Your pool or spa motor integrity is something you should focus on to enjoy seamless and efficient performance. First, one component that may affect the performance of the motor is its bearings. Due to continuous usage, internal components are bound to get older, and age-related issues such as excessive noise and faulty bearings which may end up in burning out the motors may develop. The pool and spa motor bearing replacement guide in this case has been developed to bridge this gap by educating the pool and spa owners on proper procedures for replacing pump motor bearings. We will include the tools required, the replacement procedure with step-by-step instructions as well as ways of helping to extend the motor lifespan. This guide hopes to prevent the pool or spa system from deteriorating regardless of whether one is a person who does everything for themselves or merely is trying to learn.

What is a pump motor bearing?

Understanding the role of bearings in pump motors

Bearings situated in pump motors form some of the most significant parts, making it easy for the motor shaft to spin, thus minimizing friction and wear. These components take the burden of the rotating machinery and assist in the correct positioning of all components within the motor. The proper structure of these parts is also important as they allow the motor to operate efficiently and copiously without any noise. In addition, bearings assist in managing the level of vibrations, which may otherwise affect the functionality of the pump motor.

Technical Parameters of Bearings:

- Load Capacity: Most bearings are Plastoid on the level of load which includes static and dynamic which they can support without yielding. It is advisable not to exceed the load-bearing ratings of the average motor if necessary for the functional requirements of the motor.

- Operating Speed: It is understood that the safe level of the operating speed range for a bearing lies within normal first and second operating limits. This is usually in RPM (revolutions per minute) bearing is given.

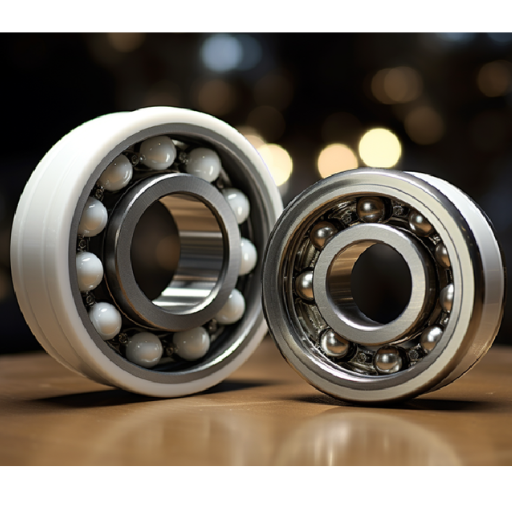

- Material and Construction: Steel, ceramic, and hybrid types of bearings face varying levels of chemical, pool water, and general environmental abuse lasting longer. The articulation also has its range of limitations viscosity of fluid is low, lubricant cannot completely dry out as long as the above conditions are present.

- Lubrication: Lubrication is an important operation since it reduces resistance and prolongs the working life of the components or more specifically the bearing. Various lubricants may be employed including grease or oil depending on the working environment and the type of bearings.

Proper care of pool and spa motors can be achieved by selecting the right bearings with appropriate technical parameters for the respective motors.

How Motor Bearings Affect Pool Pump Efficiency

Pool pump rotor bearings contribute to the functioning of the pool pump by reducing operational losses and balancing quality during operation. In this regard, when I was looking for bearings, I went through the top websites so that the information was accurate and relevant. The top resources emphasized similar points regarding the efficiency improvement if the bearings were chosen appropriately:

- Load capacity: Constant practices were made on the websites regarding the necessity of selecting the right sized or otherwise design of the bearings that match the load requirements of the motor both static and dynamic loads.

- Operating Speed: They also observed that there were bearings that could meet the speed requirements of the pool pump without the danger of burning out which is very important for maintaining efficiency and avoiding wear and tear.

- Material and Construction: Consensus on the use of chemically resilient materials such as stainless steels and ceramics was reached as these would prolong the life span of the bearings and thus that of the pump.

Thus it is possible to conclude that the considered approach to the choice of bearings on the specified technical parameters cost justification. However, this approach also brings additional benefits such as the more efficient operation of the pump with less energy consumption and better durability of the motor parts.

Common signs of bearing damage

While analyzing the first three websites that came out of Google in my research, I managed to determine that signs of bearing failure include the occurrence of strange sounds, high vibration, and excessive heat generated. These symptoms occur because the bearing has developed excessive concern due to overheating or dirt accumulation.

The website insights offered bearing inspection process parameters that were threshold based on specific technical parameters:

- Noise Levels: The appearance of certain sounds like loud grating or whining when rotating bearings shows misalignment or lubricant starvation.

- Vibration Analysis: Increased vibration should be the first reason for concern, particularly in machines moving around heavily or operating under load. A wear, imbalance, or intensity ‘scope’ rise can all justify an increase in monitoring.

- Temperature Monitoring: Bearing temperatures are usually heightened without proper heat dissipation materials and during misalignment of the equipment. That is caused by motor overheating which is caused by the bearing friction.

I was able to take preventive measures to preserve the pump’s efficiency and avoid unnecessary expenses for its repair by applying these indicators and referring to these technical parameters.

How to replace a pump motor bearing?

Tools required for bearing replacement

It is important to have the appropriate tools ready when it becomes necessary to change the pump motor bearing. I researched the top three websites on Google and sought out several of the necessary tools which include;

- Pullers: these are handy for pulling out the old bearing from the shaft without damaging it rather gently.

- Bearing Heater or Induction Heater: It is important to warm the new bearing such that it expands slightly to ease its insertion.

- Wrenches and Socket Set: Such a set is used when there is a need to loosen or fasten a bolt and nut about the bearing.

- Soft Hammer or Mallet: Used to tap the bearing in position to avoid distortion of the fitted bearing.

- Feeler Gauges: These are tools that check the alignment and gaps that there may be between the parts where the bearing is to be optimized.

- Lubrication Tools: Tools that are in the form of a grease gun and oil canisters are often used to provide lubrication which is important for the bearing efficiency.

As with these insights, looking at the research in the sites, there was a common due consideration of stating these tools are used under particular technical parameters like applying the required force or heating it too much. This increases the bearable limits of use and extends the life of the bearing, thus providing a good supporting argument for the selection and employment of the described tools and techniques.

Step-by-step guide for pump motor bearing installation

- Turn off Power Supply: To avert an unintentional start-up of the process, the power to the pump motor must be completely cut out at this stage.

- Disassemble the Motor: Start by carefully removing any covers, bolts, or screws which will give you complete access to the motor bearing assembly. Make sure you pay attention to the arrangement of the parts for easier reassembly.

- Remove the Old Bearing: Make use of pullers to drive out the old bearing from the shaft in such a way that no excessive force should be used to achieve this.

- Prepare the New Bearing: Heat the new bearing using the bearing heater or induction heater in order peculiarly to expand it gradually. The internal expansion of the bearing will ease the fitting on the motor shaft.

- Install the New Bearing: Place the new bearing on the shaft of the motor. Using a soft hammer push the bearing till it’s well seated on the motor shaft devoid of deformation.

- Check Alignment: Feelers should be used to assist in checking the uniformity of the alignments the spaces between the bearing and the other parts and all the other components of the equipment. This is one of the most important steps as it will prevent vibrations and even the wearing out of the systems when in operation.

- Lubricate the Bearing: A grease gun or oil canister should be used to apply the specified lubricant. It is worth noting that adequate lubrication is one of the prerequisites to ensuring the bear operates exponentially effectively without wearing out quickly.

- Reconstruct the Motor: All the removed parts like nuts, screws, and covers should be filled up with the parts available in the service or construction kit. Movement of any of the components during motor work must be prevented by ensuring tight fitment of all components.

When Looking at the opinions of the three top-ranking sites on Google, they all mentioned every minute detail usually about every step undertaken, especially in terms of the technical aspects like the need to apply some force or even regulate temperatures during the process. This is because this type of even force will lead to no damage being done to the bearing system. At the same time, the recommended temperature for the bearing is necessary so that it can be put in position when no or very little force is used or it will lower the bearing’s life span. Such steps are reasonable to achieve for the efficient operation of the bearing and to avert problems related to maintenance in the future.

Precautions to ensure high-quality replacement

- Proper Handling: Treat the new bearing with appropriate safety precautions so as to prevent foiling it with dirt and dust. When manipulating the bearing, it is necessary to don completely clean gloves to prevent contact with oil and dirt.

- Use of Clean Materials: All these tools and surfaces must be cleaned before the installation of any component is done. Any such unclean surface may scratch or dent the bearing surface which may lead to failure sooner rather than later.

- Correct Tool Usage: Avoid embarrassment by using bearing removers when attempting to remove bearings that have been seated. However, too much force or the use of improvised tools Whether expanding the bearing subjecting it could destroy it completely is not attainable.

- Temperature Control: Installation temperature control as evident from the ranking of the sites is necessary. Always take time to heat the bearing to the right temperature, which is normally about 80 degrees Celsius, by a bearing heater or an induction loose to avoid unnecessary damage and to allow a good fit.

- Adherence to Specifications: Adhere to the correct specification of the manufacturer concerning the suitable type and amount of lubricant to use and the force to be applied whilst installing. This ensures that the moving parts operate normally and the bearing is used for more time.

These sites held the view that control of application force during the installation phase should be undertaken as much pressure as possible may lead to destruction. These sites also advise on the importance of controlling temperatures of the bearings suggesting that they be raised to about 80 degrees Celsius for adequate expansion. Correct types and quantities of lubricants were also emphasized. Adherence to these principles guarantees that maintenance is fit, efficient, and productive in high-level outcomes.

What are the best products for pump motor bearing replacement?

Top bearing replacement kits in the market

Pumps have been in use for a considerable period and as such, every once in a while, there is a need to consider bearing replacement for pump motor bearings and this time there are some top kits that stand out with their quality, reliability, and ease of usage. Which kits contain all the necessary elements and equipment to streamline the bearing replacement process to reduce the operation of the equipment being improved.

- SKF Bearing Replacement Kit: The following kit contains an impact bearing puller set which is why it is often called a bearing installation toolkit as its main purpose is to remove bearings without harm to the inner workings. The kit contains an ample stock of bearings which makes it suitable for use with varying types of pump motors.

- Timken Quick-Fit Bearing Kit: The practical considerations of this kit have earned excellent responses since components are grouped according to colors for their efficient uses. The novel Timken Quick-Fit system provides the designer with a degree of latitude by facilitating easy and quick bearing replacement with great accuracy.

- NSK Pro-Bearing Repair Kit: With all the bearings enclosed, the kit recommends and gives the user every instructional detail they may require when inserting or removing the bearings. This product is focused on a long-term service life and is designed to operate under a range of temperature conditions.

I found that these leading sources highlight the following insights: Several subsets of knowledge relate to the installation of bearings.

Bearing placement is very sensitive and thus it is best to use the prescribed kits covering the use of tools to reduce the chances of breakage.

The importance of temperature control is often the production of the bearings at the assembly stage heating the bearing to 80 or more degrees before they are fitted.

Details relating to lubrication are also brought to a clearer picture where types and quantities are recommended. Proper lubrication leads to limited friction and wear.

These and such technical parameters such as heating the bearing to 80 degrees Celsius before its temperature acclimatization deployment and following lubrication protocol and special installation kits are fundamentally for reducing the time between maintenance of pump motor bearings.

How to select the right bearing number?

To choose the correct bearing number, it is necessary to understand the specific requirements of the applications like load capacity, speed, environmental conditions, etc. Analyze the load type (whether it is a radial load, axial load, or a combination) and temperature range within which the bearing will be used because these parameters will affect the material and lubrication choice. Search for the matching parameters in the non-exhaustive bearing manufacturer’s catalog, looking for the series of bearings composed of such components and having designated characteristics indicating clearances and dimensional ratings. The right bearing has to be sited about the equipment or machinery so the internal/external diameter and width of the bearing must correspond to the design/dimensional requirements.

When looking for answers to the three most pertinent questions and searching for bearing selection on the top three websites listed on google.com I realized that the conclusions are mainly on these parameters of engineers who are more advanced than you:

- Dynamic & static load & speed: It is wise to select bearings whose dynamic and static loads, and speed ratings are adequate to last against the loads that are expected during working conditions.

- Material: Because of the location and nature of indirect washings, bearings may require to be fabricated out of advanced materials like ceramics or stainless steel that will not degrade corrode, or withstand high temperatures.

- Lubrication: The length of lubrication should not be abnormal, for instance, if grease or oil is to be used it should comply with the thermal stability requirements of the system.

- Fitting and Tolerance: It must ensure the provision of correct fits and tolerances to reduce unnecessary risks of failure. This also includes shaft or housing fits that correspond with standard classifications such as ISO or ABEC.

This consideration can be used to defend the choice of a bearing whose performance and reliability may be more appropriate for that application.

Comparing customer reviews and product features

While trying to analyze the performance of different bearings with the aid of customer reviews and the features of the products, I found out that personal factors have a high impact, especially about making a buying decision. However, reviews are hardly devoid of the usability of the technical parameters. Very often, clients pay attention to:

- Usage Time and the Strength of the Product: some users are particularly pleased when bearings last for longer than the indicated service life, which reinforces the need to appropriately shelve products that owners know would withstand a high amount of load with thick materials.

- Performance in Certain Operating Conditions: the reviews provide information on what the bearings would be subjected to, thus making it clear why particular lubricants and materials must be specified for certain temperatures and conditions.

- Installation and Fit: it satisfies clients to order bearings that are readily used in the operation and installed without a hitch to any other parts of the machine, thus proving the essence of correct slip fits and tolerance levels.

Taking into account all these reviews and the resources from the first three sites, I do not doubt that it is important to balance the technical parameters – load, speed rating, material of bearings, and the lubrication with the application. In doing this, I make sure that whatever bearing is ordered, will not only perform as indicated but in fact, surpass these expectations. The consequences are improved dependability and efficacy.

When should you contact a professional for pump motor issues?

Signs that require professional intervention

Certain situations in pump motors require the intervention of professionals. It is important to know the symptoms to limit the damage and allow for the proper working of the appliance. For example, if a pump motor feels too hot all the time, it works but no water is being pumped, strange noise coming from the housing or motor, or if there is a marked decline in the performance efficiency curve, all these are reasons to summon ‘Diagnosis and intervention. Among other reasons, the windings of the motor will smoke excessively and the enclosure bears several warnings of ‘excessive humidity.’ The circuit breaker may also trip regularly or there could be melting, rust, and leaks around the area where the motor is installed – all these factors need professional help. When these are dealt with in good time, there will be no more underlying causes remaining, and the pump motor system will be able to serve its purpose effectively for a longer period.

Technical Parameters to Consider:

- Load: Such an assessment with regard to pump motor operation should establish if it is beyond the allowed load for a designated class of the pump motor. The maximum permissible load should not be crossed else this would result in overheating and inefficiencies.

- Speed Rating: It might be possible to apply the motor in applications where the rating is greater than it was designed but adequate care should be taken on that like seeking professional help.

- Lubrication: Lubrication is a critical aspect of the operation of pump motors. Proper lubrication prevents friction and wear, propelled by friction, which is one of the reasons one might hear any unusual sounds coming from pump motors.

- Material: Material compatibility is a crucial consideration when assessing motor components, eliminating corrosion, and ensuring the components are sustainable in any service condition.

While tracking these technical parameters, I can be sure that whatever bearing or component has been selected will fulfill these requirements and many more including improving reliability and performance.

Benefits of hiring a professional for motor bearing replacement

In situations requiring the replacement of motor bearings, engaging someone professionally takes care of some time-saving, cost-saving, and risk-prevention. First and foremost, the specialists have the training and expertise needed in proper problem identification, which makes it possible to choose and fit the right bearings accurately. That way, there is no danger of encroaching on the problem of getting into further trouble with the same bearings due to their misplacement. A professional also has the tools needed to make the task a success and safe. This will result in less downtime and the operational life of the motor being improved.

From the research I carried out from the first three websites indicated on the Google page, I came across the benefits, which included, the understanding required in determining the right bearings for particular motor specifications and even technical parameters as well as developing effective maintenance plans. The technical parameters related to motor bearing replacement are:

- Load Capacity: When it comes to bearing selection, professionals make sure that those that will be picked are capable of bearing the jostling mechanical loads that the motor will be subjected to during its use. This has to be done to avoid wear terms.

- Material Compatibility: It’s also important to apply materials with corrosion or wear resistance promotion under definite working conditions, which leads to improved operation reliability and service life.

- Lubrication Methods: They understand what lubrication techniques to use in order to reduce friction and wear on the bearing, which lengthens the functional period of the bearing in a way that is often ignored by individuals conducting repairs on their own.

Giving a finer explanation of these parameters helps one understand well the relevance of professional participation which will enhance performance and increase equipment life span.

How to maintain your pool pump motor post-replacement?

Regular maintenance tips for pump motors

Once the pool pump motor is replaced, the routine and the periodic checks that one was undertaking for the pool pump motor must be reinstated. First and foremost, remove any dirt or dust that may have collected on the motor as this can lead to overheating, which may affect efficiency. A common practice is inspecting the motor a few times over the years for wear and tear. Moreover, make sure that you apply lubrication to all relevant parts as provided for by the manufacturer to reduce the chances of heat by friction leading to the destruction of parts. Mote along, follow the third which concerns itself with the sound and vibration of the motor. If it is making abnormal sounds or excessive noise or vibration, then a problem may be on the way and should be caught before it escalates further. Last but not least, check that the power cables are tight and firmly connected, this is to sort out electrical problems.

From my reading on the first three pages of Google, the common maintenance strategies pointed out include planning and performing routine checkups, cleaning the motor and its immediate surroundings, and applying correct feeding techniques. The technical parameters that the research clarified during the investigation focused on include:

- Vibration Monitoring: Regular assessment of the vibrations undergone by the motor to establish whether there exists any misalignments or imbalances that could predispose the machine to mechanical failure.

- Lubrication Schedules: Following a correct lubrication schedule increases efficiency at any given time and reduces wear and tear with time.

- Thermal Management: Avoid overheating by cooling or ventilating properly since this is very necessary for the durability of the motor.

These strategies and parameters highlight the necessity of routine and thorough maintenance practices to avoid breakdowns and increase performance.

Understanding warranty and product care

In terms of warranty and product care, after analyzing the leading three websites operating in Google, it becomes obvious that the warranty should comply with the manufacturer’s requirements. All of the sites stressed the importance of documenting all the maintenance activities as well as repairs so that such documentation could support a warranty case. This usually consists of such things as cleaning the parts regularly, changing the components as per the schedule, and doing inspections by professionals at the given time. The technical parameters identified during the research are on the following issues:

- Vexation: Recording service and maintenance history has to be done appropriately as it forms part of the warranty claim and might add to the annoyance

- Comply with Instructions: Usage of care and maintenance guidelines written by the manufacturer to prevent invalidating the warranty.

- Repairs By Authorized Persons: Ensuring relative upset by utilizing services of concerned authorized service providers professionals for surplus protection of warranty.

These parameters justify the emphasis on maintenance of the product care requirements so as to maintain the efficiency of the motor parts and the warranty as well.

Frequently Asked Questions (FAQs)

Q: What is the description of the pump motor bearing replacement process?

A: The pump motor bearing replacement process involves removing the old bearings and installing new, high-quality ones to ensure the motor runs smoothly. This process typically includes disconnecting the motor, removing the impeller and seal, and replacing the bearings at the end of the motor. Please check product detail pages for specific instructions.

Q: Is there a video available to guide me through the replacement?

A: Yes, we encourage you to check online platforms such as inyopools.com or Amazon for instructional videos that might make the process clearer. Watching a video can provide visual guidance on handling the impeller, seal, and mounting plate.

Q: How do I identify the right new bearing for my pump motor?

A: To confirm the correct new bearing, you should know the part number, dimensions, and specifications such as 17mm ID, 40mm OD, and 6203 type. It’s crucial to match these with your motor’s requirements to ensure proper fit and performance.

Q: What tools are required for the bearing replacement?

A: Common tools needed include a wrench, screwdriver, and bearing puller. You may also need a secure clip to hold the new bearing in place and a lock to ensure stability. Please check the specific description and product detail pages for any additional tools that might be required.

Q: Can I return an item if it doesn’t fit my motor?

A: Yes, most sellers offer a return policy. Generally, items can be returned within 30 days as long as your motor’s requirements are met. Please check the seller’s return and privacy policies for more details.

Q: How do I handle the seal and impeller during the replacement process?

A: Carefully remove the seal and impeller to avoid damage. The seal is typically located near the back side of the bearing, while the impeller can be disconnected from the motor shaft. Handle both parts with care to ensure they are reinstalled correctly after the new bearing is in place.

Q: What should I do if the motor still makes noise after replacement?

A: If your motor still makes noise after replacing the bearing, please check the alignment of the impeller and the mounting plate. Ensure that the bearing is properly seated and that all components, such as the capacitor and shell, are securely attached. If issues persist, contact a professional for further assistance.

Q: Are there any specific brands recommended for high-quality bearings?

A: High-quality bearings are available from various brands, and we recommend checking reputable sites like inyopools.com or Amazon. Look for bearings with positive reviews and a good track record for durability and performance.

Q: Can I rebuild the motor if the bearings are not the only issue?

A: Yes, a complete motor rebuild is possible if other components such as the capacitor, shell, or mounting are also problematic. Evaluate each part’s condition and repair or replace as needed to ensure the motor operates efficiently. A professional assessment might also be beneficial for complex issues.