The efficiency of mechanical systems, including water pumps, automotive engines, and various industrial equipment, depends on its water pump bearings. Proper wear and tear of the components increases performance whilst maintenance costs and downtimes are reduced. This article attempts to provide the reader with comprehensive and practical knowledge on extending the service life of water pump bearings. Focus is placed on proper installation, routine maintenance, and selection of top-tier components. All of this provides an understanding of achieving maximum efficiency, reliability, and systems. So, from what has been provided, I will now give the steps and techniques to ensure the essential components are in check for the long term.

How Can You Maintain Your Water Pump Bearings?

Understanding the Basics of Pump Bearings

Bearing systems, or rather, for the sake of understanding, the simplest form of pump bearings, help rotate the pump shaft by supporting it without causing undue friction. As always, there is much to focus on their function, types, and key technical parameters before jumping to any advanced conclusions.

First, pump bearing systems allow axial “thrust” and radial “cylindrical” loads resulting from the pump’s operation. Ball, roller, and sleeve bearings are ordinary examples, and they differ in load capacity and working conditions.

Some Key technical parameters include:

Load Capacity: The maximum radial or axial force the bearing can be subjected to, which is usually given in Newtons as (N) as an example, this sates that the bearing will be adequate for the operation of a defined bearing.

Operating Speed: The characteristic maximum Revolutions Per Minute (RPM) to which the bearing is subjected without reaching its overheating or wearing threshold.

Lubrication Requirements: Lacking friction-reducing substances will lead to undo machinery wear if lubrication oil and grease are not applied to varying pump designs available.

Temperature Range: The material can withstand a specific temperature to perform between. Usually, this range is from -20 to 120 in the pump’s environment.

Focusing on these items appropriately ensures the correct bearings are selected, improving system reliability and efficiency. As mentioned earlier, the fundamentals assist in making educated choices and more effective maintenance of the pump systems for prolonged operation.

Importance of Regular Maintenance

Regular maintenance is essential for pump systems to be efficient and last a long time. Following a well-defined maintenance routine helps me note wear and misalignments while fixing issues that could lead to expensive breakdowns. This includes bearing abrasion inspections, lubrication level checks, and monitoring the pump’s temperature and vibration while it is operational, for example.

Temperature Monitoring: Operating temperatures of between -20°C and 120°C (-4°F to 248°F) need to be maintained to prevent unfavorable material reactions and loss of efficiency.

Vibration Levels: Routine checks of bearing components that have the potential to rotate quickly aid in the identification of imbalances and misalignments, assisting in avoidable damage.

Lubrication Assessment: Proper lubrication of bearings minimizes friction and wear and tear.

I can improve the pump’s operating condition by continuously maintaining these technical parameters over a long period while minimizing system downtime and maintenance costs.

Identifying Signs of Wear in Water Pump Bearings

While monitoring the water pump bearings for signs of wear and tear, I identify specific issues that may arise that are particularly important. One indicator that demands my attention is peculiar noise because a grinding or squeal-like noise is often associated with worn bearings. Another area I monitor is increased vibration levels because abnormal vibrations may be evidence of misalignment or, in the worst-case scenario, bearing failure. Visual inspection is another step that cannot be missed – seeing corrosion and leaking around the bearings often indicates poor or missing seals or material wear. I also check the operating temperature, where a significant elevation may indicate excessive friction, lack of lubrication, or internal damage.

In assessing and addressing any issues that could arise, here we are the technical parameters that I rely on to conduct diagnosing wear:

Noise Levels: During normal operations, strange sound signals, whether solicitation or destruction, are, at best, worn surfaces.

Vibration Patterns: Setting intervals for constant readings of the vibration signal’s telemetry can measure changes and mark regions of imbalance.

Lubrication Condition: The absence of dirt in the lubricating oil indicates that normal functioning is not compromised, and wear is limited.

Temperature Changes: Observing temperatures during operations to within range prevents the equipment from overheating.

By systematically assessing these parameters, I can inform the people involved in monitoring the system of changes that could permit issues and get great results today.

What Are the Common Causes of Bearing Failure in Pumps?

Impact of High Temperature on Bearings

Pumps are affected by high temperatures, especially their bearings, because the efficiency plus the life of the components greatly depends on them. In my experience, most components start experiencing problems at high temperatures during operations, boiling losses, and lubrication breakdown, and their degradation efficiency results in changes in the elastic-plastic structure of some bearing parts. Therefore, I primarily focus on monitoring the following technical parameters:

Operating Temperature Range: Lubricated bearings are best worked upon between 86°F and 140°F (30°C to 60°C). This range allows them to perform optimally, Furthermore, if the limit is exceeded, the lubricant’s viscosity can collapse and the bearing’s operating capability can be reduced.

Lubricant Condition: Thermal lubricant oxidation and evaporation lead to lubricant loss, making it difficult for pumps’ hypothetic components to operate with little to no wear. The lack of these components at regular intervals dramatically reduces their lifespan.

Thermal Expansion Tolerances: Having a high temperature exposed to parts may lead to unrestrained thermal expansion, distorting the alignment of the bearings concerning its counterparts and changing the adequate PCA clearances there. In context to that, extreme clearances lead to a lot of problems in the operations.

In context to the immense range of clearance boundaries, regular and prompt maintenance of pumps in combination with the other parameters mentioned above makes specific the more significant negative reasons for high-temperature zones can be reduced while the components function efficiently.

Effects of Improper Seal Installation

The improper installation of seals can result in various operational issues. First and foremost, it may result in leakages because of improper seating or incorrect alignment. This could lead to fluid loss and contamination while reducing the pump’s efficiency. If the seal is placed with high force or misalignment, it will likely wear off the sealing surfaces and introduce excessive wear. This, in turn, reduces the seal’s longevity and requires the seal to be replaced frequently.

Inaccurate installation tends to put the seal at a higher risk of vibration and shaft misalignment. This vibration and misalignment can damage surrounding components such as bearings and couplings. The parameters that need to be taken care of are the axial and radial clearances, which must be within the accepted values the manufacturer provides. For set seals, the axial clearance must be around 0.2-0.4 mm, while the O-rings must be compressed accordingly without deforming.

I have to make sure to eliminate those issues by following a particular set of protocols, including the employment of the required tools and monitoring tolerances throughout the whole assembly. If I devote adequate time to the training and work meticulously during those steps, I will maximize the life and efficiency of the seal.

Consequences of Imbalanced Load

Imbalanced load conditions, ranging from equipment inefficiencies to severe operational problems, such as complete breakdowns, can create dire situations. In addition to its severe consequences, an unevenly distributed load can overstress specific components, leading to premature wear on seals, bearings, and shafts. An example of improper load allocation is using an unfit radial seal, which causes over-deformation and leakage due to excessive radial stress.

Taking a more technical approach, it is crucial to outline that placing loads within tolerable limits is necessary. For example, to meet the requirements for a seal, the radial and axial forces must be within the manufacturer’s specifications. In this case, the radial load pressure should be less than 10 N/mm² to avoid distortion. Seals also exploit the vibration wear features where the disturbance’s rotation speed does not exceed 0.5 mm/s RMS. Anything more would cause excessive wear on the seal. Leaving these problems unattended can cause critical problems within the system, therefore it is best to eliminate them by employing multi-channel vibration analyzers and dynamic balancing facilities.

How do you select the right water pump bearing for your needs?

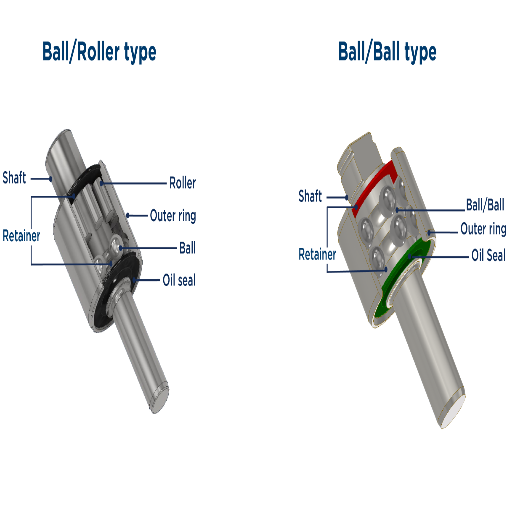

Choosing Between Ball Bearings and Roller Bearings

Whenever I choose between roller and ball bearings for water pumps, I analyze the application specifics first. Ball bearings are perfect for applications with predominantly radial loads or those that involve high-speed operations. Smaller pumps, for instance, perform far more efficiently because of their extremely low friction and excellent radial clearance. Conversely, roller bearings are better for heavier radial or a combination of radial and axial loads, which is common in industrial or high-demand systems.

The high-level technical parameters that I consider include power rating, speed, and operation environment. The typical speed rating for ball bearings for radial loads may not be as high as for roller bearings and may range from 10,000 to 20,000 RPM. Instead, the speed rating might be lower for roller bearings, in the range of 5,000 to 15,000 RPM, but the radial load capacity is much greater. Other materials and lubrication also have requirements… temperature, contamination, and expected life are among the factors that directly affect performance and must, therefore, be suitable.

Considering the Radial and Axial Load Requirements

Emphasizing the radial and axial load requirements, I always begin with the specific application and the expected encountered forces. For radial loads perpendicular to the shaft requiring a radial bearing, it is vital to use a bearing with a high radial load capacity, such as roller bearings. Roller bearings are perfect for cases where radial forces are vascular dominant, as they have higher capacities than ball bearings.

Regarding axial loads parallel to the shaft, I also check that the bearing can support an expected force without undue wear or deformation. Thrust ball bearings easily withstand high axial loads. Another example is angular contact bearings, which simultaneously support radial and axial loads.

I am optimistic about the bearings’ fidelity and efficiency of performance because I have precisely matched these parameters to specified conditions.

Consulting with a Bearing Manufacturer

Communicating with an expert at a bearing manufacturer, I speak articulately so that I am not given vague information. For instance, when I request advice on the appropriate bearing for a given application, I often state the following parameters: load type (radial, axial, or both), load magnitude, operating speed (RPM), temperature range, and lubrication requirements. These parameters are critical as they directly impact the bearing’s performance and longevity.

Load Type and Magnitude help determine whether radial, thrust, or angular contact bearings are most applicable.

Operating Speed: Typically, high-speed applications may require specialized bearings designed with ceramic balls to minimize friction.

Temperature Range: Makes sure that the bearing materials and their lubricants are appropriate for the environmental conditions.

Lubrication Requirements: Identify the appropriate lubrication needed (oil or grease) and the conditions to ensure its operational success.

This technical information, in addition to the anticipated service life and specific constraints or regulations, dictates the recommendations from the manufacturer, enabling me to achieve my requirements thoroughly. Such collaboration is vital in ensuring the best overall results when selecting and applying the bearing.

What Role Does the Manufacturer Play in Bearing Longevity?

Importance of High-Quality Manufacturing Standards

Precision in the design and construction of a bearing is vital to its dependability during operation and its life span. Considering these aspects, I believe a manufacturer abiding by these criteria can support my operational needs. Quality manufacturers who utilize exacting processes and proper materials and those with stringent processes for quality assurance issue me bearings that work well, even in the most extreme situations.

The following technical parameters are critical and must be justified about high-quality manufacturing standards:

Dimensional Accuracy: It guarantees and ensures that the bearing is placed within the intended application, resulting in no misalignments and uneven bearing wear.

Material Quality: It ensures the bearing can bear the load, resist wear, and keep its shape over time. Durability, for instance, accounts for the wearing of high-grade steel or ceramic materials.

Surface Finish: Aids in the reduction of friction; therefore, the generation of heat is minimized, which further increases the smoothness of the surface and increases the overall efficiency and lifespan of the bearing.

Heat Treatment: Increases hardness and fatigue strength for the bearing, enabling it to withstand harsh working conditions.

Inspection Standards: Complete inspections that incorporate automated and manual techniques to ensure consistent production without defects.

These parameters allow me to estimate a manufacturer’s capability to deliver quality bearings that are immediately usable and adequate for long-term use.

Benefits of Using Trusted Bearing Manufacturers

Selecting a dependable bearing manufacturer assures that I acquire products that guarantee quality and reliability. Here is why this is important to me:

Performance Assurance: When selecting a reputable manufacturer, I can rest assured that their bearings will be scrutinized through automated and manual testing to ensure defect-free application performance.

Material Excellence: High-grade steel or ceramic guarantees durability and resistance to damage under demanding conditions.

Precision Engineering: Features like precise machining, coupled with exceptionally smooth surface finishes, lead to reduced friction and heat generation, which enhances efficiency and service life.

Heat Treatment: Properly heat-treated bearings, with their enhanced hardness and fatigue resistance, allow for the flexibility to operate in high-stress environments.

Tailored Solutions: Reputable manufacturers typically offer customization options that address specific operational requirements without affecting product quality.

Focusing on a trusted partner allows me to optimize the performance of my machinery, which in turn saves considerable downtime and maintenance costs in the long term.

Understanding the Impact of Factory Conditions

The operational environment of a workshop has a significant effect on the efficiency and lifespan of machinery, which includes bearings. I have noted that temperature, humidity, level of contamination, and vibration are crucial factors that impact efficiency. For example,

Temperature—To prevent expansion or fatigue, a bearing’s operating range must be within prescribed limits (standard bearings operate between -30° C and 150° C). Well-lubricated bearings under appropriate operating conditions can alleviate this problem.

Humidity and contamination – Excessive moisture and dust can cause corrosion and excessive wear-and-tear of parts. Regularly serviced sealed or shielded bearings can adequately perform in such conditions.

Vibration and load—High vibration levels and poor load distributions lead to early failure. Using bearings with sufficient load ratings (dynamic load capacity and static load capacity) and aligning them correctly will reduce these risks.

By understanding all these outlined factors, I can identify issues that arise within my factory and choose specific components tailored to these conditions, ensuring enhanced reliability and performance.

When is the Replacement of Pump Bearings Necessary?

Signs Indicating Immediate Replacement Needs

In my experience, there are several indicators that, if not taken care of immediately, will result in operational inefficiencies or even complete equipment failure. Pump bearings, for instance, are excellent examples of such indicators:

Unusual Noise or Excessive Vibration: If the pump shows abnormal vibrations or noise, excessive bearing damage or misalignment could have occurred. Vibration levels can be monitored using ISO 10816 standards. If the levels are too high after examination, measures must be taken.

Sharp Increase in Temperature: Excessive bearings due to inadequate lubrication, excessive wear, or contamination indicate a lack of proper bearing maintenance. Standard bearings usually operate between 120 and 150 degrees Fahrenheit, and exceeding that range can be dangerous.

Decreased Performance: One of the last indicators measures the pump’s efficiency drop. An infected internal bearing, increased wear, and flow loss will dramatically increase the drop. Typically, the efficiency curve is used to measure the whole drop.

Corrosion or Debris Contamination: Rust, general debris, and pitting are among the last warning signs. These indicators hint at a much more serious problem: bearing surface degradation, heightened by the decrease in pitting intensity.

Lubrication: Replacement of the pump bearings in this scenario is highly straightforward. Once any discoloration, leakage, or contamination is visible, there is no longer sufficient lubrication, and, at the extreme, the lubricant needs to be done entirely.

Considering all the warning signs, I can conduct maintenance procedures on my factory equipment ahead of time and, as a result, avoid complete operational downtime.

Evaluating Performance and Efficiency

Abnormal Noise or Vibrations: Any abnormal noise or vibrations will prompt further investigations into the alignment tolerances and vibration limits per the equipment manual. For example, vibration levels greater than 1.0 in/sec RMS (depending on the RPM) may suggest some mechanical problems or an imbalance.

Overheating Standard Bearings: I will check the operating temperatures with IR thermometers or thermal imagers to see if standard bearings remain within 120C-150C. If they do, this indicates a problem, such as bearing overheating. Issues arising from dry lubrication or other types of wear would cause such deviations.

Performance deterioration: I will verify the performance depreciation by comparing the current flow rate and efficiency, along with the cut-off value, to the original value curve, which the manufacturer supplied. An example of such justification would be a deficiency below 80% of the base level, necessitating an investigation for internal damages or heightened resistance.

Corrosion or contamination: If there is evidence of corrosion or debris particles, I will check the humidity levels and any exposure to the bearings’ material specifications to measure the environmental conditions.

Problems with lubricants: I will check the lubricant for any signs of change in viscosity, contamination, or metal particles through oil analysis tests.

Lubricants exceeding the ISO 4406 cleanliness standards (for instance, codes above 20/18/15 for hydraulic systems) reveal the potential for operational risks, which would need corrective actions. \n \n Interlacing these findings with the set technical values and standards enables me to methodically define the root causes and take specific corrective actions to ensure consistent performance.

Cost-Benefit Analysis of Repair vs. Replacement

In deciding whether to repair or replace a component, I take into account the following specific considerations that will dictate my decision:

Economic Feasibility: I analyze the repair and replacement estimates. Replacement is preferred when the expected repair cost exceeds 50 – 60 percent of the provided estimates. However, the repair is usually more cost-effective than the replacement.

Downtime Impact: Increases in downtime have an impact and can aggravate losses during repair or replacement. Replacement may be a reasonable choice if it will alleviate significant disruption in lower production output.

Technical Condition

Efficiency: I am satisfied if the restored system achieves at least 90 – 95 percent efficiency. Lower efficiency means replacement will be the only option due to the inadequate post-repair efficiency.

Material Integrity: Structures that undergo corrosion, deformation, or excessive wear are subjected to losing integrity. Components with significant loss of material need replacement to eliminate any risk and ensure reliability.

System Benchmarks: Vibration, noise, operating temperatures, and lubricant analysis results are all parameters with acceptable standards. Exceeding the ISO 10816 vibration level indicates deeper problems that justify replacement.

By analyzing the costs, I ensure that the selected course of action meets operational priorities and safety requirements and offers a long-term economic outcome. This method dramatically helps with the reliability and maintainability of the system’s functions.

Frequently Asked Questions (FAQs)

Q: What methods guarantee the long life of wholesale pump bearings?

A: Correct lubrication, thorough inspection of wear and tear, and proper alignment and installation are required for the longevity of wholesale pump bearings. Using appropriate bearings, such as deep groove ball bearings and angular contact bearings, also increases durability.

Q: How does the water pump shaft bearing lifespan get affected by aligning the shaft?

A: Alignment of the shafts is essential for water pump shaft bearings. If the bearings are misaligned, they will experience excessive vibration and wear. Frequent alignment checks and adjustments can extend the bearing’s life.

Q: What is the importance of a cage in the performance of auto water pump bearings?

A: The cage separates and locates the rolling parts of bearings used in automotive water pumps to reduce friction and evenly distribute the load. A reliable, high-quality cage can increase the bearing’s service life.

Q: Why is using high-grade bearings in industrial pump applications critical?

A: Industrial pumps need high-quality bearing ratings to support considerable weight, minimize resource wastage, and enhance dependability and effectiveness. This guarantees maximum productivity and durability in extreme environments.

Q: In what way does deep groove ball bearing influence automotive water pump systems?

A: Deep groove ball bearings can provide an excellent design for radial and axial load that is ideal for automotive water pump systems. They are efficient and increase the water pump´s service life because of the reduced friction in their design.

Q: Why do you use angular contact ball bearings for car water pumps?

A: Angular contact ball bearings are outstandingly suitable for car water pumps as they can accommodate radial and thrust loads, which is prevalent with most automotive machines. Because of this, performance and service life under different conditions is guaranteed.

Q: What is the effect of preventive maintenance on the life span of auto bearings?

A: Preventive maintenance such as lubrication, cleaning, and inspection helps identify potential problems before they cause bearing failure. These steps ensure that auto bearings are healthy and durable.

Q: How do motor bearings affect the efficiency and performance of automotive systems?

A: The state of worn motor bearings alone influences efficiency and performance in different automotive systems. Defective bearings result in friction, excessive heat, increased energy consumption, and in the worst-case scenario, system failures.

Q: How can Chinese bearing manufacturers enhance the reliability of water pump bearings in car engines?

A: The reliability of water pump bearings in car water pumps manufactured in China can be enhanced using advanced techniques in quality control and superior-grade materials that meet specific automotive industry standards.

Q: What is the role of double-row bearings in auto water pumps that accounts for their increased durability and performance?

A: The primary function of a double row bearing in an auto water pump is to take up radial and axial loads effectively. This results in better pump performance. Other advantages of double-row bearing include increased load capacity and improved stability, thus enhancing the pump’s durability.