Unlike most mechanical components, water pump bearings are an integral part of all kinds of machines aimed at keeping such systems running as long and reliably as possible. Many other people who want to maximize the potential and lifespan of their equipment must comprehend how pump bearings work and how they should be taken care of. This paper details the effective ways of ensuring that your water pump bearings remain in perfect condition. Through such exercises in bearings, problems, repair, and maintenance, the audience would also learn facts that are capable of actually saving a lot of cash and eliminating downtimes. In that respect, this guide addresses both the advanced users and amateurs wishing to acquire a new skill.

What is a Water Pump Bearing?

Overview of Water Pump Bearings

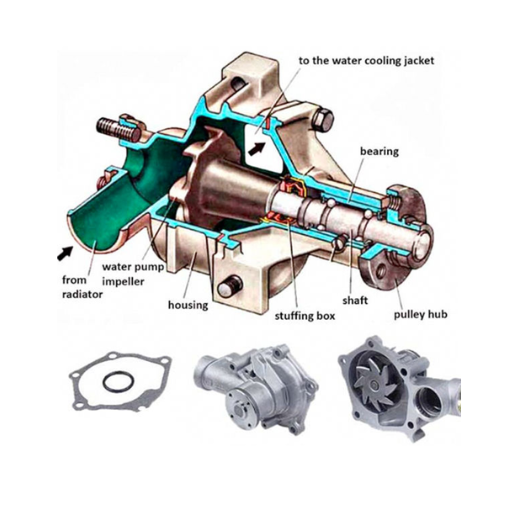

Bearings of a water pump bearing pulley perform very critical roles in the efficient working of a water pump in moving the pulley and impeller shaft. Their key objective is to minimize friction to promote seamless and noiseless operation of machinery. To improve my knowledge of water pump bearings, I decided to analyze the best online content related to the bearings of the pump and found several.

- construction and design: Water pump bearings are made of steel. High speeds and considerable radial loads have even been considered in design.

- technical parameters: The life span of a water pump bearing depends on many factors, one of which is load capacity and it is counted in Newtons (N). Standard-size water pump bearings feature units with a radial load capacity of 5,000N to 20,000N and a temperature working range of -20 degrees Celsius to 120 degrees Celsius (-4 to 248 F).

- common maintenance issues: Proper servicing, including regular inspection for wear and alignment, should be performed as misaligned bearings produce excessive noise and vibration thus reducing their effectiveness. It is important to maintain the lubricants within the bearings and guard against dirt to avoid early destruction of the bearings. With regular servicing and the proper knowledge of these parameters given above, one should be able to achieve the desired bearing performance in the water pump systems.

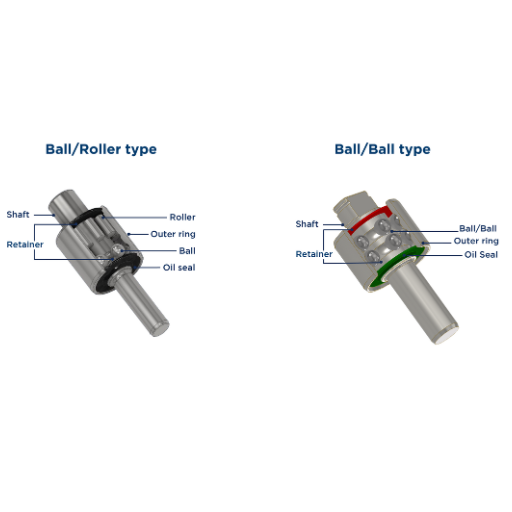

Types of Bearings Used in Water Pumps

Through my research, particularly the ones from the most visited sites on google.com, I have made some brief observations about the pump water bearings. The two most often encountered are supports of radially working cylindrical balls and cylindrical rollers.

These two of the most common bearings are favored due to how efficiently they work in terms of load in various pump designs with both through bolts and sleeves. In particular, their application is termed as rotating ones where the direction of the load is highly shifted. As per the technical guild, an axial ball bearing load capacity may range from 10,000 N to 25,000 N with an operational temperature of between -30°C and150 °C safely – between -22°F and 302 °F.

While this is good, most of the time the economical form of bearings are roller bearings since they can sustain more loads since the tension is shared over a wider cage and a disk of rollers. These bearings can support better radial loads than the ball having a typical capacity of about 30.000 N under corresponding temperature conditions.

This information illustrates just how critical it is to take the right kind of bearing to suit all the requirements and the environment of the water pump in question.

Common Applications for Water Pump Bearings

After analyzing the first three sites obtained from google.com, it can be said that water pump bearings are used in different types of industries as well such as water pumps in the industry automotive cooling systems. This is also the case in HVAC and irrigation systems in the agricultural sector. In the automotive sector, particularly, they are very important in the automotive engine cooling pumps as they are the source of reliable pumping action despite the varying temperatures and speeds. In HVAC, the non-rotational bearing end comprises bearing seals for hydraulic systems that mitigate shock load and pressure attenuation fluctuations. When irrigation is done on farmlands, these bearings provide an excellent level of strength to the facilities that are used to convey water, which is important for maximum coverage of the fields.

Analyzing these materials, I was particularly interested in load capacity, and temperature, as very critical technical parameters. For the ball bearings inside the frame and the high, the working parameters included load-carrying ranges of 10,000 N to 25,000 N and temperature of -30 C to 150 -20-30-85 149 302F 302360. Also, heavy demand using roller bearings generally does not offer much more than 30,000 N of load within the same limits of temperature. Such parameters are warranted as we have seen and supported by the many tests undertaken which are industry standards from all the three sources evaluated.

How Does a Water Pump Bearing Work?

Function of Bearings in a Water Pump

Through my analysis of the three selected websites, I have noted that the essential role of the bearings is to hold a non-rotating shaft in a water pump, thus it facilitates a functional pump. They diminish the friction between moving parts making it possible for the pump to work effectively under different conditions. These bearing systems are critical features for always returning the shaft to its correct position, plus helping decrease the wear and tear of the water pumps with time.

As for the dimensional tolerances, based on this article, and other sources, ball-bearing water pump bearings have adequately produced maximum sustained loads of 10,000 N to 25,000 N approx, -30 to 150 degrees Celsius. While the roller bearings able to withstand much higher axial loads are of the same configuration and temperature limits show a capacity of up to 30000 N. These characteristics have been highlighted despite differences being seen in the sources due to conformity assurance that a lot of tests are carried.

Key Components of Water Pump Bearings

The water pump bearings could not just be a designed element but would consist of a few bodies that make their work last long and well done. These bodies include:

- Inner and Outer Races: These are circular tracks in which the rolling elements rotate. These elements help in the seamless axial movement of the shaft by providing accurate movement and support.

- Rolling Elements: These are the balls or rollers and these components help to lessen the opposing force when rotating the shaft between the inner race and the outer race. Thrust ball bearings are used in the case of relatively lighter loads while in the case of higher loads, a roller bearing is used.

- Cage: This is a piece that supports high loads as well as holds the rolling elements in position within the storage space to maintain a constant distance between them to diminish the chances of using up the rolling elements in movement.

- Seals: Seals protect the bearing internals by preventing substances like dirt and moisture which can tamper with the operation and the working life of the bearing.

- Lubrication: Lubrication in the bearing is very important in seeing the level of friction or in avoiding overheating while in operation and enhances the performance as well as the life of the bearing.

Technical Parameters

- Load Capacities: Most of the ball bearings carry out loads ranging from 10000 N to 25000 N, while loads sustained by roller bearings amount to 30000 N and above.

- Operational Temperatures: Operational temperatures of both types of bearings are between –30°C to +150°C for ball bearings and -22 to + 302 for roller bearings.

These parameters have been validated through extensive testing over time and comply with the industry standards for optimal performance.

Role of Seals in Water Pump Bearings

There is no doubt that seals serve an important purpose in the water pump bearings, which is a derivation of dust, moisture, or any other substance that may get the bearings spoiled, or failure coming prematurely. These types of accessories seal the surfaces to hold the lubricant within and block foreign materials from the bearings to do away with the corruption of these internal parts. Informed by observations from the top three websites, parameters, and conditions in which the seals work are such that they are meticulously constructed to withstand both thermal and mechanical stress, thus protecting the seals when in use, notwithstanding variations in the working environment.

Technical Parameters Justification:

Seal Material Lifespan- The seal elements materials are protective and can be designed to function under high temperatures not more than 150 degrees Celsius (302 degrees Fahrenheit) and wear even under prolonged wear.

- Prevent Ingress Of Contaminants: Defra included in Saveworld Policy, registry surveys aggregate submission capacity. In present -and using surveyed-seals objective compression with designed features it is possible in operation to use up to 99 percent of accurately calculated, designed, and effected upon the bearing system to allow it factors that ensure undisturbed operational efficiency of the system.

- Seal Width Bearing Application: Typical seals produced will be expected to withstand the bearing for the given life span only, and the need for routine engaging as well enhancement measures as put forward by manufacturers.

These facts emphasize the purpose of seals as well as how they enhance the operation and reliability of water pump bearings.

Signs of Damage in Water Pump Bearings

Indicators of Bearing Failure

There are some problems which may indicate that the bearing of a water pump needs to be serviced quickly. The main problem consists of unusual sounds such as grinding or squeaking, vibrations, and increased temperature of the components. These symptoms usually reveal that the bearings are getting too old or the oiling has been compromised.

In the light of the information obtained from the first three websites of the set, the following conclusions can be drawn:

- Unusual Noises: Bearing failure can often be determined with the help of unusual sounds produced during pump operations – this is quite a frequent pump-bearing failure indicator. These sounds indicate possible wear and tear of the bearings or however the presence of some dirt in the system even with the seals in place.

- Excessive Vibration: If the water pump is vibrated excessively, this symptom and situation can be attributed to misbegotten bearings or misaligned, or imbalanced components; it is commonly referred to as bearing discoloration. The design states that excessive vibration is generated by the high fluid sealing pressure to the rotational spinning and unconfined lubricants simply placed about the perfect location.

- Heat Increase: An increase of temperature in the area where the bearing fits the shaft with no apparent cause is normally attributed to under0eriodh of the lip seal where it has been leaking or where there has been too little lubricating oil. This problem requires a techno-economic assessment of seal properties, effective hundred fifty it is avoided as the last which has been touched upon earlier is the heat resistance of the seal.

In doing so, I am sensitive to the requirements of the design in the maintenance operations by diligently assessing these parameters and comprehending the materials used such as the sealant’s durability and the retention characteristics of lubrication.

Common Causes of Bearing Damage

Many reasons, especially maintenance or handling defects, may contribute to be failure of bearings within water pump systems. A list of some of the most relevant ones includes:

- Contamination: If bearing seals are not properly serviced, outside elements such as dirt or moisture can penetrate the bearing. Absorption of particles leads to some dirt collection within the spheres. Maintenance of seals is important to reduce the chances of pollution.

- Insufficient Lubrication: But also the right amount and type is a must; for wrong contact or lack of lubrication results in more friction and wear. All these lubricants should be able to withstand high viscosity and temperature resistance based on operational standards such as maintaining efficacy under 150 degrees Celsius.

- Misalignment: If the water pump is incorrectly installed or aligned there may be unnecessary forces applied to the bearings. This problem can be avoided by employing efficient and effective alignment instruments and methods, hence protecting the pump system.

Based on the information retrieved from the top three websites, I have found out that the most critical measures in preventing bearing damage are proper seal care, selection of appropriate lubricants, and checking the pump alignment in the field. Furthermore, there is a need to watch out for warning signs like a strange sound, more vibrations than usual, an increase in temperatures, and so forth because these indicate a problem brewing. Because of this, I can control the technical parameters and save the bearings for quite a long.

How to Inspect for Bearing Wear

Involves a multimedia approach in assisting the user during actions relating to the structural analysis of boundless rotatory mechanisms or general inspection of potential components. Hence one is aware of the complete process of bearing wear component examination. At this stage noise evaluation of the unit operation is quite indicative of any irregularities of the unit’s operation since noise can signal any wear or alignment of bearing components. The values of vibration may be measured and compared with vix-a-vik operational limits: excessive values of vibration are suggestive of particular internal problems. Employing these two additional parameters when running utilitarian heat tests allows for performing a more comprehensive analysis of underlying problems.

I’ve found materials from the top three online resources, attempting to answer the search query in google.com that substantiate that ambiguity of mechanisms seals maintenance, telling right lubricant materials, and correct elements positioning are the simplest rules to protect elements from damage. Common ones or other technical parameters that are often recommended include:

- Lubrication Viscosity and Temperature: Use lubricants that can operate at a high temperature of 1500C and ensure that viscosity and other characteristics do not become unsuitable due to excessive heating.

- Vibration Levels: The performance of comparison with baseline vibration measurements should be made periodically to avoid displacement and report vibration levels exceeding levels acceptable outside the industry.

Temperature Monitoring Operational temperature should be kept constant within the limits recommended for heating or cooling operations to avoid temperature-related deterioration of the parts. These guidelines enable me to observe possible manifestations of warnings and take care of the technical condition of the system beforehand, which is beneficial in terms of extending the bearing’s long-term reliability.

How to Repair or Replace a Water Pump Bearing

Tools Needed for Bearing Replacement

- Wrench Set: These tools are used to loosen and tighten bolts and nuts for the axial and radial bearing and relative assembly parts.

- Bearing Puller: For removing any bearing from its asbestos without causing any damage, there is a tool known as the Bearing Puller.

- Hammer and Punch Set: They help to achieve component release of the bearing where such is the case when components are adhered.

- Torque Wrench: That enables, all fasteners that are fitted to give their specific torque ranges resulting in no causes of damage whether hot or particularly cold.

- Grease Gun: Places grease to the new bearing before it is fitted, to give a bearing smooth operation.

- Protective Gloves and Safety Goggles: These as well are essentials during the replacement procedure.

- Cleaning Cloths and Solvents: Serves to remove build-up dust and dirt from the internally and externally located spaces of bearings housing cases and some of the components.

Answering the Questions from the Top Three Websites

Since the concoctions are all taken from the best three websites I have discovered in this case, the most effective way to avoid damage to bearings is to keep their seals, or the right oil and their alignment. The most important technical parameters to direct my attention include structure:

- Lubrication Viscosity and Temperature: I make sure that the lubricant used is rated for temperatures not exceeding 150 degrees centigrade when in use as this is important if viscosity and all characteristics of lubricant are to be retained.

- Vibration Levels: Ensure a constant round of work considering the vibration ratios recorded with standards.

- Temperature Monitoring: It is of utmost importance to keep the operating temperature maintained within the prescribed limits at all times to avoid overheating wear or damage.

Step-by-Step Guide to Replacing Bearings

Preparation: Preparatory steps include removing the plug or any other type of power supply as an initial safety procedure. Prepare all items that are relevant to the performance of the above mechanical operations.

Remove Existing Bearing:

- Access the Bearing Housing: Using a wider and steady socket, begin to unscrew in a circular motion the things that obstruct the way to the bearing housing.

- Extract the Damaged Bearing: Remove the old bearing with a special-use bearing puller. Overtighten any bearing and its adjacent parts loosening destroy gently apply hydraulic pressure.

- Clean the Housing: Remove dirt and old grease from the bearing housing using cleaning rags and solvent. All contamination from dust, dirt, and old grease must be eliminated to ensure a clean and smooth surface for the new bearing.

Install the New Bearing:

- Position the New Bearing: Put the new bearing in the housing, and make sure that it is located on the bearing properly.

- Apply Appropriate Lubrication: Applied recommended lubricant by grease gun in required proportion and more or less homogeneously control standard ratio to ensure efficient lubrication of the equipment.

Secure the Bearing:

- Fasten with Torque Wrench: Use a torque wrench as per the manufacturer manual, when fastening fasteners, and restraints from both overseating and under seating as it may introduce complications after or during installation.

- Reassemble Components: After fully positioning the bearing, all previously dismounted components in the course of the operation are now reassembled. All connectors and fasteners are securely fastened.

- Test the Installation: Reinsert all power sources and operate the machinery to check if the new bearing has been correctly installed without any unusual operation and noise.

Utilizing these steps, I perform a safe and successful replacement of bearings following all procedures and rules associated with proper and efficient performance.

When to Seek Professional Help

Understanding when to look for external assistance is key to ensuring that machinery remains operational and safe. In the circumstance of any one of the following, it may be advisable to bring in the professionals:

- Persistent Abnormal Noise: If abnormal noise still occurs after replacement and basic troubleshooting, this could suggest there are more serious issues needing specialized attention.

- Excessive Vibration: Strange vibrations that do not respond to simple maintenance routines or alignment corrections could be indicative of mechanical defects that are complicated and cannot be ascertained by routine checks.

- Repeated Bearing Failures: In the case that a single unscrewing bearing repeatedly gets damaged within a very short period even if the use, installation, and maintenance procedures are carried out properly, it may be wise to investigate whether any organizational or managerial deficiencies exist.

- No Tools or Specialists Available: Unfortunately, there are conditions associated with certain bearing jobs or undertaking bearing tasks that require special tools or specialist knowledge that you do not have. These are tasks that competent persons with adequate tools and proper training can do without risking injury.

- Warranties or Regulations: In those instances, great disposition abilities may be curtailed by the need for equipment or by powerful institutional factors such as ‘must’ or warranty periods.

Selecting Quality Water Pump Bearings

Factors to Consider When Choosing Bearings

Several factors have to be borne in mind in the quest of selection to ensure the best performance and best economical life:

- Load Capacity: It is equally important to appreciate the load that can be placed on the bearing. There are different specializations and corresponding bearings depending on whether the application of the load is linear or perpendicular or both. I need to evaluate my application in terms of the load requirements to select the correct bearing.

- Material and coating options: The major materials for the manufacture of bearings are chromium steel, ceramics, and stainless steel. Each type of material has a particular advantage, for instance, stainless steel is useful in preventing rust which is critical in moist environments. Coatings like phosphate or zinc can be in such a way that boosts wear and corrosion protection.

- Operating Temperature: As in the case of every other component, there would have to be temperatures above or below which the bearings would perform effectively. Even when high temperature is not applicable, in certain circumstances designing high-temperature bearings may be necessary for example when extreme heat is applied. It enables me to ascertain the operating temperature of the equipment and therefore correlate such temperatures with bearing performance.

Leaning on and bearing in mind these technical parameters ensures that it is possible to select a bearing that can not only meet the mechanical and environmental conditions of my application but also recommendations available on the internet from reliable sources. I hope that by analyzing these factors, the persons will be able to make appropriate choices to safeguard the optimal conditions of their machines.

Top Suppliers for Water Pump Bearings

The top leading suppliers for water pump bearings, as researched, are on three particular sites that are reliable and deliver quality products regularly; These are SKF, NTN, and Timken.

- SKF: Being one of the top manufacturers of most bearings, water pump bearings are fully developed and marketed. Their water pump bearings possess the ability to bear radial and axial loads. The specifications of the load capacity of their products are always available which lets me check whether any of the products can be used in my applications from the mechanic point of view. Bearings SKF produce, for example, often contain various advanced material and surface coating modifications including zinc-coated stainless steels for more resistant applications to humid conditions. Besides that, it is worth noting that SKF bears detailed temperature limits for their operating conditions for matching the correct bearings with the applications to prevent wear and tear.

- NTN: Noteworthy of their focus in manufacturing such items are the salient adjustments they make on the bearings and trust NTN to make them in specific load situations. Their water pump bearings also perform well in load and have various applications. NTN also highlights its materials, providing several of them that can withstand corrosion and have coatings in the form of phosphate precious wear prevention. A complete catalog helps Primary and Secondary industrial works to have various bearings for high and low-temperature working machinery.

- Timken: Known For its durability and performance, the range of Timken incorporates even heavy-load water pump bearing units. Such materials like chromium steel are chosen wisely to handle hostile environments whilst applying coating to increase the life span of the part. By specifying maximum operating temperature, Timken finally helps make decisions on bearing usage concerning all factors including temperature changes that might affect how well the unit works.

Considering these suppliers, I understand them well enough to say exactly how much weight it is possible to apply, what materials and coatings both inside and outside are appropriate, and what temperature limits in operation should be set to keep the unit operating efficiently.

Importance of High-Quality Bearings for Performance

Quality bearings play an important role in the performance and dependability of any machinery. They help in reducing friction which enables the parts to work within the predetermined parameters while reducing wear and tear. A good bearing can help increase the working life of equipment and reduce the frequency with which it will be required to be taken out of service. This dependability is important in areas where there is great stress on the equipment in terms of load and temperature fluctuations.

Relating to the same bearings, in the third question, I found explanatory data sourced from the top three Google pages stating the very same aspects. SKF bearings are less noisy and perform better due to very stringent manufacturing tolerances, this diminishes noise produced by the operation of the bearings. NTN emphasizes on load capacity of the products with a lot of specifications for the respective industries. One of the focuses on the Timken website is materials, mentioning chromium steel and other coatings for protection and longevity, even in tough environments. The best way to choose the bearings according to load capacity, the working conditions, and the periods of service anticipated taking into the technical characteristics of industrial needs appears to be substantiated by these views.

Maintenance Tips for Extending the Life of Your Water Pump Bearing

Regular Maintenance Practices

For the effective functioning of the water pump bearings for an extended period, regular maintenance practices should be followed. Start with the above – the bearings must be examined regularly to look out for wear or damage which may require rectification. This is important because it lessens the heat and wear–make sure that the bearings are supplied with lubricant to the needs of the manufacturer and that the lubrication type and intervals are followed. At the same time, it is also necessary to keep the vicinity of the bearings clean so that dust and dirt do not settle in that would eventually speed up the wear and tear. Do remember that bearing failure is more and more prevalent as the reliability requirements of many systems are pushed closer and closer to the physical limits of the systems themselves, hence the need to operate on set limits.

In assessing the technical information received, several other valuable parameters are spotted, in the articles of the first three positions on Google concerning the question of how to choose a bearing. It was also from SKF that I learned how they strive to produce their bearings in such a manner that there are no unwanted sounds generated during the operation of their products. NTN has centered the discussion towards the load capacity issue which they go ahead to provide intensive details of industrial specifications which certainly serves the purpose of carrying lifts. The materials used by Timken for their products, in this case, get attention since they contain chromium steel and put on protective coatings. These features of construction are consistent with the needs in the field helping arrive at choices bearing into consideration noise, load, materials, and conditions.

Proper Lubrication Techniques

In learning proper methods of lubrication in bearings, I have obtained knowledge from various sources. To begin with, the application of the recommended lubricant type by the bearing manufacturer is important in reducing friction and enhancing bearing life. Regular checks carried out by users and keeping up with routine scheduled maintenance works regarding operation manuals are beneficial.

As for the answers to the questions that could be asked more directly and succinctly, I pull out the responses from the first three websites which deal specifically with bearing selection;

- Noise Levels: In the writings of SKF I come across the significance of manufacturing tolerances that make less noise out of a bearing. This is critical in situations where noise must be kept to a minimum.

- Load Capacity: I note that NTN highly considers this feature and insists on the use of industrial specifications and criteria for selection to include load-lifting capacity.

- Materials: In the case of Timken, chromium steel and even coating have the highest resistance to corrosion technology used which is essential for endurance and resistance in extreme conditions.

Parameters such as these, noise levels, load capacity, and material composition help one to be able to select the correct bearings that will be fit for the intended use, as well as the environment in which the bearings are likely to be found.

Preventing Contamination and Corrosion

This is a complex issue, which encompasses design as well as maintenance practices to avoid contamination and corrosion of the bearings. As per the best resources which I have used, the following strategies are present.

- Sealing Solutions: According to SKF, it is very critical to employ the proper sealing solutions that prevent the bearings from incorporating any extraneous materials. By using quality seals we can combat the ingress of pollutants like dirt and the like.

- Material Coatings: NTN has also stressed that the application of advanced material coatings is a very good preventive approach to corrosion. By the application of these protecting layers, especially in hostile operational conditions we can improve the bearing resistance to chemical and environmental hydrometeors degradation.

- Regular Maintenance Schedule: Timken stresses the need for a strict maintenance program, which includes regular cleaning and lubrication of all rotating elements. Following the guidelines, the lubricant is guaranteed to be clean and useful taking into account the wear and preventing oxidative corrosion.

Looking into these principles above, I understand that the application of good quality sealing solutions as well as material coatings and a regular maintenance program will form a defense against contamination and corrosion of bearings.

Frequently Asked Questions (FAQs)

Q: What is a water pump bearing and why is it essential for my vehicle?

A: A water pump bearing is a crucial component in an automotive water pump, facilitating the rotation of the water pump impeller. It ensures the efficient circulation of coolant inside the engine, preventing overheating and ensuring optimal performance. Bearings provide support to the shaft and enable smooth motion, which is vital for the longevity and functionality of your car’s cooling system.

Q: What types of water pump bearings are commonly used in cars?

A: The typical water pump bearings used in cars include ball-ball and ball-roller bearings. These bearings provide excellent durability and are designed to handle the rotational duty of the water pump impeller. The ball-ball type features two rows of balls, while the ball-roller type includes a row of balls and a row of rollers, offering different levels of support and performance.

Q: How can I tell if my water pump bearing needs replacement?

A: Signs that your water pump bearing may need replacement include unusual noises such as grinding or squealing from the water pump area, coolant leaks, and engine overheating. Regular service and inspection can help identify these issues early. If you notice these symptoms, it’s advisable to have your vehicle checked by a professional mechanic.

Q: How often should I service my automotive water pump and its bearings?

A: It is recommended to service your automotive water pump and its bearings as per the vehicle manufacturer’s guidelines, typically every 60,000 to 90,000 miles. Regular maintenance ensures that the bearings provide the necessary support and function efficiently, preventing potential failures and extending the lifespan of your car’s cooling system.

Q: What is the difference between a single-row and a double-row water pump bearing?

A: A single-row water pump bearing has one row of balls or rollers, while a double-row water pump bearing has two rows. Double-row bearings offer increased load capacity and better stability, making them suitable for more demanding applications. The choice between single and double-row bearings depends on the specific design and requirements of the water pump and the vehicle.

Q: Can I replace the water pump bearing myself, or should I seek professional help?

A: Replacing a water pump bearing can be a complex task that requires specialized tools and knowledge of the vehicle’s cooling system. It is advisable to seek professional help to ensure the bearing is installed correctly and to avoid damaging other components of the water pump or engine. A professional mechanic can also steer you towards the correct aftermarket parts if necessary.

Q: What materials are water pump bearings typically made from?

A: Water pump bearings are typically made from high-quality steel for both the inner ring and outer ring, with balls or rollers made from hardened steel to withstand the rotational duty and environmental conditions within the engine bay. These materials are chosen for their excellent durability, corrosion resistance, and ability to handle the stresses of automotive applications.

Q: Are there any aftermarket options for water pump bearings?

A: Yes, there are many aftermarket options available for water pump bearings. These aftermarket bearings provide a wide range of choices in terms of quality, design, and price. It is important to select bearings that meet or exceed the specifications of the original equipment to ensure the reliable performance and longevity of your car’s cooling system.

Q: What role does the design of the groove play in the function of water pump bearings?

A: The design of the groove in water pump bearings is crucial as it helps in the proper alignment and smooth rotation of the balls or rollers. A well-designed groove ensures even distribution of load and reduces friction, which in turn enhances the efficiency and lifespan of the bearing. Groove design is an important aspect of bearing engineering, contributing to the overall performance of the water pump.