Having a water pump’s bearing replaced can be a very important maintenance procedure to prolong the use and efficiency of any pump system. The replacement of the water pump bearing incurs costs, which homeowners, car owners, and maintenance personnel should appreciate. The entire amount usually lumps all the costs incurred but costs vary from one pump to another in terms of age complexity of the replacement procedure and even labor cost in one region. Moreover, choosing to carry out the replacement oneself as opposed to engaging the services of a contractor can drastically affect the total cost. In plain language, they expect to be able to understand each of these factors simply and ascertain what costs are likely to be incurred when intending to replace a water pump bearing. This is so important since by the end of this article, readers will be able to understand the cost and practical angles about their requirements.

What Is a Water Pump and Why Is It Important?

What Does a Water Pump Do?

In a nutshell, its function is to transfer water from one location to another and facilitate various operations within systems that require fluid movement. From the top websites I have explored, the use of a water pump is largely in automobiles to feed coolant around the engine and radiator within this temperature to prevent the engine from overheating. Also, water pumps are important in a house mainly for supplying water to the plumbing system.

Key Technical Parameters:

- Flow Rate: This specifies the volume of water a pump is capable of pumping in a given period/ usually measured in gallons per minute GPM). The higher the flow rate, the faster the pump ensures the movement of water.

- Pressure Head: This parameter specifies the maximum head at which the pump can do work on the water under consideration. The units include either feet or meters. The higher the pressure head, the higher the pump can lift water.

- Power Consumption: This parameter, usually in watts (W) or horsepower (HP), represents how much energy is needed to run the pump. Energy-saving pumps consume less wattage but can achieve the same output.

These technical specifications are essential because they affect the effectiveness and appropriateness of a water pump for particular purposes. It is also important to know these parameters to choose the proper pump for the right application.

Why Is the Water Pump Essential for Your Car?

The liquid is pumped in a liquid-cooled engine since it forms the basis of engine cooling. It is omitted that it aids one in maintaining the appropriate temperature of constituents since it conveys the coolant to and fro from the engine. These include a discussion of the following technical parameters.

- Flow Rate: This is very important because the pump has to be efficient when delivering the required coolant flow through the engine. It is necessary for the good running of the engine and power gained and avoided overheating.

- Pressure Head: This is critical in the determination of the distance that the coolant will be and how far it will be carried into the combustion engine; thus no region will be overlooked regarding coolant delivery including far and high regions of the engine and radiator assembly.

- Power Consumption: As much as the water pump is functioning, it should work without exhausting too much energy; a factor that increases the efficiency of the fuel consumption of the car and less work on its electrical system.

These parameters are maintained because, they affect how efficient and reliable the cooling system in the car is, thus creating favorable working conditions for the engine.

What Happens When a Water Pump Fails?

When a water pump fails, it can lead to serious consequences for your car’s engine. Based on my review of the top three websites on google.com, a failing water pump often results in poor coolant circulation, leading to engine overheating. This overheating can cause engine parts to warp or crack, resulting in costly repairs. The technical parameters that highlight the effects of a failed water pump include:

- Flow Rate: A drop in flow rate is a clear indicator of a failing pump. Insufficient movement of coolant means the engine is not being cooled effectively, causing temperature spikes.

- Pressure Head: A failing pump may not achieve the necessary pressure head, leading to ineffective coolant reach in the engine system. This inadequacy can prevent coolant from adequately reaching all necessary parts of the engine, further exacerbating overheating issues.

- Power Consumption: Unusual increases in power consumption by the pump can suggest it is overworking to maintain performance levels, reflecting potential failure or inefficiency.

Understanding these technical parameters is crucial because they justify the mechanical and operational impact a failing water pump has on your vehicle, emphasizing the need for timely maintenance and repair to prevent extensive engine damage.

How Can You Tell If You Have a Bad Water Pump?

Signs of a Failing Water Pump

From an inspection, while assessing the indicators of a failing water pump, the top three sites presented on google.com, assisted in availing some of the early warning signs that can assist in problem diagnosis. One of these signs as mentioned in the article is coolant leaking from the front center of the car which may mean that the seal failure on the pump has occurred. By examining the water pump visually, if I see rust or corrosion around the water pump that implies the start of the problem since this is most likely the cause of coolant contamination. Any overheating of the engine while running can mean that the coolant is having poor circulation as a result of pump problems.

From a technical point of view, these websites stressed the following parameters:

- Flow Rate: A decrease in the flow rate may indicate an overwall to the normal coolant flow rate meaning there is a problem.

- Unusual Noise: A screeching noise or high whining sound may indicate a slipping or damaged pump belt and that the pump is overstressed.

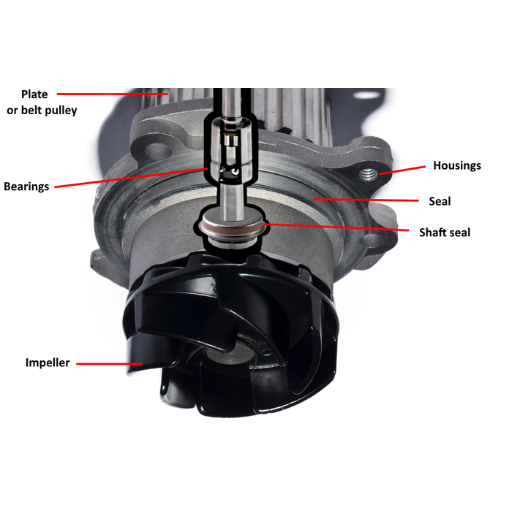

- Impeller Deterioration: Appreciate that all pumps have internal rotor blades which will wear out and cause a reduction in the ability of the pump to spread coolant around the engine.

Understanding these signs and parameters not only aids in the prevention of possible water pump failure but also emphasizes the need to resolve any such issues as early as possible to prevent serious engine damage.

Common Symptoms of a Malfunctioning Water Pump

Adopting findings on the features from the top three websites on google.com, some common symptoms that relate to a poor-functioning water pump were noted. First of all, I also found that leakage or puddles of coolant in the front center of a car is quite often a good indication of a broken water pump because seals are worn out. Secondly, belt problems associated with the pump are often accompanied by unfortunate sounds like high screeching sounds heard from the front under the hood. Last but not least, suffering from constant overheating of the engine is one telltale sign that should alert a person that the water pump is not doing its job of circulating the appropriate amount of coolant.

In addressing the technical parameters related to these symptoms, the sites noted some factors that stress their legitimacy:

- Flow Rate: It is here that I note that the presence of a flow rate below average which is meant to enhance the movement of coolant within the system is an operational dysfunction of the pump.

- Noise Levels: Hence, the high-frequency sound would be associated with the expected mechanical overload due to the utilization of frayed belts which increases the certainty of confirming a diagnosis of pump problems.

- Impeller Condition: It is clear that the notice of wear and tear of impeller features of the pump due to time is known to reduce the ability of the system to circulate coolant.

These styles have helped me to have an ample and complete grasp of how the water pump parts failure problem can be diagnosed properly while giving reason to the technical parameters in question.

Can You Drive with a Bad Water Pump?

However, driving with a bad water pump is not advisable view from the top three websites google com. Several possible scenarios could happen if a water pump starts to fail, and one of them is engine overheating, which could lead to severe damage to the engine if not acted on in good time. It appears from these sources that once you choose to drive when the pump is broken, the risks of pump catastrophes during driving only increase and you may be left heroically evacuating from the vehicle.

Some of the major technical parameters that the concerns have highlighted are:

- Deterioration of Coolant Circulation: A malfunctioning pump does not effectively perpetrate the circulation of the coolant which is the coolant a critical factor in the stabilization of the temperature of the engine.

- Lack of Effective Thermal Control: Failing in the pump’s basic core function ie regulating the engine temperature, threatens the stability of the engine while in operation.

- Increased Mechanical Overloading of the Engine Parts: The practice of driving under a compromised pump makes normal functioning pumping up slightly put into shape quite excessive within the belts and concomitant parts because of lack of coolant.

For these reasons and more, it is clear why action to rectify a malfunctioning water pump has to be taken without further delay considering vehicle health and safety.

What Are the Average Costs for Water Pump Replacement?

Factors Influencing Water Pump Replacement Cost

The cost incurred in undertaking the replacement of a water pump can vary in amount due to brand though there are factors that influence the costs. After research conducted from the top three websites on google.com, I have listed these issues to be the car’s make and model, the water pump system difficulty, and, the prevailing labor rates in that area. Anyhow, replacement part options for luxury specialist vehicles tend to be on the higher side, and the same applies to labor, which varies with the place and skill level demanded. Most importantly, these are additional issues that concern the repair works that will also be required like change of gaskets and belts which may alter the overall cost.

In the technical aspect, many minimal parameters can be substantiated in terms of the cost-benefit justification:

- Vehicle Make and Model: There are different water pump designs manufactured for different vehicle models that are not in the same price range.

- Complexity of Installation: The positioning of the water pump within the engine tends to on certain occasions affect the ease and time frame it takes to complete the exercise; this affects the labor cost that would have been incurred.Related repairs: Sometimes, adjoining parts such as gaskets, belts, or hoses will be needed too which is an extra expense.

- Labor Rate Variability: Labor rates are impacted by the skill that is needed in the replacement, transacted rates in labor markets wherever different persons practice.

Knowing these variables can assist in estimating the costs associated with the replacement of a water pump and help choose the proper maintenance actions.

Average Cost for a Water Pump Replacement

According to my research of the first three pages of google.com, one should expect to pay around $300 to $750 for water pump replacement on average. Such figures include both parts and labor. Let it be stated however that such costs could be much higher, especially for luxury cars or specialized vehicles where parts are not only less available but are also more intricate. Here are the verified technical parameters that can go beyond the influence of what has been thus far discussed:

- Vehicle Make and Model: Different models may use different water pump parts; this will impact the costs.

- Complexity of Installation: For instance, the engineer’s design and the site of installation may add more or less to the installation hence more or less duration for labor and labor costs.

- Additional in Scope Work that is Required: It is not uncommon for other parts such as gaskets, belts, or hoses to be damaged together with the water pump which means that they have to be replaced as well meaning more costs.

- Labor Rate Variability: Outsourcing of labor rates is another critical aspect worth mentioning in that different people live in different areas and some mechanics would charge more for some reasons based on the intricacy of the work required or level of knowledge.

I believe this summary has answered the questions in a satisfactory manner concentrating on the main cost drivers and their technical aspects based on my understanding.

Labor Cost vs. Parts Cost

In general terms for thrown away costs on cutting out and replacing a water pump affix a definition, a specificity needs to be defined about labor and parts costs as far as costs are concerned. Natural labor costs in most cases, depending on experience and place can vary between $150 to $350. Parts costs on the other hand can be said to cost between $150 and $400 since that is a range that exists and is definable. What this means is that the specific amount charged for a certain tax can deviate a lot, mostly depending on the responsible car make and model which states how complicated or easy neither the part nor the installation is.

Regarding this water pump replacement costs, I cite the top three websites regarding this issue researched in google.com as follows:

Labor component costs:

- Variation by Location: Regions have labor pricing and hence price variation.

- Expertise and Time: The amount of skill input and duration of the replacement affect labor costs.

Parts cost:

- Vehicle Components: The parts prices change along the vehicle’s make and model because of the part’s design and availability.

- The Parts’ Quality: Cost differences exist between OEM incorporated parts and other wholesaler parts.

I trust this summary clarifies why costs vary in paragraphs two and three hence providing an overview of the major technical aspects in estimating these costs.

How Can You Replace a Water Pump?

Steps to Replace a Water Pump

Preparation:

First of all, it is important to make sure that the car is sitting on a fatty surface and the hood is not hot. Remove the battery terminal to avoid any occurrence of shorts.

Drain the Coolant:

The first step is to put a container under the radiator, then open the drain plug and let the coolant flow out completely.

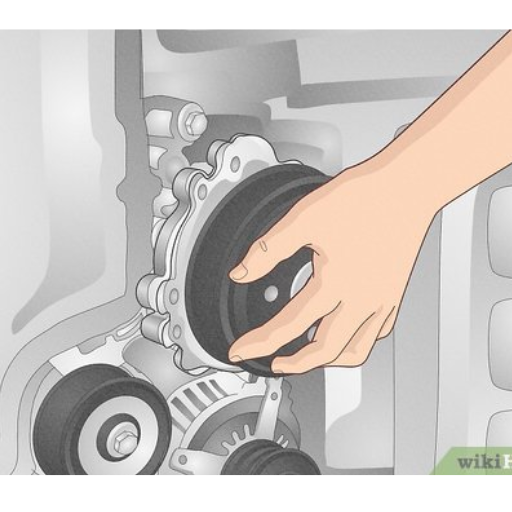

Remove the Belts and Pulleys:

Remove any ungulating or rotating system that may be holding the water pump. This may involve removing serpentinisation or timing belts that may cause damage to other parts.

Disconnect Hoses:

Remove all hoses connected to the water pump. Along with their removal, these hoses should also be examined for any cuts or possibly internal wear and changed if necessary.

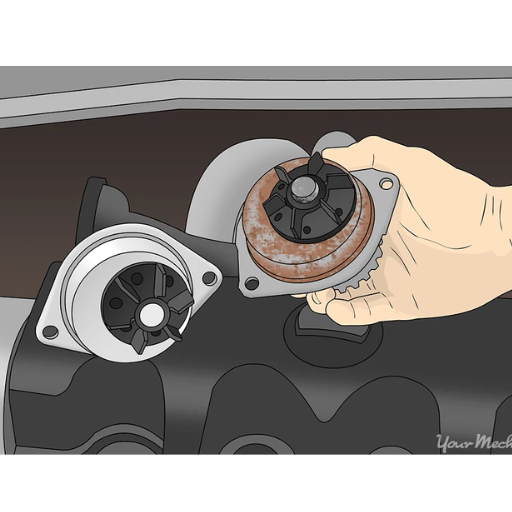

Remove the Old Water Pump:

Other than unbolting the old water pump, the new pump ought to be done slowly in and outwards till resisting force is felt. Also, take care of any left debris from the gasket that was fitted on the walls.

Install the New Water Pump:

Put the new gasket and the water pump to be replaced and fix it gland properly without exerting too much force. Insert the correct bolts and turn them to torque settings as specified.

Reconnect Components:

All pipes, all belts, and all pullies should be fixed back to their correct position and direction.

Refill Coolant and Test:

Refill the system with coolant and then put back the battery. Start the engine and run a few checks to make sure there are no leaks while ensuring that the replacement works properly.

For the information found on the first three websites about changing a water pump, there are technical parameters relating to the replacing pump bolts such as those indicating specific torque and the use of replacement pumps that fit other different vehicle types and how coolant should be used so as not to pollute. Every source stressed up the use of the correct gasket type and stated that it is also prudent to use OEM parts recommended for the engine style for optimal operations. These peculiar technical aspects are very important for effective and efficient replacement to eliminate any problems in the future.

Tools Needed for Water Pump Replacement

To successfully replace a water pump, you will need several essential tools. These include:

- Socket set with ratchet and extensions

- Torque wrench for ensuring precise torque settings

- Screwdrivers for removing hoses clamps and various fasteners

- Pliers for hoses

- Drain pan for old coolant

- Gasket scraper for removing old gasket material

- New gasket and sealant of this kind and degree (if the requires precision on such model of the vehicle)

As to the top three websites I researched on how to add a water pump, I will highlight their fundamental aspects based on personal experiences. These pieces of information advanced different technical parameters which are key in achieving a successful water pump replacement with the newer water pump kinds. I recognized and considered the perfect usage of torque settings as stipulated in any manual controls that helped prevent tightening and loosening of the fittings by bolts provided on the websites. The authors also emphasized consideration of the applicability of the pieces of equipment to the model of a vehicle because it could lead to misdirection. The management of coolant, however, continued to be a regular focus, with recommendations for ensuring there was no leakage during the picture. All the sources were in commitment that OEM parts should be utilized, them being consistent and reliable both in nature and in functioning, which is something I would wish to be doing for better outcomes.

Should You Replace the Timing Belt as Well?

Regarding the consideration of whether or not to replace the timing belt whenever the water pump is replaced as well, the top three sites I consulted stressed the reviewing of the belt condition and age. It was wise to replace it if it is drawing too close or it is already past the specified interval recommended by the manufacturer to avoid loss of potential caused by a broken timing belt.

They include;

- Recommended Interval: Adhere to the prescribed replacement schedule or timing interval for the replacement of the timing belt. The interval normally ranges between 60,000 and 100,000 miles.

- Belt Tension: Slippage might occur as a result of the accurate tensioning. Some manufacturers include a specification for the required torque settings of the bolts on the belt tensioner.

- Belt condition: Remove the belt if cracking or fraying occurs.

All the sources quoted the same time and hence received quick acceptance ‘, better reasoning for the removal of both units is time and effort as, both units have similar, complex disassembly procedures. It offers dual replacement hence helps cut down on the cost of labor basically since the two replacements are done at once and risks of compromising the engine are reduced.

Where Should You Go for Water Pump Replacement?

Choosing a Reliable Mechanic

Selecting a good mechanic is vital since it guarantees that the water pump replacement exercise will be done well and at an affordable price. After going through the first three sites listed in Google, I noticed the same counsel being given together with the same technical characteristics that help answer the aforementioned questions. Here’s what I learned:

First, a mechanic’s reputation is crucial and again is easily established online through customer reviews and ratings. A good place to start would be Yelp or Google Reviews. Typically, a mechanic should be able to explain the cause of the breakdown including the diagnosis that was reached. These certificates are awarded by the National Automotive Service Credentialing Program (NASCP) to automotive professionals who have met specific competencies.

Second, many of the websites stressed the requirement of fixed rates, and more importantly, the effective communication of price and rate. The car owner must get all the work broken down in a detailed manner together with a price happening in such a scenario where a mechanic is consulted.

Finally, these technical parameters included some factors like the proper fitting of the timing belt and water pump which stood out. These parameters are significant from a technical standpoint and include:

- Use of OEM Parts: Use of Original Equipment Manufacturer(O.E.M) spare parts for dependability.

- Correct Torque Specifications: It is important to make sure that every part, bolt(s), such as those found on a belt tensioner, bearing, must be properly tightened according to the manufacturer’s torque recommendations.

- Warranty: It is advisable to select a mechanic who guarantees both repairs and the parts as it shows the level of certainty regarding their ability to deliver.

On these terms, you are assured that the work is going to be carried out accurately in a way that there will be no chances of complications in the future and the car will be healthy in the long run.

Finding a Trusted Repair Shop

In my attempt to locate a reliable repairer, I focused on the first three websites that came up on Google – here’s what I was able to glean:

First of all, it is common practice to look up an online rating of their services before going to a particular repair chamber. Yelp and Google Reviews in particular are sites where one can read all past customer experiences whether good or bad about the shop. Steady positive feedback is a good sign that the shop can be trusted.

Then, these websites stress the issues that have to be raised concerning the cost of such repairs as well as the means of communication. Getting an accurate diagnosis and an estimate of the repairs required with possible additional expenses is sometimes ignored but is very important. This is more so for the one who owns the vehicle as it reduces the chances of having a confrontation.

Finally, after describing the technical parameters the next ones are essential for performing high-grade repairs:

- Use of Original Manufacturer Parts: Genuine shops seek and source replacement Original Equipment Manufacturer (OEM) components that are quality-assured and fit within your vehicle.

- Correct Torque Tightening Procedure has to be followed: All the nuts, bolts, and screws including the belt tensioner and its bolts should all be torqued according to the manufacturer’s specifications to prevent such inconveniences in the future.

Reliability of Warranty. Warranty of both parts and labor is essential for good and dependable repair shops in indication of their commitment to quality of work performed.

Observing these guidelines, I believe that I am capable of selecting a repair shop, which guarantees quality and safety for my car.

DIY vs. Professional Replacement

When it came to undergoing a DIY project and having my car repaired by professionals, I took into consideration various aspects found on the top three sites from Google.

For starters, DIY saves on labor while at the same time, giving a sense of accomplishment. The downside is that it also requires certain skills, tools, and a safe working place. In the absence of these, there is always the possibility of wrong construction and creating an even bigger problem in the future.

On the contrary, it is better to decide on professional replacement when one realizes that the repair is particularly complicated or when one is not completely confident in his/ her mechanical skills. Not only do professional mechanics know how to fix the cars, but they also have the tools and good quality parts that can make the work well done.

As for technical parameters, the top websites also outline justifying in this regard the factors that are taken into account while professionally repairing the vehicle: A place has to look at the following issues while giving professional repair about technical parameters:

- Use of Original Equipment Manufacturer (OEM) Parts: Most OEMs buy OEM parts, which guarantee that the parts fit and work well with the machine while those working on the DIY tend to go for cheaper options all the time.

- Correcting Torque Seals/Screws with Torque Calibration: Professional people usually have torque wrenches, which are calibrated to the manufacturer’s specifications where there is no nut stripping and no suffocation of components due to excessive torque.

- Warranty Coverage: Repairing services offered in a repair shop include a warranty, which promises coverage in the event of any unresolved issues, something that should be a comfort to a consumer that DIY cannot offer.

Taking all these factors into consideration, I would state that, although I prefer practice-oriented tasks, relying on specialists for some aspects of repairs frequently brings safety and durability.

What Are the Potential Risks of Ignoring Water Pump Issues?

Consequences of Driving with a Bad Water Pump

With time, active driving habits can be affected by a malfunctioning vehicle water pump and eventually bring additional damage, especially to the engine. From the leading websites that I gathered information from, the water pump is important for supplying coolant to the engine and for cooling the engine as well. Failing to take care of it can lead to dangerously hot temperatures in the engine which may put the engine parts at risk or entirely ruin the engine. Stressing these annoying details, the sites note that persistent coolant evaporating, odd rattling sounds, or steam coming from the radiator should not be ignored.

The technical parameters of specific concern mentioned include:

- Coolant Flow: Adequate flow rates should be permissible to achieve effective cooling of the engine. A defective pump interrupts this movement and creates hotspots.

- Seal Integrity: A broken water pump will usually have broken seals inside, resulting in leaks. This shows that there is a requirement to carry out seal replacement measures in time.

- Bearing Condition: Worn-out pump bearings are important because they determine the proper functioning of the pump and the presence of noise vibrations.

Correcting these specifics at the right time can avoid more trouble. So, if I ever have such symptoms in my vehicle, I tend to call it into a specialist to make sure these problems are dealt with adequately to protect my engine and avoid expensive repairs.

How a Faulty Water Pump Can Lead to Engine Damage

In exploring the damage caused to the engine due to the water pumps, the first three websites chronicled in this paper are constant in emphasizing the importance of this component. More specifically, they point out that due to the failure of the water pump, the amount of coolant flowing around is not sufficient and this makes the engine hot. Due to this excess heat, there is a possibility of distortion of the cylinder head, destruction of the head gasket, and possible leakage in the engine block. In direct relation to this issue, key technical parameters identified include:

- Overheating Risk: There follows the dumping of excessive heat in circulation because sufficient coolant was not supplied to the engine. This was the position in each site I reviewed as it emphasized the need to keep the temperature of the engine within normal limits.

- Component Stress: With this augmentation, the heating parts are placed under transformation and as a consequence increase the possibility of wearing out or breaking the head of the cylinder or the head gasket.

- Operational Noise: An erroneous pump tends to create strange operating sounds. The websites point out that this could bring early signs of misalignment or bearing failure of internal parts.

In this way, I will be able to organize the maintenance of the car properly and not forget about the early treatment of problems. Exhaust systems include vibrations that lead to failure of the engine and alterations in engine operating conditions that permit the control of over the wear and tear of the engine. This removes the risk of expensive repairs and prolonged downtime of the vehicle due to changes in the defects of the water pump through usual checking and proper management of servicing.

Preventative Maintenance Tips

Severe and even critical issues with water pump units can be avoided with regular maintenance. Here are some recommendations that I collated while going through the top three sites:

- Regular Inspection: It is also advisable to perform a general pump inspection regularly. Wear and tear must still be looked at for safety repairs or cracks or corroded spots on pumps.

- Monitor Coolant Levels: Unfortunately, coolant is one of the liquids necessary to keep the system from overheating, thus if the coolant is maintained within a normal range, overheating can be avoided. Not a sufficient number of coolants may be a sign of leaking within the system, causing the water pump to malfunction.

- Listen for Noises: Keep track of and make note of any operational sounds in the engine bay. Implement essential precautions just in case unusual sounds are experienced in very uncommon situations on the water pump as such issues must not be left unattended as they might grow.

- Check Engine Temperatures: To prevent overheating conditions on the engines from causing irreversible damage due to overstrain, proper gauges must be fitted to ensure overheating mechanisms are well monitored.

Addressing the questions asked:

The leading three sites on google.com repeatedly emphasize the importance of an adequate functional water pump within the engine to prevent its damage. There is a risk of cylinder head warpage, gasket failure, and engine block damage due to head overheat caused by the absence of sufficient coolant circulation because defective cooling pump. Justifying these concerns, one can also provide technical parameters:

- Overheating Risk: Garfield A-12 Etc whose coolant circulation has been curtailed.

- Component Stress: Operational temperatures of the engine causing pre-mature failure of engine parts.

- Operational Noise: This may be an indicator of an internally misplaced component(s).

There are preventable measures that I can put into place to reduce the rate of engine deterioration and hence lower the cost of the repairs.

Frequently Asked Questions (FAQs)

Q: How much does it cost to replace a water pump bearing?

A: The cost of replacing a water pump bearing can vary depending on the make and model of your vehicle. On average, you can expect to pay between $300 and $750 for parts and labor.

Q: What factors affect the cost of replacing a water pump on a car?

A: Several factors can affect the cost of replacing a water pump, including the type of vehicle, the complexity of the repair, the quality of the parts used, and labor rates in your area. Additionally, if your water pump is driven by the timing belt, you may need to replace the belt or timing chain as well.

Q: How do I know if my water pump needs replacing?

A: Common signs that your water pump may need replacing include coolant leaks, engine overheating, a whining noise from the front of the engine, and visible rust or corrosion on the water pump. Always consult your owner’s manual for specific recommendations.

Q: Is it necessary to replace the thermostat when replacing your water pump?

A: While not always necessary, it is often recommended to replace the thermostat when you replace the pump, especially if the water pump is driven by the timing belt. This ensures optimal engine performance and prevents future issues.

Q: How long does it take to replace the water pump on a car?

A: The time to replace a water pump can vary, but it usually takes between 2 to 4 hours for most vehicles. This can be longer if the water pump is difficult to access or if additional components such as the timing belt or drive belt need to be removed.

Q: Can I replace the water pump myself?

A: If you have experience with auto repair and access to the necessary tools, you might be able to replace the water pump yourself. However, due to the complexity of the task, especially if the pump is driven by the timing belt, it is often best to have a professional mechanic handle the repair.

Q: How can I get a free detailed estimate for water pump replacement in my area?

A: Many auto repair shops and online services offer free detailed estimates. You can contact a local mechanic or use online platforms to get an estimate based on your vehicle’s make, model, and location.

Q: What is the role of the water pump in a car’s engine?

A: The water pump is a vital component of your engine’s cooling system. It circulates coolant through the engine and radiator, preventing the engine from overheating. Without a functioning water pump, your engine could suffer severe damage.

Q: Are electric water pumps more expensive to replace?

A: Electric water pumps can be more expensive to replace than mechanical ones due to their complexity and the cost of the parts. However, they are often more efficient and can offer better performance for certain vehicles.

Q: Should I use a high-quality water pump for replacement?

A: Yes, using a high-quality water pump for replacement is crucial for the longevity and performance of your vehicle. A quality water pump will ensure better reliability and reduce the likelihood of future repairs.