The role of a dependable and economical component in water pump systems is self-evident regarding their superior functionality and durability. From automotive engines to industrial machines where efficient performance, precision, and unmatched durability are the utmost priority, these components pump life into innumerable applications. Knowing how high-quality water pump bearings work will help you to make informed, cost-efficient decisions that bolster maintenance planning and operational efficiency. This blog aims to deliver valuable insight into reliable water pump bearings’ features, benefits, and applicable concerns and their impacts on different systems.

What Are the Key Features of a Water Pump Bearing?

Understanding the Role of a Pump Bearing in an Engine

The water pump bearings are crucial because they help an engine function smoothly by supporting the rotation of the water pump shaft. Their main roles are to ensure proper spacing, alignment, and friction to allow coolant to flow in the engine’s cooling system, preventing the engine from overheating, protecting vital components, and improving performance.

In other words, the water pump bearings affect essential technical parameters like load capacity, rotational speed, and durability. Take, for example, high-load-capacity bearings; these optimized bearings are most needed where tension from the belt and radial forces are exerted. Increased tolerance towards wear enables effective operation at higher rotational speeds and even under increased radial forces and weaker flowing conditions, and coolants tend to be stuck in a flowing state. The most important thing, however, is durability—superior materials and precise manufacturing ensure effective resistance to vibration, thermal expansion, and corrosion. With these considerations, engine operating life enhancement and required maintenance reduction is possible.

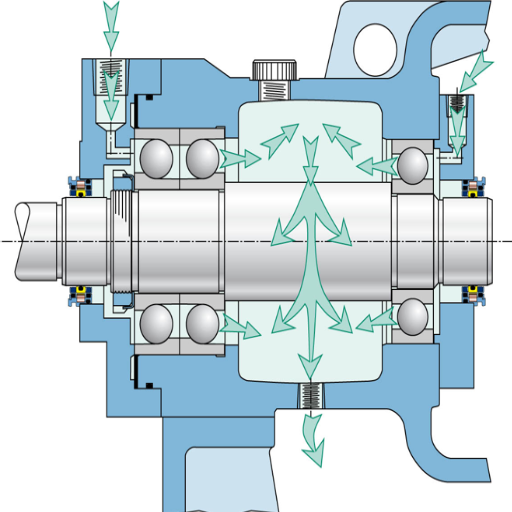

How Does a Water Pump Bearing Cool the Engine?

In short, the water pump bearing supports the shaft of the water pump, which is responsible for driving the impeller. This ensures efficient engine cooling. The imperative circulates coolant throughout the engine block and radiator to maintain an optimal temperature. If the bearing operates correctly, smooth rotation will be achieved, ensuring proper coolant flow. On the other hand, bearing deterioration or failure can cause coolant regulation issues, engine overheating, or even damage.

Rotational speed – bearings must withstand speed without losing efficiency in impeller movement.

Load capacity – bearings can endure radial and axial forces while ensuring long-term performance.

Material quality – materials must be corrosion resistant and high grade to enhance cooling efficiency.

Lubrication and sealing – effective seals help prevent contamination, while proper lubrication reduces heat buildup and friction.

All the components of the water pump bearing system are interdependent, and their function is to control the engine temperature and improve overall aesthetic functionality.

Identifying the Seal and Shaft Components

To answer the questions asked directly, let us now look into the seal and shaft parts in the summary and their relevant aspects from a technical point of view.

Seal Operability—A seal is an element that protects the boundaries between different compartments in a water pump. A seal that functions correctly in a water pump system will block the escape of lubricant and coolant to other parts of the system. If a seal is breached, there will be direct implications for the lubrication maintenance and system, as well as significant stand corrosion and a reduction in the bearing system’s life. Thus, a seal material should be durable and not degrade at high temperatures to be reliably operational.

Shaft Properties—Water can consistently circulate through the system as a result of the efficient rotation of the shaft. The strength of the material and its design affect its ability to withstand thermal expansion and its physical bulk. An imprecisely designed and manufactured shaft can throw a system out of balance due to excessive wear on specific points of the bearing’s actions and, thus, be unreliable in sustaining life in the system. Shaft alignment and the material type of the system directly depend on its efficiency.

These factors fully utilize the system’s capacity and prevent breakdowns by narrowing down seals, shafts, and other parts. These technical factors encompass a fully functional water pump system, and special care should be taken to observe them.

How to Choose the Right Pump Bearing for Your Vehicle?

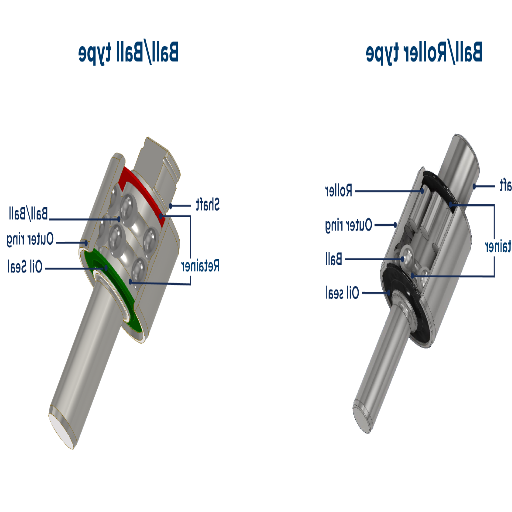

Comparing Ball Bearings and Roller Bearings

Choosing between ball bearings and roller bearings always depends on how each type affects the technical aspects of the particular water pump system. I pay attention to two things: the estimated speed of the water pump and how much radial and axial load the water pump system has. Precision ball bearings are often superior when dealing with radial and axial loads in high-speed applications. However, roller bearings are the best at handling heavy radial and high axial loads, making them ideal for long-lasting systems that focus on reliability and high load at moderate speeds.

Parameters such as the load capacity, the speed rating, the alignment tolerances, and the overall durability of the component should always be considered. Ball bearings are always best in high-speed systems due to their rolling resistance. In contrast, roller bearings outperform ball bearings in most other applications, especially ones that involve high torque but tend to have more friction. Proper material composition of lubricants is also critical since it affects bearing lifetime and system efficiency, at least in most cases. Ultimately, there is always a compromise between these technicalities, which are focused on the demands set by the water pump system in the vehicle.

Why Opt for High-Quality Automotive Bearings?

“Smoothing operations by reducing wear automatically extends the lifespan of critical automotive pump systems. As a result, the vehicle systems will always be high-performing and durable. Costly repairs, as well as downtime, can easily be avoided by using premium automotive bearings. Repairing vehicles is one option that no owner wants to take, key components are expensive and there is no guarantee that the repairs will work. A firm, clear solution for the problem is the use of premium automotive bearings from renowned manufacturers.”

Optimal quality automotive bearings aid in ensuring system efficiency while improving vehicle performance. High-precision bearings are identified through the following key aspects:

Bearing material composition: Automotive premium bearings need to be more resistant to corrosion, extreme temperatures, and wear. Offering these resistances requires the use of premium-grade steel or ceramic materials.

-load capacity: reliable bearing materials can endure radial and axial loads and extreme operating conditions.

-friction coefficient: Optimized bearing materials lessen system performance energy loss and improve overall effectiveness; the material also has other positive anti-resistive characteristics.

-dimensional precision: Tight tolerances that ensure smooth and quieter operation always lead to more accurate manufacturing.

-lubrication: minimal maintenance and advanced performance guarantee pre-lubricated designs incorporating an advanced lubrication system.

The direct benefits of using high-quality aids include automatically reducing energy consumption while improving vehicle longevity and safety. Premium automotive bearings enable all these benefits, clearly highlighting their importance in differing automotive applications.

Factors to Consider: Temperature, Rate, and High Speed

If you’re choosing bearings for high-performance applications, it is incredibly important to review the following factors: temperature, load capacity, and high speed.

Considerations: The internal construction of the part in question has to endure extreme heat or cold without exacerbating ineffective issues. To accomplish this, it is recommended to use ceramic or high-grade steel that can be relied on to work between -40 to 500 (-40 to 260). Also, a reasonable measure of heat dissipation and lubrication is key in preventing material modification and expansion due to heat. Lastly, proper measures must be taken to ensure the part lasts long and works effectively.

The dimensions of the working part constructed have to sustain the expected load, both dynamic and static. Ensure the part has a dynamic load rating that either accumulates with or exceeds the operational loads range, which is often covered in the technical specifications, is the value most likely associated with the aforementioned overloading factor, which ends up causing tolerances to be excessively worn down.

High-speed parts tend to heat and produce friction at a higher rate. As such, the dynamic capacity, usually called RPM, tends to require severe amounts of lubrication, which puts additional constraints on the assigned bearings. Any ultra-high-speed loom works most effectively using angular contact or hybrid ball bearings that accommodate stronger centrifugal forces.

Fine-balancing these limits with regard to the references garnered from manufacturer specifications ensures that specific claims as to the functional parameters rely on the claim made for their manufacturing.

Who Are the Leading Water Pump Bearing Suppliers?

Exploring Options: Koyo, Timken, and China Suppliers

When looking for water pump bearings suppliers, Koyo and Timken, along with other reputable companies from China, are indeed good choices. Here’s a matrix of their products and other relevant details that might help you choose.

1. Koyo

Koyo is known for its quality bearing production, where precision is highly regarded. Their water pump bearings are well known because of:

Material: Corrosion-resistant, premium steel ensures durability for long periods.

Load Capacity: Competently manages and withstands high radial and axial loads.

Speed Ratings: Operates at 6000 RPM and above for automotives.

Koyo bearings are associated with and are known for making a consistent rotary motion requiring minimal servicing during long periods.

2. Timken

Timken ensures their products are focused on innovation and reliability by producing bearings that function perfectly in challenging conditions. Here are some product highlights:

Self-Lifting Seals: Enhanced protection against all types of contaminants.

Load Support: Customized for construction shock and heavy-duty work with thick super coated.

Temperature Tolerance: Immediately operational under extremities of over -30F and +250F.

Applications needing strength under changing operating conditions greatly benefit from Timken bearings.

3. China Suppliers

Chinese manufacturers offer less expensive alternatives that produce competitive results. Quality can be an issue with some suppliers, but on average,e some critical parameters include:

Customization: Bearing design, materials, size, and other parameters can be tailored to the customer’s requirements.

Affordability: Prices are classified as cost-effective without undue tradeoffs on the primary functionality.

Standards Compliance: Many products have claimed to comply with accepted international standards (ISO, ASTM) and are therefore considered reliable.

When sourcing from China, appropriate checks on certificates, processes, and even the supplier might be needed for constant quality.

With a little effort in defining their technical parameters, these suppliers can match any selected water pump application for high performance, low cost, or a combination of both.

Evaluating OEM and Aftermarket Spare Parts

At the forefront of the information bosoms of water pump systems performance, compatibility, OEM (Original Equipment Manufacturer), and aftermarket spare parts can suit most of the requirements. Original parts manufacturers are reputable and custom-made by the originating equipment manufacturers (OEM). They have the highest reliability and consistency with the equipment specifications. Also, OEM parts norms and standards, such as ISO or ATSM, ensure long-lasting effectiveness. On the flip side, aftermarket spare parts refers to parts manufactured by other companies, these are usually cheaper and or may offer different levels of added value.

Components and Castings: Check if the castings and components made of bronze, cast iron, or stainless steel are appropriate for the work environment, e.g., are corrosion—or abrasion-resistant.

Casting Precision: Determine if the measurements of the water pump match to eliminate any fitment or operational problems.

Functional Precision: Verify if the pressure and temperature satisfy the system’s requirements.

Efficiency Rating: Examine the flow’s speed, energy use, and noise production in relation to the desired operational goals.

Coverage and Average Life: Evaluate based on a comparison of warranty period and life expectancy for accuracy, reliability, and long-run expense.

Mix and match these parameters to cover almost every possible aspect of the specific system requirements to optimize costs, durability, and functionality.

How to Find a Reliable Supplier?

To locate a dependable supplier, you must first assess their ability to maintain in-depth quality standards, consistency, and technical capability:

Experience and Knowledge: Evaluate whether the supplier possesses the required industry experience and can deliver components or services that satisfy your technical requirements. Check if they have any relevant certifications that make them credible.

Product Quality Standards: Cogently ensure compliance with prevailing standards such as ISO certifications or any other compliance. Confirm that the supplier has technical data sheets outlining essential parameters like material grade, operating limits, and performance characteristics.

Delivery and Lead Times: Check whether the supplier can deliver their products to you on time and within any specified deadlines on the given projects, especially bulk or custom orders.

Customer Assistance and Service: Suppliers with exceptional customer service value their customers’ needs and issues. They also provide technical support, which ensures seamless operation of the product throughout its life cycle.

Meeting these criteria and clearly requesting product documentation will help you qualify a supplier who meets your precise technical and operational requirements.

How to Maintain and Extend the Life of Your Water Pump Bearing?

Regular Checks: Preventing Water Pump Leakage and Seal Failures

Routine maintenance and inspections must be done to prevent water pump leakage alongside seal failures. The first step is to note visible leaks or strange noises, which may indicate damage to the seals or the bearings due to wear. Furthermore, ensure the pump is operated within the technical parameters prescribed by the manufacturer, such as:

Operating Temperature: To avoid thermal stress, the coolant and the pump components should always maintained within the manufacturer’s specified range of (185°F – 230°F) or whichever value the manufacturer has expressly provided.

Pressure Levels: Validate that the system pressure does not exceed the predetermined designed pressures typically maintained at 15 – 20 PSI for standard water pumps.

Alignment and Tension: Check the belt for correct tension and alignment. These settings impact the amount of strain put on the pump seal, which could increase the chances of premature failure.

Lubrication: Use the appropriate grade of lubricant to reduce friction and overheating on water pumps that require lubrication.

It is also of utmost importance to regularly replace components that tend to wear over time, such as the gaskets and seals. It is equally essential to flush out the cooling system to remove debris and any contaminants that would otherwise hinder the process. Adhering to these procedures while following the technical specifications outlined will increase the lifespan of the water pump and guarantee positive reliability.

Lubrication Tips: Using Grease for Optimal Performance

To achieve optimal results and life expectancy of a water pump bearing, the proper grease selection and application has to be done with precision. Following are some brief direction and their respective values:

Choosing Appropriate Grease: Select and apply water-resistant grease that is compatible with bearing material and prevents corrosion. NLGI Grade 2 lithium grease with a drop point above 190 degrees should perform well in operating conditions. The recommended grease specification is also good for high-temperature and high-speed applications.

In addition, make sure the grease is compatible with the bearing material to avoid corrosion and water resistance.

Lubrication Amount: Engineers are advised against excess and deficit lubrication. Both scenarios are detrimental to bearing life. Apply grease until the bearing housing is approximately halfway filled. Or check the manufacturer’s instructions for exact values.

Lubrication Period: The lubrication intervals vary based on temperature, load, and speed at which the bearing will operate. For moderate conditions, reapply grease every 500-1,000 operational hours. When working under more severe conditions (above 90 degrees or 194 degrees and above extreme load), attempt frequently diminishing the intervals to better suit the conditions.

Application Procedure: To avoid grease contamination, clean the bearing and surrounding region before applying lubricant. Grease guns should always be used to ensure control and even application. Grease should be applied evenly into the housing’s opening.

If these limits and requirements are adhered to, efficient lubrication, reduced wear, and uniform water pump operation maintenance can be achieved over a given period.

Signs of Wear and When to Replace Your Pump Bearing

Early detection of wear and tear in a pump’s bearing is key to optimal pump functioning and minimizing equipment failures. The following are the significant indicators of wear with regard to technical parameters that one needs to keep track of:

Extreme Noise or Vibration: Abnormal bounce or phantom noise during pump operation above 0.1 – 0.2 inches per second RMS signals a need for immediate bearing inspection since it might suggest bearing misalignment or wear.

Excessive Heat Generation: Running bearing temperatures greater than the nominal range of 70-80 degrees Celsius or 158 – 176 degrees Fahrenheit usually suggest bad loaning, leading to component wear and friction damage.

Leaking or Contaminated Grease: Unusual color, grit-filled, or metallic particles murdered grease is disallowed due to the suggested internal damage that ultimately makes the bearing contaminated.

Radial or Axial Play: To check if a bearing’s internal components are lying loose, measure and set the impressed radial and axial barometer dial. Failure to do so denotes the loss of defined tolerance limits for damaged components.

Decrease Efficiency: Observing a drop in overall functionality, particularly in pressure or flow rate, spotting a malfunctioning bearing signals the need for prompt intervention.

If these indicators are religiously checked against some standard values, technically sensible maintenance can be achieved for a water pumping system, making repairs or shutdowns nondeliberate and inexpensive.

What Are the Cost Benefits of a Reliable Water Pump Bearing?

Understanding the Cost of Replacing a Pump Bearing

On top of the direct cost of purchasing the part, the most relevant deterioration costs include the labor and even the downtime incurred. The pricing for standard water bearings will often start at around $50 and culminate at $300 , depending on the size, material, and brand of the bearings. In most cases, labor for the replacement will cost $100 to $500 in the ballpark, depending on the location and type of the pump construction.

Material Quality: Most pre-built or custom-made bearing parts using high-grade steel or ceramic material are available at a higher price point in the market due to their durability.

Bearing Dimensions (e.g., inner/outer diameter, width): Confirm the dimensions with the specified tolerances noted by the pump’s construction to ensure there is no installation issue.

Load Ratings (dynamic and static): Always choose a bearing designed to support the operational load conditions to avoid excessive wear or failure.

Operating Speed and Temperature: A bearing’s capability to handle the pump’s prescribed RPM rotational speed and the temperatures outlined in the pump’s technical details should always be checked.

Lubrication Requirements: Long-term maintenance could be affected by whether the bearing requires servicing in the form of regular lubrication or comes pre-sealed.

All of these parameters must be considered. If the above is fulfilled, appropriate bearings can help the water pump function at peak efficiency and cost less in future repairs.

How a High-Quality Bearing for a Car Can Reduce Repair Costs?

High-quality bearings minimize repair costs by ensuring optimal performance and increasing the longevity of their supporting components. Here’s how they achieve this and the technical parameters to consider.

Increased Lifespan: High-grade bearings can resist high-stress levels, vibrations, and other environmental factors, leading to extended service life and fewer replacements. Bearings with a higher dynamic load rating (C value) will perform better under operational loads, reducing wear and tear.

Higher Operating Increments: Highly specialized bearings increase efficiency by lowering the amount of energy spent per cycle and the strain on other components. This reduces friction on crucial systems like the transmission or wheels. Low friction coefficient and high rotational accuracy tolerances conforming to ISO standards should be the bare minimum.

Proper temperature ranges: High-quality Bearings can maintain functionality in extreme temperature ranges, which reduces the risk of failure. Bearings designed with low-grade materials are robust support. Bearings with a temperature range of -30deg to 150deg are optimal for automotive applications.

Minimal Maintenance Attention: Long-term maintenance expenditure is reduced as sealed or pre-lubricated designs do not require regular lubrication. The desired lubrication should be checked for compatibility, and the sealing structure should be checked for harsh conditions to ensure optimal performance.

Minimized Noise and Vibration: Noise and vibration are significantly reduced or eliminated because the best-designed bearings effortlessly work with the precision-crafted parts of the system. This ensures that focus systems like wheel hubs or powertrains are safeguarded from interlinking damage.

Ensuring these parameters with the use of the best bearings enhances vehicle reliability, minimizes repairs, and reduces downtime throughout the vehicle’s life. To ensure efficiency and effective workability, follow the manufacturer’s guidelines for the bearings’ specifics.

Evaluating Long-term Benefits for Automotive and Industrial Applications

A comprehensive investigation into the benefits for the automotive and industrial sectors reveals a vital list of factors to consider when utilizing high-quality bearings. These factors with their critical parameters are discussed as follows:

Optimized Service Life: Bearings that are fatigue-resistant and can endure extreme wear greatly extend the allowed service intervals. Take, for example, chrome or ceramic-coated bearings. Features like these enable reliable operations for 50% longer when compared to conventional bearings with similar loads and conditions.

Energy Efficiency: Bearings eliminate losses incurred through mechanical friction. Bearings with a coefficient of friction of less than 0.1 are ideal for enhancing overall efficiency in automotive drivetrains and even industrial-grade machinery.

Operating Temperature Range: The use of superior heat-resistant materials allows bearings to perform optimally in extreme conditions. When dealing with industrial or automotive engines, bearings rated for -40C to 200C ensure that high thermal stress will not cause the bearing to fail.

Corrosion Resistance: Bearings featuring stainless steel or polymer components offer higher resistance to corrosion in aggressive environments such as those found in marine or chemical industries. It is advisable to conduct more advanced quantifying performance, such as corrosion test rating (for instance, ASTM B117 testing).

Noise and Vibration Control: Noise and vibration produced during the operation of Electric vehicles and other precision machinery are critical factors that must be kept to a minimum. These could be achieved through the appropriate manufacturing tolerances bearings, such as ISO P5 or P4 precision class.

The adoption of such selected bearings would, over an extended period, offer industries increased reliability, performance, and cost savings. Provide feedback for each case using the manufacturer information and performance monitoring as the primary tools so that targeted results are achieved.

Frequently Asked Questions (FAQs)

Q: What would benefit from using a deep groove ball bearing in a water pump?

A: Water pumps function efficiently with deep groove ball bearings because they can carry both radial and axial loads. When mated with a low-friction, high-speed vacuum cleaner, a water pump achieves optimal work pace. These types of bearings accomplish these goals by providing the smooth rotation and long service life required. Thus, these types of bearings make them ideal for water pump applications.

Q: How do I know whether I should replace my water pump bearing?

A: If you notice unusual noises or vibrations being generated at the pump region, coolant leaks, the engine getting heated up, or perhaps even wear and tear marks on the pump bearing, you may want to consider changing the water pump bearing. If any of these symptoms are observed, it would be advised to consult a specialist to prevent severe damage to the water pump and bearing.

Q: Can inexpensive water pump bearings still be used in automobile machinery?

A: When worrying about price, choose reliable options. Bearings from some reputable manufacturers are well-priced and durable for thermoplastic or rubber water pumps. Using automotive specialty bearings such as those used on Toyota vehicles will ensure that OEM thresholds are met or surpassed.

Q: How do I choose the bearing of the right size for my water pump?

A: To select the proper size of bearing, you must know all dimensions, such as inner diameter, outer diameter, and width. These measurements are usually symbolized by numbers, for example, 6203, which indicates a specific type of bearing composed of different parts. In this case, ‘62’ indicates the bearing type, and ‘03’ indicates the bore diameter. Check the manual on your water pump or ask a bearing expert to ensure you choose the correct size for your application.

Q: Can I use a motorcycle wheel bearing for my water pump bearing?

A: Some motorcycle wheel bearings and water pump bearings may have the same external dimensions; however, they are not interchangeable. Water pump bearings are built to operate under the pump’s special conditions, such as coolant and high temperature. Regarding water pumps, using the intended components to get the best result is always best.

Q: What are the key factors when purchasing a cheap water pump bearing?

A: When trying to buy a cheaper water pump bearing, consider the following key factors: manufacturer history, bearing type (deep groove ball bearing), dimensions, sealing (2RS or ZZ), and load, speed, and material quality. Make sure the bearing is also appropriate for the specific working context, whether it is for automotive, agricultural, or industrial machinery.

Q: How can I ensure I get a good quality bearing from an online seller?

A: Sellers that trade in bearings and have a positive reputation, as reflected in their reviews and ratings, are a good option. Checking if the seller has a warranty or returns policy is helpful. Ensure that the bearing comes from a proper manufacturer that meets your requirements. Be wary of prices that are too low or unrealistic since this may suggest the conflict between genuine and fake parts or inferior quality options. If you ever want to return the purchased item or make any claims, make sure you keep your receipt.