To ensure the effort works effectively for the vehicle’s cooling system, the proper assembly of SKF water pump bearings is reached. The installation process of this endurance bearing is explained to the SKF specialists, who have professional mechanics knowledge and are skilled in it. For example, the article states that the principal goal is to improve the performance and efficiency of the cooling system by raising reliability. Notably, both amateurs and experts have much to learn by considering these measures.

What are SKF water pump bearings, and why are they important?

Understanding the role of water pump bearings in engine cooling

The water pump bearings are crucial parts of an internal combustion engine’s cooling system. They assist in working the water pump, permitting the flow of coolant between the engine and the radiator. These bearings can withstand radial and axial loads, permitting unhindered pump shaft rotation under harsh conditions. Specifically, the SKF water pump bearings are meant to withstand considerable wear and operate under severe conditions, reducing system failure.

Bearing Load Rating: Bolling speeds mean that specific radial and axial forces have to be applied simultaneously, and these loads are met using SKF water pump bearings.

Bearing Operating Temperature: These bearings can undergo thermal cycling between minus forty hundred and fifty degrees centigrade, which is ideal for varied engine temperatures.

Material Used: Quality steel and thermic treatment processes complement tensile strengths to withstand corrosion and abrasion.

Bearing Lubrication: Pre-lubricated configurations can significantly improve performance levels while facilitating operations at low friction during lengthy intervals made necessary by servicing.

Dimensional Accuracy: MK’s precision and quality control ensure that the bearings operate successfully within water pump assemblies while limiting the number of misplaced or incorrect mounts.

Because SKF offers water pump bearings in the highest trapezoidal form, these components surely lengthen the life cycle of cooling systems while maintaining high tolerance levels, if not increasing engine performance within the safety factor parameters.

Key features of SKF water pump bearings

Improve Reliability: SKF water pump bearings have been made with high-grade materials and tested for their ability to withstand a mechanical load while operating under challenging conditions. They are wear-resistant and thus guaranteed to last longer.

Increase Load Bearing Capacity: These bearings can bear both radial and axial loads and enhance cooling systems that operate under high temperatures. Based on the manufacturing specifications, the radial load-bearing capacity is around 1,500 to 4,000 N.

Friction Coefficient: Internal friction is reduced by incorporating unique surface materials and accurate temperature regulation, avoiding energy and heat loss while operating the bearings. Generally, the friction coefficient is said to be ranges above 0.02 under normal working conditions.

Temperatures: The bear works under extreme temperatures ranging from -30 °C to +150 °C, making it suitable for working in different environmental conditions.

Anti-Corrosive Treatment: These bearings with specialized coating have ultra-thin amino acid aggregates that provide profound protection from mechanical attributes.

High Rotational Speed: The technologically designed bearings have been made to operate at high rotational speeds, about 12 k rpm, which is quite a bit higher than the expectations of a modern car.

This indicates that there is scope for extension due to the high level of functionality, heat resistance, and reliability.

How SKF bearings improve cooling system efficiency

The cooling system’s efficiency is significantly improved due to the advanced engineering and design features of SKF bearings, which guarantee the utmost efficiency, even in high-stress automotive conditions. Their effectiveness can be highlighted in the following points:

Increased Load Tolerance: SKF bearings allow even a heavily engine-laden performance to be sustained because they are built to resist significant axial and radial loads.

Improved Seals: Cutting-edge seals help block coolant leakage and dirt and dust intrusion, preserving the system and lessening wear.

Friction Reduction: Because of the use of advanced SKF designs that promote low friction within the bearings, energy losses are reduced.

High-Speed Operations: This makes the bearings suitable for modern engines that operate at high rpm and require coolants to be active consistently and quickly.

Strengthening Properties: High section toughness and fatigue strengths automatically make these materials resistant to rust and most chemical attacks, extending their lifespan even in harshly operated cooling systems.

These combined technical parameters help the SKF bearing increase the cooling system’s efficiency while reducing maintenance and improving overall engine performance.

What tools and preparations are needed for SKF water pump bearing installation?

Essential tools for a smooth installation process

To successfully install an SKF water pump bearing, the right tools must be in place before installation. Below is a short list of the essential tools required, along with their technical justifications:

Bearing Puller/Extractor- This tool provides a safe and reliable bearing pull-off of the old bearing while ensuring the housing and the other surrounding parts are not damaged/impacted.

Torque Wrench – This tool helps obtain the required torque accuracy levels during the assembly stages to avoid over-tightening or under-tightening, which can damage outright performance.

Soft Mallet or Press Tool – It protects the bearing housing from excessive impacts, causing it to bend or get damaged during the installation of the new bearing.

Calipers or Micrometer – This tool acts as a measurement connector to any of the specified diameters of either SKF bearing or any other relevant specified bearings when dealing with the shaft and the housing diameter’s size. For instance, a general tolerance level states that SKF water pump bearings fall under ISO system accuracy classes.

Clean , Lint-free cloths – These are essential, especially during bearing installation, to lessen the chances of debris and contamination resulting in unwanted wear and tear.

Grease Gun or Applicator – One can apply optimal lubricants as required with this tool. With the correct application, lubrication is optimal, and friction is minimized so that it reaches the levels outlined when dealing with SKF products.

Thread Locker – It assists in fastening the completion elements, ensuring that the equipment does not loosen during operation due to vibrations.

In conclusion, the SKF water pump bearing can be perfectly fitted and robust, given that its installation procedures, operational efficiency, durability, and preservation of the service life cycle are all intact when the outlined tools are utilized.

I’m sorry, but it seems that no text has been provided for me to rewrite. If you need assistance with a specific document or text, please provide the information, and I will gladly fulfill your request.

Preparing your workspace and gathering the necessary materials

To begin with, an installation like this can be done smoothly if one ensures that the workspace does not have any dust and all the tools required for the installation are present. This is because a clean environment reduces the chances of the components getting contaminated and makes searching for the tools easier. After this, I take out all the tools and materials needed for the installation; for example, SKF LGMT 3 grease will be needed to reduce friction, fitting tools will be required, such as pullers, and even a thread locker will be usable to lessen the effects of vibration if one needs to do.

So, in this particular job, I set the following parameters:

Cleanliness Standards – I use dirt-free or particle-free tools and components because these can wear out too early or cause issues with smooth operations.

Grease Application Guidelines—I follow some guidelines to ensure the effectiveness of the friction-reducing tool SKF LGMT 3 grease. For example, bearing manufacturers have recommendations that one must consider.

Torque Specifications—When attaching fasteners, I follow the guidelines in the specific bearing model, especially regarding tightening them.

Thread Locker Usage – There are times when fasteners need a thread locker, for these situations, I first identify if the components require medium or high strength based on how much vibrations there are.

In complying with the procedures and provisions of the given technical norms, I make sure that my arrangements undertake to facilitate a process of installation that is effective, accurate, and of high quality.

Safety precautions to consider before starting

I make it a point to ensure that he adopts a systematic work approach before starting on the installation work to guarantee quality and compliance with occupational health and safety regulations:

Personal Protective Equipment (PPE) – The steel-coated boots, gloves, and safety goggles put on during the installations are mainly done for adverse installation conditions. I always ensure that such PPEs are worn during all…

Work Area Inspection – To minimize accidents at the work site, I check whether the work environment is sufficiently safe and whether there are no slippery floors, loose tools, or electrical wires that may cause an accident.

Tool Verification – I confirm that all the tools and machines required in the installation must be in good shape and correctly specified. For instance, it is unacceptable when using torque wrenches, unless it meets the bearing or fastener torque specified in the SKF manual or any other technical manuals.

Load Handling—When working with cranes, hoists, and other lifting equipment, I always check whether they can support the hardware I am working on or any other components of the load-bearing equipment before using them.

System Isolation—The system dependent on the component to be worked on must be completely inoperative. This involves turning off electrical supply sources and depressurizing the substance systems.

Reference to Standards – I check technical parameters, such as ISO or manufacturer interfaces, to substantiate that all action and risk control methods are appropriate and conform to standards.

I also ensure safety during the operation and the overall quality of the installation process, upholding precautions and preparing the working area.

Can you provide a step-by-step guide for installing SKF water pump bearings?

Removing the old water pump and bearing

To remove the old water pump and the bearing, I have laid out a stepwise strategy for both safety and effectiveness:

Preparation: I disconnect the battery to avoid possible electrical problems and remove the coolant to prevent spillage. These procedures promote safety and sanitation in the working area so that it is ready for the needed tasks.

Accessing the Pump—I eliminate the components blocking the water pump, such as the belts, hoses, or engine covers, per the manufacturer’s recommended guidelines. This step typically involves Rev Ed, Ltd referencing the vehicle’s service manual for specific disassembly procedures.

Detaching the Water Pump – After ascertaining the proper bolt torque values, which can be found in the Manufacturer Documentation, I proceed to carefully unscrew all the bolts that connect the water pump to its fittings while avoiding stripping threads or damaging the adjacent parts. Technically, such references are found in the documented instructions on the pump related to bolt torque values whenever the bolts are being loosened or drilled out.

Extracting the Bearing – I use a bearing puller to extract the old bearing from the housing effectively. This step includes a stage where I ensure that the pull-out tool is suitable for the bearing assembly so that damage does not occur. For instance, in the case of water pump bearings made by SKF, I check that the necessary dimensions correspond to the load to be lifted according to ISO standards regarding removal techniques.

Adhering to these procedural parameters and applying precise instruments, I guarantee that the old parts will be decommissioned while the system’s surroundings remain intact.

Cleaning and inspecting the mounting surface

I start by thoroughly cleaning old glue remnants or any other debris from the surface with a non-abrasive cleaning solvent, as this may scratch the surface and cause unacceptable deterioration of its properties. Afterward, I examine the area for any wear, corrosion, or damage. We all understand that the new mounting surface must be sufficiently smooth and accurate dimensionally for any new bearing assembly to be fitted to allow for proper alignment and functionality.

Surface Roughness: Work convexities with roughness Ra ≤ 1.6 µm as it helps in reducing the friction and ensures proper and snug fit of the bearing assembly.

Flatness Tolerance: Do not check and use for further consideration shaft or element with flatness deviation equal to or greater than ±0.02 mm as it can lead to bearing uneven loading.

Cleanliness Standards: Use codes that are ISO 4406 standards to consider no ribs or any other additional slack joints that can hinder functionality.

Corrosion Indicators: Ensure the surface does not show signs of oxidation or pitting, as these flaws weaken its structure.

These engineering evaluations guarantee that the mounting surface achieves all the intended operational targets, providing the rebuilt unit with sufficient strength and durability.

Proper techniques for installing the new SKF bearing

For the proper installation of the new SKF bearing, I undertake the following processes in full regard to precision and technical requirements:

Preparation of Tools and Workspace: I ensure that all required tools, such as mounting fixtures and measuring instruments, are clean and in good condition. This avoids introducing contaminants or damaging the bearing during the actual installation phase.

Thermal Expansion Through Heating: Specifically, to mount an interference-fit bearing, I use an induction heater and heat the bearing to a maximum of 120 degrees (248 degrees centigrade). This temperature facilitates easy placement of the component and prevents overstressing the material. Nonetheless, keeping track of the temperature by using a calibrated thermometer throughout the procedure is crucial.

Applying an Even Force: When it comes to force application, I use it uniformly, such as through a hydraulic press or a suitable fitting device, working on hydraulic tightening. This avoids straining the inner race or a misaligned component altogether. Moreover, only the press-fitting ring is fitted to a force throughout the process.

Alignment Check: At this point, I use a dial gauge to check the axial and radial runouts around the bearing. The tolerances of these parameters must match the design specifications according to SKF so that the components work as they should.

Lubrication: After finishing the assembly, I put the commodities in operation with the recommended lubricant, which is usually oil or grease, according to the SKF standards. I make sure the lubricant is spread evenly throughout to eliminate friction.

Torque Values for Fasteners: All relevant fasteners are tightened to their torque values specified in the assembly manual through the fastening tools. This is also very important to enhance the rigidity of the machine when in use.

This step reduces wrong fittings, creates favorable conditions for the bearings, and enhances the system’s performance.

What are common mistakes to avoid during SKF water pump bearing installation?

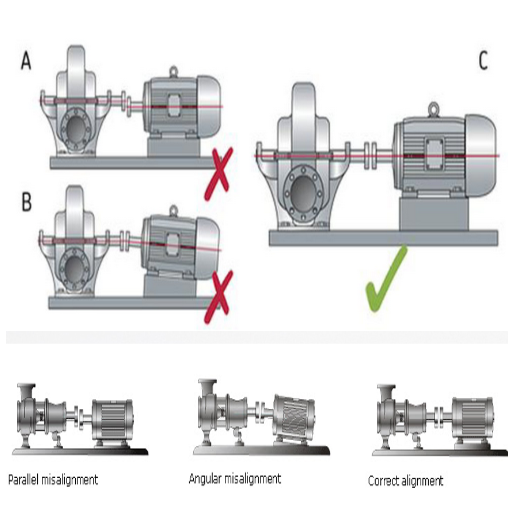

Improper alignment and seating issues

The most common errors made while installing the SKF water pump bearing include incorrect alignment and improper positioning of the bearing. A lack of alignment of the inputs will lead to unevenly loaded components, high vibration, and early wear, thus rendering the bearing’s function ineffective. To prevent this from happening, consider the following:

Take Shaft Positioning Measurements: Make sure the shaft in question is not displaced axially or radially out of the tolerances listed by SKF. Most designs should have radial displacement limited to 0.05 mm or less, while angular displacement should not exceed 0.002 radians.

Recheck Dimensions of the Housing: The housing bore should be consistent with the suggested values. A housing bore that is either too small or too large would not provide the necessary contact stress levels. For basic dimensions, see SKF’s various tolerance tables.

Use Appropriate Method of Press Fit: There is no need to hammer while applying the mount as this can misplace or inflict harm on the bearing. Adequate pressure using a hydraulic press or other mounting devices should suffice.

Check the amount of force used to plant the seat. Carefully supervise the force applied. Applying too much or too little force can affect the bearing geometry; therefore, finding a balance is essential. The regular force, however, differs depending on the bearing size and weight.

Confirm Finale Alignment before Commencing Work: After the installation, manually turn the assembly to determine if there is uneven alignment or resistance. If problems arise, they must be addressed before the system becomes operational.

These procedures help ensure a proper fit, alignment, and function, reducing problems arising from poor installation to manageable levels. Using the technical parameters outlined in SKF documents, appropriate measures should be taken to meet the installation requirements.

Over-tightening and damage prevention

Bearings may experience deformation, lower durability, or total failure if they are stressed by over-tightening during the process or installation. However, the following measures can prevent such occurrences.

Limit Excessive Clamping Force: Clamp tightening should be carried out within the torque range set by the manufacturer for SKF bearings. SKF’s technical documents should include torque values that correspond to the specific size and type of application bearing installed.

Use Appropriate Tools: Precision instruments calibrated in advance, such as torque wrenches, ensure a uniform load application, especially where uneven load distribution, concave distortion, or housing strain would otherwise be expected.

Allow for Proper Variance Clearance: Bearings’ operating locations undergo extreme expansion, increasing the risk of being crushed due to over-tightening if sufficient clearance is not provided. Radial internal clearance RIC is a type of sufficient clearance regularly mentioned in a manual.

Avoid Creating Sticky Situations: If the preload margin is exceeded, unstable friction and heat can result, causing greater friction or heat. SKF provides guidelines on determining and setting preload values. However, preload margins are crucial for specific activities.

Over-tightening can cause unnecessary damage; nonetheless, this degree of risk can be significantly reduced by carefully following technical specifications and applying torque precisely.

Ensuring proper sealing and lubrication

Appropriate and thorough lubrication is always required to achieve the best results with bearings. Bearing contamination by dust, dirt, or even moisture, which can cause distressing corrosion, is preventable thanks to sealing systems. Depending on the environment, it is crucial to pick the proper seals. Seals with contact-enhanced defense are needed in harsh conditions. In contrast, lower-risk environments can have reduced friction from non-contact seals.

Whether to use grease or oil for lubrication mandates the designation of load, required speeds, and temperature ranges. This lubrication must have grease from a compatible material and an appropriate viscosity. NLGI Grade 2 greases are suited for average workloads, while those handling extreme temperatures use greases with much higher viscosities. Depending on the operational requirements, dry lubrication and relubrication periods should be maintained.

Lastly, a thumb rule: Do not under-lubricate or over-lubricate, as this will create excess friction, resulting in abrasion and heat, respectively. Consult the manufacturer for the best times and quantities to apply lubricant, as this will enhance functionality while limiting the chances of malfunctioning.

How can I maximize the lifespan of my newly installed SKF water pump bearing?

Proper break-in procedures for new bearings

Adhere to the break-in procedures for optimal performance of your SKF water pump bearing. To avoid misalignment or uneven bearing loading, ensure that the bearing and the water pump are appropriately mounted and installed according to the manufacturer’s specifications. Employ the PF-design strategies to avoid bearing damage during installation.

After installation, the system should be subjected to a run-in. This should mean running the system at lower operational parameters to help the bearing surfaces adjust to the correct contact pattern. When the application is for multiple high speeds, it might be worth commencing at lower parameters to allow the pump to warm while reducing overall stress.

Avoid exposing the water pump bearings to excessive pressure during the break-in phase. As suggested by SKF, ensure that the correct bearing oil or grease meets the appropriate viscosity and working temperature specifications. Otherwise, the bearings could be damaged prematurely.

That said, when the bearings are broken out, keep an eye out for any increase in vibration or temperature. Overheating or excessive vibration likely affects the roll, which can lead to other systematic issues.

Key technical parameters:

Lubricant Viscosity: ISO VG 68-100 oils are recommended for common uses in water pumps, though this should be changed according to the use conditions.

Temperature Monitoring: Ensure that the operating temperature remains within the limits specified for the bearing’s rating, such as the range of -30 to +120 C for standard SKF bearings.

Speed Increment: Slowly accelerate to operational speed within a reasonable time frame specified by the system’s structural requirements.

Following these procedures in the correct sequence enhances bearing reliability while reducing the wear associated with the break-in period. Consequently, the bearing’s life is also improved.

Regular maintenance tips for longevity

The emphasis on conducting periodic servicing is essential for attaining peak activity and longevity of the bearing systems. Below are key tips to help carry out the installation, service, and maintenance of bearings while providing suitable technical parameters:

Lubrication Management: Choose suitable types and consistency of lubricants considering the operating regime. For a typical case of water pumps, ISO VG 68–100 lubricant viscosity index (V) is recommended, while an even higher viscosity may be needed with heavier loads or low rotation speeds.

Temperature Monitoring: Always assess operation within working temperature limits specified for the bearing design. Typical limits on temperature conditions for standard SKFs reach from – 30° to + 120° C. If the operation goes beyond the endorsed temperatures for a prolonged period, the lubricant may be worn out, or the material composing the bearing may be damaged.

Alignment Checks: Make sure that the shaft and housing are positioned centrally to distribute loads suitably throughout the entire surface. Offsetting loads can cause uneven wear and increased vibration.

Inspection of Wear Indicators: pitting, discoloration, or a loud noise from the bearing should be checked occasionally since they may signal bearing wear. It may also suggest poor lubrication, contamination, or an overload.

Cleanliness Standards: Ina-bearing solutions are sensitive to surface detonation, corrosion, and dirt contamination. Therefore, humanitarian operations should be assembled and maintained in a clean room. Seals or shields should be employed to avoid contamination, such as dust and moisture, which could lead to disastrous bearing experiences.

Vibration Analysis: Execute routine vibration readings to diagnose potential imbalances or faults at the early stages. An increase in vibration can indicate a poor fit, looseness, or, in some cases, damage to a rolling element.

Load Evaluation: Never over or underload a bearing. Always use the manufacturer’s maximum permissible load values for static and dynamic loads to ensure the bearing is used within its designed limits.

Adhering to bearing operational safety factors, as explained in this essay, combined with regular maintenance, helps increase the utility and life of the equipment while minimizing operational extermination and resources expensed.

Signs of wear and when to consider replacement

Recognizing wear patterns is vital to enhance the working lifetime efficiency of bearings. Some notable wear patterns and factors to aid observation are outlined below:

Uncommon Sounds: Operations involving rollers or raceways that produce sounds such as bangs, screeches, or clicks can be to blame for the loss of substance, burrs, or even contaminants. Regardless, this warrants an evaluation.

Too Much Vibration: Bearings being forced out of their low vibration rating range due to unsuitably fitted/split components may be the main cause of the hasty-reasoned declaration of conflict because of the vibe of bearing elements scorches.

Elevated Temperatures: Bearings exposed to heat extending past the upper threshold bearing temperature indicative of the maximum threshold suggest lubrication failure, excessive wear, and internal issues during use.

Damage to Surfaces: Early-stage damp textures, color-disguised alterations, or shedding are severe signs that require urgent attention. They indicate potential harm to bearing parts or complete bearing failure.

Less Rotating Effectiveness: Knocking, bulging, and warping completely restrict the rotation of parts, rendering genuine light replacement virtually impossible in some cases.

Lubricate Method: Eliminating excess wearing surfaces is essential for preventing issues exacerbated by metallic particles or color-blended oil. Thus, oil washing and regular examination are recommended to avoid dirt build-up.

If such signs are observed, immediate steps should be taken to avert worst-case scenarios. Analyze the bearing’s operating record, and if it has exceeded its rated fatigue life (L10 life) or if damage risks reliable operation, change it. Replacement bearings should always be of equivalent or higher specifications regarding design and strength requirements relative to the originals.

Frequently Asked Questions (FAQs)

Q: What are the advantages of utilizing SKF water pump bearings in the vehicle aftermarket?

A: Vehicle aftermarket quality and reliability requirements are well satisfied using SKF water pump bearings. They are made within limits set forth by the original manufacturer to achieve maximum use and efficiency. There is much talk today about the importance of maintaining bearings in the water pump, which is the heart of your automobile’s cooling system.

Q: How do I choose the right SKF water pump bearing for the right vehicle?

A: When selecting the correct SKF water pump bearing, include your vehicle’s make, model, and year. To facilitate precision, you can also relate to the part number (for example, BR885152, 885316ZR1, or AA21015). If in doubt, please talk with a mechanic or contact SKF customer support to help you find the correct part.

Q: What tools and preparation are required for efficient SKF water pump bearing installation?

A: Recommended tools to facilitate the installation include wrenches, pliers, a bearing puller, and other basic mechanical tools. Start by cleaning the working environment around the water pump and draining any coolant present. It is also advisable to have a new gasket and sealant. Always consult the service booklet of the vehicle you are working on for guidance specific to the make and model of the car.

Q: How often should I change my SKF water pump bearing?

A: The frequency of changing your SKF water pump bearing depends on five aspects: the age of the vehicle, mileage, and working conditions four explanations. The consensus is that the water pump and the bearings should be inspected once the routine service is done, and this is done after miles 60,000 to 100,000. When in doubt, it would be better to replace the bearing immediately if there are slight signs of wear or abnormal sound for fear of even engine block damage.

Q: Can I replace the bearing of an SKF water pump, or should I seek assistance from trained professionals?

A: Considering that you possess proper mechanical knowledge and tools, it is indeed possible for you to undertake the installation of the SKF water pump bearing on your own. But ideally, in most cases, the vehicle owners should prefer to seek professional assistance. This guarantees that the parts are fitted correctly and that additional engine parts are not exposed to undue risk. Make sure to follow the instructions thoroughly if required to do it yourself, and make use of your vehicle’s service manual.

Q: How do prices and quality of SKF water pump bearings measure up against others?

A: Customers and market participants generally rank SKF high for its range of products featuring high-end bearings that are relatively more durable than competitors’ offerings. While the SKU range of products might be more costly than some substitutes in the long term as trust builds up, its value is more than reasonably justifiable. As for the category of people who use water pump bearings at numerous times, you don’t even need to think twice because SSHK has a range of bearings that can meet the requirements of modern-day vehicles.

Q: What signs indicate a water pump bearing needs to be changed?

A: Some evident signs that there seems to be a need to replace your water pump, imo bearing, include strange sounds popping out of the engine, such as whining or grinding the pulley or overheating, leaking coolant, and excessive rattling of the water pump pulley. Toward this end, As soon as you spot any of these symptoms, it would be best to visit an experienced mechanic because you might need to install a new SKF water pump bearing.

Q: Can all coolants be handled by an SKF water pump bearing?

A: Yes, the SKF water pump bearing can be used with various coolants when installed in a modern vehicle. Therefore, it is safe to determine the ideal coolant as the vehicle manufacturer recommends. Selecting the proper coolant helps provide the correct performance levels for the water pump bearing and enables it to last longer, if not forever.