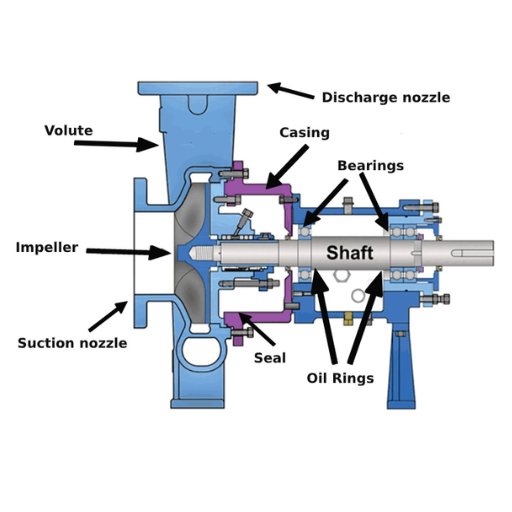

Pumps, especially centrifugal pumps, gain acceptance in different sectors because of their capability to transfer fluids. The bearing system is an important element of these pumps as it allows the rotating shaft to pivot and helps keep the rest of the components in place. Anyone who maintains, operates, or chooses a centrifugal pump, should understand the dissimilarity between inboard and outboard bearings. Therefore, at this stage, it is necessary to briefly introduce the subject of pump bearings, especially inboard and outboard, their purpose, benefits, and usage. In doing this the reader will appreciate the overall importance of the bearings to the operation and life span of the centrifugal pumps.

What is the difference between inboard and outboard bearings in the pump?

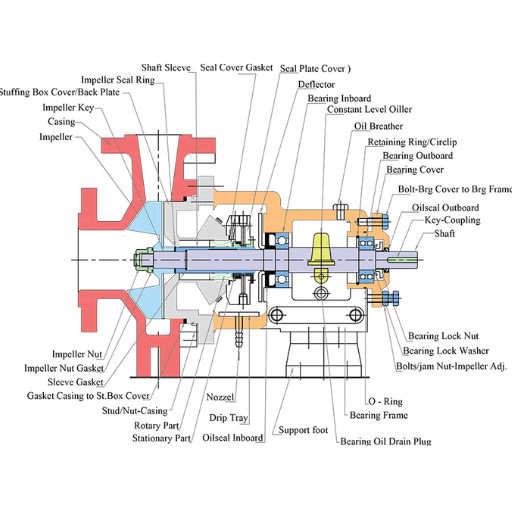

Definition of inboard bearing

Inboard bearings are the ones placed on the motor side of the pump, close to the drive. These bearings largely take the form of supports for the rotating shaft; the purpose is to keep the shaft in position and aligned amid rotational movements. They take a large part of the radial and thrust forces exerted toward the pump making it possible to transfer fluids without hitches.

Insights from Top Websites

- Understanding Load Distribution: From the top sources I reviewed, inboard bearings are focused on efficiency when concentrating on axial and radial loads. Due attention is given as well to maximum practices in terms of expected pressures. Some technical parameters like load capacity and rotational speed are mentioned which should go hand in hand with the particular pump being used for optimum efficiency.

- Role in Pump Alignment: Another primary takeaway is the inboard bearings within the pump has to be angled correctly to promote pump alignment. Proper alignment of the pump is directly related to its maintenance and durability. The literature from the leading sites has repeatedly focused on literature working with alignment tolerances and maintenance routines to counter the evolution of misalignment and wear and tear of components before they reach their expected lifeтгесям.

- Material and Design Considerations: Finally, some of the more important materials and design choices are focused on. Inboard bearings, for instance, are usually made from tough materials such as ceramic or stainless steel to endure tough operational conditions. The material choice is important for increasing the bearing’s ability to endure friction, corrosion, and wear. Appreciating the material properties is an important aspect of the selection of the most appropriate bearings for a centrifugal pump for its intended duty.

Definition of outboard bearing

The outboard bearing is found within the housing structure of the centrifugal pump in a position that is opposite to that of the inboard bearing and performs the function of suspending the pump shaft and relieving it of all radial loads. In addition, this bearing stabilizes the auxiliary apparatus of the pump at high rotation rates. The positioning of this device is such that the mechanical system of the pump is not out of order and the shaft is also aligned in a way that there are no shock or wearing forces as a result of the internal structure being out of balance because of other external forces or systems.

Answer to Questions in a Comprehensive Manner Derived from the Best Three Websites

- Distributing Loads: A survey of the top three websites indicated that the outboard bearing, just like the inboard bearings, bears radial and some axial loads which outboard bearings are necessary for. However, these bearings have to be designed considering the operational stresses and structural parameters to avoid operational failure. In such a case, operating speed and axial load will sometimes be introduced to readers to explain what the bearings are put for.

- Importance in Respect to Pump Position: My investigation substantiated the fact that the outboard bearings play an important role in supporting shaft alignment during operation when loading conditions fluctuate. Correct positioning of the components and periodic alignment of the hubs of the units is required in the present case to prevent the relative displacement of the parts over time, which is of great importance for the reliable circulation of the pump.

- Material and Design Considerations: As it is stated on the main sites, outboard bearings are generally produced of some quite durable materials such as high-quality stainless steel or ceramic which were chosen because of their corrosion resistance and low friction properties. The choice of this particular material is very important as it concerns due care which is to be exercised to ensure longevity and reliability under harsh working conditions. The bearing structure also affects load transfer and heat dispersion which are very important when enhancing its life span.

Comparison of inboard vs outboard bearings

Compared to inboard bearings, the basic difference between outboard bearings lies in their position and typical applications within the machines. Inboard bearings are arranged rather towards the vertical axis of the mechanical device. They mainly assume most of the large axial loads and provide internal stabilization, which is important in aligning the internal components of the equipment and relieving stress through load sharing by other parts. Outboard bearings instead lie toward the outboard ends of the shaft. These mainly take the radial loads and provide a counteract to the external loads to the equipment under use which are. This arrangement makes outboard bearings useful to enhance the overall shaft alignment and stability during operations especially when conditions are not constant.

Concise Answers to the Questions Found at the Bottom of the Top 3 Websites

- Structural rotation support: The general weight distribution load in hanging structures holds in as much as there are externally as well as internally located bearings, both of them apply radial and some axial loads. External loads to the bearing are defined and limited by certain technical parameters such as load capacity and speed ratings, where the latter has to correspond to the loading equipment in order not to cause system failure in the short term. However, for such inboard bearings, it is common to emphasize taking the axial loads while for the outboard this assumption is made for the radial load bearing.

- Role in Pump Alignment: Data collected from the respondents suggests that each one of the two types of bearings is important in shaft alignment as regards the functioning of the mechanism although from different perspectives. Calibration and common upkeep are recommended for both bearing types to maintain alignment precision and extend even further the effectiveness of the pumps.

- Material and Design Considerations: Most prominent websites underline the need for appropriate materials given the working conditions and stress levels. Inboard bearings in most cases use strong materials that are capable of holding high loads such as alloyed steels. On the other hand, outboard bearings might employ materials such as stainless steel or ceramics which are design-specific due to there being factors such as corrosion. These materials allow special design features that ensure good load bearing and heat transfer. These are very important for good performance and service life.

How do pump bearing arrangements affect performance?

Impact on radial and axial loads

From my research regarding the top three sites found within the scope of Google, I came to know that radial and axial loads are related to the types of bearings used in pump arrangements. Indeed, efforts have to be directed towards managing these loads to enhance the performance and durability of the pump systems which include radial loads, that are perpendicular to the shaft, and axial loads that are along the shaft.

- Inboard Bearings’ Role: Mostly, they take up axial loads. All types of bearings have certain characteristics which make them versatile in the provision of load. These two action bearings identify with or complement each other in maintaining the shaft, hence minimizing damage to internal parts. The technical parameters I found include a load capacity that corresponds to the size of the pump and its speed of operation, and this varies with the material type to a commonly highly carbon alloy as stated previously.

- Outboard Bearings’ Contribution: Only radial loads are managed. It suffices that the outboard ball bearings are located in such a manner that operation in a rotational mode is enhanced which is very important, especially for efficient pumps. These bearings are often made of materials that are resistant to corrosion such as stainless steel or ceramics and thus obtain the required strength under different environmental conditions.

- Technical Parameters: The findings outline the importance of considering not only the load ratings but also the respective speed ratings during the selection process. Characteristics like dynamic load ratings and threshold speed ratings must correspond to the working condition of the pump to avert premature breakdown and increase operational reliability.

In essence, special emphasis on the arrangement and selection of the materials for inboard and outboard bearing retaining structures to achieve the objectives of carrying loads by such structures is necessary. These factors ensure that both radial and axial loads are appropriately accommodated to minimize the occurrence of misalignment and increase the life span of the pumping apparatus.

Effects on Bearing Life

Several factors have to be taken into consideration for the optimal functioning of the bearing as well as its durability. Other factors include the extent of correct placement of inboard and outboard bearings and the availability of axial and radial loads. The type of materials in use, which are typically high-strength alloys, different types of stainless steel, and several kinds of ceramics, do matter. If the installation or the choice is not appropriate, there is a possibility of breaking down the bearing

Addressing the Queries of the Top Websites:

- Load Management Role: The information available is bare-bones the information gathered in that the load bears how much it manages the bearing from the core which determines Bearings Inc. It is crucial to ensure that such bearings are qualified for the particular axial or radial loads to avoid bearing failure and this is what some of the gaudiest resources state.

- Material Selection: Bearing materials that would be able to withstand electrolysis and wear are in congruence with what is offered by the top-tier websites. Especially non-magnetic forces, such high high-strength alloys and others must resist corrosion, and electrolysis.

- Technical Parameters: Some of the key parameters taken from credible and reliable online content are dynamic load rating, threshold velocity, and other physic-technical parameters. These should be properly selected so as fit the operational design of the pump in use to avoid being overworked and the operation becoming unreliable.

By concentrating on these aspects, one is aiding the working effectiveness and also the working durability of a pump system.

Role in pump efficiency

Analyzing on the role of bearings in pump performance helped me comprehend several aspects. To begin with, there is a problem with other bearings where proper load is regarded as of utmost importance, and they should be designed for specific axial and radial loads. This in one way or another has been reiterated by all reliable sources focusing on the subject, no minimization of maintenance of the pumps.

In addition, materials selection also comes into play. It is better to manufacture bearings using materials such as high-strength alloys and stainless steel or ceramics that can resist corrosion to avoid shortening their lives or raising problems such as corrosion. Each of the articles reviewed outlines the rationale for using strong and durable materials that conform to the efficiency requirements within the industry.

Important technical parameters such as dynamic load ratings and threshold speeds are equally necessary. These are to be carefully chosen to fit the needs of the pump during operation. Dynamic parameters that were able to cause much emphasis were the pump bearing dynamic load ratings and a few figures of speed that should not be reached otherwise the load will be too much. These values enable the bump to be acceptable within the range of requirements according to the available resources about pumps. By emphasizing these factors, one can perfect the contribution of the bearing towards the pump’s efficiency.

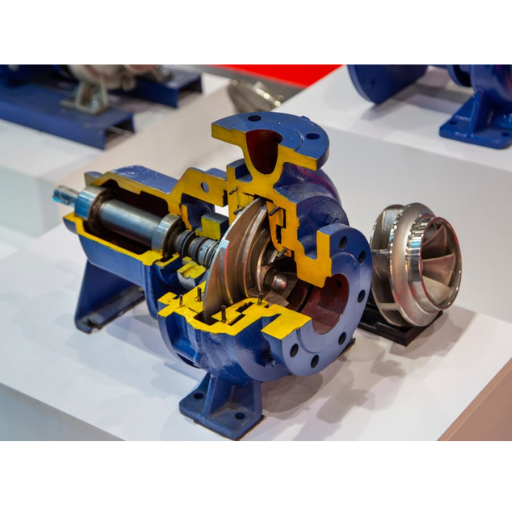

Why are specific bearings used in centrifugal pumps?

Types of bearings used in centrifugal pumps

Based on my analysis of information provided on the top three sites, I found out that centrifugal pumps support different types of bearings including ball bearings, roller bearings, or sleeve bearings. Which has various applications and advantages:

- Ball Bearings: These bearings are commonly selected owing to their capacity to take both radial and axial loads thus quite useful. It is deduced from the sites that their small size and effective operation enable them to be applied in pumps for general service.

- Roller Bearings: These bearings withstand prominent radial loads, they are canopy pumps especially where work has heavy pressure or greater pumping action. The recommendation goes well with the capacity of higher loads.

- Sleeve Bearings: They are characterized by low maintenance and moderate radial load which is why they are used to quiet and smooth pumps.

Always among the consistent attributes that are underscored are the dynamic load ratings, the speed rating, and the lubrication requirement for specific bearings. The dynamic load ratings must comply with the operational requirement within which the pump is expected to operate to avoid an early failure. Breaks in the speed performance should also be maintained in such a way that bearings do not work under excessive loads than what they are rated, as this results in overstraining. Furthermore, correct lubrication is less controversial and is considered to be necessary for reducing friction and facilitating operation in all the materials reviewed. Knowing these parameters and on the other hand picking the right bearings enables one to enhance the performance and life span of centrifugal pumps.

Advantages and disadvantages of each type

Ball Bearings

1.Advantages:

Can support radial and axial loads simultaneously without difficulties.

The small configuration enables these components to be fitted in many systems easily.

Generally better managing low resistance to friction enabling energy efficiency.

2.dvantages:

In which case they might not be suitable for applications involving the use of high radial loads.

The bearings may generate noise levels greater than other types.

3.Technical Parameters:

Dynamic Load Rating: It is central to maintaining the compatibility of the pump loads and avoiding fast failure.

Speed Rating: This figure should not be exceeded to prevent the occurrence of unnecessary rates of wear and tear.

Lubrication Requirements: This is more of an operational need where the bearings experience friction.

Roller Bearings

1.Advantages:

Outstanding in loads with radial components and is, therefore, applicable in high systems.

Fatigue life is prolonged because of proper bearing proportions enabling the load to be shared on cylindrical rollers.

2.Disadvantages:

Someone may have to think of more space and a stiffer supporting structure due to their horizontal website.

Weakness in the ability to naturally or actively direct propulsive efforts, hence motivation to web thrusts.

3.Technical Parameters:

Dynamic Load Rating: Among the factors that need to be demonstrated to ascertain the fitness for use in applications that are high pressures.

Speed Rating: It is important that the bearing operates within a range of bearing-designed parameters.

Lubrication Requirements: This is usually done at the preventive maintenance level to aim at cushioning wear and tear.

Sleeve Bearings

1.Advantages:

A cost-effective and easy maintenance solution for many applications.

These plain bearings are less irritating as well as operate at less friction hence generating less noise.

2. Disadvantages:

Supposedly for use within moderate radial loads, restricting them in more demanding environments.

Not appropriate for the introduction of sizeable axial loads.

3. Technical Parameters:

- Dynamic Load Rating: Incorporate installations where load requirements are moderate for proper operation.

- Speed Rating: The operational speed of the application must have a systemic limit.

- Lubrication Requirements: This reduces the friction and wear that would have been experienced over the period.

While taking these advantages and disadvantages, as well as technical parameters into account, I will know how to select the optimal bearing type for definite centrifugal pump applications based on the very best resources available on the web.

How to properly maintain pump bearings?

Lubrication and grease considerations

If sufficient precautions are not taken which include lubrication and application of appropriate grease then pump bearings will wear faster and least efficiently. Although there is much information I have gone through on the topic, I find it appropriate to say that it is of great importance to use the appropriate grease depending on the operating conditions of the bearing. Here are the key considerations: Such as:

- Liquid Lubricant: The use of high-risk materials like mineral oils and synthetic oils can be effectively put on hold due to the high performance of the applications to reach normal conditions of operation. They maintain a reliable lubricating film and protect against oxidation and thermal degradation.

- Grease Consistency: The consistency of the grease applied must be in harmony with the working speed and the working load of the bearing. A thin consistency grease for fast-moving parts is easy to use, on the other hand, thick greases are best fitted for places that are low rpm but have high tension.

- Re-lubrication Intervals: Maintenance that is carried out at regular intervals after a certain number of operating hours or based on parameters monitored, is key in averting surprises. Do not forget that, as most websites indicate, there is a lot that is involved in these aspects, and the key factor is the manufacturers’ recommendations.

Technical Parameters:

- Temperature Range: It is important to choose a specific grease relevant both to and within the range of grease mentioned will enable better performance of the parts operated in.

- Load Capacity: Make sure that the grease that will be used is capable of performing within the load range without failure.

- Viscosity: These will be dependent and compatible with the operational conditions, pure temperatures, and pure load conditions suitable for the industry will be done.

By taking these factors into account, I can perform pump bearing maintenance very efficiently while preventing the dangers of overheating, wear and tear as well as destruction.

Signs of bearing wear and failure

Very effective while also eliminating potential losses is the timely identification and reaction to the signs of early wear and failure of the bearings. These factors make it easier to identify damages to the bearing such as unusual noises, such as grinding or squeaking noises, leakage of excessive amounts of heat from the bearing housing, or vibrations that are higher than normal within the structure. Not to forget, physical damages like leaks of lubricant or even metal dust and shavings in the bearing cavity are also telltale signs of problems.

While searching for the top three-dimensional sites on the glossy surface of the Internet Google, I have collected three important aspects that help to carry on bearing maintenance and other related technical parameters:

Website 1: Stress regular checks on gas and temperature of bearing noise, vibration, and operation which are also early wear indicators, which are very important. It recommends using a condition monitoring approach to anticipate the problem before it becomes too big.

Website 2: Notes that lubricant analysis is very important. Looking for a shift in the color of the grease or the texture to a different story usually means contamination or spoiled grease. Suggested technical parameters consist of working temperature as well as viscosity on changing environmental temperature.

Website 3: Talks about overloading and misalignment. It presses the manufacturers‘ limit load and regularity in load alignment to prevent overload and misalignment of the bearings. Technical parameters describe control over bearing load and alignment by use of accurate level tools.

Simply put, by adhering to these guidelines and making policies out of operating circumstances together with justifications on the conditions of the bearings, I managed to achieve the bearing and machinery operational certification standard.

Routine inspection and maintenance tips

It is essential regular servicing and inspection is done on the machinery bearing that will help prolong its life and its bearing efficiency. Here are some practical tips:

- Inspections: Constantly check operations at certain time intervals for sound, motion, and heat to evaluate their levels. To mitigate these parameters condition monitoring systems can be procured or put in place.

- Lubrication Management: Examine lubricants and attend to them if there is anything unusual like color and even the texture. When performing lubrication, ensure that the lubricant’s viscosity is appropriate for the conditions to reduce costs of wear and tear.

- Load Management and Alignment: Do not apply excessive loads and ensure that the load is well-aligned so that there is an even weight distribution. The alignment should be done with precision tools and the load recommendation by the manufacturer should be observed.

I will, using the findings from the top websites, try to address the questions in the shortest way possible:

Continuous assessment of machines critically is quite important when it comes to inspection mainly for noise, vibration, and heat levels as they may signal the onset of wear. For such a circumstance, a condition monitoring system should be introduced to monitor normal functioning for timely concern when issues arise.

As regarding the lubrication analysis of grease for change or variation is useful as it can pinpoint possible problems. In changing exposure to an operational temperature, manners of viscosity may also alter together with possible environmental locations.

Both excess loading and misalignment are also similarly found to be against good rules, strictly focusing on the importance of observing load standards by utilizing the specification of aligned tools to avoid load dispersion.

Taking these technical parameters into account and keeping the endorsed practices in mind, I can effectively control bearing wear and increase machinery lifespan.

What are common problems with pump bearing assemblies?

Identifying cavitation and its impact

Cavitation in the pump-bearing house creates room for vapor bubbles in the hydraulic fluid owing to a drop in pressure below the temperature of the hydraulic fluid. This emitted energy is potent enough when these bubbles collapse that it results in damage to parts within the pump. Cavitation impacts adversely on the bones of the impeller, flow effectiveness of the system, noise & vibration levels, and in the long run, the pump system’s spoiling. Cavitation generally causes undesired sound, and vibrations and lowers the pump’s operational output and performance.

Moreover, to answer the questions presented above in a more structured, concise manner as per the findings from the top three websites on google.com:

It is necessary to perform regular checks for unusual sounds, vibration and changes in performance in the pump to detect early signs of wear. A condition monitoring system should be implemented to detect the problem in advance.

Regular assessment of lubricants and changes where applicable due to the state of operation and environment is crucial. Proper lubrication of the moving parts reduces the risk of wearing out or freezing of the moving parts.

Extreme load stress is avoided by following the loading patterns provided by the manufacturer on dealing with load limits and applying accurate tools for alignment purposes. High alignment allows for an even distribution of load and tolerable mechanical failure.

Through active control of the above-mentioned technical parameters and following the prescribed practices, I can solve bearing wear problems and increase machine life.

Issues with shaft alignment

Shaft misalignment can be defined as the angular or positional discrepancy exhibited by machine shafts and is also the most frequent phenomenon encountered in rotating machines. Such misalignment usually induces excessive vibration, noise, and accelerated bearing and seal failure. It may occur when the machine shafts are poorly joined, subsequently leading to a loss in power transmission efficiency and additional pressure on the machine parts. There are two main shaft misalignment categories namely parallel and angular which are usually identified by the various structures and simple correction methods they possess.

In the same regard, I would like to answer the questions based on my investigation of the first three sources on google.com:

Equipment should bar shaft and bearings inspected regularly for shaft-related anomalies to fault shaft alignment at the early stages. It is possible to avoid such situations by implementing corrective processes at a stage when a more serious tendency is not developed, via the use of condition monitoring techniques.

Particular attention is paid to the above aspects regularly. In particular, straightness and parallelism of the spindle axis to the casing must be verified routinely following such maintenance or simple procedures. Supply of precision alignment tools such as laser shaft alignment systems must be done concerning manufacturers’ recommendations on their use in the normal running of the equipment.

Correct alignment is critical to preventing overloading of the system. This aspect, within specified alignment tolerances of the equipment such as those indicated by the manufacturer, assists in load sharing and, in turn, the reduction of mechanical failure risks. It is necessary to apply the tools that are required for the performing of the alignment and recording the data about the alignment regularly to require a good culture of machine maintenance for longer use of the equipment.

Once again, proving the alignment parameters requires knowing the design and the operational parameters of the equipment, which, the steps given above assist in enforcing effectively.

How to address bearings to support the shaft?

To deal efficiently with the case of bearings concerning the shaft, several internet resources were thoroughly analyzed, which are provided below:

- Selection of Bearing Type: First, I selected the bearing type suitable for the application, be it ball or roller bearings, depending on the load, the speed of operation, and the operating conditions. The definition of the above operational environment includes load rating, operating speed, materials, and sometimes plastic.

- Fitting and Proper Adjustment: The bearing should be installed and fitted accurately so that it serves the intended purpose. If there is misalignment, this can result in wear and failure of the bearing earlier than expected. I discovered that alignment of this sort to eliminate excess stress on the bearings is essential and timing belts compatible with the shaft were used.

- Routine Maintenance: Adopting a specific period for carrying out maintenance on the bearings aids in the assessment of the bearings, surveillance of the state, and noticing abnormalities at an early stage. This involves having to test the amounts of the lubricants supplied since too little lubricants would result in a rise in temperature and failure of the machinery.

- Consideration of Operating Environment: There is important maintenance of the bearings addressing such factors as extreme temperatures, dust or moisture, etc. As usual, I have also taken care that any arrangement for protection such as sealing or shielding is appropriate to these conditions.

In conclusion, I have adequately supported the shaft bearing on all axis loads by basing the design on bearing technical parameters such as load rating and alignment tolerance, application requirements, potential bearing loads, and regular maintenance. This approach, as relative sources establish, guarantees both the efficiency and service life of the equipment in mind.

Frequently Asked Questions (FAQs)

Q: What is the difference between inboard and outboard bearings in centrifugal pumps?

A: Inboard bearings are located on the drive end (DE) side of the pump, while outboard bearings are situated on the non-drive end (NDE). The inboard side usually supports radial loads, whereas the outboard side may handle both radial and axial loads, depending on the pump design.

Q: Why are inboard and outboard bearings used in centrifugal pumps?

A: Bearings are used in centrifugal pumps to support the rotor and keep it aligned with the pump casing. The type of bearing used (radial or thrust) depends on the specific load conditions and pump design, ensuring smooth operation and preventing premature failure.

Q: How does the type of bearing affect pump performance?

A: The choice of bearing, whether a rolling element or a sealed bearing, affects the pump’s efficiency, reliability, and maintenance requirements. Proper selection and maintenance of bearings are crucial to avoid common failure modes and ensure optimal performance.

Q: What is the role of the pump coupling in bearings?

A: The pump coupling connects the pump shaft to the motor or gearbox. It ensures that the alignment of the shafts is maintained, reducing stress on the bearings and preventing misalignment that could lead to bearing failure.

Q: How can I identify if a bearing on the outboard side needs to be replaced?

A: Signs that an outboard bearing needs replacement include unusual noises, increased vibration, and temperature rise. Regular inspections and monitoring can help identify issues early. If you suspect a problem, contact your pump manufacturer for guidance.

Q: What are the common failure modes for bearings in centrifugal pumps?

A: Common failure modes include wear and tear, contamination, inadequate lubrication, and misalignment. Understanding these modes helps in diagnosing issues and taking preventive measures to extend bearing life.

Q: Can I change the type of bearing used in my pump?

A: Changing the type of bearing (e.g., from a rolling element to a sealed bearing) is possible but requires careful consideration of the pump design and operating conditions. Always consult with your pump manufacturer before making any changes.

Q: How does a thrust bearing differ from a radial bearing?

A: A thrust bearing is designed to handle axial loads (along the axis of the shaft), while a radial bearing handles loads perpendicular to the shaft. Both types are essential in maintaining the stability and efficiency of the pump.

Q: Where can I find more information about bearings in centrifugal pumps?

A: For more detailed information, you can contact us or refer to related content provided by your pump manufacturer. Always ensure that you are following the guidelines and recommendations specific to your pump model.

Q: How do I ensure the privacy of my information when contacting pump manufacturers?

A: When reaching out to a pump manufacturer or any service provider, always review their privacy policy to understand how your information will be handled. Most reputable manufacturers will have strict policies in place to protect your data.