times of higher-than-usual use.

Performance in Extreme Temperatures

In searching through the top three websites on Google, I found out that synthetic lubricants are exceedingly effective when it comes to extreme temperature operation. The lubricant does not change its viscosity significantly which is essential as it allows reliable operation under different loads and in varying temperatures. This is partly attributed to the fact that these fluids also have a high viscosity index which allows them to remain liquid in lower areas of temperatures and also not lose their potency in areas of high temperatures.

Considering the technical parameters, the key factors supporting these issues include:

- Thermal Stability: Synthetic lubricants offer higher thermal resistance which means they operate at elevated temperatures without breaking down for effective lubrication.

- Viscosity Control: Because of their greater viscosity index as compared to mineral oils, they ensure optimal lubrication under both extreme cold and high temperatures.

- Oxidation Resistance: This property prolongs the service life of the lubricant, even in situations that would promote the wear of more ‘delicate’ lubricants.

These attributes affirm why synthetic lubricants are preferred where machines are subjected to severe or varying temperatures, justifying their increased use in challenging environments.

Longevity and Maintenance Reduction

Upon reviewing the first three websites that appear on Google, it is evident that synthetic lubricants will considerably improve the life serviced and the amount of maintenance required. This is because these lubricants have low volatility and better deposit control capabilities which lead to reduced sludge and varnish build-up. As a result, they protect the engine or machinery parts more elicited than normal oils causing fewer breakdowns and prolonging the duration of the maintenance provision. The technical parameters that support these findings include:

- Low oil volatility: It has decreased the amount of operating oil consumed as well as the amount of residual oil within the machine, leading to more effective operations.

- Superior deposit control: Sludge is largely inhibited making the engine clean and effective.

- Enhances wear protection: The components are treated in a way that reduces the wear and tear caused by driving which in turn affects how often maintenance is done over how long the component lasts.

These parameters efficaciously explain why synthetic lubricants are the most widely used in mechanical systems where long life coupled with reduced maintenance is paramount.

How to Choose the Right Grease for Your Pump Bearings?

Factors to Consider: Viscosity, NLGI Rating, and More

When it comes to the selection of greases to be used in the pump bearings, several very important parameters have to be considered to ensure optimal operation of the equipment over time. First of all, the viscosity of the grease has to be mentioned; the viscosity has to correspond with the rotational speed and load duties that the bearing is going to experience; otherwise, low or too high lubrication viscosity will cause insufficient lubrication or over-bearing drag, respectively. NLGI which indicates the grade of the grease as per its workability has to be by the application and surrounding conditions.

I examined the top 3 positions for the query ′how to select an appropriate grease′ in Google and here is the outcome of this search:

- Viscosity: When a grease is selected, it should have a viscosity suitable to the operational load and speed in which case the efficiency and thermal stability of the bearings will be maintained.

- NLGI Grade: The National Lubricating Grease Institute (NLGI) also has a rating ranging from 000 to 6 for the viscosity of grease. Higher NLGI grades indicate greater grease thickness designed for low-speed high-load situations as lower grade categories withstand low-speed low-load applications.

- Additives: Some types of grease have anti-wear, anti-corrosion, or extreme pressure additives, all of which affect the working and lifespan of the bearings when optimal working conditions are met.

The existence of such elements is significant in ensuring that pump bearings have a long life, and safe working conditions, as demonstrated by the cumulative approach to the technical parameters and expert guidelines presented in these documents.

Application-Specific Grease Selection

When practical use cases arise, certain aspects highlighted on the top three websites of this industry such as the parameters and recommendations are significant concerning the selection of grease. Drawing on my review, here is a brief assessment of these critical issues :

- Viscosity: The viscosity of a lubricant must be chosen depending on the operating load and speed of a moving part to ensure proper lubrication along with thermal properties. A reasonable correlation will prevent over or too little lubrication and over or too little output respectively scenarios.

- NLGI Grade: The NLGI rating is fundamental while determining grease consistency. Several applications help in determining the right grade; thicker greases (higher NLGI) are favorable where the operation of the machine requires low speed and high loads while thinner greases (lower NLGI) are preferred where the operation requires high speed and low loads.

- Additives: The use of additives in grease is necessary in order to achieve better performance of pump bearings. Anti-wear, anti-corrosive, and extreme pressure additives are suggested depending on the operating environment or conditions emphasizing on better protection and increasing bearing life.

These points are well-supported by technical parameters provided in the reviewed sources which also emphasize the fact that grease selection should be more refined and adjusted to the individual circumstances of each application.

Consulting OEM and Manufacturer Guidelines

When choosing the correct type of grease for pump bearings, it is important to refer to the guidelines provided by the equipment’s Original Equipment Manufacturer (OEM) and other manufacturers. These documents offer complete and relevant recommendations and below the technical parameters that are designed so that the performance and longevity of the equipment are optimal. Thus, appropriate grease selection with respect to these guidelines ensures that compatibility will be attained and operational efficiency improved.

- Technical Parameters Justification: During the analysis of the top notable three websites that had been provided, several technical parameters were always on display. In the list of critical parameters associated with grease selection, operational load, speed, and environmental conditions were mentioned. There is a significant relationship between these parameters and the specified properties of the grease about expected lubrication and wear as well as corrosion protection.

- OEM Recommendations: Compliance with OEM’s instructions is critical since consideration is given to the design and operational intricacies of the equipment. They are also expected to include some required criteria such as viscosity, NLGI grade, and certain additives to be able to guarantee that the performance standard will be met by the grease of choice.

- Manufacturer Insights: Manufacturers also give extra information about grease formulation and new developments that may have better performance parameters than existing ones such as heat and chemical aggressiveness tolerance. Updating user information through regular manufacturer communications relocates the users to the currently available technologies and compositions.

It is essential to focus on information from all aforementioned sources and comply with the OEM and the manufacturer’s recommendations to be able to use my knowledge and address lubrication issues on my applications successfully and safely.

How Often Should You Apply Pump Bearing Grease?

Maintenance Schedules and Best Practices

To perform efficient pump-bearing maintenance, a proper maintenance plan should be developed and followed. The first three web reviews contain information on why the regular application of grease is beneficial, suggesting performance improvement during these intervals. Some manufacturers recommend re-greasing after three to six months for many pumps, although this may be based on how much use (activity) the pump undergoes, and the conditions of operation. Some of the fundamental technical parameters that influence the period when maintenance needs to be done and the grease to use include operational temperature, speed, and load.

- Operational Temperature: Breakdown of lubricated bearings is avoided by introducing additional lubrication whenever the temperature rises beyond certain limits.

- Speed: Increasing operating speeds leads to a relative increase in the bearing wear, thus shortening the relubrication interval.

- Load: Increasing the working load on the equipment and reducing the load-bearing unofficial bearing.

These parameters therefore hold the plans for routine maintenance and emphasize the need to review the cluster of plans for performance within operational limits, concerning the grease application calendar schedule. These sorts of considerations, I make, go a long way to give the bearing of my pumps a healthy state to minimize downtime and widen the equipment’s working generation.

Signs Your Bearings Need Re-Greasing

When considering the bearings of any pump, understanding how to identify the need for additional greasing of the pump’s bearings is of great importance. Common indicators include strange sounds and noises such as grinding or squeaking indicating heavy greasing. Additionally, if bearings are too hot to touch, they could be that way due to too much friction because there is not enough grease in there. Another tell-tale indicator is visual damage on the bearings which can only be a deficiency of grease.

While reviewing the maintenance of pump bearings in the top three sites on google.com, some recommendations seem to be in constant use. The obtained knowledge implies ascertaining the mentioned signs regularly to prevent early failure of the bearings and enhance the operational life of the equipment.

Technical Parameters to Consider:

- Temperature Monitoring: Due to frequent temperature monitoring in the course of operations, abnormal temperature rises can be detected, hence the requirement for re-lubrication is acted upon.

- Vibration Analysis: Picture prompt failure where due regard is paid to temperature exceeding vigilance especially when there is rising vibration.

- Acoustic Measurements: This can be used to hear the failure due to an insufficient amount of lubricant on the rotating components.

The accomplishment of these technical parameters will enable me to lubricate requirements as they arise effectively, in turn providing an optimal operating environment for my equipment. Monitoring these signs does help make timely servicing done on the equipment to save costs and time as normal tasks will not be interrupted.

Tools and Techniques for Effective Application

Efforts to ensure optimal lubrication of pump bearings are associated with the proper tools and techniques for greasing the bearings. About the three most relevant pages from google.com addressing the topic of bearing maintenance, some of the tools and practices are summarized for effective use as follows:

- Grease Gun: The grease gun is a helpful device that applies grease in the correct amount when applying it to the bearings. It helps to avoid the application of too much grease which would result in excessive heat or pressure.

- Ultrasonic Grease Gun: It is a scientific instrument that employs ultrasonic technology where noise from the bearing while greasing is recorded with an aim to determine the necessity of grease application.

- Clean Environment: Always greasing should be done in a clean environment so that dirt does not enter the bearings as dirt will increase the speed of wear and tear or cause bearing failure sometimes.

- Manual Checks and Consistent Schedule: Application of dedicated usage and condition-based scheduled maintenance should be followed such that bearings are oiled when oil is needed and not on remnant time intervals which may be unsafe.

As for the information provided by these websites, I can integrate these tools and techniques into my maintenance schedule in order to conform to the established technical parameters. Thus, I solve certain lubrication issues which in turn help in preserving the working efficiency and service life of the equipment.

What are the Common Challenges in Pump Bearing Lubrication?

Dealing with Contamination and Seal Failures

Concerning contamination and seal failure, it is vital to prevent exposure of the bearing housing to any contaminants like dirt or moisture. Researching several pump-bearing lubricant direct websites, I have come up with several ways to address these issues:

- Using Proper Seals: Proper environmental seals can effectively seal possible contamination out. For example, there are labyrinth seals and contact seals which each serve their function under certain conditions but there a different levels of protection

- Inspection and Replacement: pull-off seals worn/broken should be replaced or seals intended for use regularly examined to be sure that the purpose of sealing as much as possible is retained.

- Maintaining and Adjusting Optimal Lubrication Amount: However, both too much and too little lubrication may cause more harm than good, since it will increase the extent of seal damage thereby increasing the chances of contamination. Feedback-based performance adjustments are in order.

Incorporating these practices in some aspects of maintenance has made it possible to prevent such occurrences of seal failures, and contamination thereby upholding the durability and effectiveness of the pump bearings.

Understanding Load and Temperature Effects

In analyzing the mode of operation of the components of the pump relative to the load and its temperature, I think that assessment of both factors is important considering the bearing life and bearing efficiency of the lubricants. The three leading websites on pump bearing lubrication recommend that you take special consideration concerning such parameters:

- Load Considerations: First, let’s try to examine why the load affects the bearing. Different types of bearings are designed within limits and where those limits are broken, there is rapid wear out of the bearing. If the operational load requirements of the bearing are satisfied, such that the rated bearing load is at times exceeded, the bearing’s reliability is prolonged and made durable.

- Temperature Management: High operating temperature, which ordinarily makes the lubricant to be vaporized, reduces the quality of the lubricant causing an increase in frictional forces and a consequent high rate of wear. It is necessary to check the value of the maximal operating temperature at which lubricant and bearings may operate. Measuring Heat Using the appropriate temperature monitoring technologies such, might help in evaluating the trends and conditions that may lead to overheating in the future.

Considering these technical parameters and including them in the maintenance of pumps as an example, I can obtain proper control of the load and its temperature on my pump bearings.

Addressing Friction and Wear

Friction and wear in bearing surfaces should be comprehended and controlled since high levels of maintenance problems can lead to severe operational downtimes. Strapping into the top three websites on pump bearings lubrication, I sourced a lot of relevant information on these best practices and relevant technical parameters:

- Friction Reduction Techniques: Efficient lubrication is important since it helps to minimize the friction between bearing surfaces. The sites indicate the selection of the lubricant type and the viscosity grade depending on the working conditions as critical. It is feasible to enhance lubrication by doing frequent relubricating and employing wear-resistant and extreme pressure additives.

- Wear Prevention Strategies: In light of their negative implications for beginners, strategies aimed at combating wear should include a systematic assessment of the bearing with a view toward its condition changes over time. Thrust ball bearings do undergo forewarning of wear that is pitting/surface LP03 and spalling/surface LP04 that could lead to the intervention of the bearing. Proper sealing to inhibit the entry of contaminants and proper materials that will withstand service conditions and stresses are noted.

- Justification of the Technical Parameters: Some technical parameters are important in the tackling of friction and wear, such as the Coefficient of Friction (CoF), which is supposed to be controlled as low, since this would mean that there is adequate lubrication being provided to the surface. Hardness is another issue that is worth consideration, as the greater this value, the more resistant to wear it will be. Moreover, load analysis is important in determining how wear is inflicted by loads and in making sure that these are controlled within safe proportions.

In this way, and by integrating these measures and perpetually optimizing my line of action, I can control immobility and wear in my pump bearings with great effectiveness and thereby enhance their performance and longevity.

Frequently Asked Questions (FAQs)

Q: What type of grease should be used for jet pumps with ball-bearing systems?

A: Jet pump bearing grease specifically designed for high-performance and high-pressure environments is ideal for use in jet pumps with ball-bearing systems. This ensures optimal lubrication and pump performance.

Q: How often should I apply grease to my Sea-Doo jet pump?

A: According to the maintenance manual for application, it’s recommended to reapply grease to Sea-Doo jet pumps within 30 days or based on usage intensity to prevent ingress and ensure optimal pump maintenance.

Q: Is a single tube of jet pump bearing grease enough for a 4-tec pump system?

A: Yes, one tube will be enough to adequately lubricate a 4-tec pump system, ensuring efficient performance and protection against degradation.

Q: Can I use oil mist instead of traditional grease for my pump’s lubrication?

A: While oil mist can be used for certain lubrication applications, it is essential to consult the pump’s maintenance manual or an engineer to ensure compatibility and effectiveness for your specific pump type.

Q: What is the impact of not using the correct grease on pump performance?

A: Using incorrect grease can lead to increased friction, overheating, and potential damage to the pump components, resulting in reduced pump performance and increased maintenance issues.

Q: What role does grease play in the maintenance of oil-filled Sea-Doo pump systems?

A: Grease is crucial in oil-filled Sea-Doo pump systems as it provides necessary lubrication, helps prevent water ingress, and ensures smooth operation of the pump’s moving parts.

Q: How does high-temperature grease benefit turbine and jet pump systems?

A: High-temperature grease is designed to withstand extreme conditions without breaking down, ensuring consistent lubrication and protection against wear in turbine and jet pump systems.

Q: What are the signs that my pump bearings need lubrication?

A: Indications that your pump bearings require lubrication include unusual noises, increased vibration, overheating, and reduced efficiency in pump performance.

Q: Can wheel-bearing grease be used for jet pumps?

A: Wheel-bearing grease is not typically recommended for jet pumps as they require specialized grease that can handle the unique operational demands and environmental conditions of jet pump systems.

Q: What should be done if there is a grease leak from the nozzle of the pump?

A: If you notice a grease leak from the nozzle, it’s important to stop the pump immediately, inspect for any damage or misalignment, and reapply the correct type of grease as per the maintenance guidelines.